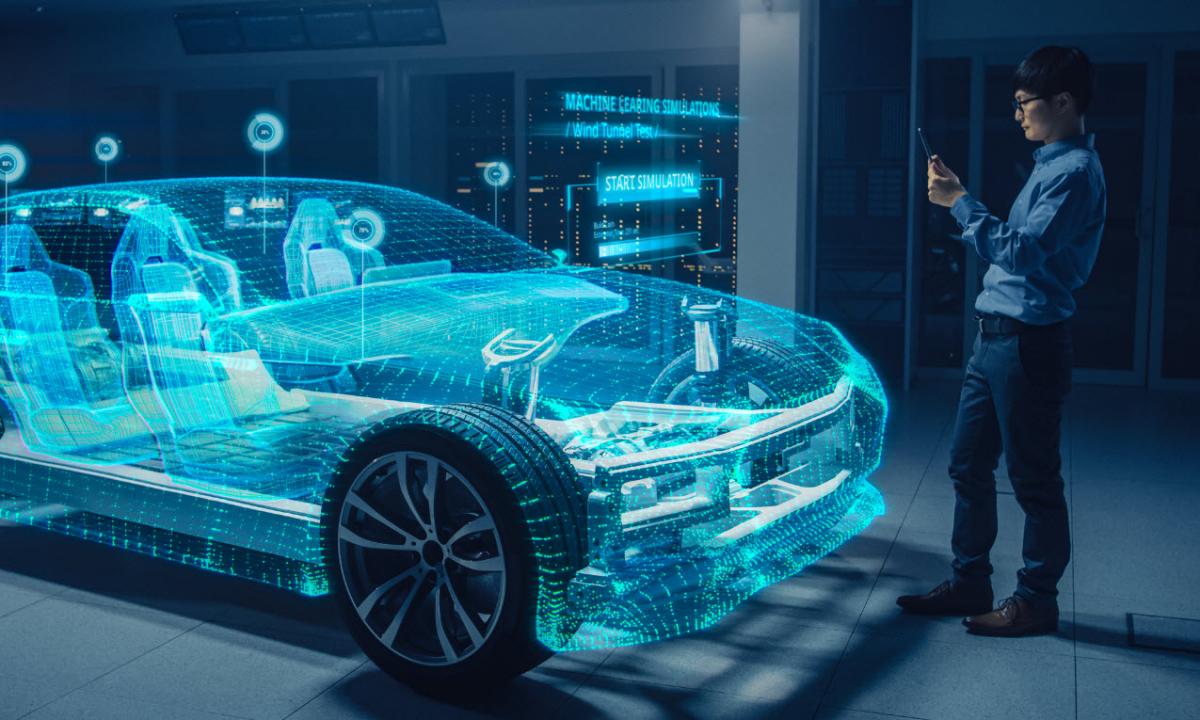

Transportation & Mobility

Accelerating vehicle innovation and business growth through advanced technology

Aerospace & Defence

Bridge the gap between the virtual and real world to deliver on time and on cost

Industrial Equipment

Digital solutions provide manufacturers with flexibility to deliver customized machinery

Natural Resources

Solutions to improve operational efficiency, increase productivity & ensure compliance

Life Sciences

Bring quality medical devices to the market faster with sustainable innovation

Consumer Goods & Retail

Deliver innovation from concept to the consumer to drive sustainable growth

Infrastructure, Energy & Utilities

Rethink innovation to create a sustainable future for Infrastructure, energy & utilities

Cities & Public Services

Design and deliver sustainable living environment and public services