Aerospace

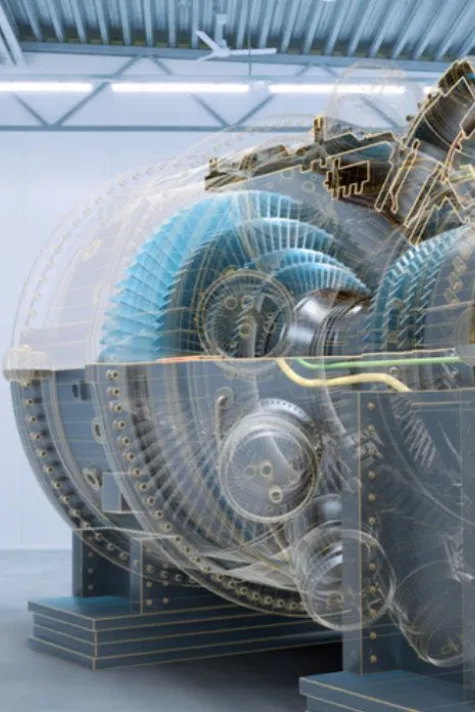

Integrating advanced solutions such as design, simulation, digital twins, and additive manufacturing enhances efficiency and innovation. These technologies ensure precise component design, real-time monitoring, and the creation of complex, lightweight structures. Incorporating ergonomics and virtual simulation ensures user-friendly and safe designs, leading to superior performance and reliability.

Solutions for Aerospace

Ensuring Design Reliability for Consistent Performance

Design reliability is a key factor in ensuring that products perform as expected throughout their lifecycle, with minimal risk of failure. In industries ranging from automotive to aerospace, electronics to consumer goods, the ability to design products that can withstand real-world conditions while maintaining performance and durability is crucial.

Real-Time Visibility in APQP & Process Adherence for Better Quality Control

Advanced Product Quality Planning (APQP) is a critical process in the automotive industry, originally developed to ensure products meet stringent OEM and consumer quality standards. Automotive suppliers often face challenges such as lack of real-time visibility, inconsistent process adherence, fragmented communication, and difficulties in managing the extensive data associated with product development.

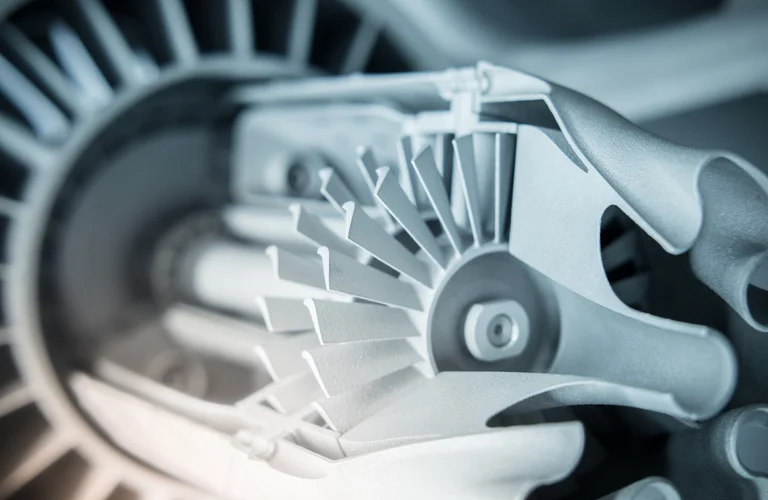

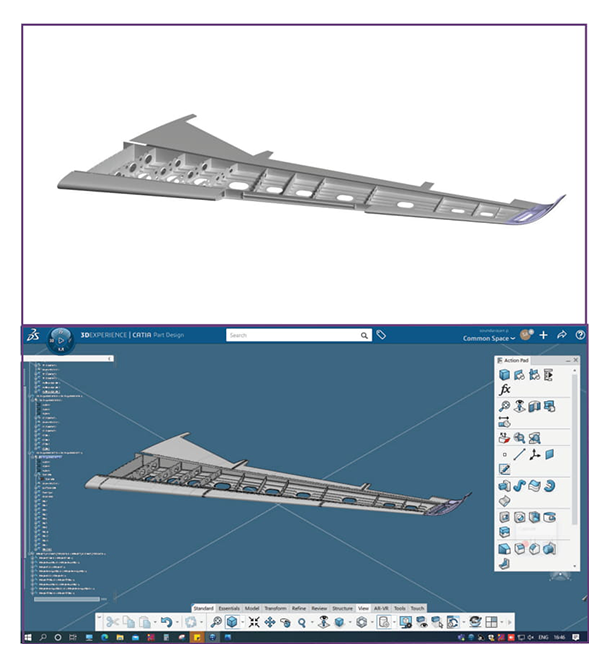

Advanced Composite Design for High-Performance Applications

Composite materials are increasingly being used across industries like automotive, aerospace, and defense due to their exceptional strength-to-weight ratio and ability to withstand harsh conditions. However, designing composites requires specialized tools to optimize material usage, ensure structural integrity, and meet performance standards. Advanced composite design involves not only sele

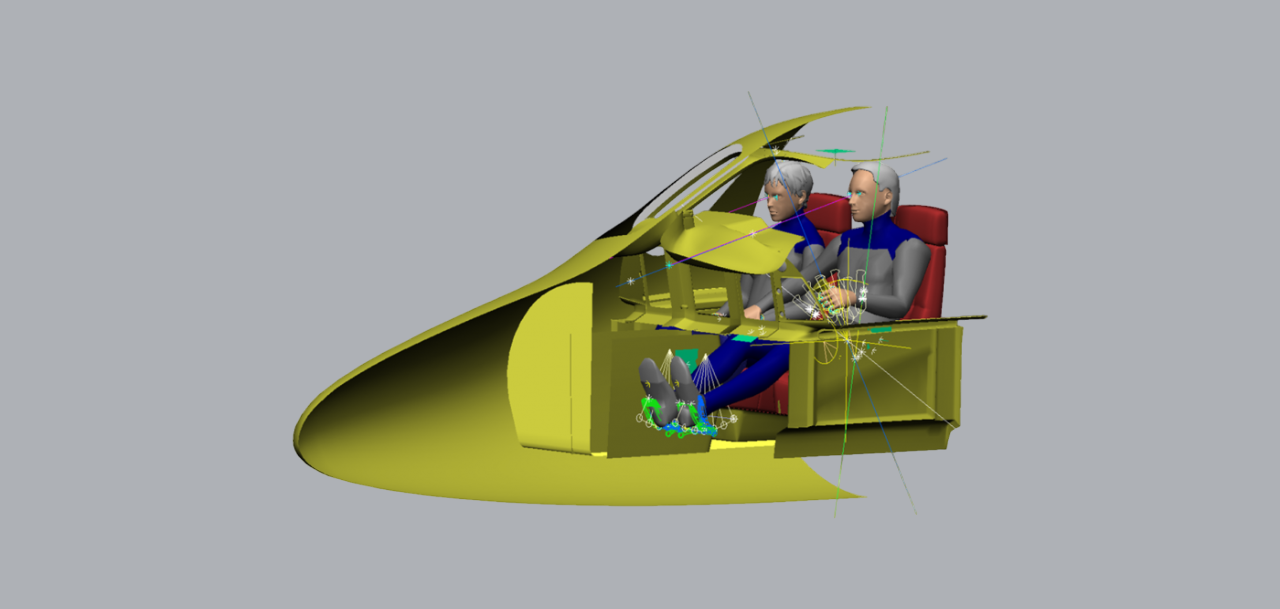

Optimizing Human Ergonomics for Safety and Comfort

Human ergonomics is essential for enhancing safety, comfort, and productivity in industries such as automotive, industrial equipment, and heavy machinery. Designing vehicles, machinery, and workspaces that are optimized for human factors reduces operator fatigue, improves posture, and prevents injuries. Optimizing ergonomics ensures operators can work efficiently and safely over extended periods.

Lightweighting for Enhanced Performance and Efficiency

Lightweighting is a crucial strategy for improving performance, fuel efficiency, and overall sustainability across industries like automotive, drones, electric vehicles (EVs), and consumer goods. By reducing component weight, manufacturers can enhance product performance, increase energy efficiency, and reduce emissions, all while improving durability. Achieving lightweight designs requires advanced tools that can optimize strength, material usage, and durability.

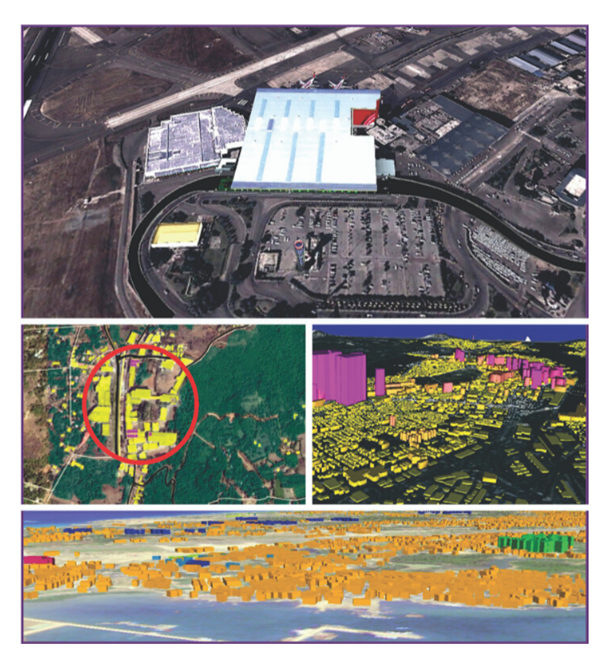

Streamlining Project Management with Data-Driven Insights and Collaboration

In today’s fast-paced environment, data-driven project management is essential for ensuring projects are delivered on time and within budget. By leveraging real-time data, teams can track progress, manage resources efficiently, and identify risks early. This approach enables quick decision-making, reduces delays, and optimizes project outcomes.

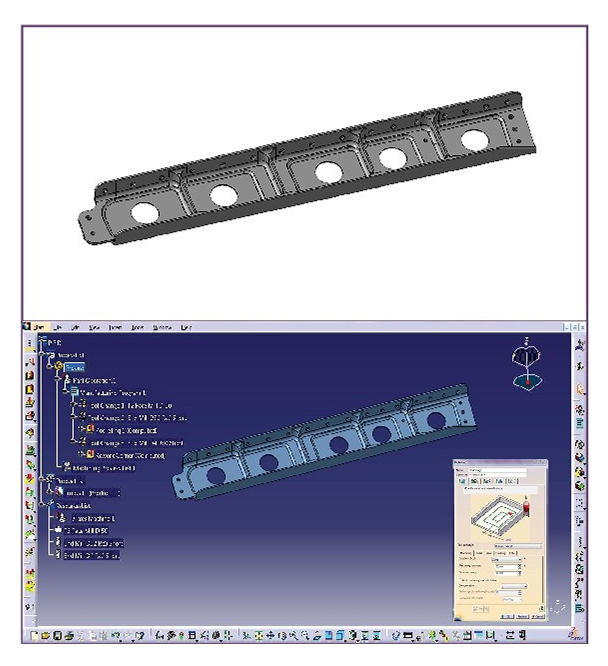

Enhancing Manufacturing Efficiency with Integrated Design Workflows

In today’s competitive manufacturing landscape, the integration between design and manufacturing workflows is critical for achieving higher efficiency, reduced costs, and faster time-to-market. When design and manufacturing processes are disconnected, errors, delays, and inefficiencies can arise, slowing down production and increasing operational costs. A seamless connection between these processes ensures that design intent is faithfully executed during production, improving product quality and reducing the need for rework.

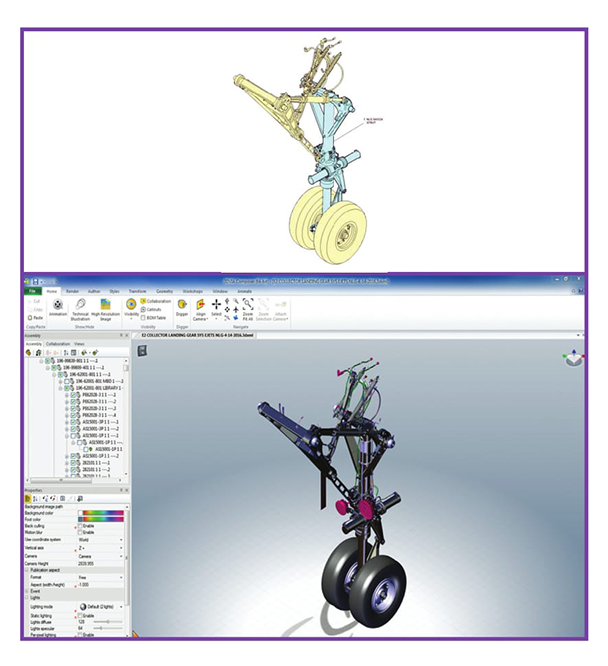

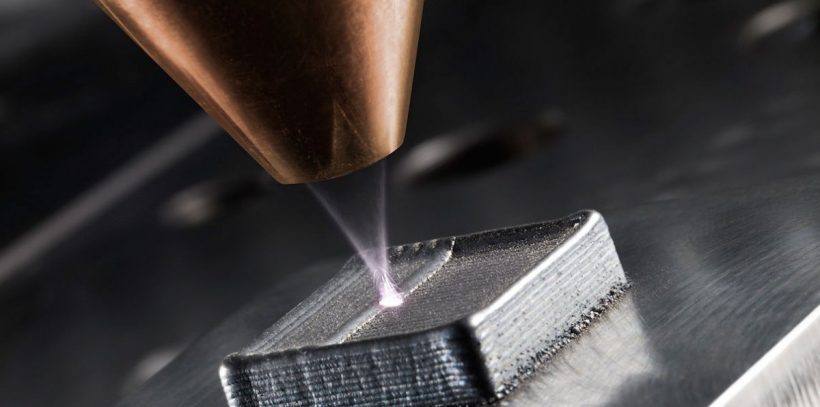

Optimized Design for Additive Manufacturing (DFAM)

Design for Additive Manufacturing (DFAM) transforms traditional design processes by enabling more efficient, innovative, and cost-effective solutions tailored for additive manufacturing technologies. This approach ensures that designs are optimized for 3D printing, making it possible to create complex geometries that were previously difficult or impossible to manufacture. By integrating advanced simulation, material selection, and process planning, DFAM accelerates product development cycles while maintaining or improving performance, reducing weight, and cutting costs.

Products

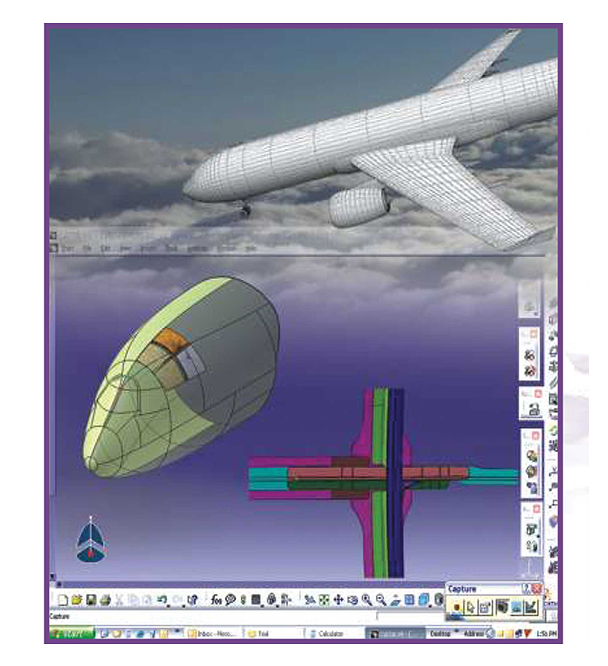

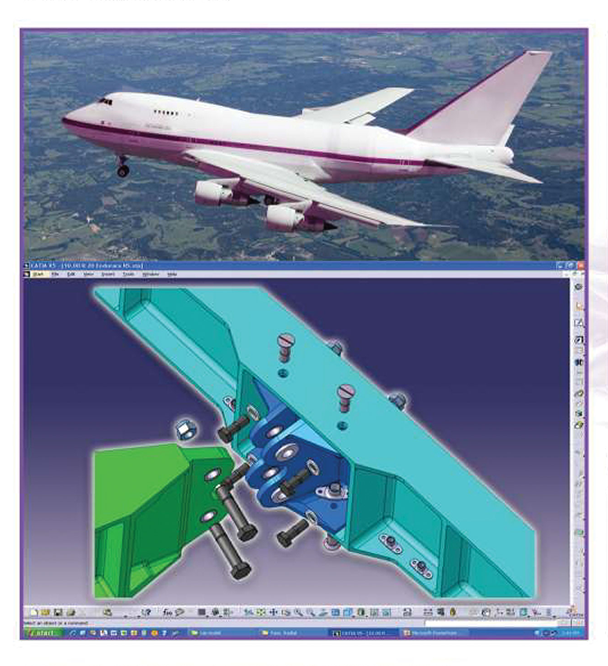

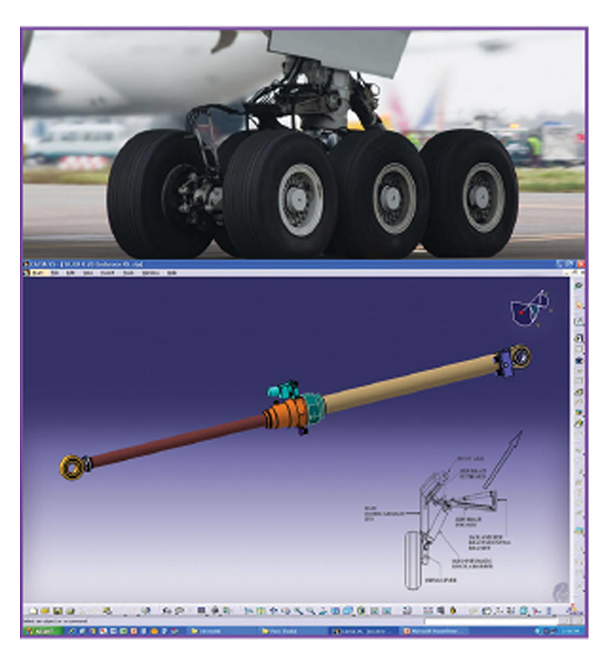

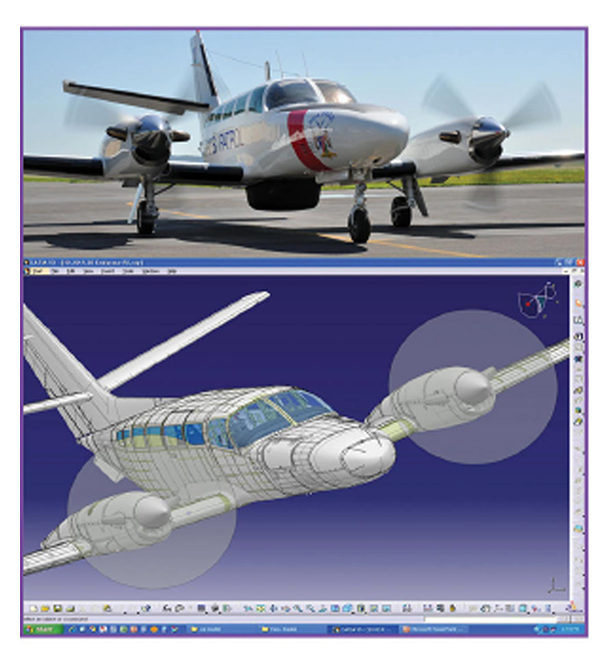

CATIA

Design complex aerospace and defence systems with unparalleled precision and scalability

SIMULIA

Enhance safety, durability and reliability with advanced simulation for aerospace and defence systems

DELMIA

Optimize production and assembly processes, and deliver quality and efficieny for manufacturing aerospace and defence systems

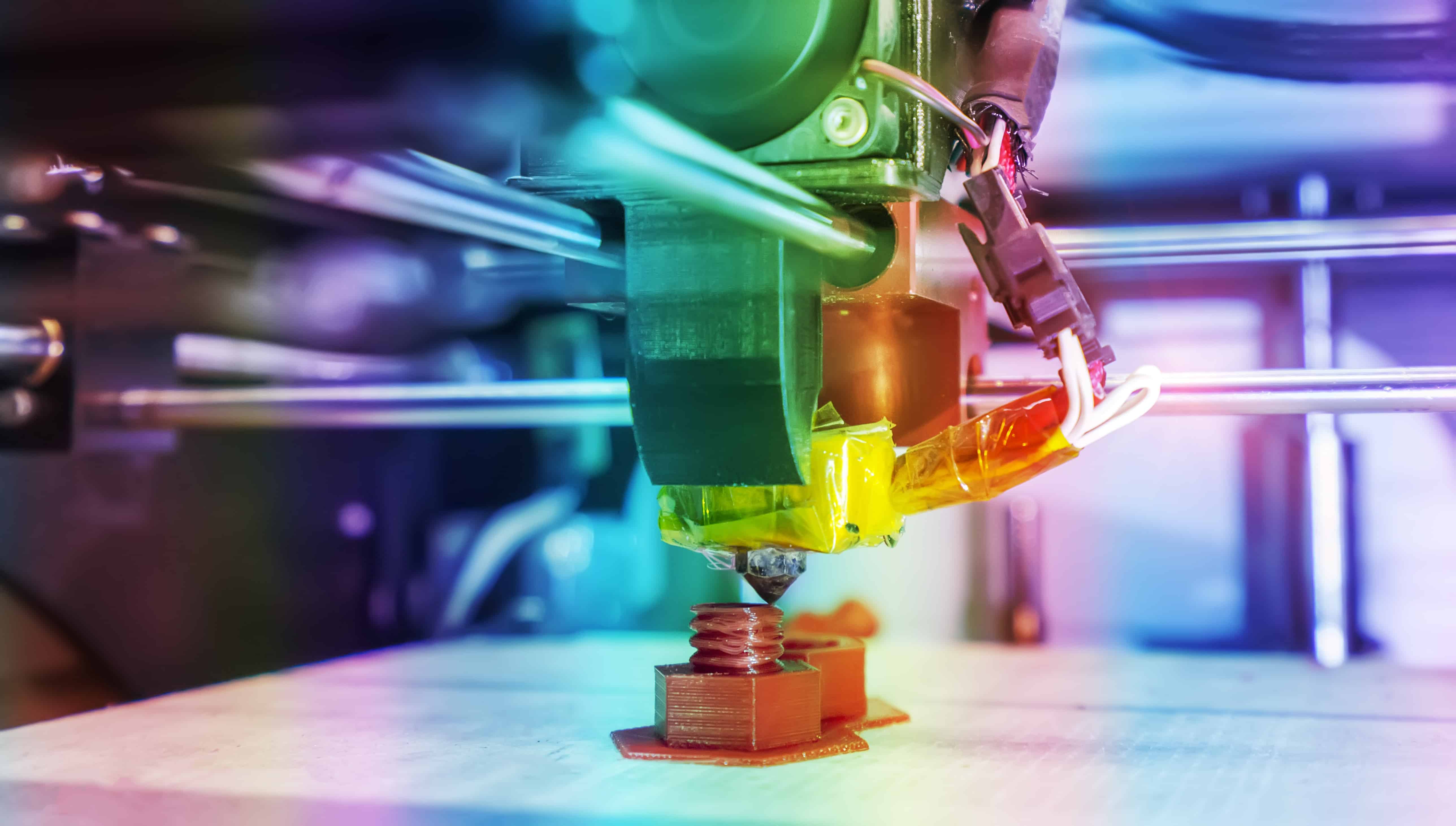

EOS 3D Printing

Revolutionize aerospace part production with lightweight, durable 3D printing solution

RAMSIS

Optimize human factors in cockpit and ensure cabin ergonomics and safety with RAMSIS

Q-Checker

Accelerate aerospace development with first-time-right design validation—enhancing precision, reducing rework, and speeding up time-to-market

MAK COTS Products

Enhance training, simulation, and mission readiness with MAK COTS software applications

Trends

Enhance Aerospace and Drone Performance Through Advanced Lightweight Materials

In the aerospace and drone industries, improving performance and fuel efficiency while maintaining safety and durability requires the use of advanced lightweight materials. These materials help reduce weight, increase payload capacity, and enhance overall efficiency. However, designing components with these materials and ensuring their manufacturability can be complex. EOS, a leader in 3D printing technology, enables the production of high-performance lightweight parts using additive manufacturing. CATIA, Dassault Systèmes' design software, provides powerful tools for designing these components with precision and optimizing them for performance. By combining EOS for 3D printing and CATIA for design, aerospace and drone manufacturers can create innovative, lightweight structures that boost performance, reduce costs, and ensure sustainability, all while maintaining the necessary strength and reliability.

Accelerate Pilot Training with Full Flight Simulation

In the aerospace industry, effective pilot training is crucial for ensuring safety, efficiency, and preparedness in real-world flight operations. Traditional training methods, while valuable, often lack the ability to replicate complex flight scenarios and adverse conditions. Aechelon's full-flight simulation solutions offer a transformative approach by providing highly immersive and realistic flight experiences. These simulations accurately model aircraft behavior, weather conditions, and emergency scenarios, allowing pilots to train in a controlled, risk-free environment. By utilizing Aechelon's advanced simulation technology, airline training can accelerate pilot development, reduce training costs, and ensure better-prepared pilots, all while enhancing safety and operational efficiency.

Revolutionizing Aircraft Interior Design with Human-Centered Ergonomics

In the aerospace industry, designing aircraft interiors that prioritize passenger comfort, safety, and usability is essential to enhancing the overall flying experience. However, achieving this balance requires a deep understanding of human-centered ergonomics, as well as the ability to test and optimize designs for various body types and seating configurations. RAMSIS, an advanced human simulation software, empowers designers to create ergonomic, comfortable, and functional aircraft interiors by simulating real-world human interactions with cabin spaces. Using RAMSIS, aerospace manufacturers can analyze seating arrangements, aisle space, and emergency evacuation scenarios to ensure optimal comfort and safety for passengers and crew. This human-centered approach revolutionizes interior design by making it more adaptable, user-friendly, and efficient, ultimately improving the passenger experience and meeting the evolving demands of modern air travel.

Reduce Risk and Enhance Quality with Integrated Lifecycle Management

In the aerospace industry, managing the complexity of product development, from design to manufacturing and maintenance, is critical to reducing risks and ensuring the highest standards of quality. Traditional processes can lead to inefficiencies, errors, and costly delays. ENOVIA, a leading product lifecycle management (PLM) solution, integrates every phase of the aerospace product lifecycle, enabling real-time collaboration, data sharing, and complete visibility across teams. By providing a unified platform for design, manufacturing, and maintenance, ENOVIA helps aerospace manufacturers identify and address potential risks early, streamline workflows, and ensure compliance with industry regulations. This integrated approach enhances product quality, reduces development time, and ensures a more efficient, reliable, and safe end product, ultimately contributing to greater operational success and customer satisfaction.

Latest Blog Posts

Discover our most recent posts across all industries, brands and topics

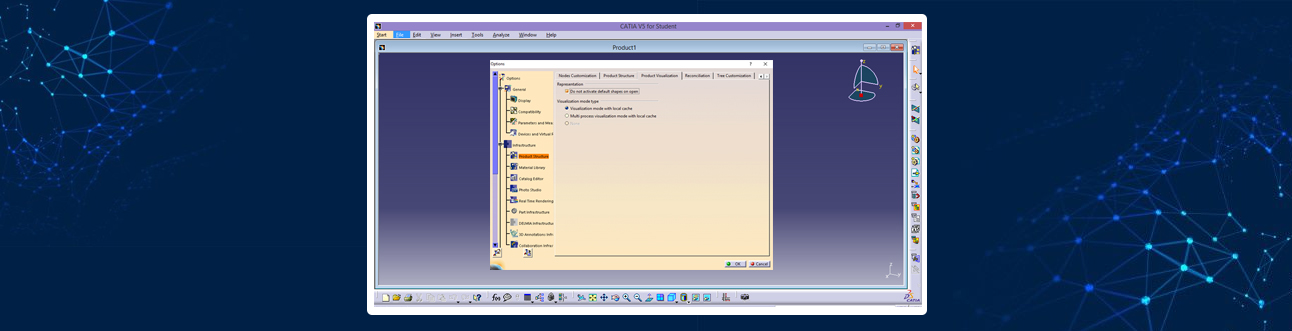

Large Assembly Management in CATIA V5

Working with large assemblies in the CATIA V5 system can be very demanding. Even with the use of extremely powerful machines and workstations, working with…

Overview on DMLS Process for 3D Printing and its Applications in Space Industry

Additive Manufacturing Additive manufacturing is a specific 3D printing process where parts are built layer by layer by depositing material according to digital 3D design data. For…

Transforming the Aerospace & Defense landscape with industry-specific experiences for enhanced efficiency with digital continuity

Customer expectations are growing with the need for lower costs, higher quality, increased capabilities and the ever-growing complexity making it even more challenging for manufacturers.…

A Deep Dive into the Future of Additive Manufacturing

Additive Manufacturing (AM) Additive Manufacturing (AM), commonly referred to as 3D printing is a manufacturing process to form 3D physical parts from CAD DATA. In…

How to Design Complex Aero Parts using the 3DEXPERIENCE Platform?

Designing aircrafts is becoming an increasingly complex task these days. As it becomes increasingly sophisticated, the wiring needed to power and control the electrical systems…

References

Magellan Aerospace

Know More

Avantel

Know More

Maini Precision Products

Know More

Genser Aerospace

Know More

Dynamatic Technologies

Know More

Altran Technologies India

Know More

FairTech Engineering Services

Know More

Sattva Aero Accessories

Know More

Aero Euro Engineering

Know More