In today’s rapidly evolving world, companies across all industries are constantly looking for ways to innovate, streamline their processes, and reduce time-to market. Dassault Systems’ 3DEXPERIENCE platform is at the forefront of this revolution, providing a unified, collaborative, and intelligent environment for product development. This powerful platform is transforming industries by enabling the design, simulation, and manufacturing of products in a digital world, before bringing them into reality. What is the 3DEXPERIENCE Platform? The 3DEXPERIENCE platform is a comprehensive, end-to-end suite of tools that empowers companies to design, simulate, manufacture, and operate products in a virtual environment. Whether you’re an engineer, designer, or manufacturer, this platform connects people, data, and processes in a way that drives efficiency and enhances collaboration.

- Unified Environment: Instead of relying on different software for CAD, CAM, CAE, PLM, and other processes, 3DEXPERIENCE offers all these capabilities in a single, integrated platform.

- Collaboration Across Teams: It facilitates real-time collaboration, no matter where teams are located, ensuring that the right people have access to the right information at the right time.

- Cloud-Based Flexibility: With the 3DEXPERIENCE platform being cloud-based, companies can scale their operations, access data anywhere across the globe and ensure that their digital infrastructure grows with them.

Revolutionizing Industries with 3DEXPERIENCE

-

Enhancing Product Design

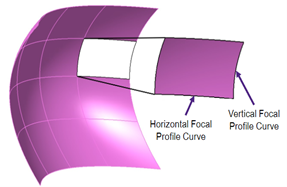

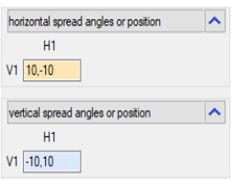

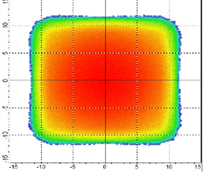

The core of the 3DEXPERIENCE platform is its ability to help businesses create innovative products. With tools like CATIA, engineers can design products with incredible detail and accuracy. The platform also integrates advanced simulation tools that allow for testing and optimization before a physical prototype is created, saving time and reducing costs.

-

Streamlining Manufacturing

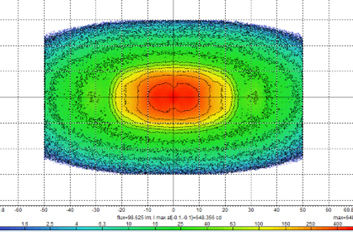

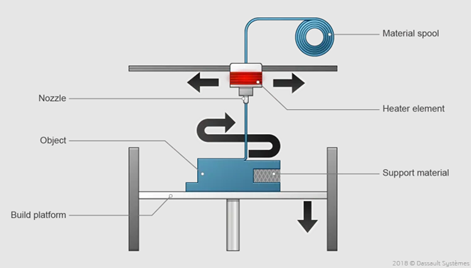

Through DELMIA, the 3DEXPERIENCE platform also offers solutions for digital manufacturing and production planning. Manufacturers can virtually simulate their entire production process, ensuring efficiency and minimizing waste before the first item is produced. Additionally, using tools like SIMULIA, companies can predict product performance under real-world conditions.

-

Building Digital Twins for Better Decision-Making

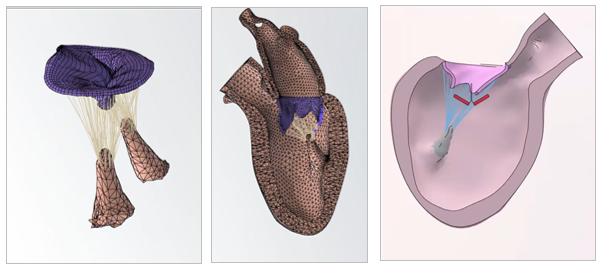

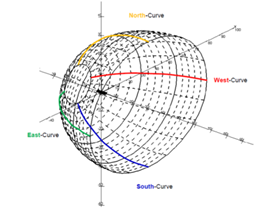

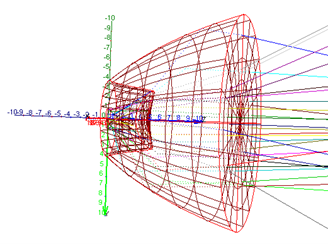

A virtual twin experience is a representation of the real world based on mathematical models and scientific laws, not just a digital copy of it. It combines the virtual, in the form of an abstract model of an object and the real, in the form of data coming from the enterprise, the Internet of Things and the cloud.

Powered by the 3DEXPERIENCE platform, virtual twin experiences enable a closed-loop connection between the virtual and real worlds. Stakeholders continuously experiment, derive knowledge and optimize it by exploring all possibilities and scenarios. This convergence of the virtual and real worlds and the continuous cycle of information between the two achieve a closed loop allowing the following benefits:

- Accelerate sustainable innovation

- Support creation of value network

- Empower the workforce of the future.

One of the standouts features of the 3DEXPERIENCE platform is its ability to create “Digital Twins” virtual representations of physical assets. This allows businesses to monitor, manage, and optimize products throughout their lifecycle. The digital twin can provide real-time insights into the performance of an asset, enabling predictive maintenance, design improvements, and more informed decision-making.

The Future – Cloud-Based Collaboration

In today’s globalized world, collaboration is key to innovation. The 3DEXPERIENCE platform excels in enabling real-time collaboration across different teams, departments, and even geographical locations. This cloud-based platform removes the barriers of distance, enabling teams to share data, work on the same models, and contribute to projects seamlessly.

Companies are no longer tied to their physical locations or specific hardware. Whether teams are in the same office or scattered across the globe, the 3DEXPERIENCE platform allows everyone to stay connected and engaged in the development process.

Driving Sustainability and Innovation with 3DEXPERIENCE

The platform is also crucial for companies focused on sustainability. By enabling virtual testing, optimization, and simulations, 3DEXPERIENCE helps reduce the need for physical prototypes, lowering material waste and energy consumption. Furthermore, the platform’s advanced analytics capabilities help businesses optimize their designs and operations for maximum sustainability.

In an Era, where environmental impact is more important than ever, Dassault Systems’ 3DEXPERIENCE provides the tools necessary to innovate sustainably, without compromising on quality or performance.

Conclusion: The Future of Product Innovation

The 3DEXPERIENCE platform from Dassault Systems is more than just a set of tools, it is a comprehensive solution that empowers companies to innovate, collaborate, and grow in a rapidly changing world. With its ability to integrate design, simulation, manufacturing, and lifecycle management into one platform, businesses can reduce time-to-market, cut costs, and enhance the quality of their products. The future of product development is digital, collaborative, and intelligent and the 3DEXPERIENCE platform is leading the way.