OPTIMIZED ADDITIVE BLENDING IN INDUSTRIAL MINERALS

LIVE E-SEMINAR | ENGLISH

APRIL 28,2020 | 3:00 PM – 4:00 PM

Getting the mix right is a constant GAP in the industry. Cement companies need to add blending materials to achieve the right chemistry of the clinker – it’s part of the mine planning. The complexity of understanding what materials to blend, taking into account cost and availability at each mine and cement plant, is often overwhelming.

Many industrial mineral companies face challenges in maintaining product quality when their product needs to be blended with third-party additives to achieve a predictable and consistent result.

The calculations required to blend the chemical characteristics and mining parameters necessary to extract material from the mine with keeping the cost of third-party raw materials to a minimum, and at the same time maintaining a consistent, quality product is usually a struggle.

Frequently those calculations are completed in a spreadsheet or by guesswork resulting in excess additive cost and an increase in product variability. Watch this webinar and understand how to optimize a mine tactical schedule through simulation.

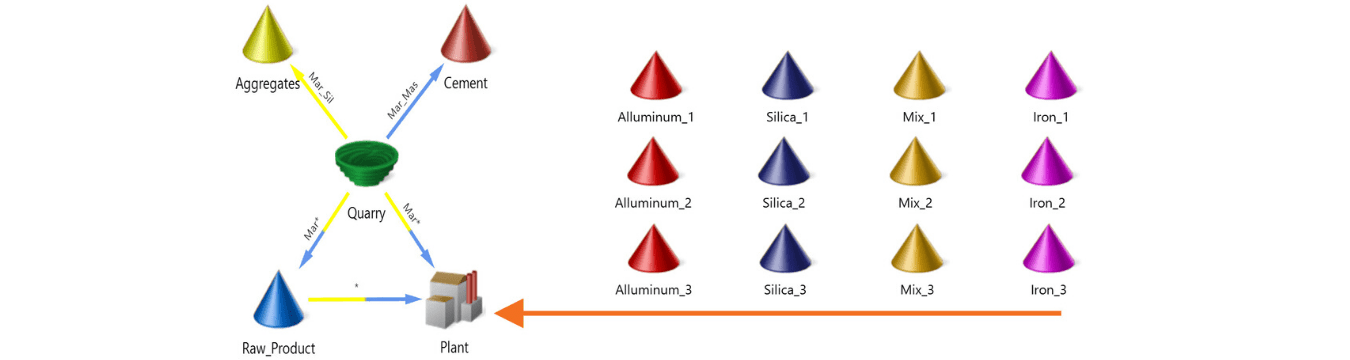

There are specific solutions from Dassault Systemes preconfigured for cement and industrial mineral companies. It improves predictability and reduce operating expenses through greater optimization of blending.

- Integrated solution of GEOVIA MineSched and SIMULIA Isight delivers:

- Decreased cost in the blending materials

- Increased confidence and predictability of the blending requirements per period

- Increased LOM by optimizing the use of the resource

- Improved quality and reduced cost of the cement

Direct Benefits

- Optimize the use of blending material, according to:

- Availability of material by region

- Cost per mine/plant/or period

- Technical plant requirements to LSF, MA & MS or others

- Run more than one mine or one plant at the same time.

- Quick evaluation with different sets of blending materials.

- Quick reaction with a new mine planning according market price.

- Quick simulation of scenario with production increment or new plant constraints

Indirect Benefits

- Improve cement quality

- Reduce cost of maintenance and stops of the kiln

- Reduce risk of environmental fine by unwanted gases