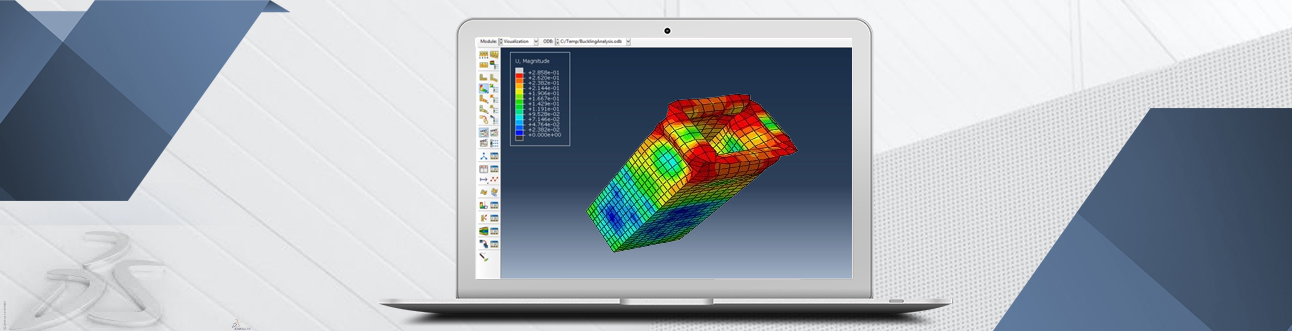

A nonlinear static problem can be unstable as a result of global buckling or material softening. If the load-displacement response of the model seems to be reaching a load maximum and there is the possibility of global instability or negative stiffness, two approaches to solving the problem can be used — static or dynamic analysis.

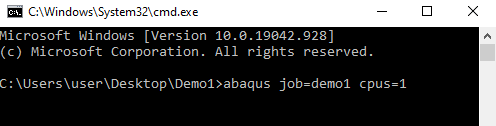

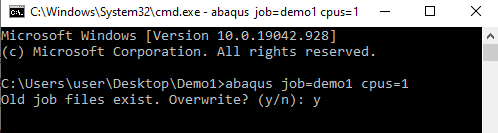

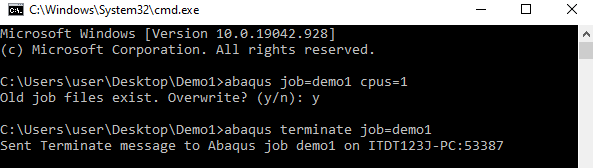

If the structure is reaching a buckling load in a static analysis, perform a Riks analysis

The Riks method assumes that the global instability can be controlled by modification of the applied loads. This means the loss in stability cannot be too severe; that is, there cannot be a sharp bifurcation in the load-displacement curve. Therefore, structures such as flat sheets, cylinders, and spheres that have a sudden significant loss of stiffness after buckling must have some imperfection built into the original geometry.

This can be done by using the *IMPERFECTION option to modify the original geometry by adding imperfections. The best approach is to use experimentally determined imperfections; however, since these measurements may not be available, the *IMPERFECTION option can use combinations of the eigen modes from a previous buckling analysis as the imperfections to the original geometry.

If the Riks method fails to converge near a limit or bifurcation point (buckling load), the problem may be that the loss in stiffness is too severe. Instability problems that exhibit a sharp transition often require a limit on the maximum incremental arc length to get past the transition point or to have larger imperfections built into the geometry.

If a dynamic analysis is desired

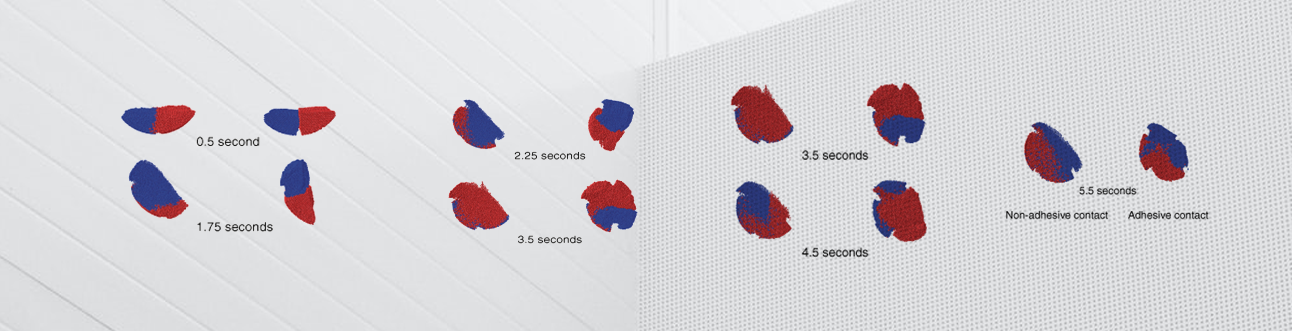

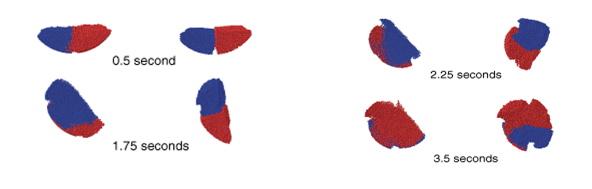

Abaqus/Explicit should be considered as the most robust approach, particularly in the presence material failure, extreme deformation, or rapid changes in contact state. If the loss in stability is not too severe, or only the load maximum is to be computed rather than a fully collapsed configuration, then a dynamic analysis in Abaqus/Standard may be completed with less run time. Choose the APPLICATION parameter on DYNAMIC to control the amount numerical damping that is applied to the integration operator. If a dynamic analysis is used in Abaqus/Explicit, the structure will vibrate once it has passed the instability and you must decide how to damp the vibrations if a quasi-static solution is required.

Global instabilities can also be stabilized in a static analysis with viscous forces. Although not intended as a primary solution technique for global instabilities, automatic stabilization can be used in the static, coupled temperature-displacement, soils and quasi-static procedures. Automatic stabilization will add viscous damping to the structure, which may allow the solution to go beyond the instability point.

Discrete dashpots can also be used to stabilize a problem of this type

With either technique, the energy dissipated by the artificial viscous forces (output variable ALLVD for discrete dashpots or ALLSD for automatic stabilization) should remain small compared to the total internal energy (output variable ALLIE) in the problem. The nodal viscous forces should also be small when compared with typical forces in the problem (use nodal output variable VF).