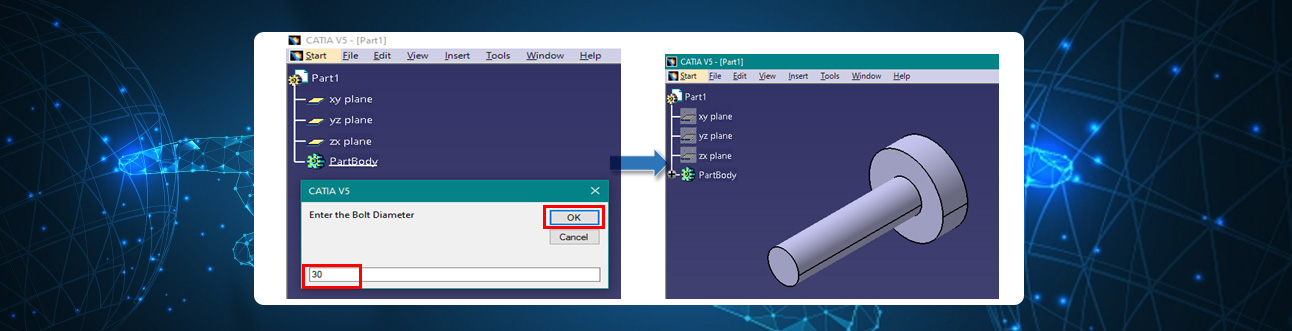

Performing repetitive tasks manually leads to a loss of productivity. This is one of the major reasons why organizations are increasingly trying to automate processes which helps to reduce manual labour, design time and increase productivity. In CATIA V5, repetitive manual tasks can be automated using CATIA V5 Macros. There are two ways to create CATIA V5…

Category: CATIA V5

CATIA is one of the widely used software applications for product design across various industries. CATIA has helped organizations to conceptualize, design and conform to the ever-changing industry standards and requirements. Across industry lines, CATIA still proves to be the most preferred product design application for any organizations. CATIA, now powered by the 3DEXPERIENCE platform delivers unmatched…

Organizations are adopting Lightweight Engineering solutions to optimize their design, engineering and manufacturing processes. R&D departments in the Automotive and Aerospace sector is increasingly considering ways to adopt Lightweight Engineering solution to develop the new product designs. There are multiple methods to optimize the weight, shape and material selection of parts and assembly. However, Lightweight Engineering is…

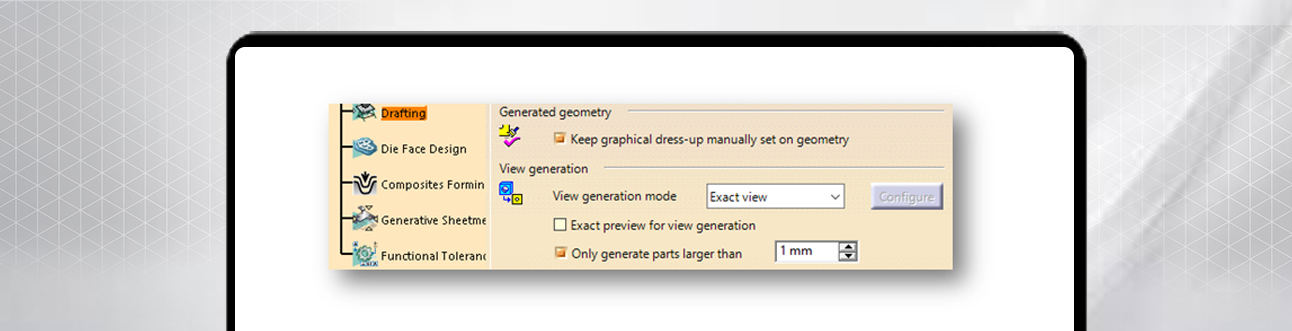

Memory consumption in CATIA V5 drafting depends on the CAD data that is loaded in the CATIA session. The memory consumption increases due to loading of both 2D and 3D data, which further increases due to loading of the data in design mode. This blog focuses on the causes of high memory consumption and the ways to…

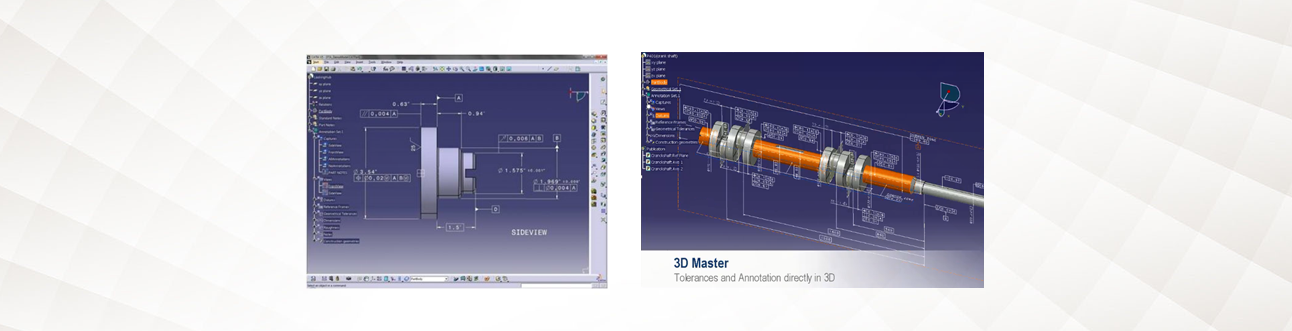

The emerging trends in the market and the progression towards Industry 4.0 indicate an increased need for “Model Based Definition” (MBD) or 3D GD&T in design and manufacturing companies. GD&T is used by engineers in drawings to convey design details to manufacturing teams. With the increased adoption of Model Based Definition, engineers now place GD&T directly into…

There are multiple ways to save a document in CATIA V5. It sometimes depends on organization guidelines. In this blog, multiple options of saving a document in CATIA V5 are discussed. For saving a CATIA V5 document, three options are available. Click on Tools ➜ Options ➜ General ➜ under General tab ➜ Data Save to access…