Advanced Tyre Analysis with SIMULIA: Unveiling the Secrets of Performance and Durability

- Kedar Gokhale

- December 26, 2024

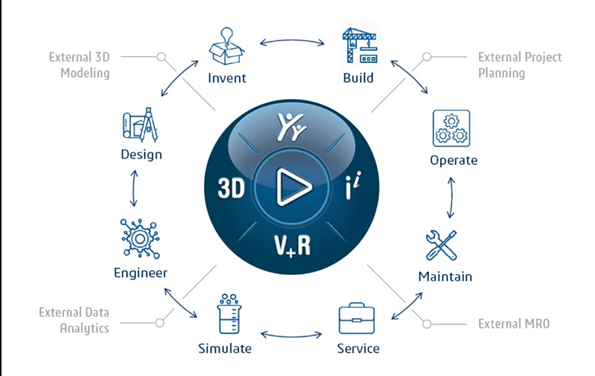

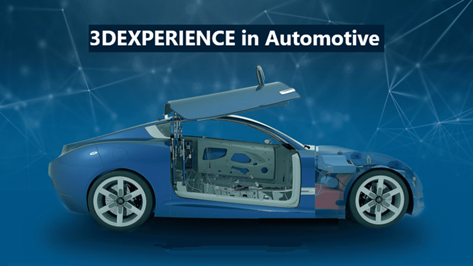

When it comes to automotive engineering, the tyre is one of the most critical components influencing vehicle performance, safety, and durability. Tyres are one of the most important components of the vehicle. The brakes stop the wheels, not your car! It’s actually your tyres that stop the car, through a contact patch no larger than an 8 ½ X 11 inches sheet of paper. Understanding tyre behavior under various conditions—whether on dry, wet, or rough terrains—requires advanced simulation and testing. This is where SIMULIA, Dassault Systèmes’ powerful suite of simulation tools, comes into play. SIMULIA’s capabilities offer automotive engineers the tools to perform detailed tyre analysis, enabling more efficient design, testing, and optimization processes.

The Importance of Tyre Analysis in Automotive Design

Tyres are the sole point of contact between a vehicle and the road. As such, their performance affects handling, comfort, fuel efficiency, braking efficiency, and even the overall safety of a vehicle. Tyres must strike a balance between traction, durability, and overall cost. Tyres must be designed to perform well under a variety of conditions, from extreme temperatures to varying road surfaces. However, designing such tyres through traditional physical testing methods can be time-consuming, costly, and potentially inefficient.

SIMULIA addresses these challenges by offering powerful tools to simulate tyre behaviour across a wide range of real-world conditions. Through simulation, engineers can predict tyre performance early in the design cycle, reducing the need for expensive prototype testing and accelerating time-to-market.

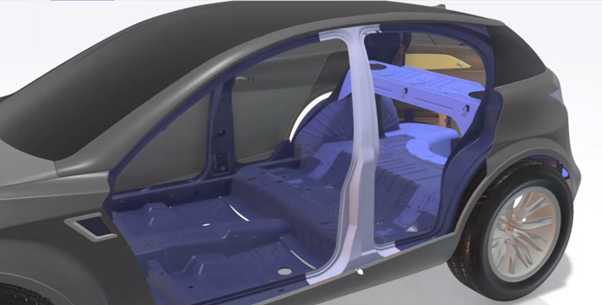

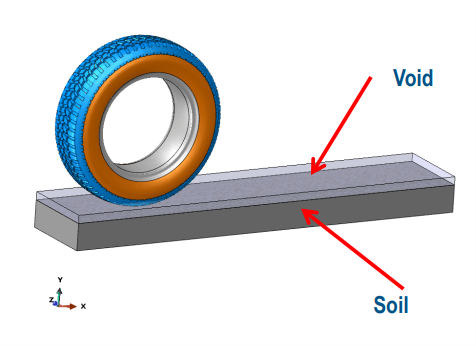

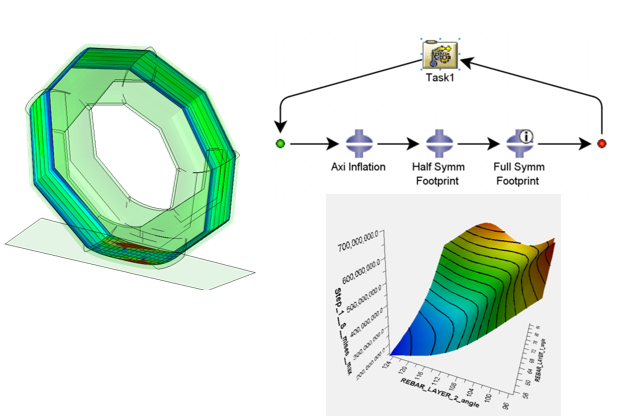

Fig.1: Integrated tyre workflow with one master model

SIMULIA’s Role in Tyre Analysis

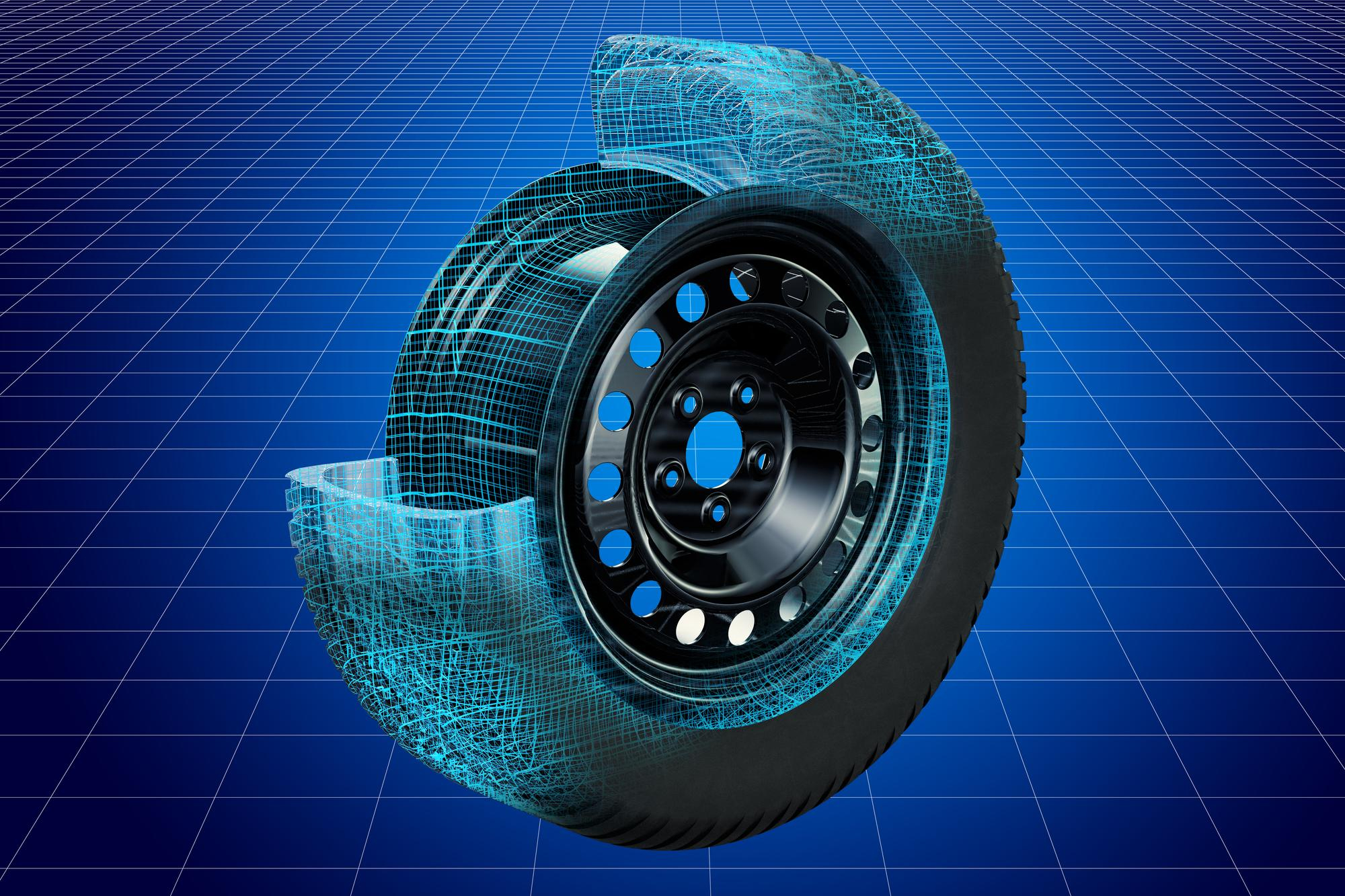

SIMULIA provides comprehensive simulation solutions that enhance the design and testing of tyres. The platform integrates advanced finite element analysis (FEA), multi-body dynamics (MBD), and computational fluid dynamics (CFD) to give engineers an in-depth understanding of tyre performance.

Here are some of the key aspects of tyre analysis that SIMULIA excels in:

- Tyre Performance Modelling: SIMULIA’s Abaqus and Isight tools allow for precise modelling of tyre materials and structures. Engineers can simulate how different materials (rubber compounds, reinforcements, etc.) behave under stress and deformation, which is essential for determining tyre longevity and performance. By simulating the tyre’s interaction with various road surfaces and temperatures, engineers can optimize tread patterns, sidewalls, and overall tyre construction.

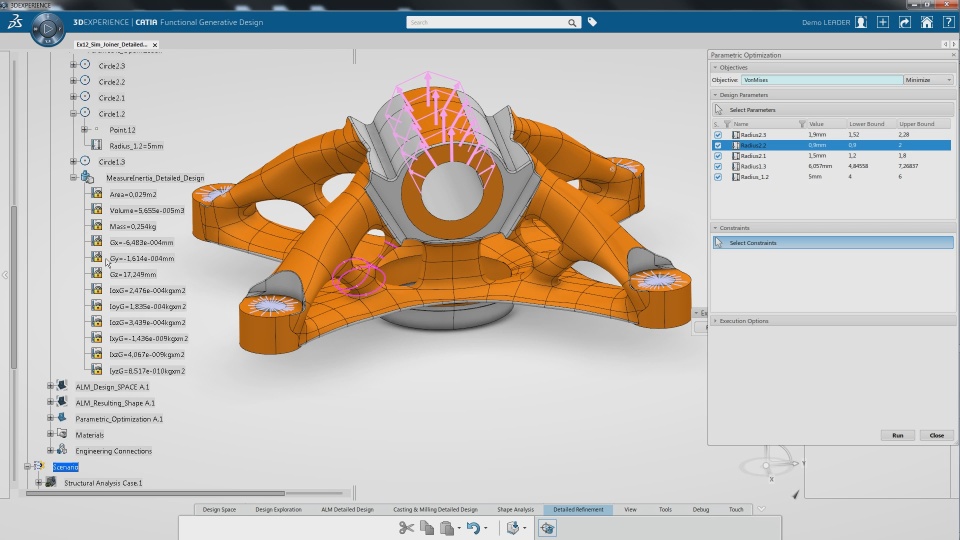

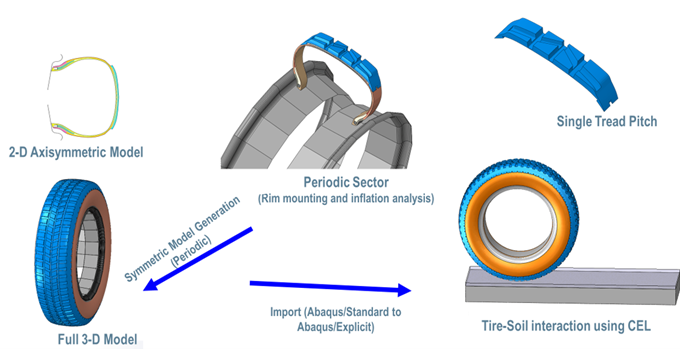

Fig.2: Tyre ply angle optimization

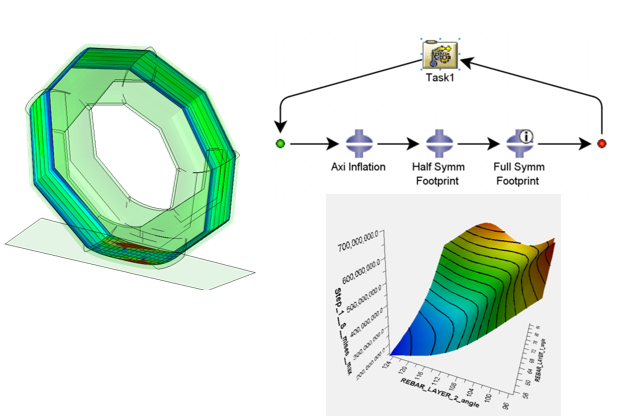

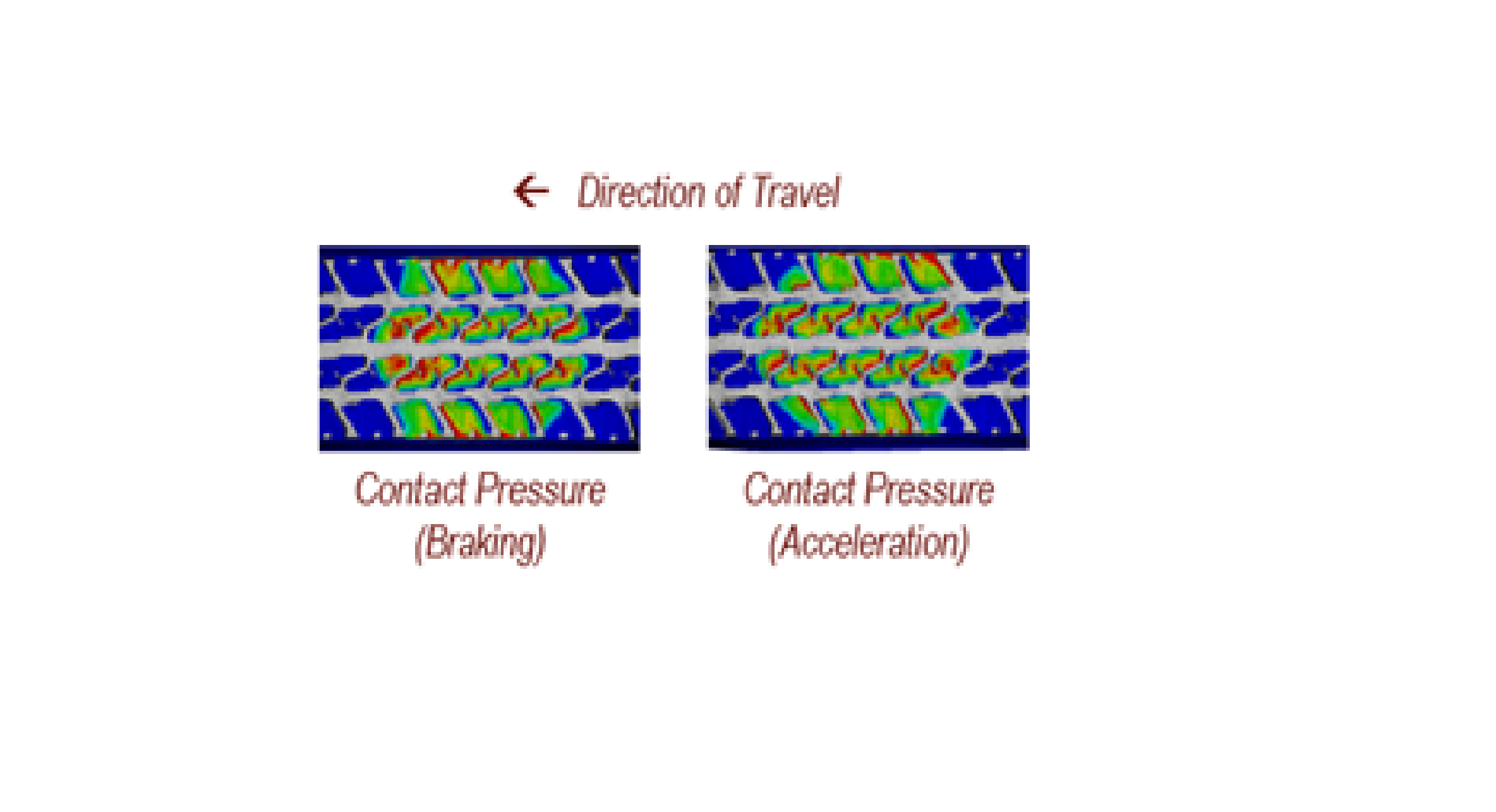

- Stress and Strain Analysis: Tyres undergo significant stress during operation, from the forces generated by braking and acceleration to the impacts from road obstacles. SIMULIA’s Abaqus allows for the detailed simulation of tyre deformation under these forces. Engineers can visualize tyre strain patterns, identify areas of high stress, and optimize designs to enhance durability, comfort, and performance.

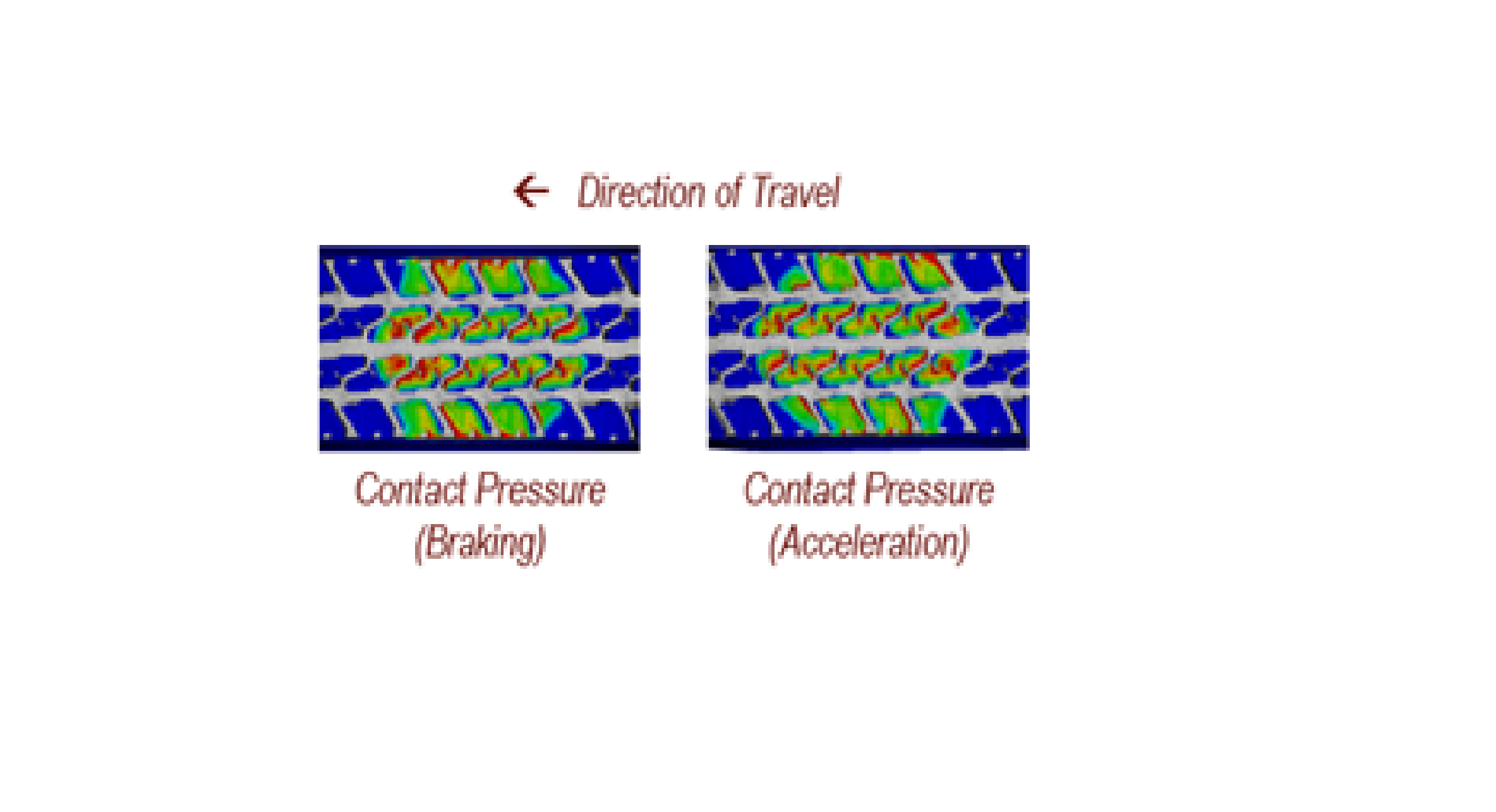

Fig.3: Contact pressure pattern

- Rolling Resistance and Fuel Efficiency: Rolling resistance is a critical factor in vehicle fuel efficiency. SIMULIA enables the analysis of rolling resistance through tyre-road interaction models, allowing designers to minimize energy losses while maximizing performance. By understanding the effects of tyre tread design and rubber compounds on rolling resistance, automotive manufacturers can produce tyres that contribute to better fuel economy and lower emissions.

- Tyre-Road Interaction: The interaction between a tyre and the road surface is complex. SIMULIA’s capabilities help engineers simulate how tyres interact with different surfaces—whether dry, wet, icy, or gravel. These simulations take into account parameters like friction, contact pressure, and deformation, helping to predict tyre behavior under various driving conditions. This ensures that tyres provide the necessary grip and stability, improving safety and handling.

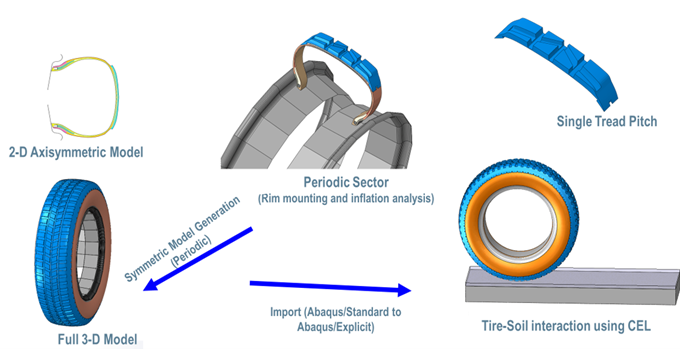

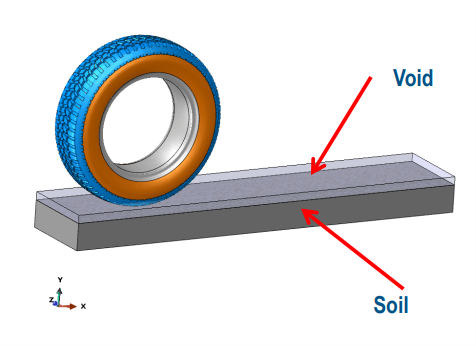

Fig.4: Tyre-Soil interaction

- Wear and Durability Analysis: The durability of a tyre is influenced by various factors, including its design, material properties, and driving conditions. Using SIMULIA’s fatigue and wear simulation tools, engineers can predict tyre lifespan, identify potential failure points, and optimize tyre design to maximize durability. This can lead to improved tyre longevity and reduced maintenance costs for consumers.

- Noise and Vibration Analysis: Tyres generate noise and vibrations, which can negatively affect the ride comfort of a vehicle. SIMULIA’s simulation tools help engineers analyze and mitigate these effects. By optimizing tyre design, including tread patterns and material choices, engineers can reduce road noise and vibrations, enhancing the overall driving experience.

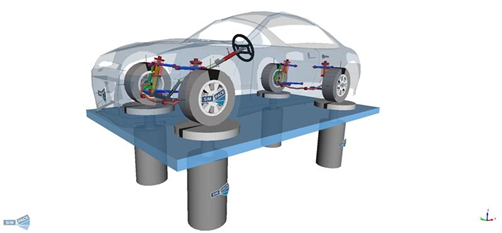

- Multi-Body Dynamics (MBD) Simulations: Tyres play a critical role in vehicle dynamics, influencing handling, stability, and safety. SIMULIA’s Simpack and Abaqus tools offer multi-body dynamics simulations that model the entyre vehicle system. Engineers can simulate how the tyre interacts with the suspension system, steering, and braking systems to optimize vehicle handling and performance. These simulations can account for tyre deformation, camber, and contact patches, ensuring the vehicle’s stability and safety under various driving conditions.

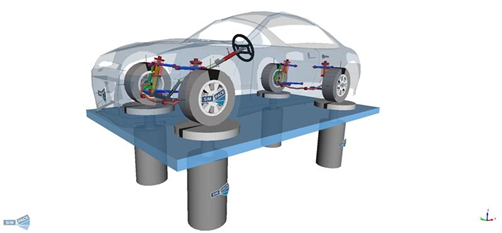

Fig.5: Hydropulse Test using SIMPACK

Benefits of Using SIMULIA for Tyre Analysis

The integration of SIMULIA’s advanced simulation tools provides several key benefits for tyre design and testing:

- Cost Reduction: By simulating tyre behaviour early in the design process, engineers can reduce the need for expensive physical prototypes and testing. This leads to significant cost savings in the development cycle.

- Faster Time-to-Market: With detailed tyre simulations, manufacturers can accelerate the design process and shorten the time needed for testing, resulting in faster product launches.

- Improved Tyre Performance: Advanced simulations allow for the optimization of tyre materials, tread patterns, and structures, ensuring better performance in terms of handling, safety, fuel efficiency, and durability.

- Enhanced Safety: By accurately simulating tyre-road interactions and stress conditions, manufacturers can create safer tyres that perform reliably under various real-world conditions, ultimately improving vehicle safety for consumers.

- Sustainability: With the ability to optimize rolling resistance and material usage, SIMULIA helps manufacturers produce more fuel-efficient tyres that reduce environmental impact.

Conclusion

SIMULIA’s suite of simulation tools revolutionizes tyre analysis by offering automotive engineers the ability to simulate tyre behavior under a vast range of real-world conditions. By leveraging these tools, manufacturers can design more efficient, durable, and high-performance tyres, ultimately improving vehicle safety, comfort, and sustainability. The powerful capabilities of SIMULIA not only help reduce development costs and time-to-market but also enable the creation of tyres that meet the ever-growing demands of the automotive industry and consumers.

- Kedar Gokhale

- December 26, 2024

Advanced Tyre Analysis with SIMULIA: Unveiling the Secrets of Performance and Durability

When it comes to automotive engineering, the tyre is one of the most critical components influencing vehicle performance, safety, and durability. Tyres are one of the most important components of the vehicle. The brakes stop the wheels, not your car! It’s actually your tyres that stop the car, through a contact patch no larger than an 8 ½ X 11 inches sheet of paper. Understanding tyre behavior under various conditions—whether on dry, wet, or rough terrains—requires advanced simulation and testing. This is where SIMULIA, Dassault Systèmes’ powerful suite of simulation tools, comes into play. SIMULIA’s capabilities offer automotive engineers the tools to perform detailed tyre analysis, enabling more efficient design, testing, and optimization processes.

The Importance of Tyre Analysis in Automotive Design

Tyres are the sole point of contact between a vehicle and the road. As such, their performance affects handling, comfort, fuel efficiency, braking efficiency, and even the overall safety of a vehicle. Tyres must strike a balance between traction, durability, and overall cost. Tyres must be designed to perform well under a variety of conditions, from extreme temperatures to varying road surfaces. However, designing such tyres through traditional physical testing methods can be time-consuming, costly, and potentially inefficient.

SIMULIA addresses these challenges by offering powerful tools to simulate tyre behaviour across a wide range of real-world conditions. Through simulation, engineers can predict tyre performance early in the design cycle, reducing the need for expensive prototype testing and accelerating time-to-market.

Fig.1: Integrated tyre workflow with one master model

SIMULIA’s Role in Tyre Analysis

SIMULIA provides comprehensive simulation solutions that enhance the design and testing of tyres. The platform integrates advanced finite element analysis (FEA), multi-body dynamics (MBD), and computational fluid dynamics (CFD) to give engineers an in-depth understanding of tyre performance.

Here are some of the key aspects of tyre analysis that SIMULIA excels in:

- Tyre Performance Modelling: SIMULIA’s Abaqus and Isight tools allow for precise modelling of tyre materials and structures. Engineers can simulate how different materials (rubber compounds, reinforcements, etc.) behave under stress and deformation, which is essential for determining tyre longevity and performance. By simulating the tyre’s interaction with various road surfaces and temperatures, engineers can optimize tread patterns, sidewalls, and overall tyre construction.

Fig.2: Tyre ply angle optimization

- Stress and Strain Analysis: Tyres undergo significant stress during operation, from the forces generated by braking and acceleration to the impacts from road obstacles. SIMULIA’s Abaqus allows for the detailed simulation of tyre deformation under these forces. Engineers can visualize tyre strain patterns, identify areas of high stress, and optimize designs to enhance durability, comfort, and performance.

Fig.3: Contact pressure pattern

- Rolling Resistance and Fuel Efficiency: Rolling resistance is a critical factor in vehicle fuel efficiency. SIMULIA enables the analysis of rolling resistance through tyre-road interaction models, allowing designers to minimize energy losses while maximizing performance. By understanding the effects of tyre tread design and rubber compounds on rolling resistance, automotive manufacturers can produce tyres that contribute to better fuel economy and lower emissions.

- Tyre-Road Interaction: The interaction between a tyre and the road surface is complex. SIMULIA’s capabilities help engineers simulate how tyres interact with different surfaces—whether dry, wet, icy, or gravel. These simulations take into account parameters like friction, contact pressure, and deformation, helping to predict tyre behavior under various driving conditions. This ensures that tyres provide the necessary grip and stability, improving safety and handling.

Fig.4: Tyre-Soil interaction

- Wear and Durability Analysis: The durability of a tyre is influenced by various factors, including its design, material properties, and driving conditions. Using SIMULIA’s fatigue and wear simulation tools, engineers can predict tyre lifespan, identify potential failure points, and optimize tyre design to maximize durability. This can lead to improved tyre longevity and reduced maintenance costs for consumers.

- Noise and Vibration Analysis: Tyres generate noise and vibrations, which can negatively affect the ride comfort of a vehicle. SIMULIA’s simulation tools help engineers analyze and mitigate these effects. By optimizing tyre design, including tread patterns and material choices, engineers can reduce road noise and vibrations, enhancing the overall driving experience.

- Multi-Body Dynamics (MBD) Simulations: Tyres play a critical role in vehicle dynamics, influencing handling, stability, and safety. SIMULIA’s Simpack and Abaqus tools offer multi-body dynamics simulations that model the entyre vehicle system. Engineers can simulate how the tyre interacts with the suspension system, steering, and braking systems to optimize vehicle handling and performance. These simulations can account for tyre deformation, camber, and contact patches, ensuring the vehicle’s stability and safety under various driving conditions.

Fig.5: Hydropulse Test using SIMPACK

Benefits of Using SIMULIA for Tyre Analysis

The integration of SIMULIA’s advanced simulation tools provides several key benefits for tyre design and testing:

- Cost Reduction: By simulating tyre behaviour early in the design process, engineers can reduce the need for expensive physical prototypes and testing. This leads to significant cost savings in the development cycle.

- Faster Time-to-Market: With detailed tyre simulations, manufacturers can accelerate the design process and shorten the time needed for testing, resulting in faster product launches.

- Improved Tyre Performance: Advanced simulations allow for the optimization of tyre materials, tread patterns, and structures, ensuring better performance in terms of handling, safety, fuel efficiency, and durability.

- Enhanced Safety: By accurately simulating tyre-road interactions and stress conditions, manufacturers can create safer tyres that perform reliably under various real-world conditions, ultimately improving vehicle safety for consumers.

- Sustainability: With the ability to optimize rolling resistance and material usage, SIMULIA helps manufacturers produce more fuel-efficient tyres that reduce environmental impact.

Conclusion

SIMULIA’s suite of simulation tools revolutionizes tyre analysis by offering automotive engineers the ability to simulate tyre behavior under a vast range of real-world conditions. By leveraging these tools, manufacturers can design more efficient, durable, and high-performance tyres, ultimately improving vehicle safety, comfort, and sustainability. The powerful capabilities of SIMULIA not only help reduce development costs and time-to-market but also enable the creation of tyres that meet the ever-growing demands of the automotive industry and consumers.