How to Design Complex Aero Parts using the 3DEXPERIENCE Platform?

Designing aircrafts is becoming an increasingly complex task these days. As it becomes increasingly sophisticated, the wiring needed to power and control the electrical systems are also becoming complex.

Large OEMs and companies are dependent on electrical CAD systems which will enable them to execute the electrical diagram which will help in 3D Mock-Up and manufacturing preparation. This will help these OEMs and companies to lower production costs and also to reach the market faster than before.

What are the typical challenges with respect to Wire Harness?

- Multi applications and different data sources

- Time consuming, repetitive and error prone creation of electrical system

- Lack of 3D integration with electrical system schematics which will lead to difficulty in understanding the overall design quality

- No associativity between 3D wire harness design and its manufacturing

Due to the complexity and stringent safety regulations in the Aerospace sector, virtual testing and validation plays a significant part in design and manufacturing.

How 3DEXPERIENCE addresses these challenges?

Large OEMs and companies have adopted Dassault Systèmes’ 3DEXPERIENCE platform which accelerates the process from design to manufacturing with compliance to required standards.

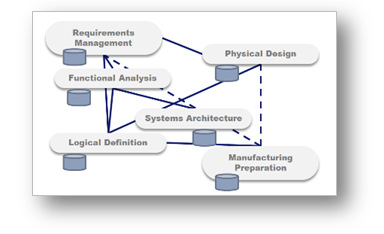

The 3DEXPERIENCE platform provides end-to-end electrical development environment from schematics through 3D design up to manufacturing.

Some of the solutions which the 3DEXPERIENCE platform offers with respect to Wire Harness are described below:

CATIA 3DEXPERIENCE – 3D Wire Harness Design

- Shared electrical systems data model which enables schematic to 3D Design synchronization

- Best-in-class 3D wire harness design solution

- In-context wire harness modelling and simulation

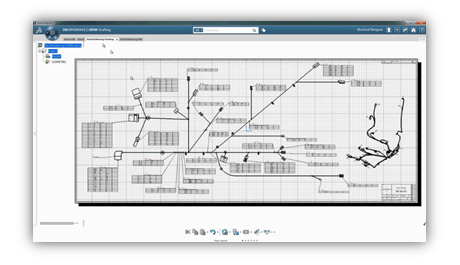

CATIA 3DEXPERIENCE – Harness Manufacturing Preparation

- World class wire harness layout solution

- Automatic generation of full-scale drawings for form-board manufacturing

- Synchronization of flattened harness and automatic drawing updates

Large aerospace OEMs and suppliers have reaped multiple benefits by adopting Dassault Systèmes’ 3DEXPERIENCE platform. Some of these are mentioned below:

- Integrated process coverage to reduce cycle time from design to manufacturing

- Detect issues in the early phase of design by validating virtually and avoid expensive errors in manufacturing

- Automatic propagation of modification from design to documentation

- Quick electrical space reservation within the product to avoid physical prototypes

Thus, the 3DEXPERIENCE platform and its various applications help OEMs as well as suppliers to design and manufacture complex parts rapidly and with accurate precision while adhering to safety standards.

Mr. Goutham started his career as Design Engineer, worked on different CAD software applications. He is currently working as Solution Consultant with EDS Technologies & he is part of CATIA 3DEXPERIENCE CoE team. He has good exposure on manufacturing aspects with respect to Aerospace Industry. He carries a rich experience of 8 years in the field of PLM/Digital EXPERIENCE platform.