From Repair to Rapid Prototyping: The Role of LENS DED Technology in Aerospace Industry

- Aniket Rehpade

- March 17, 2025

What is Lens DED Technology?

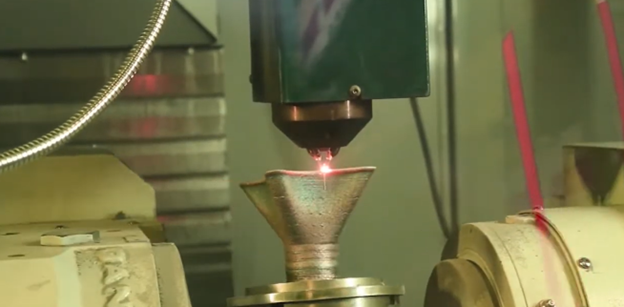

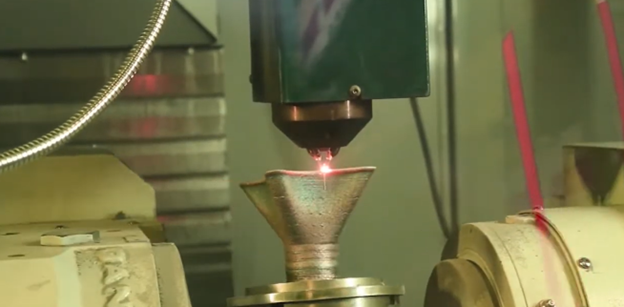

Lens DED (Laser Engineered Net Shaping Directed Energy Deposition) is an advanced additive manufacturing process that uses a high-power laser to melt and deposit metallic powders or wire feedstock layer by layer. This technology enables the creation, repair, and enhancement of components with high precision, offering advantages such as material efficiency, the ability to produce complex geometries, and reduced lead times. It is widely used in industries like aerospace, automotive, and medical for manufacturing custom parts, repairing damaged components, and improving product performance. Lens DED also allows for minimal material waste and customization, though post-processing may be needed to achieve the desired surface finish.

Applications of Lens Directed Energy Deposition Technology in Aerospace

-

Component Repair

Aerospace components, including turbine blades, engine parts, and structural elements, are subjected to extreme conditions that lead to wear and damage over time. Traditional repair methods are often costly and time-consuming, necessitating complete part replacement. Lens DED technology, however, provides a highly effective solution for repairing these components. By precisely depositing material only where needed, Lens DED can restore parts to their original specifications, significantly extending their service life and reducing the need for expensive replacements.

-

Prototyping and Production

The aerospace industry frequently requires the production of complex geometries and parts that integrate multiple materials. Lens DED excels in this domain, enabling the creation of intricate designs that would be challenging or impossible with conventional manufacturing techniques. This capability makes Lens DED ideal for both prototyping and low-volume production of high-performance aerospace parts. Engineers can rapidly iterate on designs, test them in real-world conditions, and bring innovative products to market faster than ever before.

-

Material Development

Material performance is critical in aerospace applications, where components must withstand extreme temperatures, pressures, and environmental conditions. Lens DED technology facilitates the development and testing of new materials and alloys tailored for specific aerospace applications. By allowing precise control over the material composition and microstructure, Lens DED enables the creation of parts with enhanced performance characteristics, such as increased strength, durability, and resistance to corrosion and wear.

-

On-Demand Manufacturing

In the aerospace sector, maintaining a large inventory of spare parts can be both costly and inefficient. Lens DED technology offers a solution through on-demand manufacturing, allowing companies to produce critical components as needed. This approach not only reduces lead times and inventory costs but also ensures that parts are available when and where they are required, minimizing downtime and improving operational efficiency.

Conclusion

Laser Engineered Net Shaping Directed Energy Deposition technology is revolutionizing the aerospace industry by providing advanced solutions for component repair, prototyping and production, material development, and on-demand manufacturing. As the industry

- Aniket Rehpade

- March 17, 2025

From Repair to Rapid Prototyping: The Role of LENS DED Technology in Aerospace Industry

What is Lens DED Technology?

Lens DED (Laser Engineered Net Shaping Directed Energy Deposition) is an advanced additive manufacturing process that uses a high-power laser to melt and deposit metallic powders or wire feedstock layer by layer. This technology enables the creation, repair, and enhancement of components with high precision, offering advantages such as material efficiency, the ability to produce complex geometries, and reduced lead times. It is widely used in industries like aerospace, automotive, and medical for manufacturing custom parts, repairing damaged components, and improving product performance. Lens DED also allows for minimal material waste and customization, though post-processing may be needed to achieve the desired surface finish.

Applications of Lens Directed Energy Deposition Technology in Aerospace

-

Component Repair

Aerospace components, including turbine blades, engine parts, and structural elements, are subjected to extreme conditions that lead to wear and damage over time. Traditional repair methods are often costly and time-consuming, necessitating complete part replacement. Lens DED technology, however, provides a highly effective solution for repairing these components. By precisely depositing material only where needed, Lens DED can restore parts to their original specifications, significantly extending their service life and reducing the need for expensive replacements.

-

Prototyping and Production

The aerospace industry frequently requires the production of complex geometries and parts that integrate multiple materials. Lens DED excels in this domain, enabling the creation of intricate designs that would be challenging or impossible with conventional manufacturing techniques. This capability makes Lens DED ideal for both prototyping and low-volume production of high-performance aerospace parts. Engineers can rapidly iterate on designs, test them in real-world conditions, and bring innovative products to market faster than ever before.

-

Material Development

Material performance is critical in aerospace applications, where components must withstand extreme temperatures, pressures, and environmental conditions. Lens DED technology facilitates the development and testing of new materials and alloys tailored for specific aerospace applications. By allowing precise control over the material composition and microstructure, Lens DED enables the creation of parts with enhanced performance characteristics, such as increased strength, durability, and resistance to corrosion and wear.

-

On-Demand Manufacturing

In the aerospace sector, maintaining a large inventory of spare parts can be both costly and inefficient. Lens DED technology offers a solution through on-demand manufacturing, allowing companies to produce critical components as needed. This approach not only reduces lead times and inventory costs but also ensures that parts are available when and where they are required, minimizing downtime and improving operational efficiency.

Conclusion

Laser Engineered Net Shaping Directed Energy Deposition technology is revolutionizing the aerospace industry by providing advanced solutions for component repair, prototyping and production, material development, and on-demand manufacturing. As the industry