Smart Factory

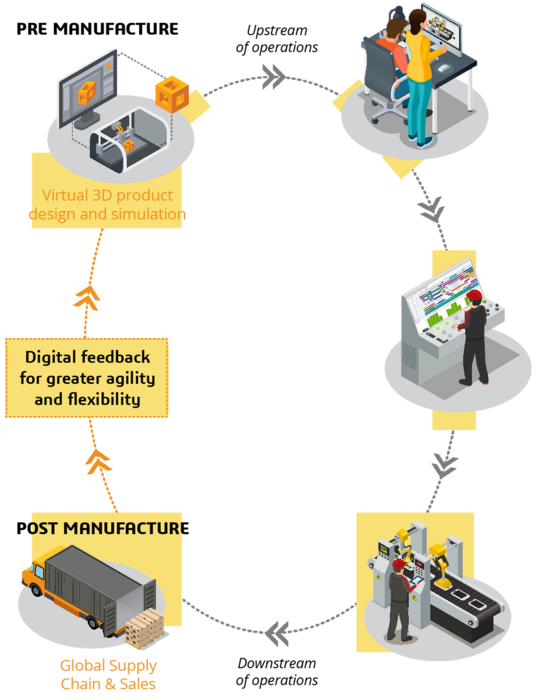

Rise in demand, globalization and uncertain pandemic conditions have made manufacturing sector adopt various changes, one of which is smart factory or digital factory. Due to the pandemic, the adoption of digital factory is accelerated across the globe and the actual potential of digital transformation is realized even better now.

What is a Smart Factory?

Smart factory leverages digital platform and technology to make significant improvements in productivity, quality, service and flexibility.

Basically, the machines are connected to cloud network with the help of smart sensors. The digital platform gets real time data from all the connected machines through smart sensors to assess the on-going production and also to tackle the risk of machine breakdowns and other unavoidable situations.

How we help customers adopt Smart Factory?

With the manufacturing landscape increasingly customized and demand driven, complex manufacturing processes must be navigated towards achieving cost and production efficiencies. This can be ensured by DELMIA – developed with leading global manufacturers – over 3DEXPERIENCE platform which will give a competitive advantage.

DELMIA delivers four desired outcomes:

- CONNECTIVITY

Digital continuity with back office and supply chain systems for fast and accurate change management.

- INTEGRATION

Smart data integration with analytics, reporting and visualization across the value chain

- CENTRALIZATION

Manage, orchestrate and monitor the full production process with real-time simulation on a 3D virtual shop floor twin.

- INFORMED DECISION-MAKING

Intelligent planning, scheduling and resourcing on a smart and data-integrated single source of truth.

Through DELMIA, digital optimization can be achieved of the below 3 operational disciplines:

- DIGITALIZATION OF MANUFACTURING ENGINEERING

- Robotics

- Fabrication

- Ergonomics

- Process planning

- Collaborative manufacturing

Create 3D virtual processes on a data-integrated 3D virtual twin of the shop floor, to minimize risks and maximize opportunities with full operations visibility.

- ADVANCED PLANNING & SCHEDULING

- Sales and operations planning

- Master planning

- Detailed production scheduling

Enable data-driven what-if scenario planning, and informed decision making.

- ENHANCED MES (MOM)

- Labour

- Maintenance

- Warehouse

- Traceability

- Intelligence

- Production

- Quality

- Centre of Excellence

Optimize Manufacturing Execution Systems with smart integration to ERP and machines.

Benefits of a Smart Factory:

- Manufacturing industries get greater visibility

- More-informed decisions can be taken

- Achieve faster turnaround times

- Lower costs

Thus, smart factory leverages digital platform and technology to make significant improvements in productivity, quality, service and flexibility.

Mr. Goutham started his career as Design Engineer, worked on different CAD software applications. He is currently working as Solution Consultant with EDS Technologies & he is part of CATIA 3DEXPERIENCE CoE team. He has good exposure on manufacturing aspects with respect to Aerospace Industry. He carries a rich experience of 8 years in the field of PLM/Digital EXPERIENCE platform.