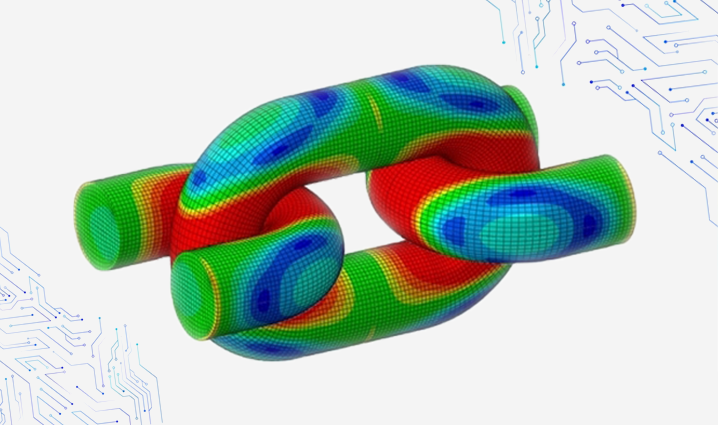

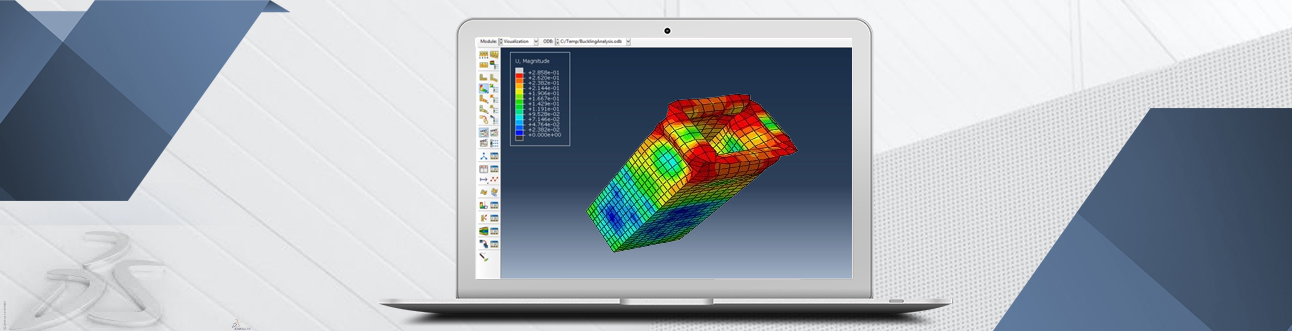

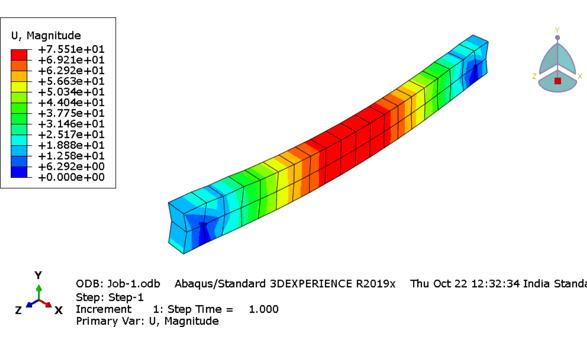

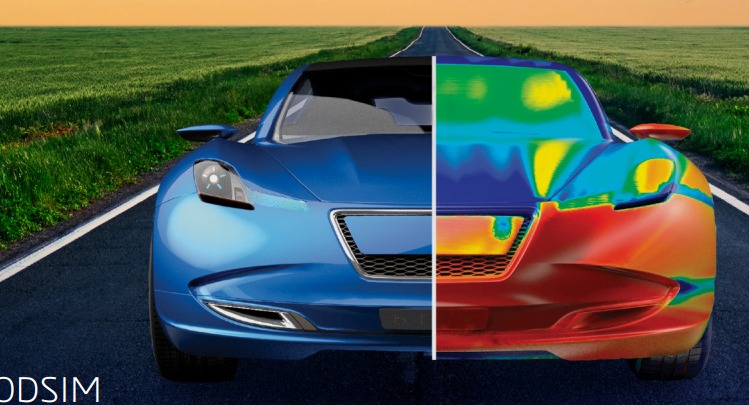

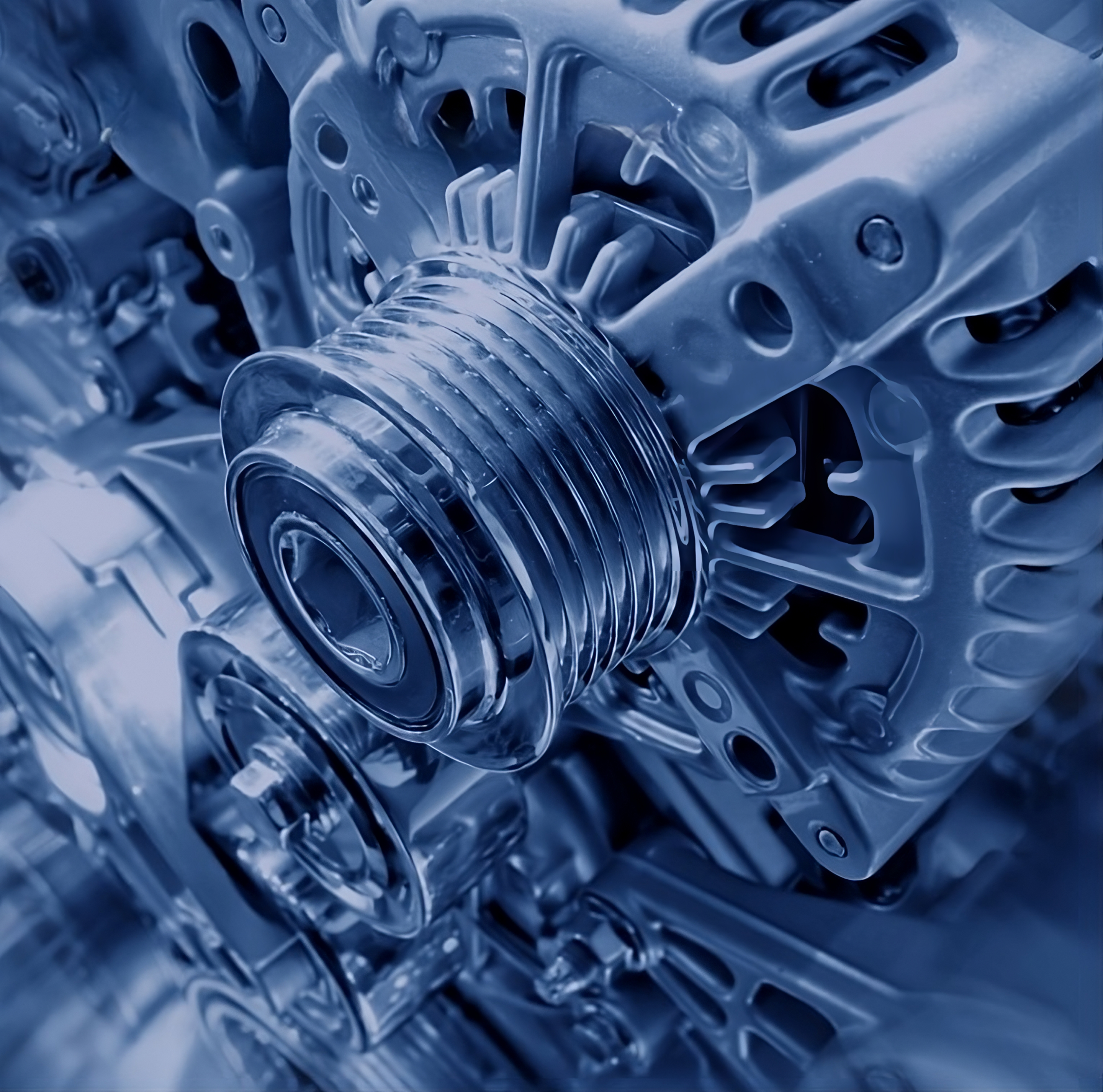

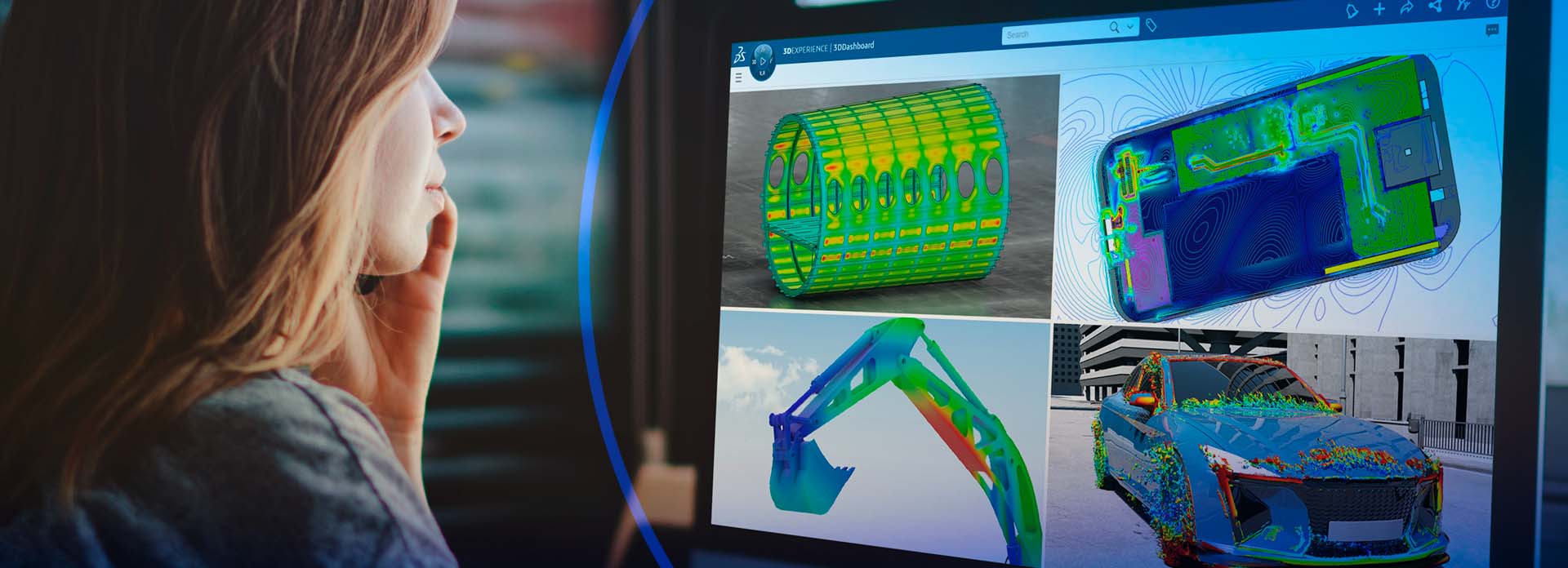

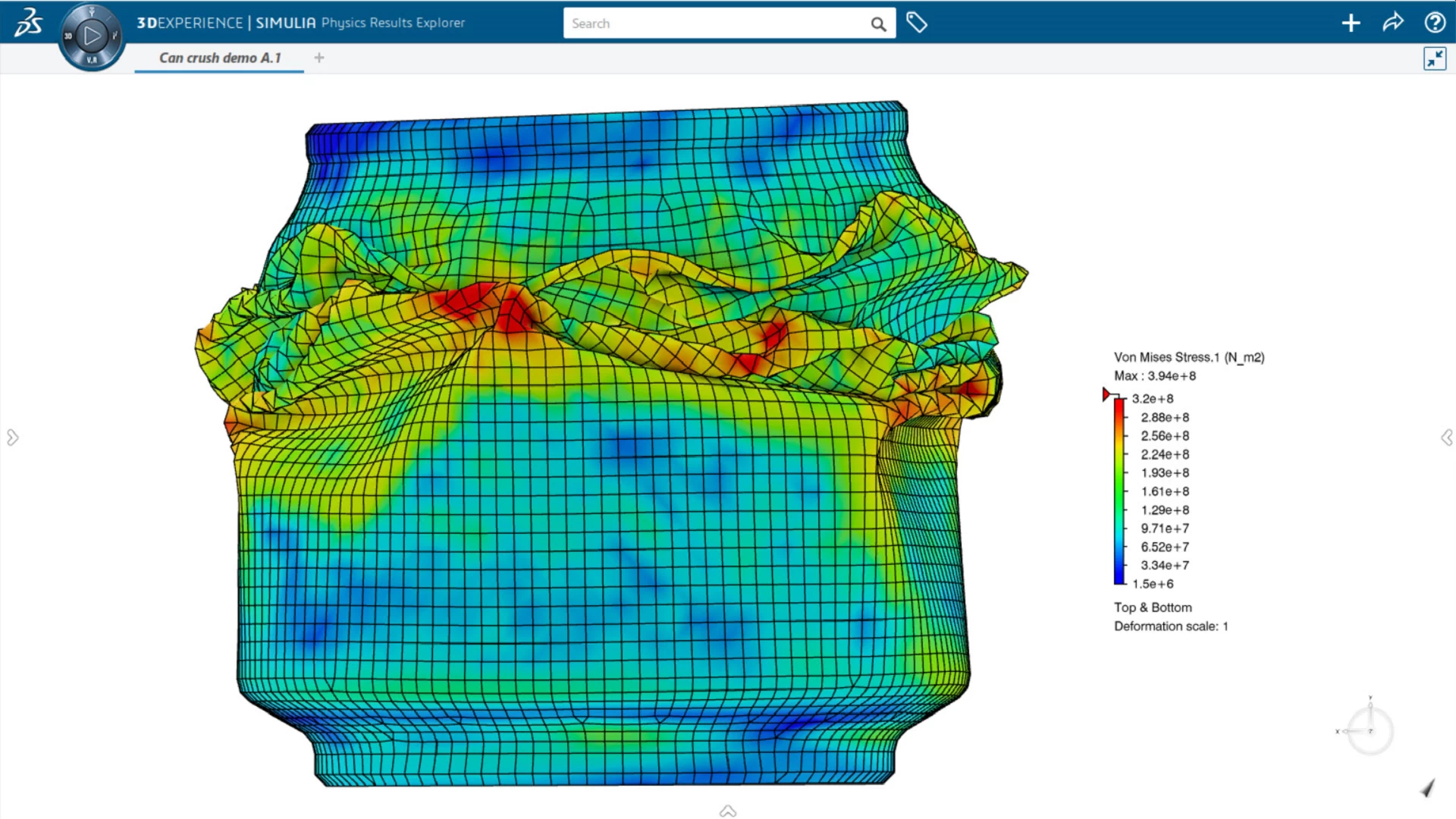

SIMULIA’s structural simulation using Finite Element Method (FEM) provides deep insights into product performance under real-world conditions like varying loads and temperature. By creating virtual prototypes, it evaluates critical performance indicators such as stiffness, strength, safety, durability, and comfort. This approach ensures accurate predictions, enhanced product quality, and cost-efficient prototyping.

Structural Simulation Roles

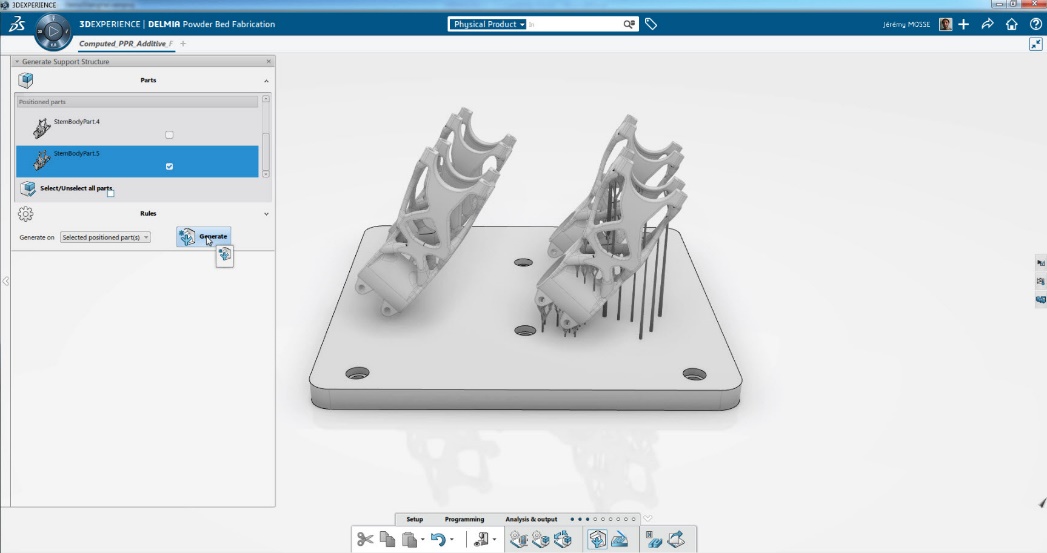

Additive Manufacturing Analysis Engineer

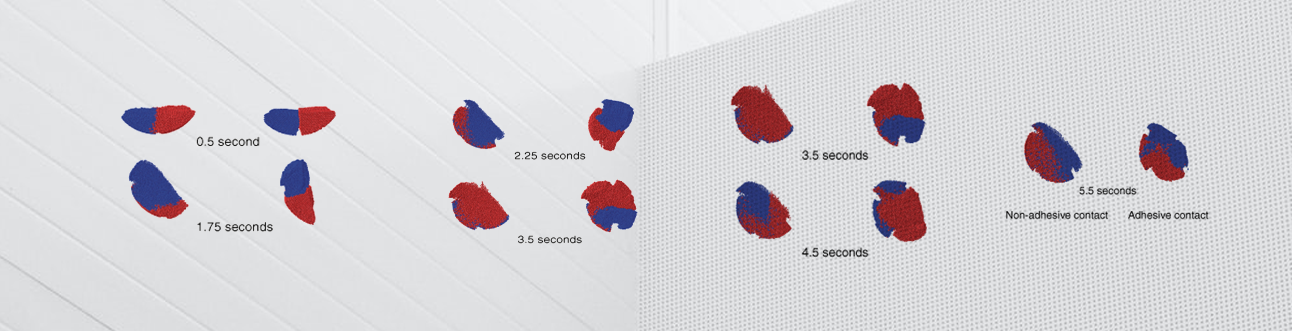

Realistic simulation of the additive manufacturing process enables companies to optimize part designs and process parameters for additive manufacturing

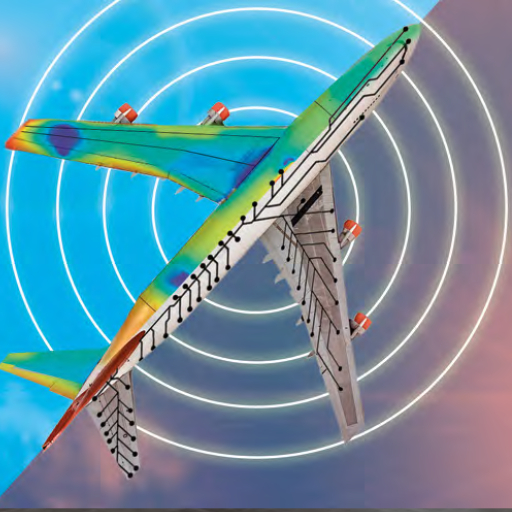

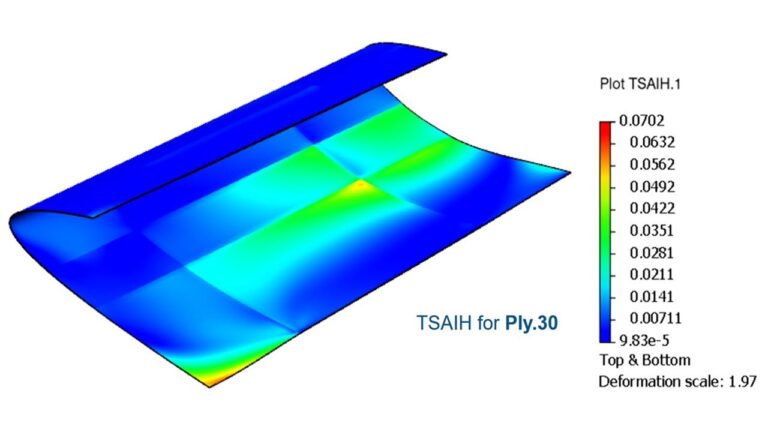

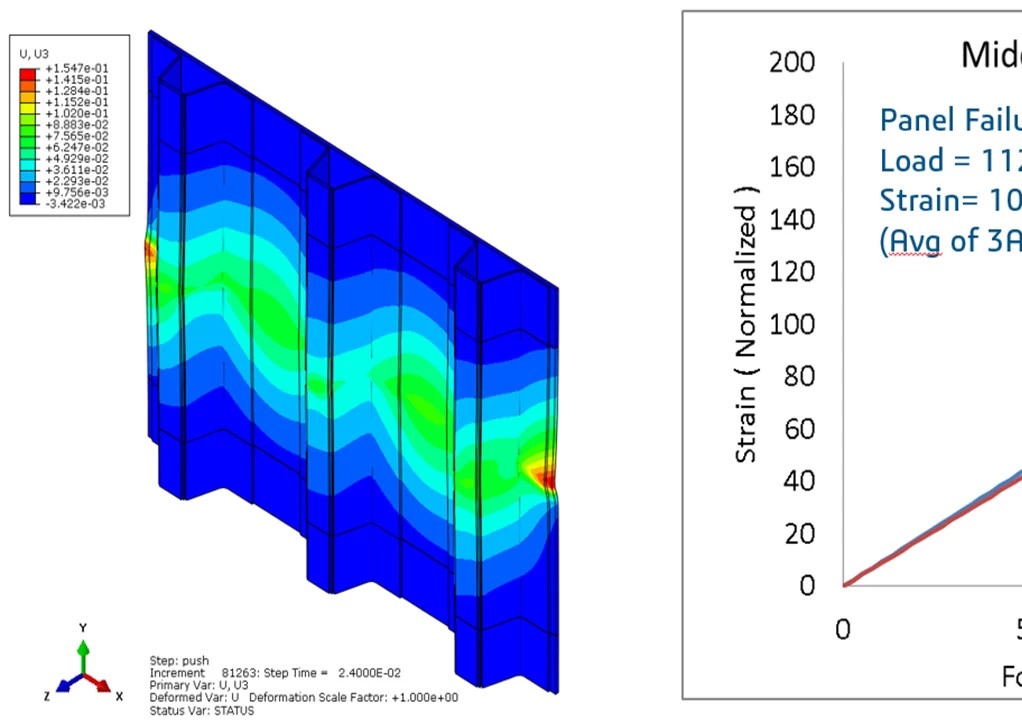

Composite Structures Analysis Engineer

Perform detailed simulation of composite structures for stiffness, strength, manufacturability, and damage tolerance, while optimizing weight and performance...

Composite Structures Performance Engineer

Model and validate composite designs for stiffness, strength, and performance requirements, to reduce cost in composite structure prototypes and testing..

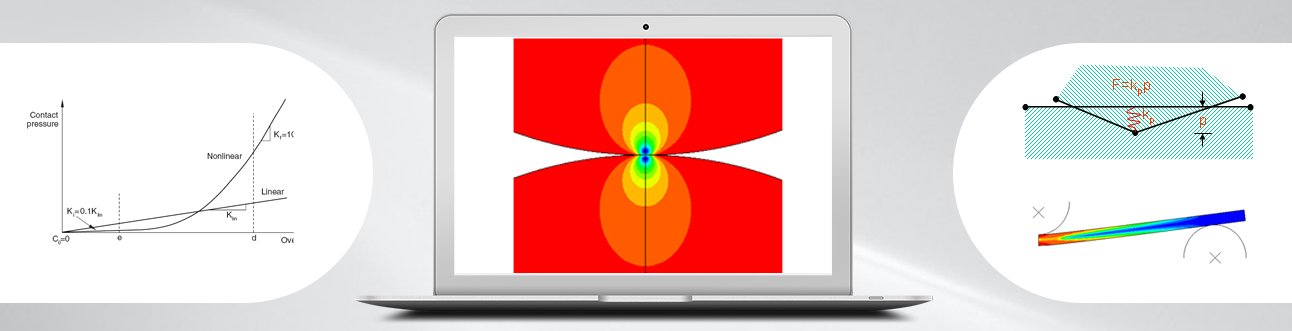

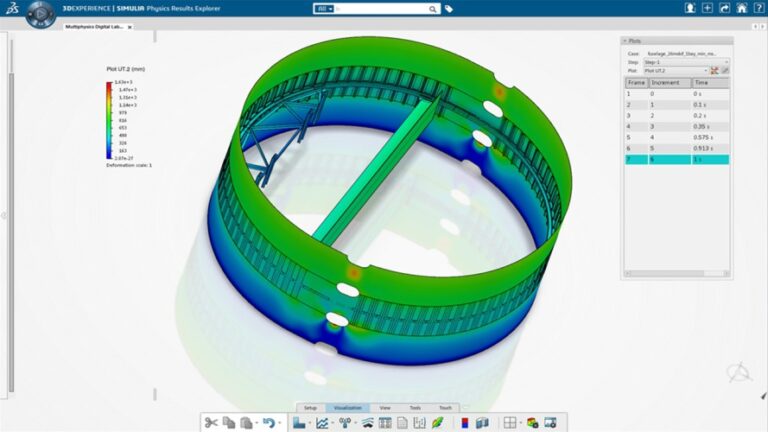

Concept Structure Analyst

Generate high-performance design concepts meeting structural requirements based on advanced linear and nonlinear simulation

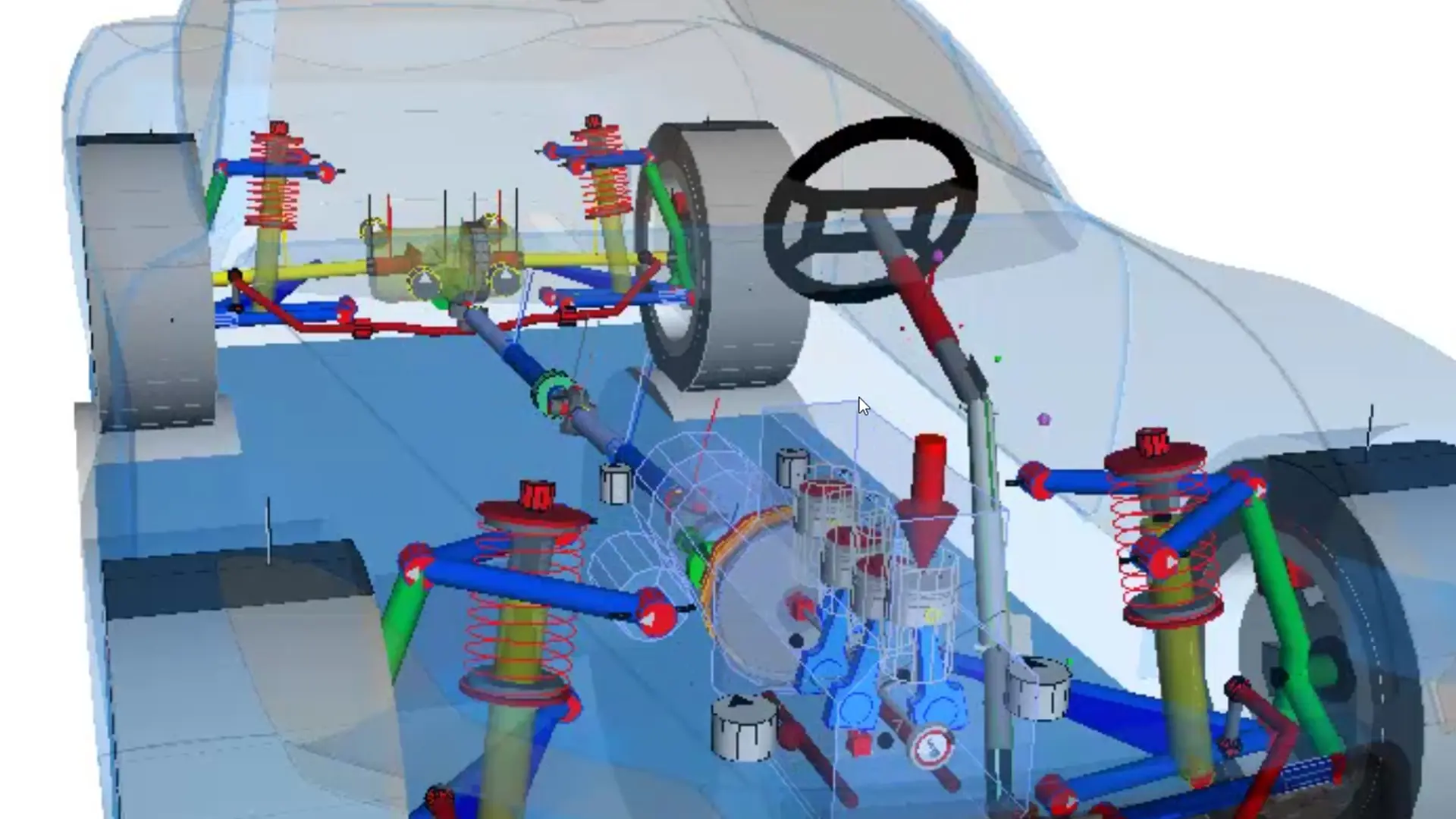

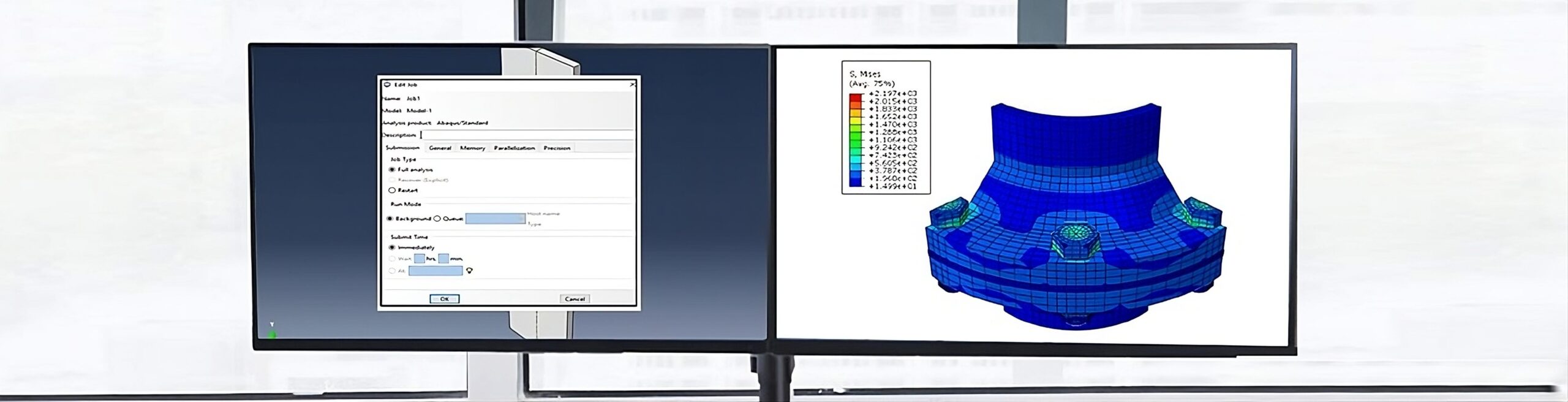

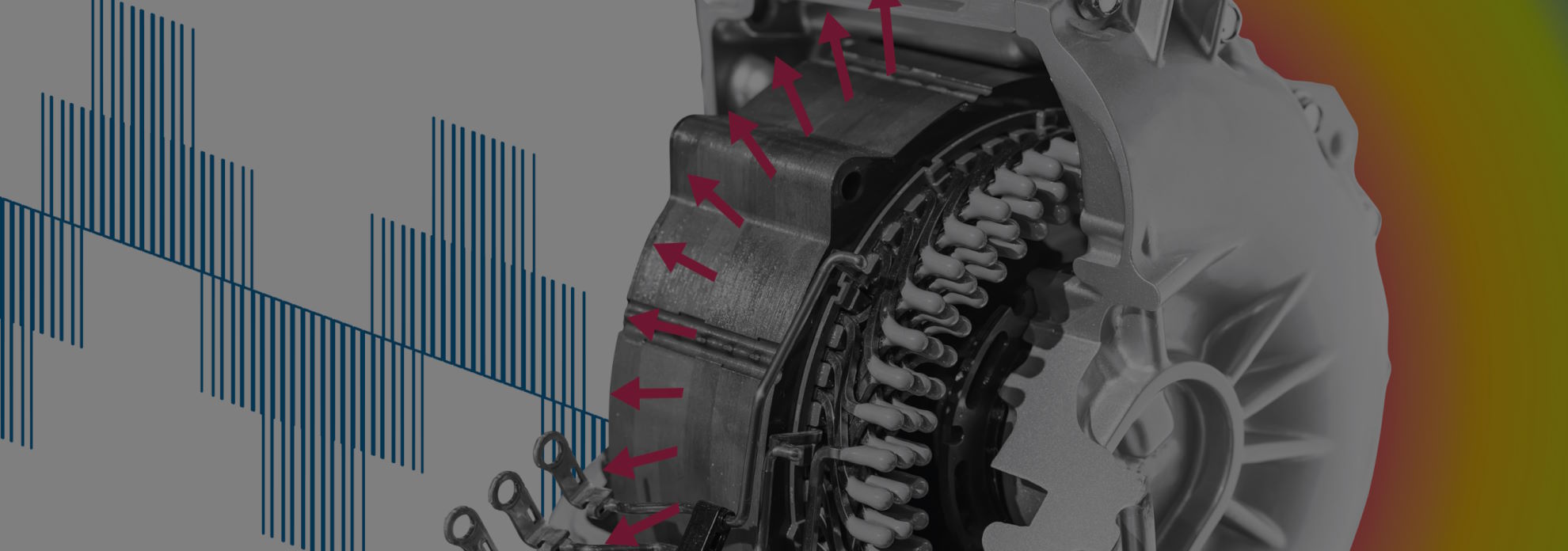

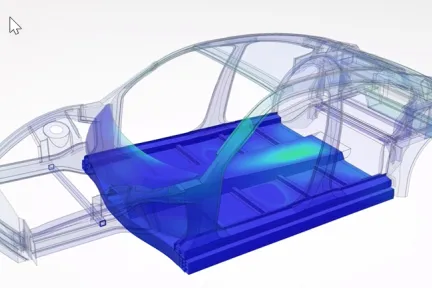

Durability Performance Engineer

Assess the structural performance and durability of products during the design process and intuitively guide design decisions

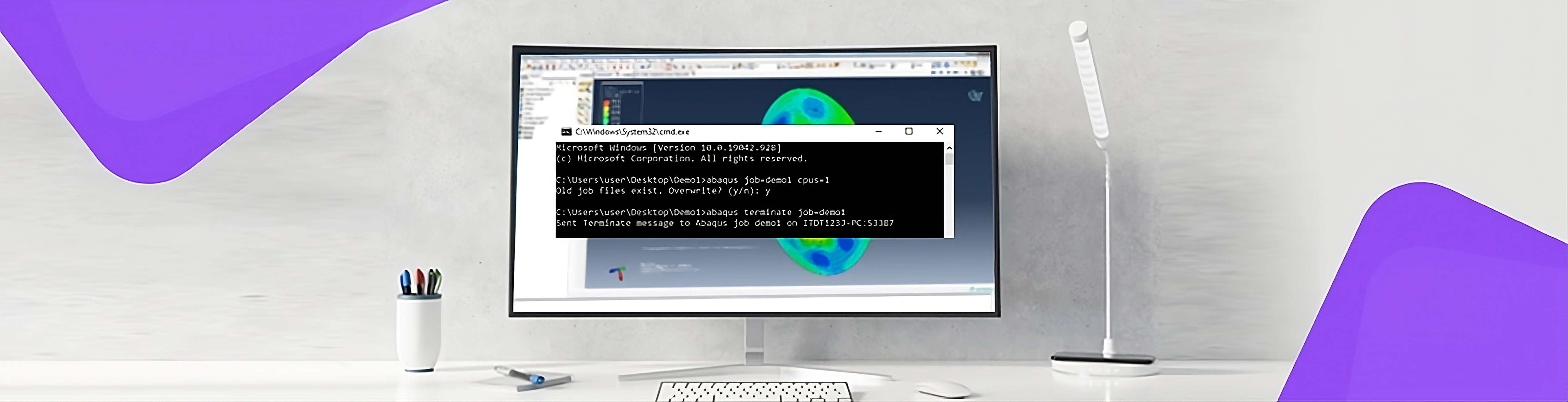

Durability and Mechanics Engineer

Enables comprehensive structural simulations covering statics, implicit and explicit dynamics and fatigue to assess structural integrity of any type of product...............

Latest Blog Posts

Discover our most recent posts across all industries, brands and topics