Innovative Design with 3DEXPERIENCE on Cloud

- Mr. Vivek Sirohi

- October 12, 2020

Consumer’s expectation to experience a product before buying has triggered organizations to adopt new solutions for developing innovative products by unleashing creativity and brainstorming ideas in their ecosystem with a collaborative platform.

Industrial designers do real-time collaboration with other teams like engineering, marketing, and production. They propose their ideas, take feedbacks, incorporate changes, and improve the product quality.

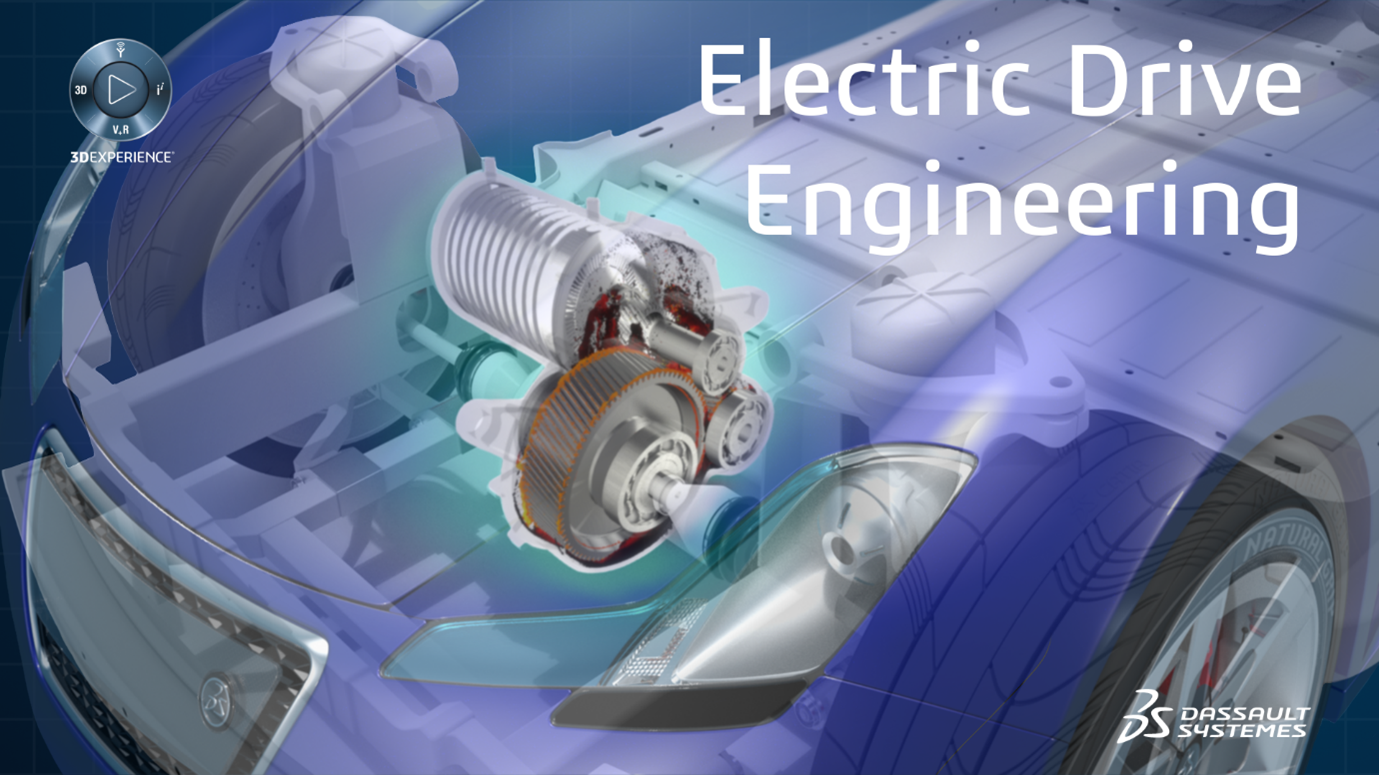

Mechanical engineers explore innovative solutions and workable concepts for the detailed design. They try and enhance design of mechanical parts, overcome new challenges by enriching their design with sophisticated and complex surfaces and by benefitting from existing designs. They even use engineered parts and explore new manufacturing possibilities by editing specific features and drill down to rough components. 3DEXPERIENCE on Cloud offers multiple applications with industry leading features for detailed mechanical design of the rough parts and also check the feasibility to ensure proper manufacturing requirements are met.

Today, I would like to discuss 3DEXPERIENCE Natural Shape which enables forging industry to create and redesign innovative products and tooling.

3DEXPERIENCE Natural Shape enables inverse design for precision forging

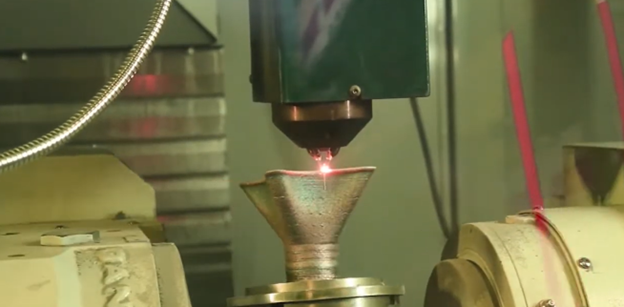

Today, the forging industry has replaced the conventional forging process (forging with flash) by precision forging enabling them to manufacture forging parts in large quantities with lower cost. This benefit is in terms of enhanced geometrical and dimensional accuracy. This approach tries to create a net shape or at least a near-net shape part due to which process design, die design and die manufacturing have become critical for forging suppliers.

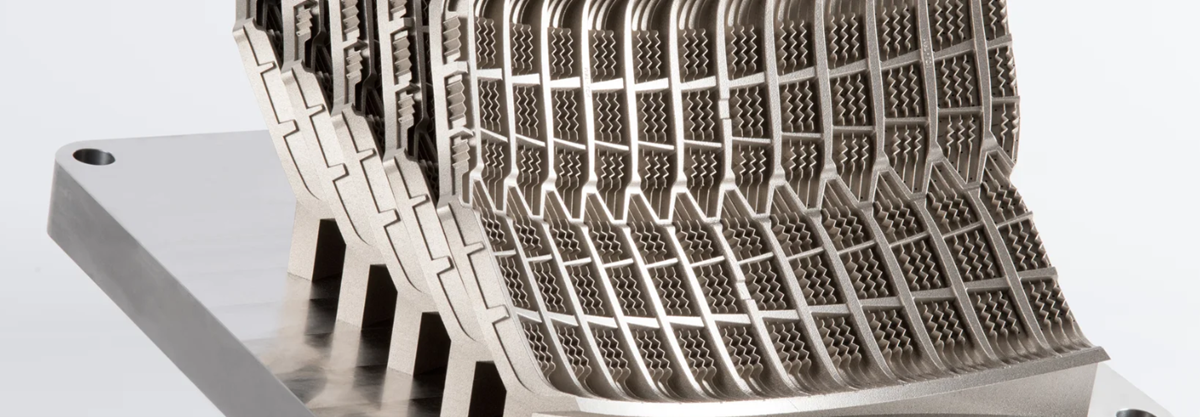

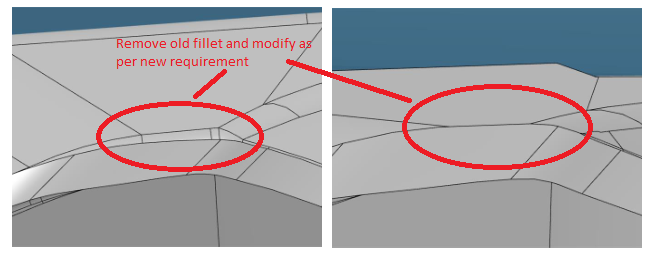

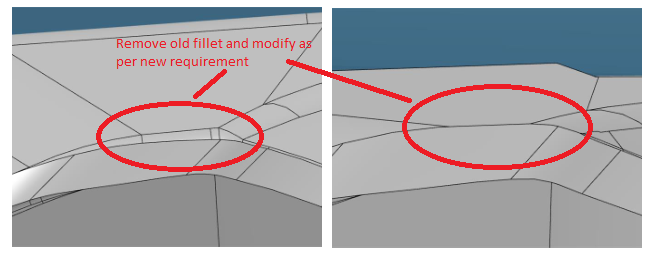

Recently, many forging suppliers faced the challenge of inverse design. We analyzed this challenge and realized that they are receiving non-history CAD data of finished forging part as input. Thus, the designers adopted reverse approach starting from the geometry of the finished forging part and then proceeded to determine the geometry of the work piece from previous stages (intermediate stages) going backwards towards the starting billet. 3DEXPERIENCE CATIA Natural Shape allows direct manipulation of the 3D geometry; creating and modifying volumes and surfaces; edit any other CAD formats; precise geometry definition; respecting mechanical design semantic like fillets, drafts, patterns, etc. Natural Shape unified user interface allows designers to accelerate their design with natural manipulations and contextual interactions. Furthermore, designers can go ahead with the detailed design process; they can also benefit from all the CATIA modeler capabilities, including functional design, advanced feature-based approach, tolerant modeling capabilities and knowledge-ware design automation.

Natural Shape, Natural Sketch and Natural Assembly applications of 3DEXPERIENCE on Cloud provide today’s industry a complete and unified design solution to enhance creativity and design quality. With these and other 3DEXPERIENCE on Cloud apps, one can bring together all aspects of their customer business on a single cloud-based platform to increase collaboration, improve execution and accelerate innovation.

3DEXPERIENCE Cloud platform enables industries to design innovative products by:

- Imagining and exploring creative styling ideas in 3D with 3D sketching.

- Creating and fine-tuning 3D shapes and surfaces with integrated surfacing technologies.

- Experiencing design intent in the context of high-end real-time visualization and immersive experience.

- Presenting and making design decisions with interactive real-time experience and reducing decision-making time using concurrent engineering.

- Designing complex mechanical parts.

- Avoiding repetitive tasks by reusing existing design assets.

- Exploring innovative solutions and workable concepts for detailed design.

- Collaborating with your team and others.

- Working on large assemblies.

- Being more efficient in everyday tasks.

- Reducing design and manufacturing errors with process-oriented features.

- Mr. Vivek Sirohi

- October 12, 2020

Innovative Design with 3DEXPERIENCE on Cloud

Consumer’s expectation to experience a product before buying has triggered organizations to adopt new solutions for developing innovative products by unleashing creativity and brainstorming ideas in their ecosystem with a collaborative platform.

Industrial designers do real-time collaboration with other teams like engineering, marketing, and production. They propose their ideas, take feedbacks, incorporate changes, and improve the product quality.

Mechanical engineers explore innovative solutions and workable concepts for the detailed design. They try and enhance design of mechanical parts, overcome new challenges by enriching their design with sophisticated and complex surfaces and by benefitting from existing designs. They even use engineered parts and explore new manufacturing possibilities by editing specific features and drill down to rough components. 3DEXPERIENCE on Cloud offers multiple applications with industry leading features for detailed mechanical design of the rough parts and also check the feasibility to ensure proper manufacturing requirements are met.

Today, I would like to discuss 3DEXPERIENCE Natural Shape which enables forging industry to create and redesign innovative products and tooling.

3DEXPERIENCE Natural Shape enables inverse design for precision forging

Today, the forging industry has replaced the conventional forging process (forging with flash) by precision forging enabling them to manufacture forging parts in large quantities with lower cost. This benefit is in terms of enhanced geometrical and dimensional accuracy. This approach tries to create a net shape or at least a near-net shape part due to which process design, die design and die manufacturing have become critical for forging suppliers.

Recently, many forging suppliers faced the challenge of inverse design. We analyzed this challenge and realized that they are receiving non-history CAD data of finished forging part as input. Thus, the designers adopted reverse approach starting from the geometry of the finished forging part and then proceeded to determine the geometry of the work piece from previous stages (intermediate stages) going backwards towards the starting billet. 3DEXPERIENCE CATIA Natural Shape allows direct manipulation of the 3D geometry; creating and modifying volumes and surfaces; edit any other CAD formats; precise geometry definition; respecting mechanical design semantic like fillets, drafts, patterns, etc. Natural Shape unified user interface allows designers to accelerate their design with natural manipulations and contextual interactions. Furthermore, designers can go ahead with the detailed design process; they can also benefit from all the CATIA modeler capabilities, including functional design, advanced feature-based approach, tolerant modeling capabilities and knowledge-ware design automation.

Natural Shape, Natural Sketch and Natural Assembly applications of 3DEXPERIENCE on Cloud provide today’s industry a complete and unified design solution to enhance creativity and design quality. With these and other 3DEXPERIENCE on Cloud apps, one can bring together all aspects of their customer business on a single cloud-based platform to increase collaboration, improve execution and accelerate innovation.

3DEXPERIENCE Cloud platform enables industries to design innovative products by:

- Imagining and exploring creative styling ideas in 3D with 3D sketching.

- Creating and fine-tuning 3D shapes and surfaces with integrated surfacing technologies.

- Experiencing design intent in the context of high-end real-time visualization and immersive experience.

- Presenting and making design decisions with interactive real-time experience and reducing decision-making time using concurrent engineering.

- Designing complex mechanical parts.

- Avoiding repetitive tasks by reusing existing design assets.

- Exploring innovative solutions and workable concepts for detailed design.

- Collaborating with your team and others.

- Working on large assemblies.

- Being more efficient in everyday tasks.

- Reducing design and manufacturing errors with process-oriented features.