Digitized Lean Shop Floor – 3DLean

Innovation is at the forefront of the manufacturing industry. They are exposed to multiple challenges such as supply chain disruptions, shorter product life cycles, change in customer requirements, environmental compliances etc. Meanwhile, there are multiple opportunities to expand their footprint into multiple geographies, applications, product lines etc. These challenges and opportunities are forcing manufacturing companies to adopt transformational changes in a very short time. Fostering these innovations while managing industry growth and capturing market share requires getting new products to market as fast as possible with high quality and low cost.

In order to achieve this, you need your teams to operate like a well-oiled machine. While dealing with complex operations within many constraints, it can be all too easy to slip up through miscommunication, a lack of focus on key objectives and poor engagement from team members. This usually leads to a lot of wastage in time and productivity from all the back-and-forth communication to get your teams on track. Traditional team interactions are not truly collaborative, resulting in many missed opportunities, which is especially harmful during important phases of collaboration like problem-solving and follow-ups, leading to the creation of more operational problems.

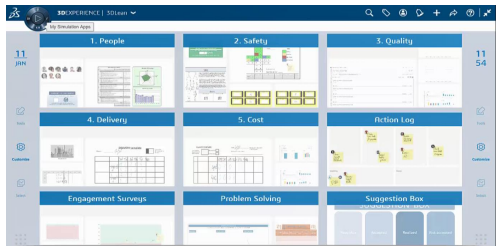

Lean is a mindset to capitalize knowledge and know-how to improve continuously business practices and methods. Applying digital Lean practices in a company allows each team to take the right actions, cascade decisions to stakeholders, and collaborate seamlessly regardless of their role or job.