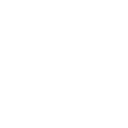

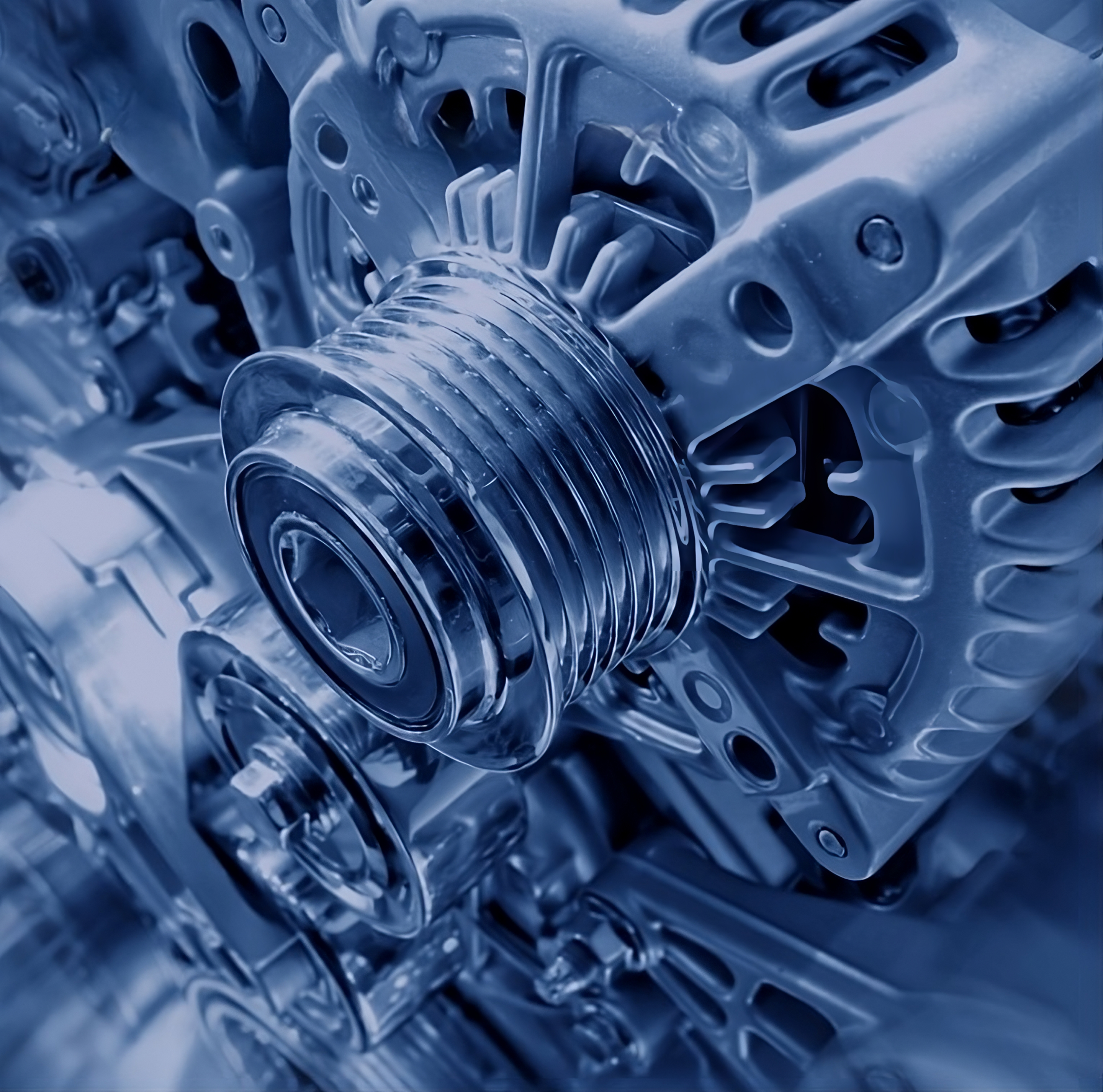

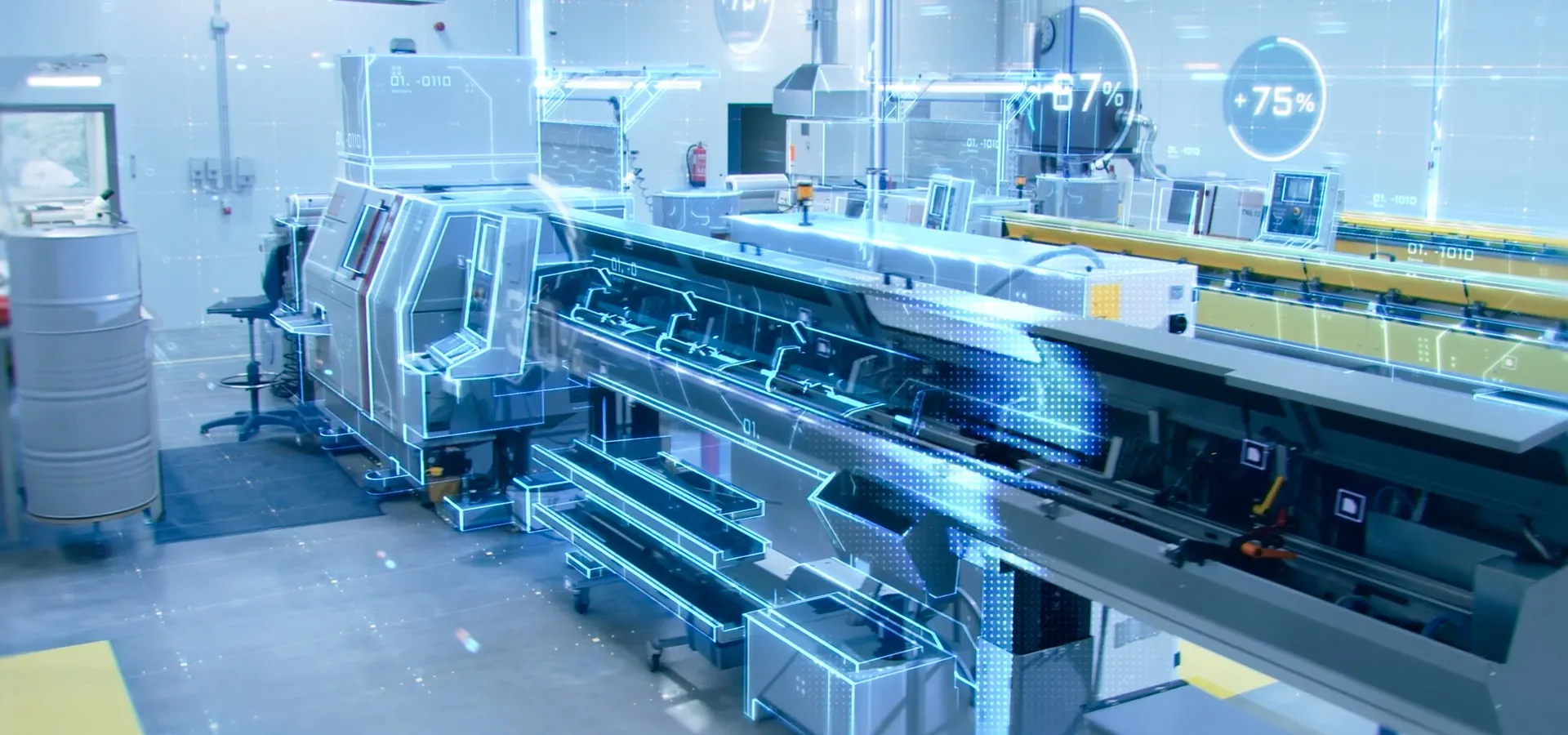

Fabricated Metal and Plastic Products

Fabricated metal and plastic products are essential in many industries, offering durable and versatile components for sectors like automotive and aerospace. Advanced technologies, such as design, simulation, and additive manufacturing, enhance their precision and efficiency, ensuring high quality and performance.

Solutions for Fabricated Metal and Plastic Products

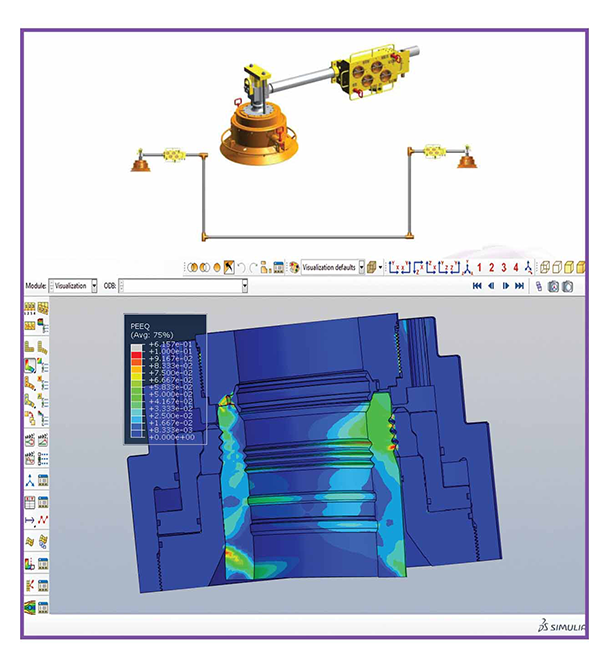

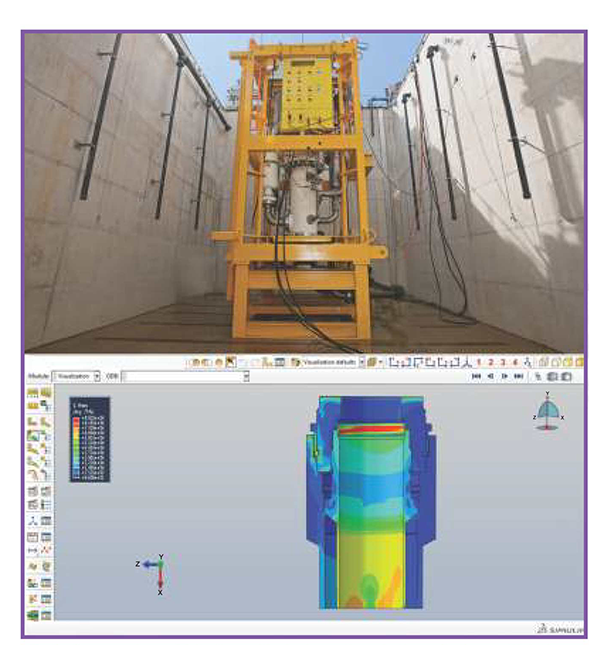

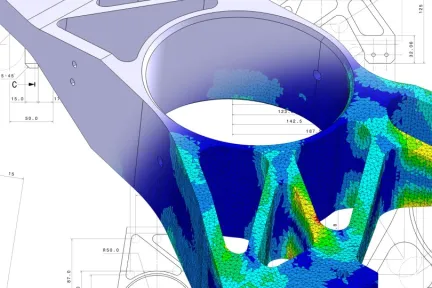

Ensuring Design Reliability for Consistent Performance

Design reliability is a key factor in ensuring that products perform as expected throughout their lifecycle, with minimal risk of failure. In industries ranging from automotive to aerospace, electronics to consumer goods, the ability to design products that can withstand real-world conditions while maintaining performance and durability is crucial.

Streamlining Project Management with Data-Driven Insights and Collaboration

In today’s fast-paced environment, data-driven project management is essential for ensuring projects are delivered on time and within budget. By leveraging real-time data, teams can track progress, manage resources efficiently, and identify risks early. This approach enables quick decision-making, reduces delays, and optimizes project outcomes.

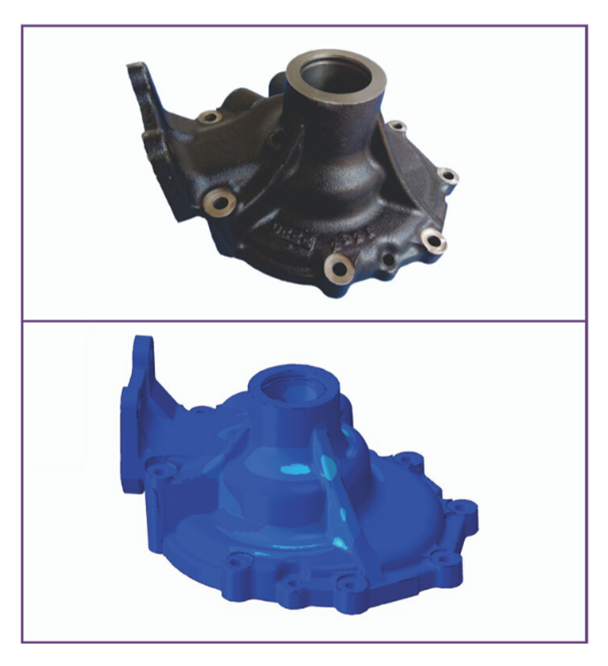

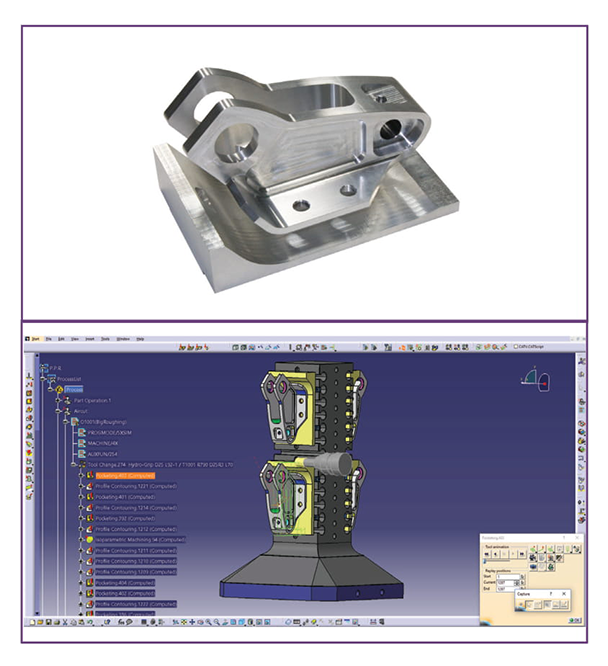

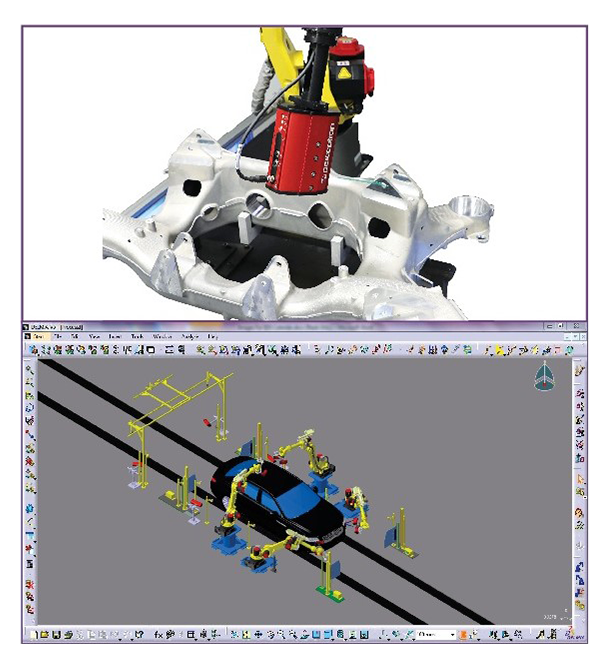

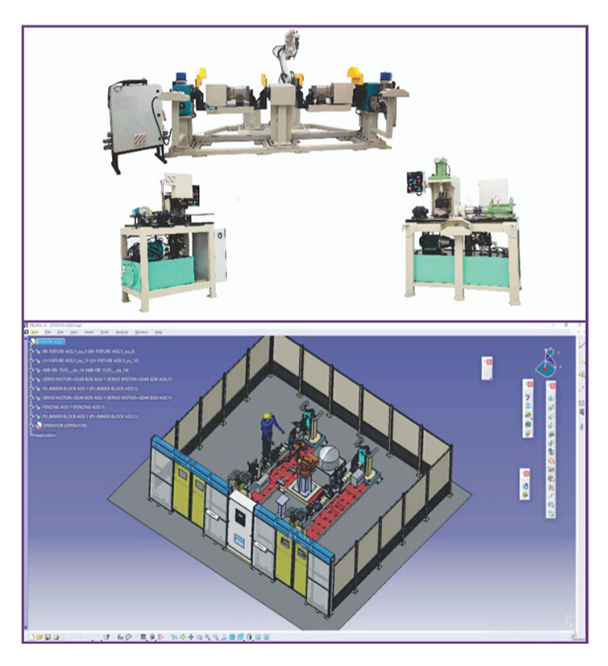

Enhancing Manufacturing Efficiency with Integrated Design Workflows

In today’s competitive manufacturing landscape, the integration between design and manufacturing workflows is critical for achieving higher efficiency, reduced costs, and faster time-to-market. When design and manufacturing processes are disconnected, errors, delays, and inefficiencies can arise, slowing down production and increasing operational costs. A seamless connection between these processes ensures that design intent is faithfully executed during production, improving product quality and reducing the need for rework.

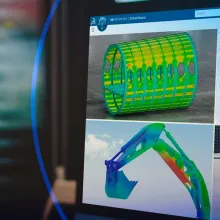

Optimized Design for Additive Manufacturing (DFAM)

Design for Additive Manufacturing (DFAM) transforms traditional design processes by enabling more efficient, innovative, and cost-effective solutions tailored for additive manufacturing technologies. This approach ensures that designs are optimized for 3D printing, making it possible to create complex geometries that were previously difficult or impossible to manufacture. By integrating advanced simulation, material selection, and process planning, DFAM accelerates product development cycles while maintaining or improving performance, reducing weight, and cutting costs.

Products

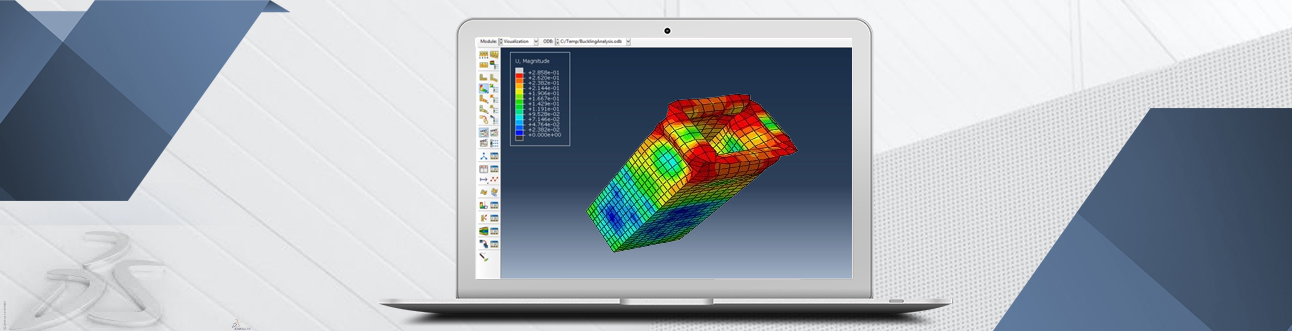

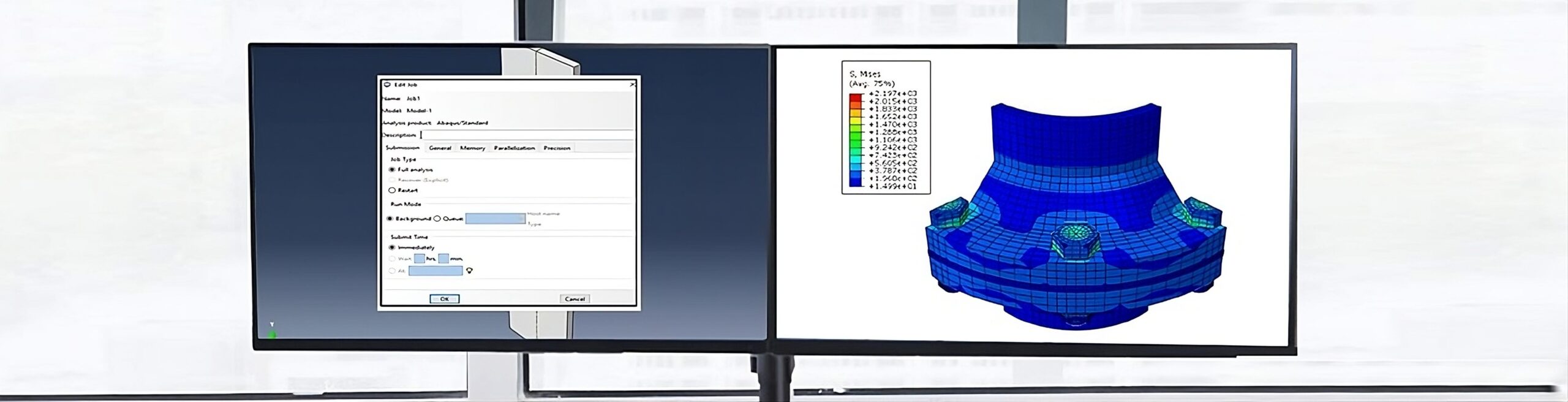

SIMULIA

Ensure the performance and reliability of specialized machinery with advanced simulation tools

DELMIA

Digitally transform production and assembly workflows for efficient equipment manufacturing

ENOVIA

Empowering manufacturing innovation through efficient planning, collaborative value networks, and virtual product development

EOS 3D Printing

Revolutionize aerospace part production with lightweight, durable 3D printing solution

Trends

Optimize Dealer Management

Optimizing dealer management in the fabricated metal and plastic products industry is essential for improving distribution efficiency, customer service, and supply chain visibility. Companies in this sector often face challenges like poor communication with dealers, difficulty tracking inventory, and inefficient logistics

Elevate Quality Management in Metal and Plastic Manufacturing

Elevating quality management in metal and plastic manufacturing is crucial for ensuring product consistency and meeting stringent industry standards. In the fabricated metal and plastic products industry, companies often face challenges such as inconsistent quality control processes, difficulty tracking defects, and managing complex compliance requirements. ENOVIA addresses these issues by providing a comprehensive product lifecycle management (PLM) solution that integrates quality data across the entire ma

Streamline Engineering to Manufacturing for Advanced Product Solutions

Streamlining engineering to manufacturing for advanced product solutions is crucial in the fabricated metal and plastic products industry to enhance efficiency and ensure high-quality outcomes. However, manufacturers often face challenges such as siloed teams, miscommunication, and difficulties in managing complex product data across the development lifecycle. ENOVIA addresses these issues by providing a robust product lifecycle management (PLM) solution that connects design, engineering, and manufacturing teams on a single platform. It enables real-time collaboration, centralized data management, and seamless transition from engineering to production, ensuring consistency, reducing errors, and accelerating the time-to-market for advanced product solutions.

Maximizing operational efficiency in the fabricated metal and plastic products

Maximizing operational efficiency in the fabricated metal and plastic products industry is essential for staying competitive and meeting growing demand. However, manufacturers often face challenges such as siloed data, inefficient workflows, and difficulty in coordinating between design, engineering, and production teams. ENOVIA addresses these challenges by providing a robust product lifecycle management (PLM) platform that centralizes data, enhances collaboration, and streamlines processes across

Latest Blog Posts

Discover our most recent posts across all industries, brands and topics.

Digitalization of Lean Practices in Shop Floor

Lean Manufacturing The word “lean” means no excess. So lean manufacturing can be explained simply as manufacturing which involves nominal waste. Lean manufacturing is all…

Understanding DELMIA Virtual Simulation

Typically, in a manufacturing organization, after the design stage and before manufacturing, there is a stage involving planning/PPC and manufacturing engineering. DELMIA (Digital Enterprise Lean…

An Integrated Solution for Manufacturing Complex Parts

Globalization and the fluctuations in customer demand in various industries have made manufacturing companies to rethink their current manufacturing process. The components are becoming very…

Smart Factory

Rise in demand, globalization and uncertain pandemic conditions have made manufacturing sector adopt various changes, one of which is smart factory or digital factory. Due…

How to model a structure undergoing global instability in Abaqus?

A nonlinear static problem can be unstable as a result of global buckling or material softening. If the load-displacement response of the model seems to…

How to Ensure Uninterrupted Analysis in Abaqus by using Restart Analysis?

The one aspect which is the most desirable while performing an analysis is that it should complete without any errors or interruptions. However, this is…

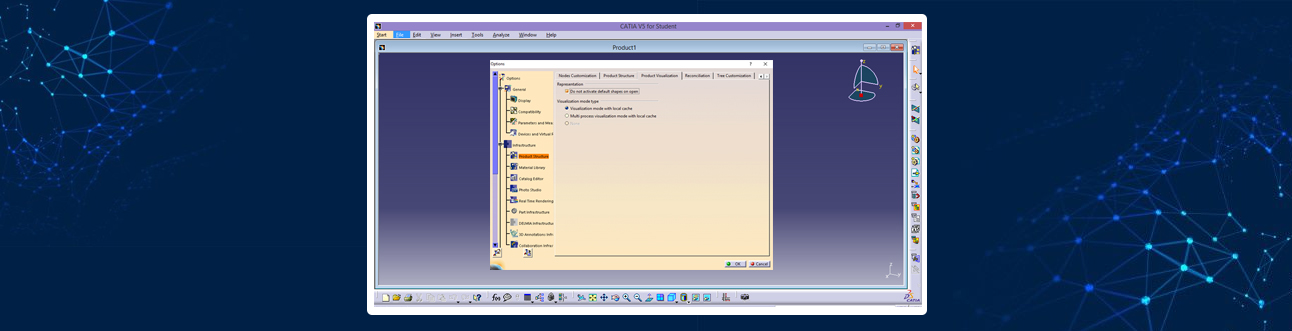

Large Assembly Management in CATIA V5

Working with large assemblies in the CATIA V5 system can be very demanding. Even with the use of extremely powerful machines and workstations, working with…

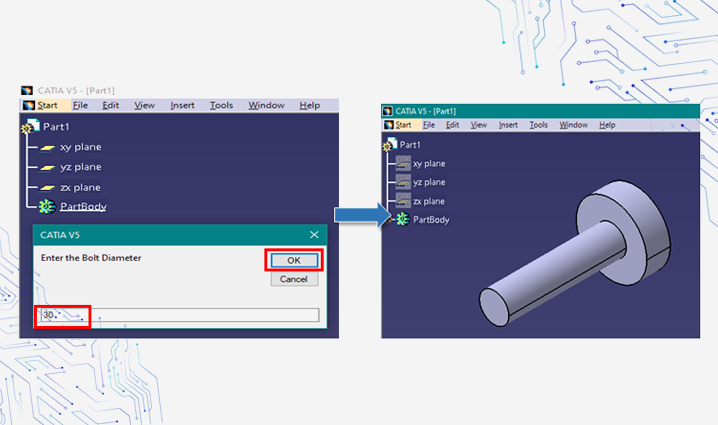

Automate your CAD using CATIA V5 Macros

Performing repetitive tasks manually leads to a loss of productivity. This is one of the major reasons why organizations are increasingly trying to automate processes…