Industrial Equipment

Solutions for the Industrial Equipment

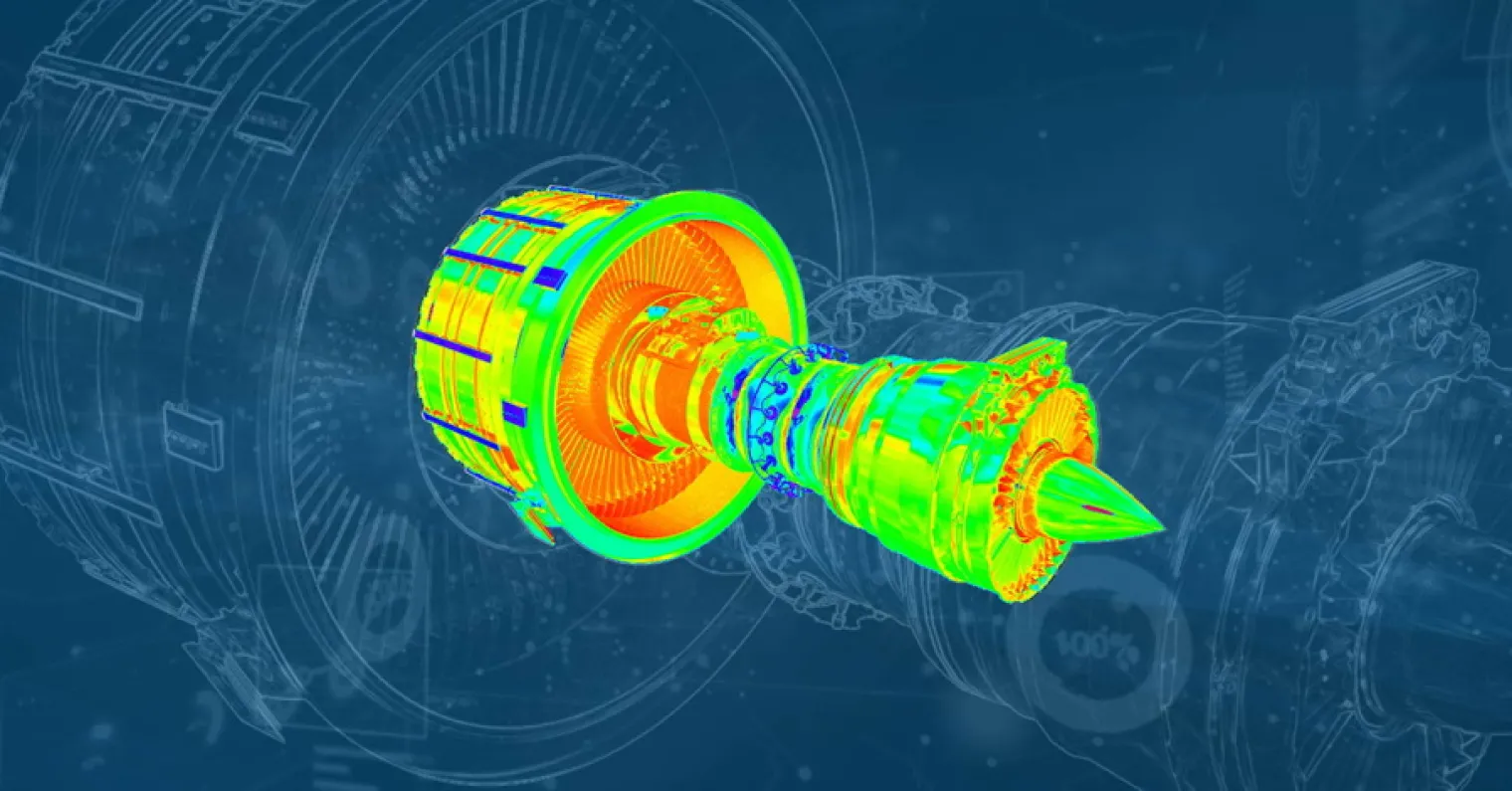

Ensuring Design Reliability for Consistent Performance

Design reliability is a key factor in ensuring that products perform as expected throughout their lifecycle, with minimal risk of failure. In industries ranging from…

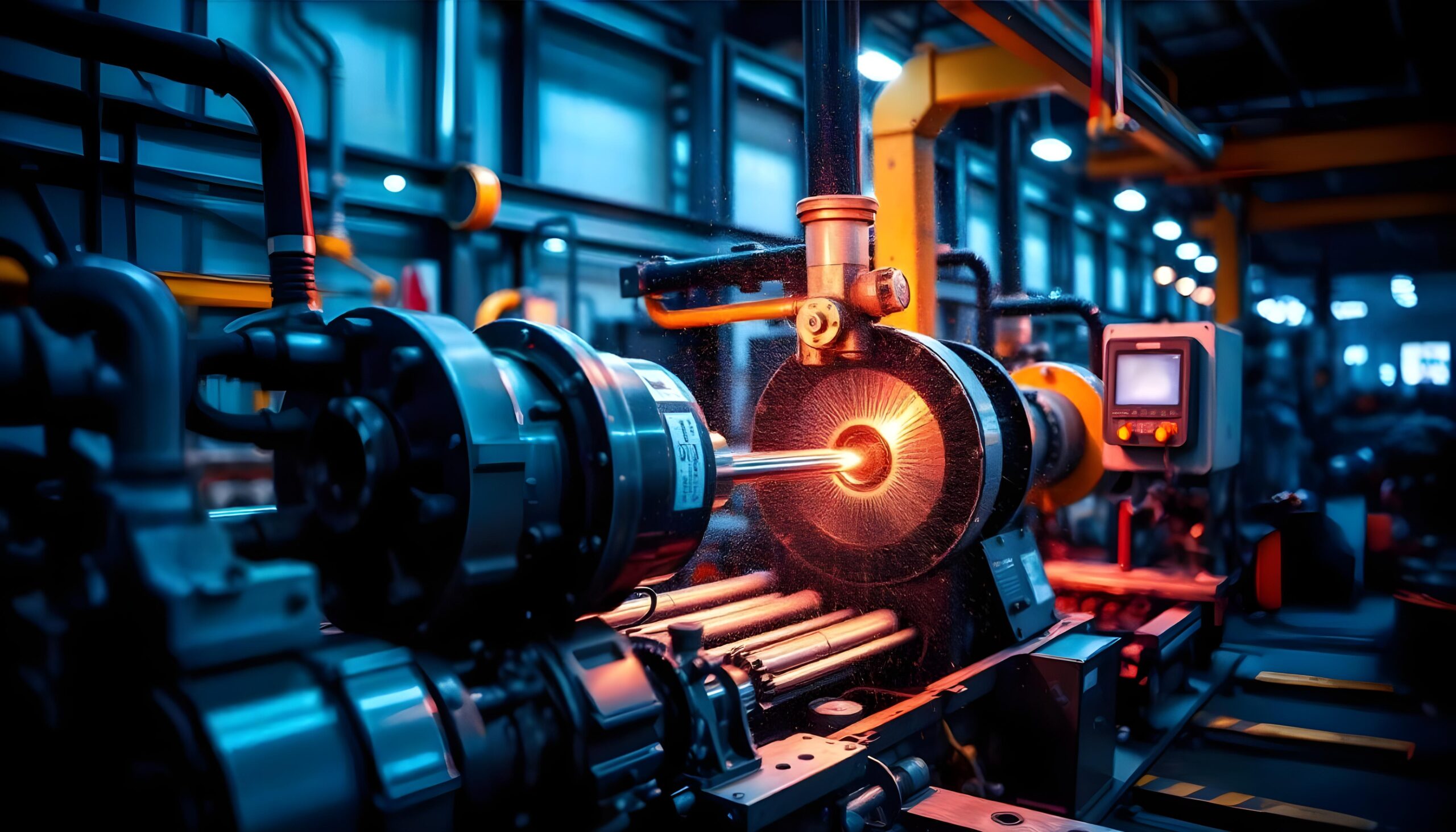

Streamlining Project Management with Data-Driven Insights and Collaboration

In today’s fast-paced environment, data-driven project management is essential for ensuring projects are delivered on time and within budget. By leveraging real-time data, teams can…

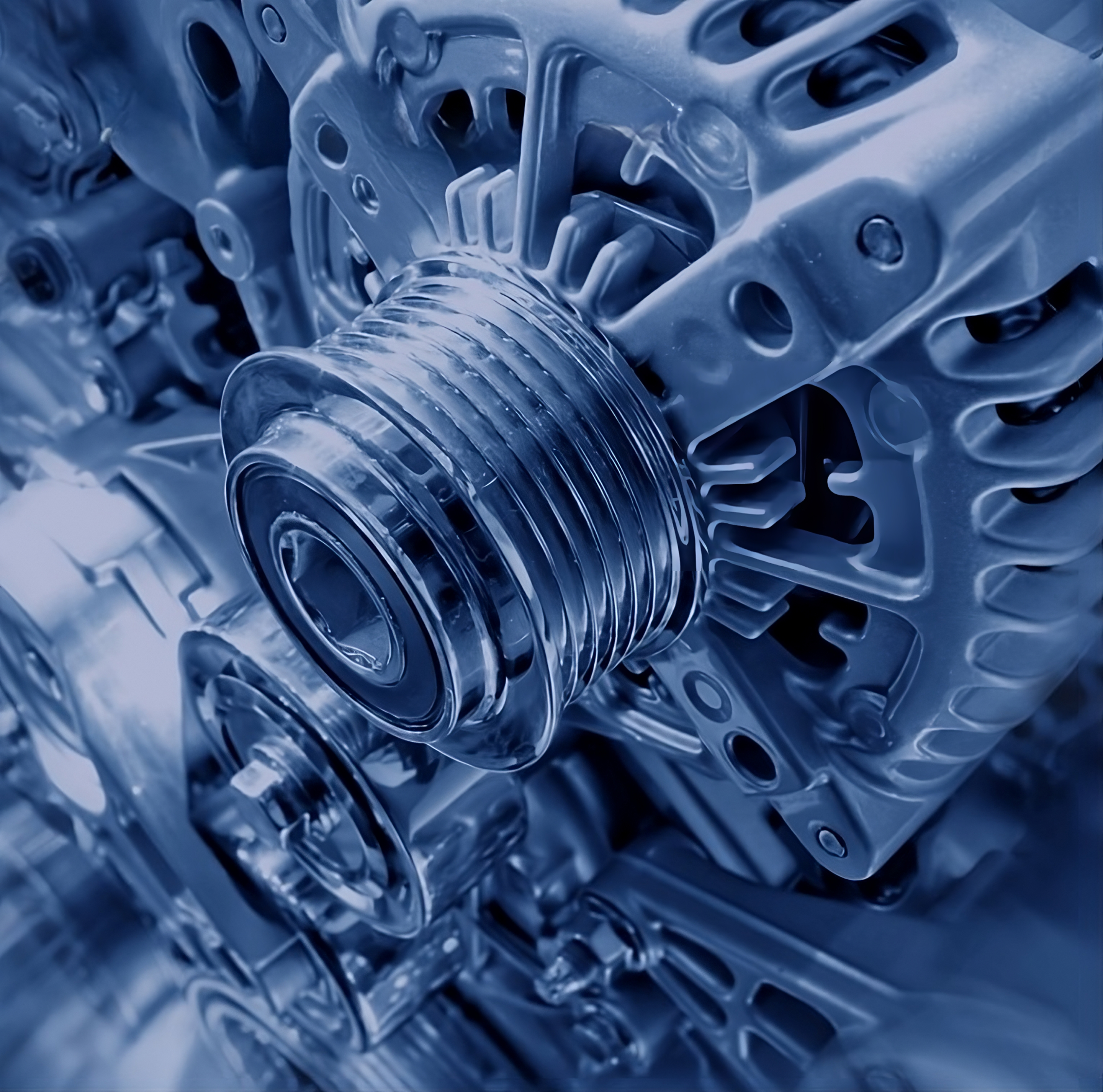

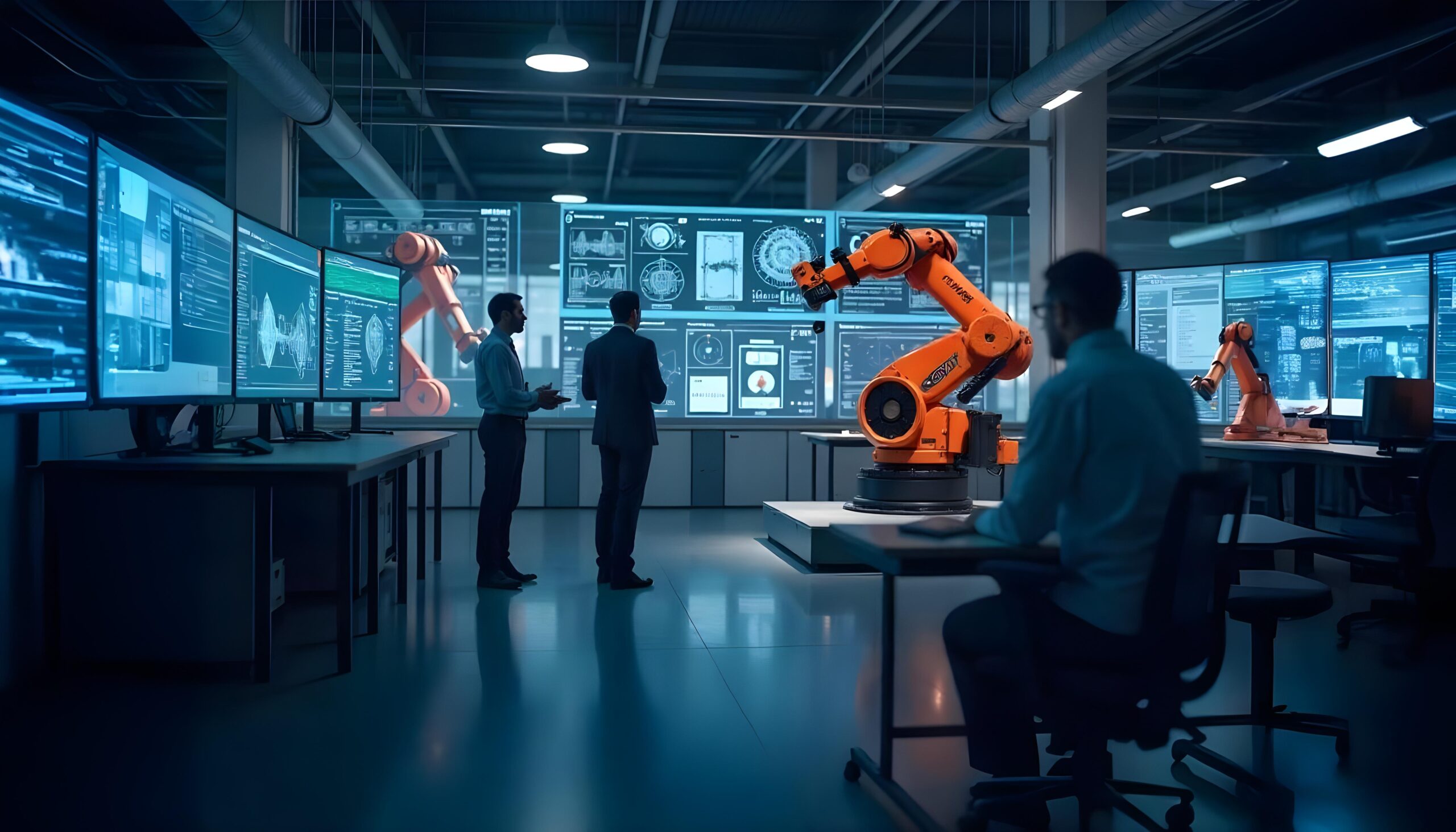

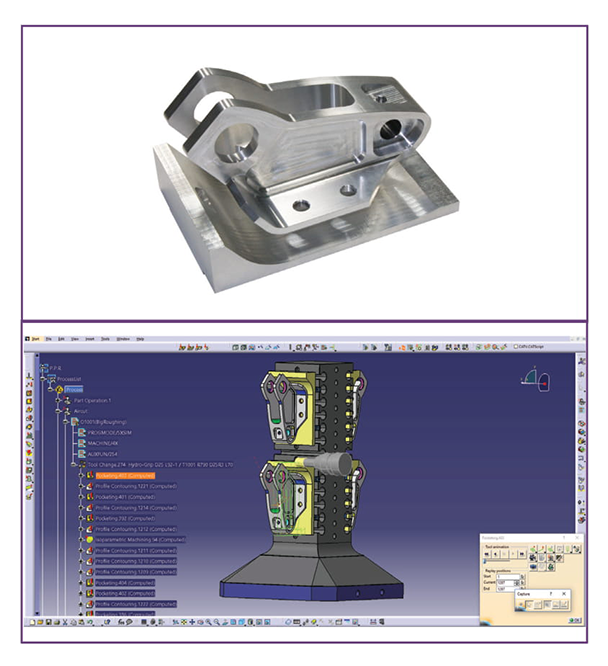

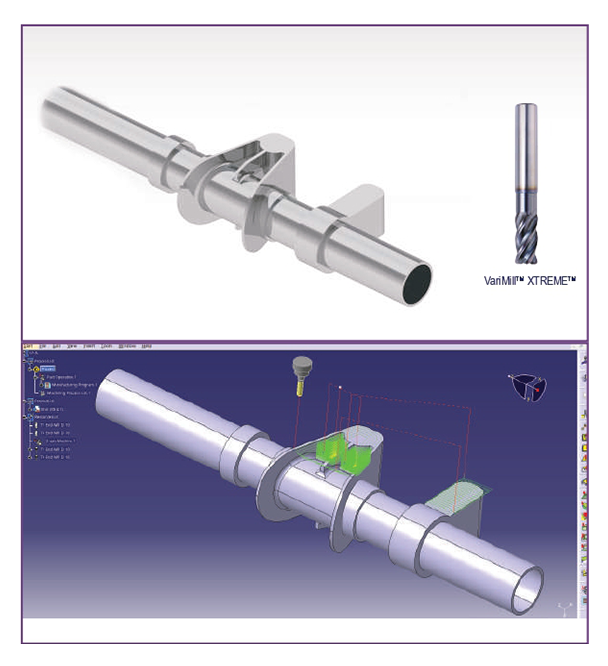

Enhancing Manufacturing Efficiency with Integrated Design Workflows

In today’s competitive manufacturing landscape, the integration between design and manufacturing workflows is critical for achieving higher efficiency, reduced costs, and faster time-to-market. When design…

Optimizing Human Ergonomics for Safety and Comfort

Human ergonomics is essential for enhancing safety, comfort, and productivity in industries such as automotive, industrial equipment, and heavy machinery. Designing vehicles, machinery, and workspaces…

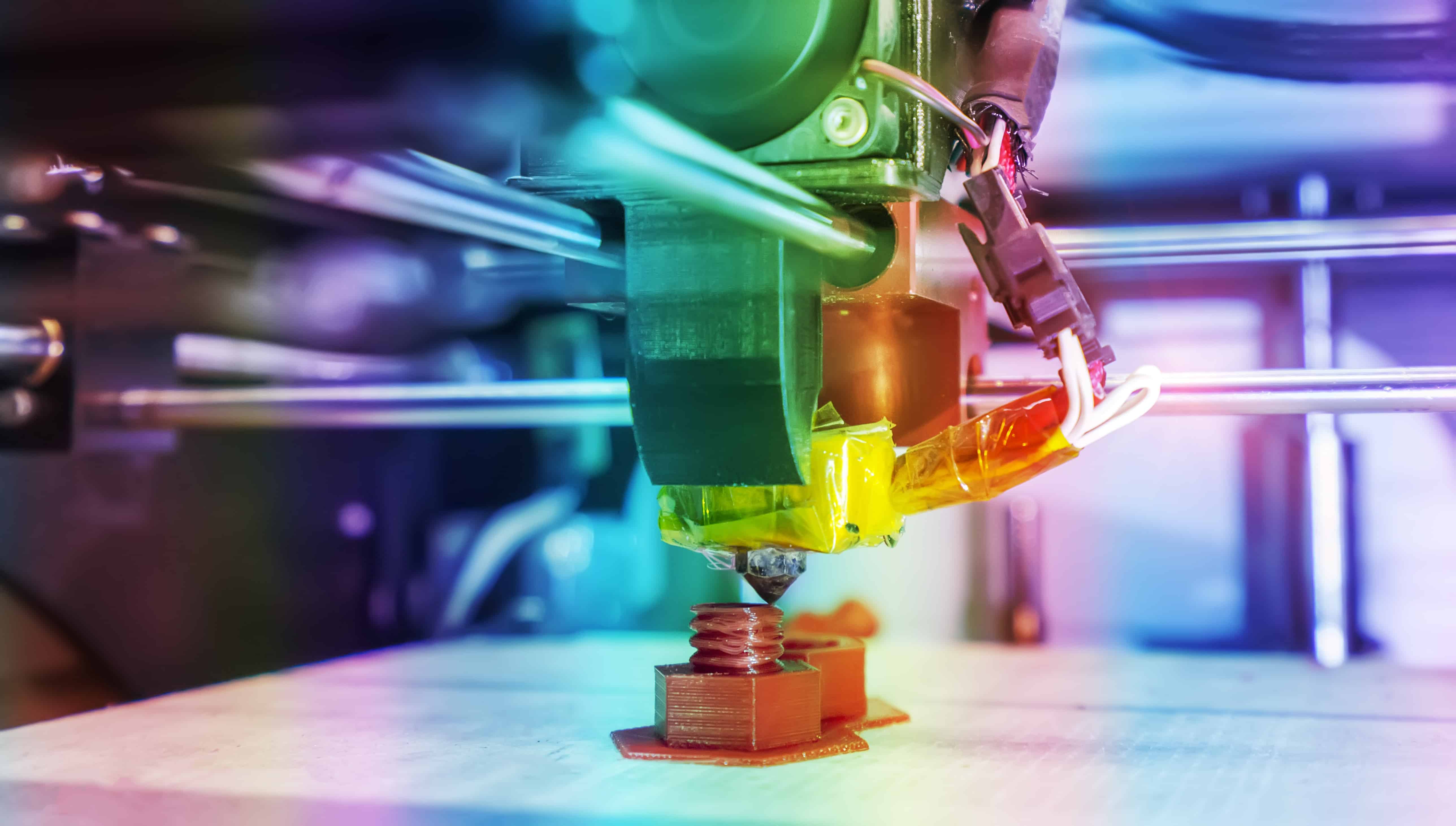

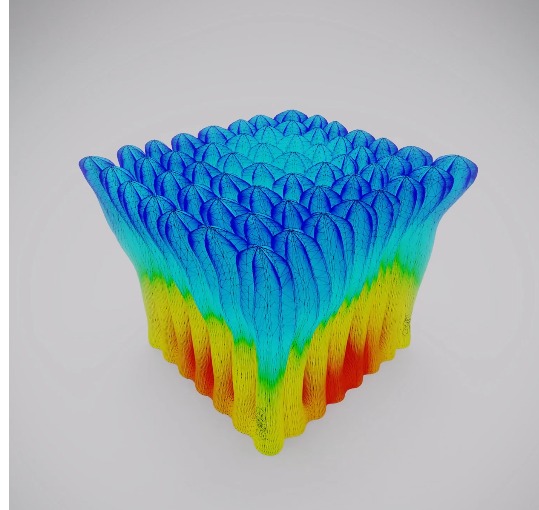

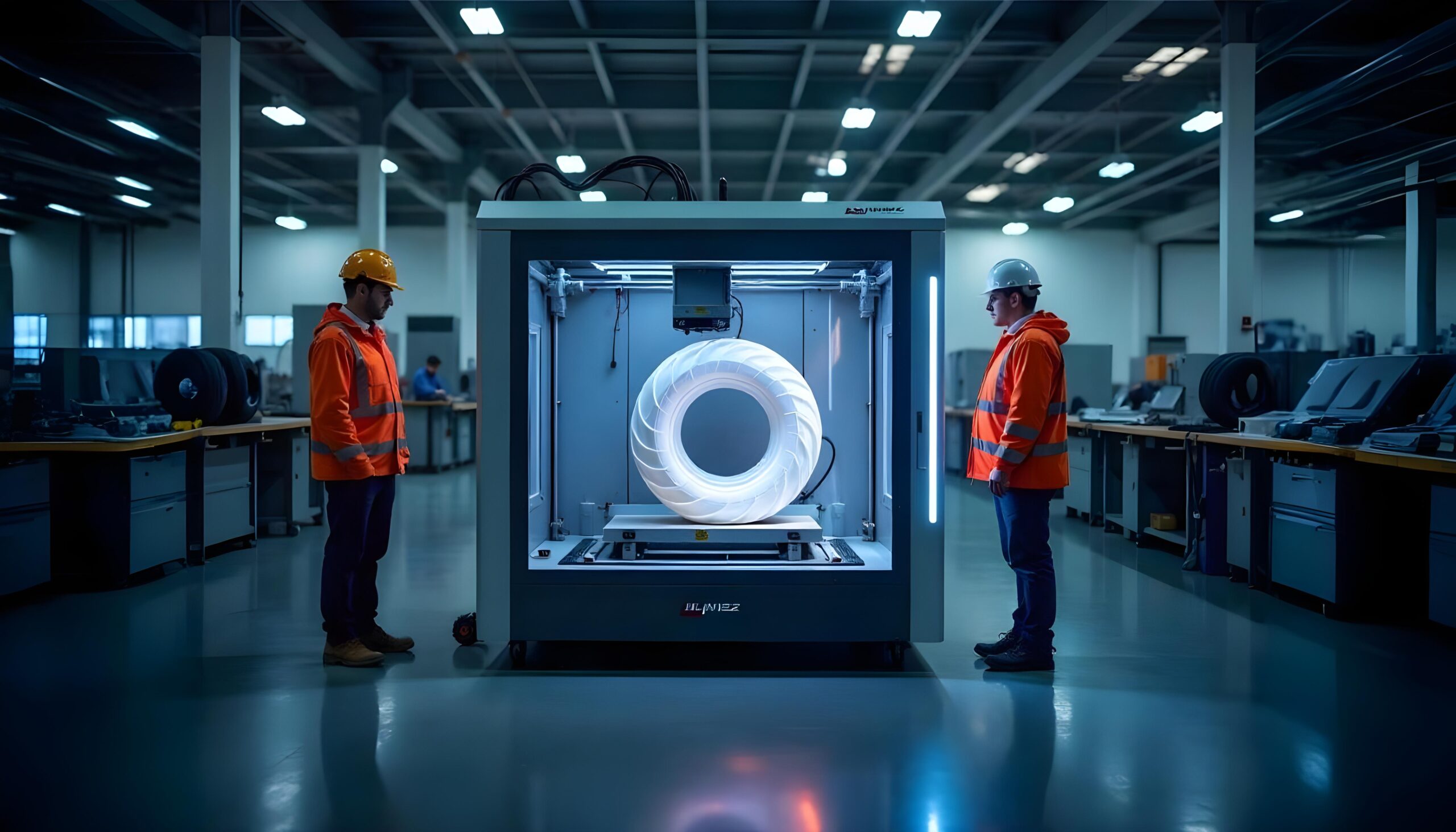

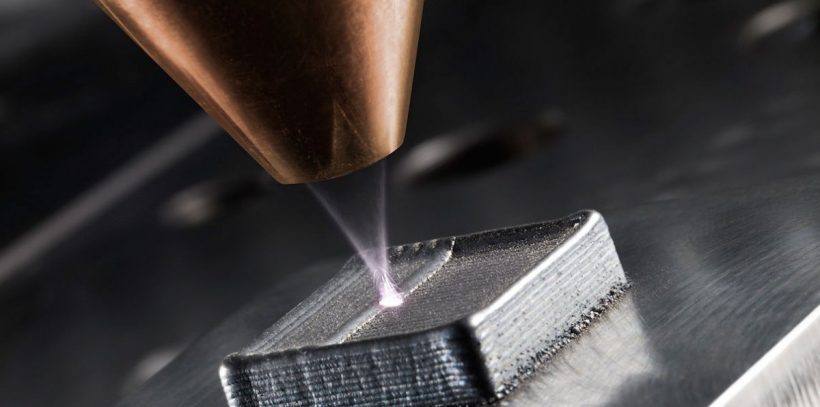

Optimized Design for Additive Manufacturing (DFAM)

Design for Additive Manufacturing (DFAM) transforms traditional design processes by enabling more efficient, innovative, and cost-effective solutions tailored for additive manufacturing technologies. This approach ensures…

Segments

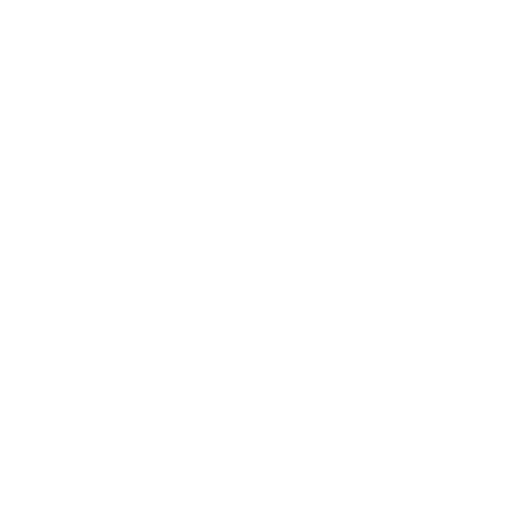

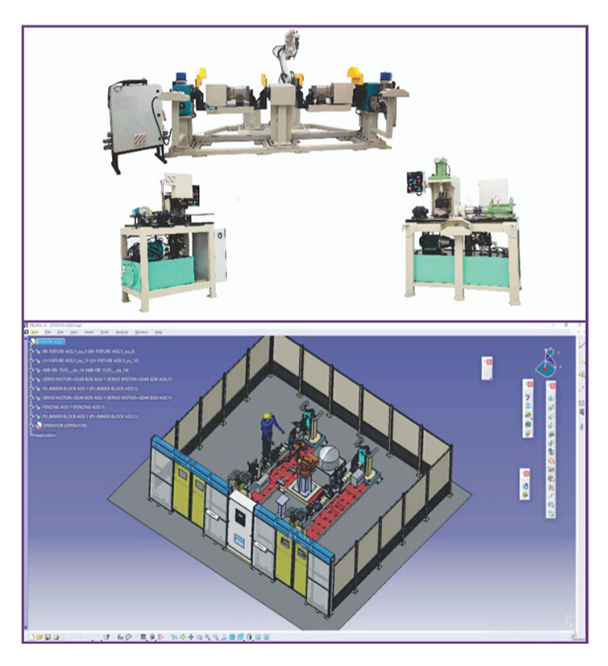

Specialized Manufacturing Machinery

Precision-engineered machinery, driving efficiency in every step of production

Fabricated Metal and Plastic Products

Crafting durability and innovation with every metal and plastic product

Heavy Mobile Machinery and Equipment

Powering progress with robust mobile machinery built for the toughest jobs

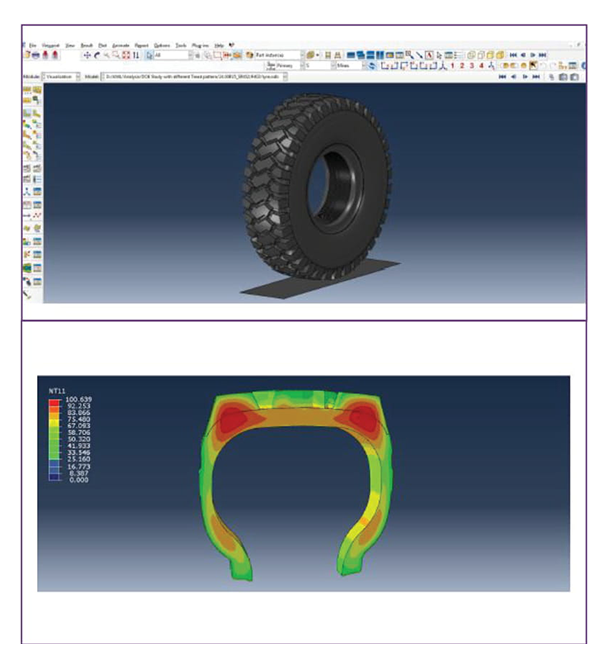

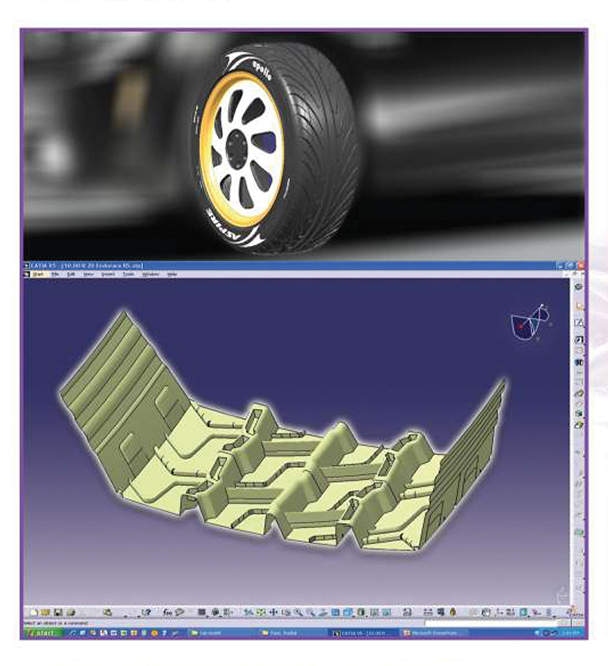

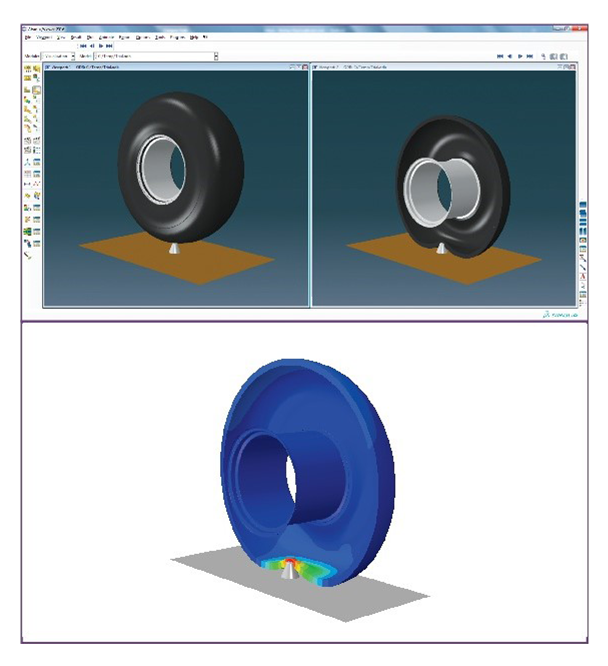

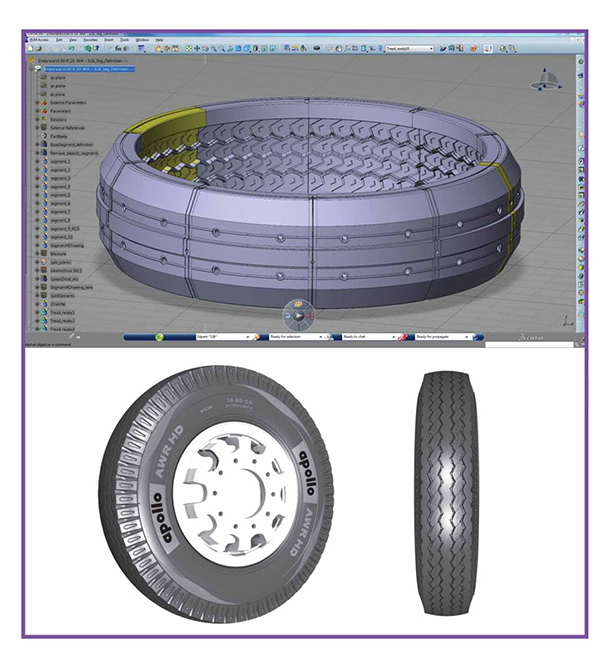

Tyre Manufacturers

Driven by quality, built for the road – excellence in every durable tyre

Specialized Manufacturing Machinery

Precision-engineered machinery, driving efficiency in every step of production

Fabricated Metal and Plastic Products

Crafting durability and innovation with every metal and plastic product

Heavy Mobile Machinery and Equipment

Powering progress with robust mobile machinery built for the toughest jobs

Tyre Manufacturers

Driven by quality, built for the road – excellence in every durable tyre

Products

CATIA

Accelerate industrial innovation with CATIA’s advanced design and modeling capabilities

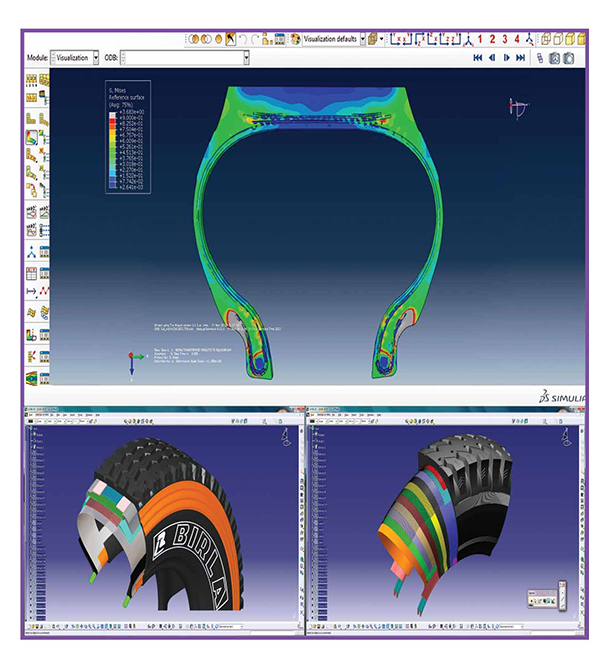

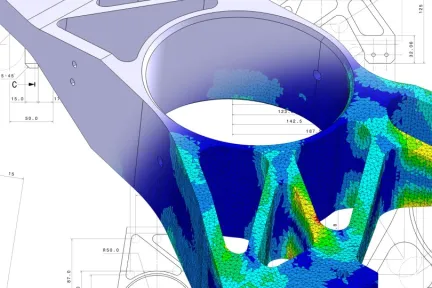

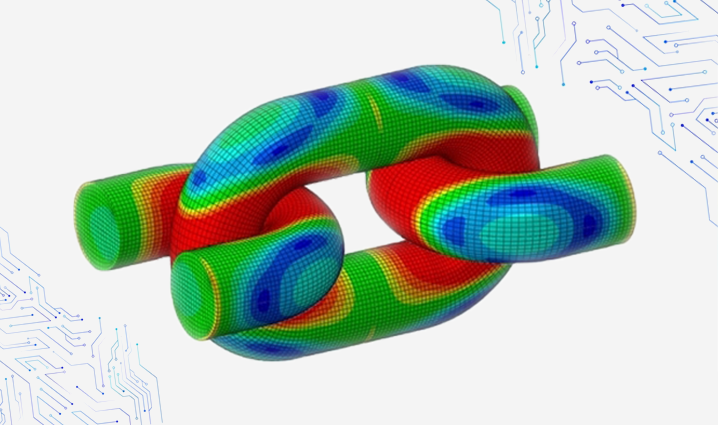

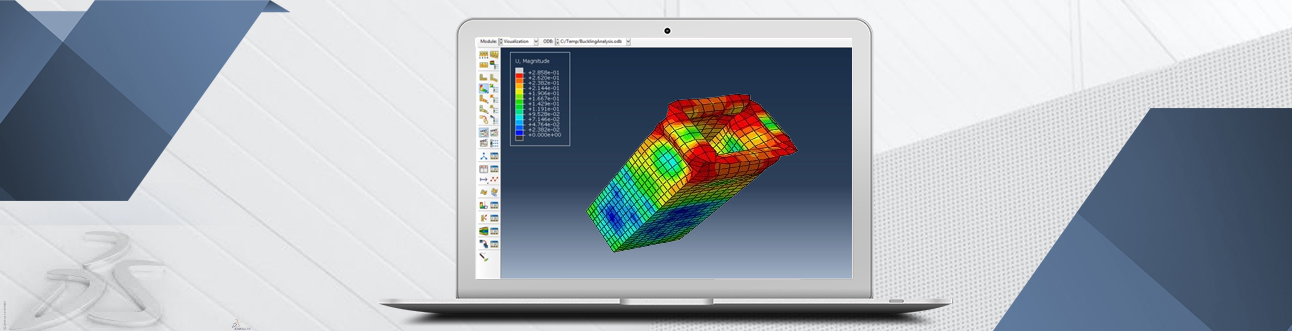

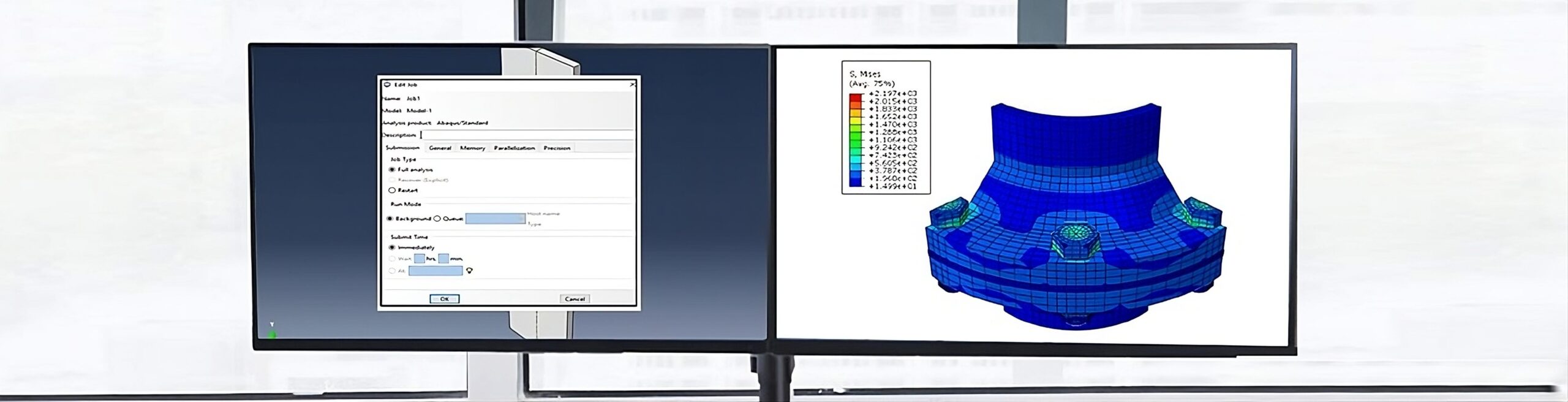

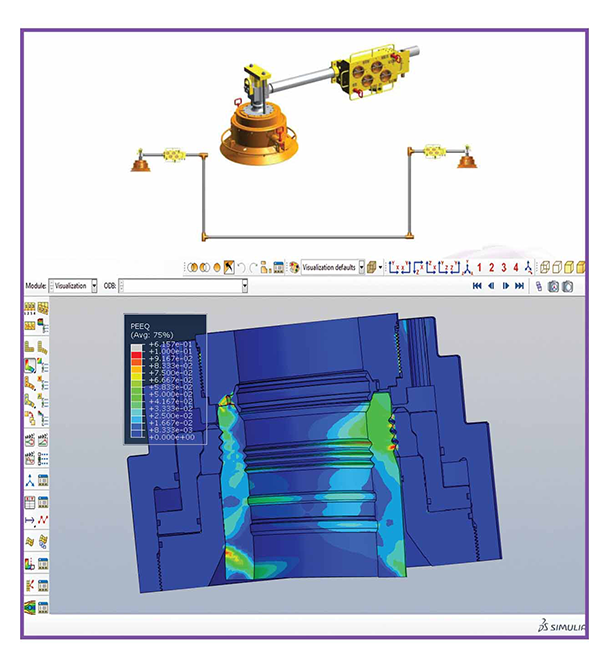

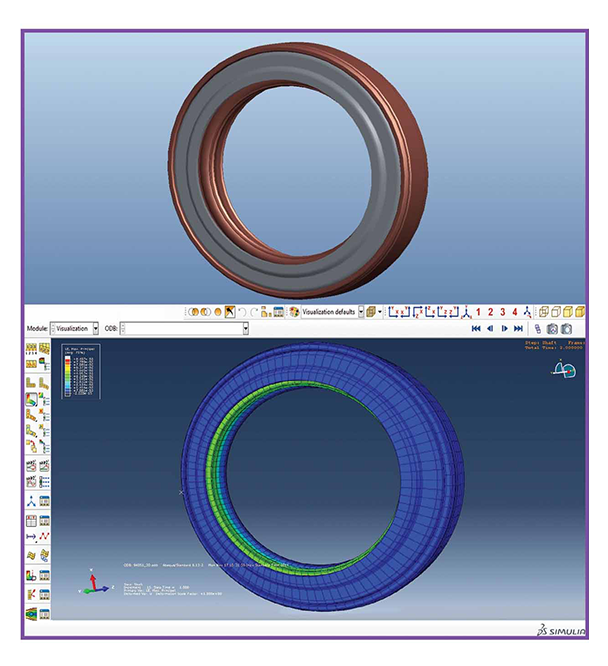

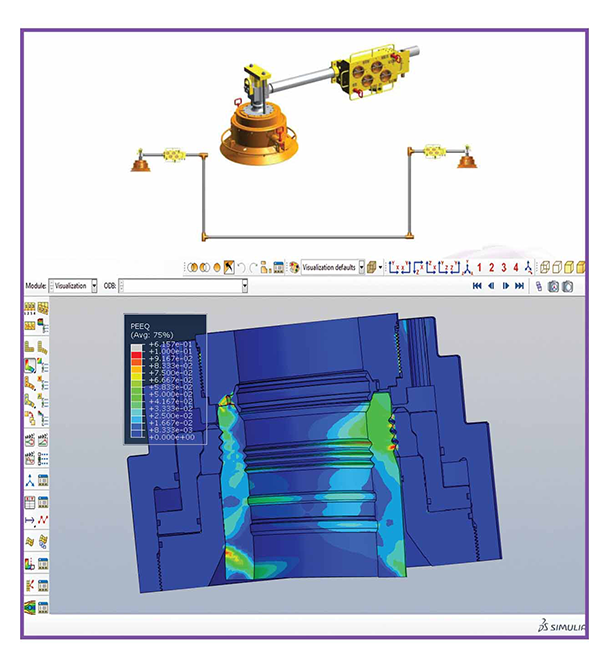

SIMULIA

Optimize performance, durability, and safety of industrial equipment with advanced simulation

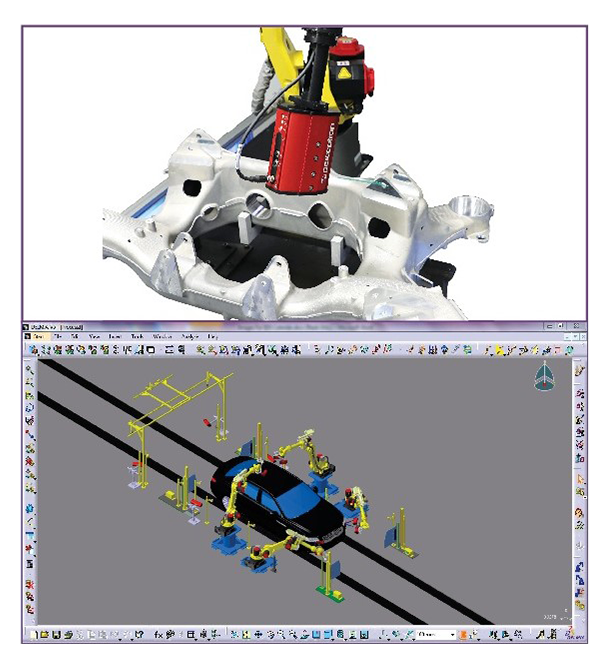

DELMIA

Digitally transform production and assembly workflows for efficient equipment manufacturing

EOS 3D Printing

Accelerate prototyping and production of industrial parts with precision 3D printing solutions

RAMSIS

Ensure ergonomic efficiency and safety in industrial machinery design with advanced human modeling

Trends

The Future of Operations with Advanced Manufacturing Technologies

The future of operations in the specialized manufacturing machinery industry is being shaped by advancements in automation, artificial intelligence, and data analytics. As industries push for higher efficiency, precision, and flexibility, manufacturers are faced with challenges such as managing complex supply chains, optimizing production processes, and ensuring product quality at scale. DELMIA, a leading digital manufacturing solution, addresses these challenges by offering cutting-edge tools for virtual manufacturing, production planning, and real-time monitoring. By integrating AI-driven insights, DELMIA helps manufacturers streamline operations, reduce downtime, and enhance overall productivity, enabling them to stay competitive in a rapidly evolving market.

Maximizing operational efficiency in specialized machinery production

Maximizing operational efficiency in specialized machinery production is crucial for meeting growing market demands and maintaining competitiveness. However, manufacturers face challenges such as complex design processes, inefficient collaboration, and difficulty managing product lifecycle data across multiple teams. ENOVIA, a robust product lifecycle management (PLM) solution, tackles these issues by providing a unified platform for managing design, engineering, and manufacturing data. By enhancing collaboration and ensuring real-time access to critical information, ENOVIA streamlines workflows, reduces errors, and accelerates time-to-market. This empowers manufacturers to optimize their operations, improve product quality, and drive efficiency throughout the entire production cycle.

Revolutionize Automation with 3D Printed Extraction Grippers

Revolutionizing automation in specialized manufacturing machinery, particularly with 3D printed extraction grippers, is transforming how industries handle precision tasks. Traditional manufacturing methods face challenges such as the high cost of custom tooling, long lead times, and limited design flexibility. EOS 3D Printers address these iss

Drive efficiency in machinery design and manufacturing with integrated life cycle management

Driving efficiency in machinery design and manufacturing requires seamless integration across the entire product lifecycle. In the specialized manufacturing machinery industry, companies often face challenges like fragmented data, inefficient collaboration, and difficulty managing complex design revisions. ENOVIA addresses these issues by offering an integrated life cycle management solution that connects all stages of product development—from design and engineering to manufacturing and maintenance. By providing a single platform for data management and real-time collaboration, ENOVIA streamlines processes, improves accuracy, reduces errors, and accelerates time-to-market, ultimately driving greater efficiency and innovation in machinery design and production.

Optimize Dealer Management

Optimizing dealer management in the fabricated metal and plastic products industry is essential for improving distribution efficiency, customer service, and supply chain visibility. Companies in this sector often face challenges like poor communication with dealers, difficulty tracking inventory, and inefficient logistics

Elevate Quality Management in Metal and Plastic Manufacturing

Elevating quality management in metal and plastic manufacturing is crucial for ensuring product consistency and meeting stringent industry standards. In the fabricated metal and plastic products industry, companies often face challenges such as inconsistent quality control processes, difficulty tracking defects, and managing complex compliance requirements. ENOVIA addresses these issues by providing a comprehensive product lifecycle management (PLM) solution that integrates quality data across the entire ma

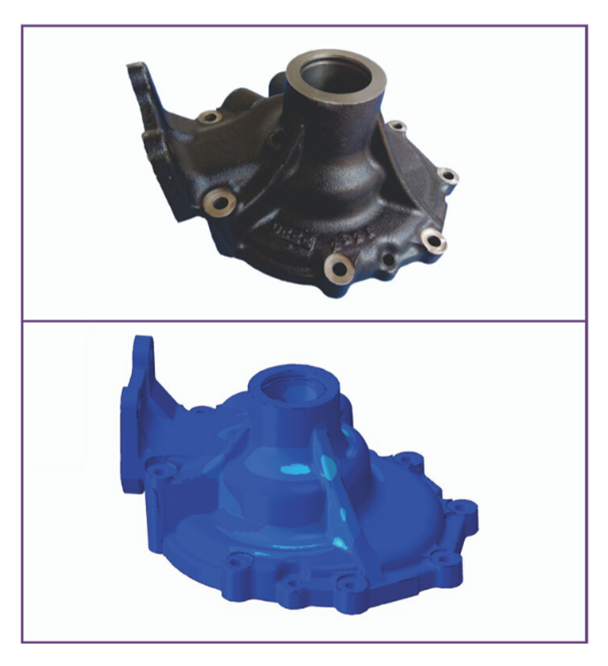

Streamline Engineering to Manufacturing for Advanced Product Solutions

Streamlining engineering to manufacturing for advanced product solutions is crucial in the fabricated metal and plastic products industry to enhance efficiency and ensure high-quality outcomes. However, manufacturers often face challenges such as siloed teams, miscommunication, and difficulties in managing complex product data across the development lifecycle. ENOVIA addresses these issues by providing a robust product lifecycle management (PLM) solution that connects design, engineering, and manufacturing teams on a single platform. It enables real-time collaboration, centralized data management, and seamless transition from engineering to production, ensuring consistency, reducing errors, and accelerating the time-to-market for advanced product solutions.

Maximizing operational efficiency in the fabricated metal and plastic products

Maximizing operational efficiency in the fabricated metal and plastic products industry is essential for staying competitive and meeting growing demand. However, manufacturers often face challenges such as siloed data, inefficient workflows, and difficulty in coordinating between design, engineering, and production teams. ENOVIA addresses these challenges by providing a robust product lifecycle management (PLM) platform that centralizes data, enhances collaboration, and streamlines processes across

Enhance Operator Comfort and Safety for Heavy Machinery and Equipment

Enhancing operator comfort and safety is crucial in the heavy machinery and equipment industry, where operators face physically demanding and potentially hazardous working conditions. Key challenges include improving ergonomics, reducing operator fatigue, and ensuring safety during operation, especially in complex and high-risk environments. RAMSIS addresses these challenges by providing advanced simulation tools that allow manufacturers to design and analyze machinery cabins, operator seats, and contr

Collaborative Mechatronics Engineering for Heavy Mobile Machinery

Collaborative mechatronics engineering is essential for optimizing the design and performance of heavy mobile machinery, where multiple engineering disciplines—such as mechanical, electrical, and software—must work together seamlessly. However, key challenges in the heavy machinery industry include fragmented

Streamline Engineering to Manufacturing for Heavy Machinery

Streamlining the engineering to manufacturing process is crucial in the heavy mobile machinery and equipment industry to reduce production time, improve product quality, and increase overall efficiency. However, key challenges include disconnected workflows, inefficient communication between design and manufacturing teams, and difficulty in managing complex product data. A robust product lifecycle management (PLM) solution addresses these issues by providing a centralized platform for managing all stages of product development. By improving collaboration, enabling real-time dat

Maximize Operational Efficiency for Heavy Equipment Manufacturing

Maximizing operational efficiency in heavy equipment manufacturing is essential to meet market demands while controlling costs and maintaining high-quality standards. However, manufacturers face challenges such as complex supply chains, inefficient production scheduling, and difficulty optimizing machine utilization.

Unlock Advanced Tyre Insights with SmarTyre Technology

Unlocking advanced tire insights is essential for tire manufacturers to enhance performance, safety, and longevity. However, challenges such as limited real-time data, the complexity of tire behavior under various conditions, and the need for continuous innovation can hinder the development of optimized products. SIMULIA, with its SmarTyre technology, addresses these issues by providing high-fidelity simulations that analyze tire performance in real-time, accounting for various road conditions, loads, and wear patterns. By leveraging advanced computational models, SIMULIA enables manufacturers to gain deeper insights into tire behavior, leading to more accurate predictions, improved product designs, and faster time-to-market for advanced tire solutions.

Optimize Road-Load Prediction with High-Fidelity Simulation

Optimizing road-load prediction is crucial for tire manufacturers to improve product performance, durability, and safety. However, key challenges include accurately simulating complex tire-road interactions, predicting load responses under varying conditions, and ensuring tire designs meet regulatory and consumer expectations. SIMULIA addresses these issues by providing high-fidelity simulation tools that enable manufacturers to model and analyze tire behavior with precision. By using advanced compu

Reduce Tyre Moulding Cost and Lead Times with 3D Printing

Reducing tire molding costs and lead times is crucial for tire manufacturers to stay competitive and meet market demands efficiently. However, key challenges include high tooling costs, lengthy production cycles, and limited flexibility in mold design. EOS and OPTOMEC 3D Printers address these issues by enabling the production of highly customizable, cost-effective molds through additive manufacturing. By using 3D printing technology, manufacturers can rapidly prototype, iterate, and produce molds with complex geometries at a fraction of the traditional cost and time. This not only reduces lead times but also enhances design flexibility, ultimately lowering production costs and improving overall efficiency in tire manufacturing.

Maximizing Fuel Efficiency Through Innovative Tyre Design

Maximizing fuel efficiency through innovative tire design is a critical goal for tire manufacturers aiming to meet growing environmental demands and improve vehicle performance. However, key challenges include optimizing tire tread patterns, materials, and structures to reduce rolling resistance without com

Latest Blog Posts

Discover our most recent posts across all industries, brands and topics.

A Deep Dive into the Future of Additive Manufacturing

Additive Manufacturing (AM) Additive Manufacturing (AM), commonly referred to as 3D printing is a manufacturing process to form 3D physical parts from CAD DATA. In…

Overview on DMLS Process for 3D Printing and its Applications in Space Industry

Additive Manufacturing Additive manufacturing is a specific 3D printing process where parts are built layer by layer by depositing material according to digital 3D design data. For…

Digitalization of Lean Practices in Shop Floor

Lean Manufacturing The word “lean” means no excess. So lean manufacturing can be explained simply as manufacturing which involves nominal waste. Lean manufacturing is all…

Understanding DELMIA Virtual Simulation

Typically, in a manufacturing organization, after the design stage and before manufacturing, there is a stage involving planning/PPC and manufacturing engineering. DELMIA (Digital Enterprise Lean…

An Integrated Solution for Manufacturing Complex Parts

Globalization and the fluctuations in customer demand in various industries have made manufacturing companies to rethink their current manufacturing process. The components are becoming very…

How to Enforce Contact Constraints using Augmented Lagrangian Method in Abaqus/Standard?

There are three methods of contact constraint enforcement that are available in Abaqus/Standard: The direct Lagrange multiplier method, The augmented Lagrangian method, and The penalty…

How to model a structure undergoing global instability in Abaqus?

A nonlinear static problem can be unstable as a result of global buckling or material softening. If the load-displacement response of the model seems to…

How to Ensure Uninterrupted Analysis in Abaqus by using Restart Analysis?

The one aspect which is the most desirable while performing an analysis is that it should complete without any errors or interruptions. However, this is…

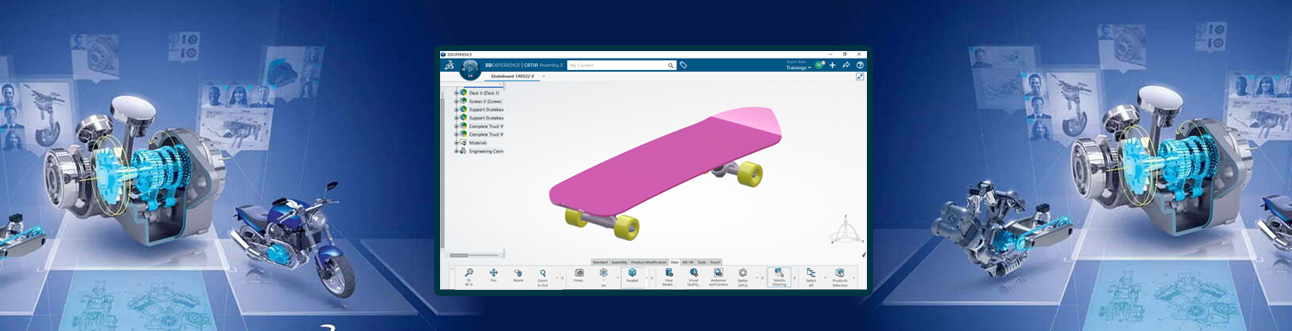

Achieve Product Design Excellence with CATIA 3DEXPERIENCE

CATIA is one of the widely used software applications for product design across various industries. CATIA has helped organizations to conceptualize, design and conform to…

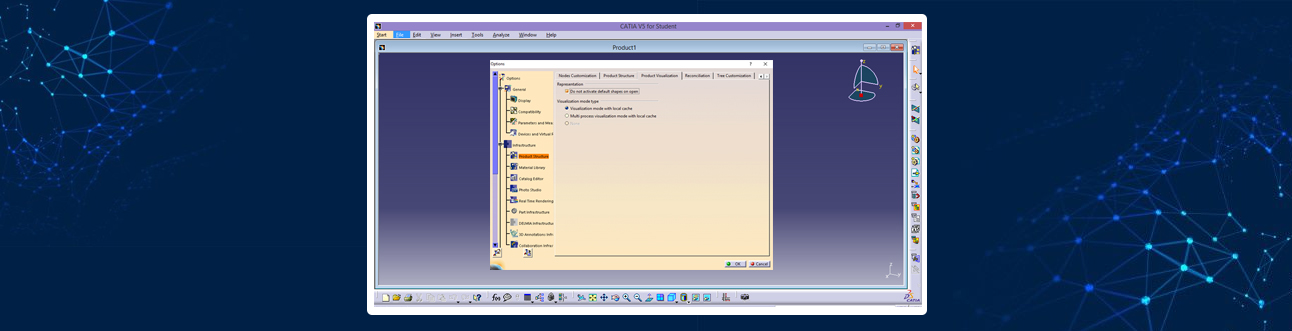

Large Assembly Management in CATIA V5

Working with large assemblies in the CATIA V5 system can be very demanding. Even with the use of extremely powerful machines and workstations, working with…

Large Assembly Management with Volatile Ghosting in 3DEXPERIENCE CATIA

When working with large assemblies, visualizing each and every component of assembly is very important in design process. Often it is tough to see all…

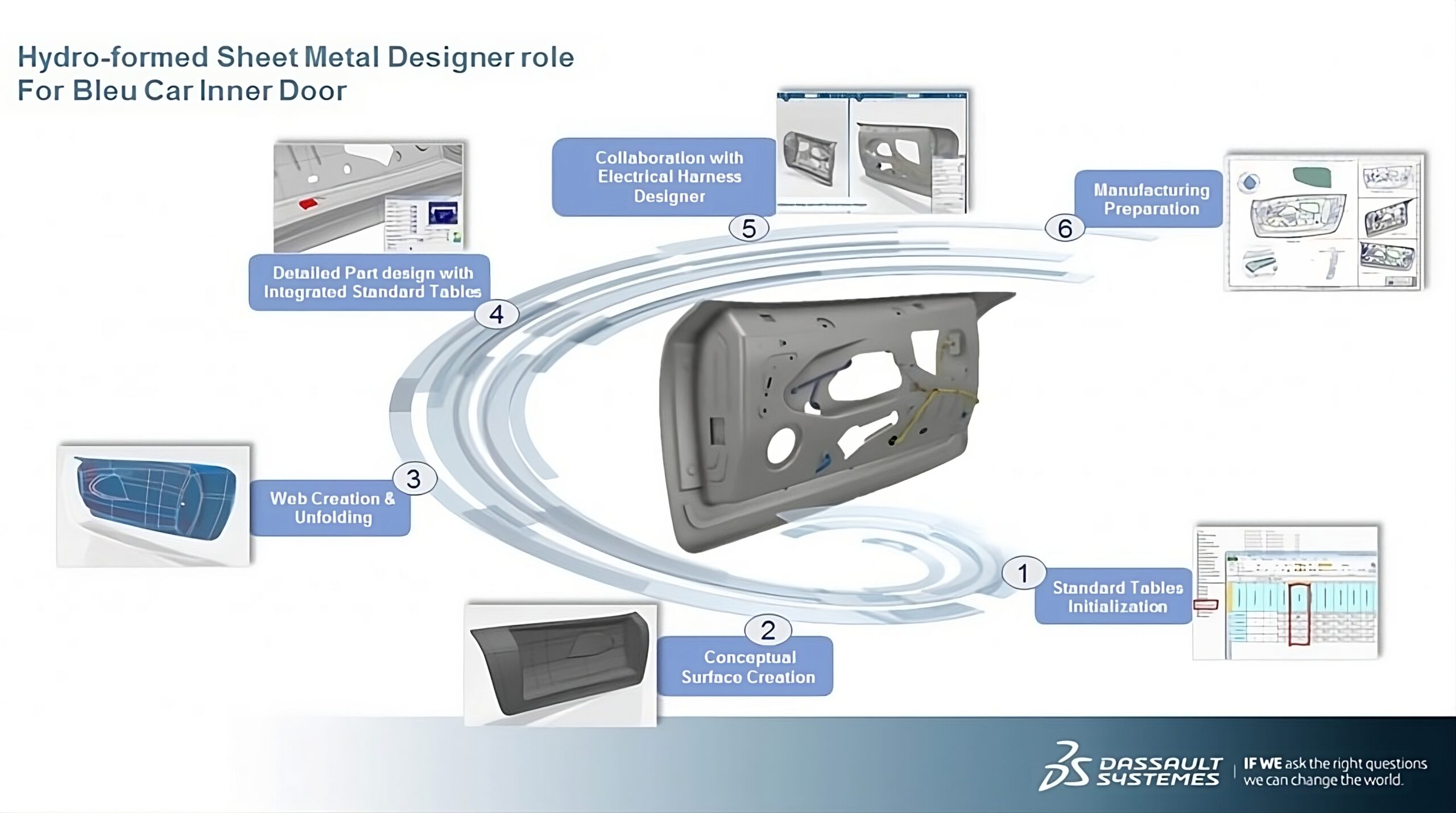

How CATIA 3DEXPERIENCE helps in the design of hydroforming-manufactured parts

Introduction There is always a challenge to meet the high expectations of auto and aero industry when it comes to the parts. The suppliers need…

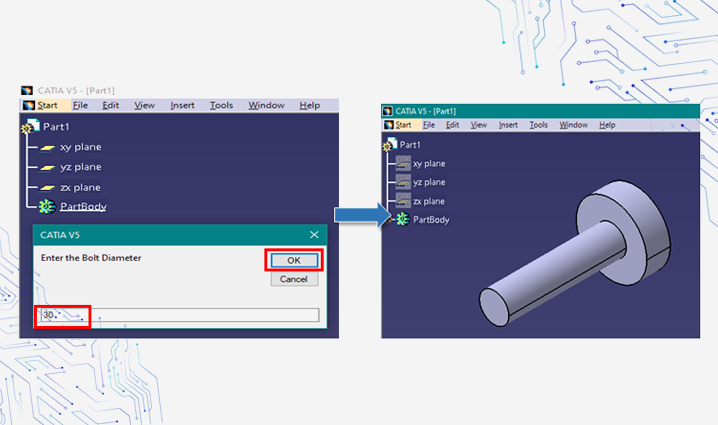

Automate your CAD using CATIA V5 Macros

Performing repetitive tasks manually leads to a loss of productivity. This is one of the major reasons why organizations are increasingly trying to automate processes…

Reference

Legrand India

Know More

FMC Technologies

Know More

Makino India

Know More

Beri Udyog (Fieldking)

Know More

J K Fenner India

Know More

Kennametal India

Know More

Senvion India

Know More

JK Fenner (India)

Know More

FMC Technologies

Know More

Perceptron India

Know More

Maini Precision Products

Know More

Tool Tech Toolings

Know More

Balkrishna Industries

Know More

Apollo Tyres

Know More

Birla Tyres

Know More

CEAT Specialty Tyres

Know More

Apollo Tyres

Know More

Birla Tyres

Know More

Balkrishna Industries

Know More

Apollo Tyres

Know More