How does Adoption of CATIA 3D Master benefit Design and Manufacturing Companies?

The emerging trends in the market and the progression towards Industry 4.0 indicate an increased need for “Model Based Definition” (MBD) or 3D GD&T in design and manufacturing companies.

GD&T is used by engineers in drawings to convey design details to manufacturing teams.

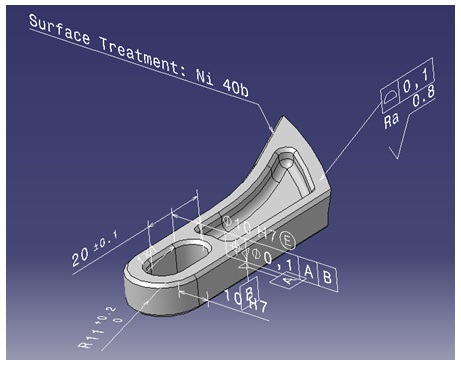

With the increased adoption of Model Based Definition, engineers now place GD&T directly into 3D models instead of generating in 2D drawings. This would make 3D geometry as a “Single Source of Design Information”.

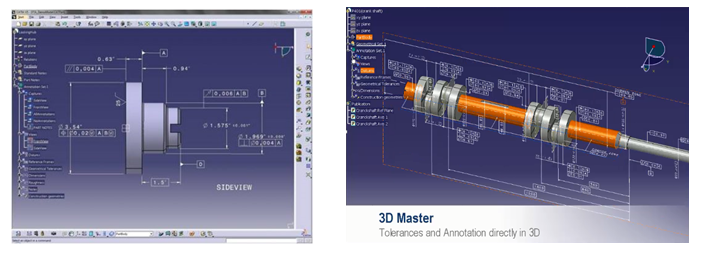

CATIA 3D Master (FTA) allows the designer to create GD&T for designed parts as well as for assemblies.

Once the FTA is done, the same data can be shared to manufacturing teams so that they can directly access the design data along with GD&T eliminating the need for traditional drawing sheets.

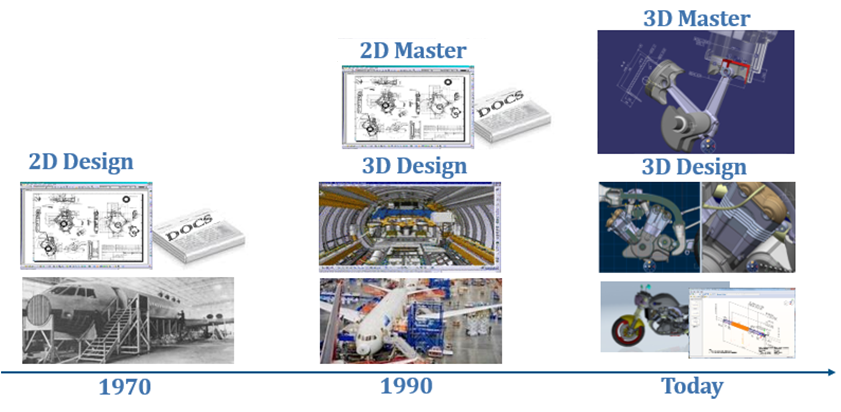

Evolution of the Design Process:

The design process has undergone a transformation over the past 50 years. The below infographic shows the evolution of the design process from 1970 to the present day.

Advantages of CATIA 3D Master (FTA):

There are many advantages in using CATIA 3D Master as compared to creating GD&T in 2D drawing sheets. Some of them are listed below:

- Eliminates the effort to generate and update 2D documents according to the 3D geometry definitions

- Can re-use the design from previous projects quickly

- FTA implementation can eliminate the time taken to create the drawings

- Since CATIA 3D Master acts as a “Single Source of Truth”, the latest version of the data is always available

- Helps to increase the quality of manufactured products

- Ensures compliance to international standards

- Leads to better communication since the work flow is entirely 3D based

- Reduces drafting time, supports paperless design and increases the collaboration with customers and suppliers

Adopting and implementing CATIA 3D Master (FTA) ensures companies to reduce design time and that the products reach the market quickly.

Mr. Goutham started his career as Design Engineer, worked on different CAD software applications. He is currently working as Solution Consultant with EDS Technologies & he is part of CATIA 3DEXPERIENCE CoE team. He has good exposure on manufacturing aspects with respect to Aerospace Industry. He carries a rich experience of 8 years in the field of PLM/Digital EXPERIENCE platform.