Shaping the Future of Automotive Lighting with Advanced Simulation

- Niharika R K

- February 25, 2025

In today’s modern automotive sector, headlamps have evolved into distinctive design elements that contribute significantly to a vehicle’s overall aesthetic. Each brand strives for a unique lighting signature that reflects its identity and enhances its visual appeal while adhering to the performance standard required to ensure driver safety. One can efficiently design all exterior automotive lamps using LucidShape.

Designing a headlamp system that meets stringent regulatory requirements and delivers optimal light distribution is a complex, iterative process. Traditionally, engineers must meticulously define the geometries, curvatures, and rotations of each optical element. This involves a time-consuming cycle of input parameter adjustments, simulation, and analysis, often requiring numerous design iterations before achieving the desired output. This leads to prolonged development cycles, increased costs, and reduced efficiency.

LucidShape addresses this challenge with its innovative Functional Geometry feature where engineers can explicitly define the target light distribution they wish to achieve, instead of manually tweaking individual parameters. This represents a beneficial reverse engineering approach, streamlining the design process and enabling faster prototyping.

FunGeo Design Features

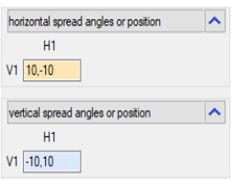

Functional geometry (FunGeo) adheres to the principle of ‘form follows function.’ Since determining precise curvatures of each facet of the reflector can be complex, LucidShape allows direct specification of desired light spread angles or distances. This approach focuses on achieving desired lighting performance by defining functional requirements rather than relying on mathematical calculation of curve shapes.

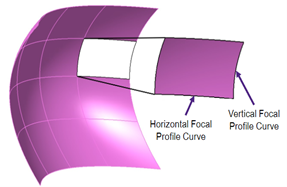

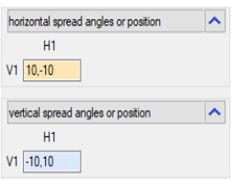

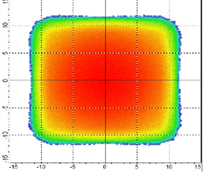

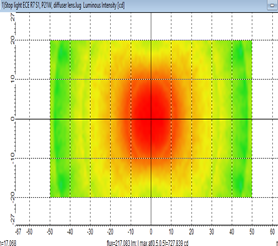

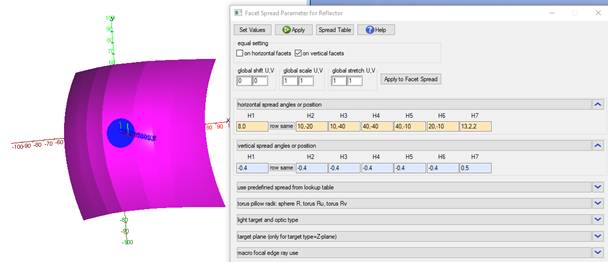

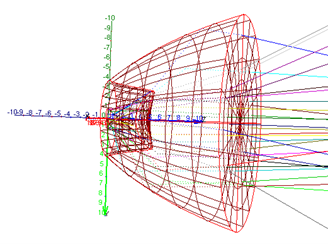

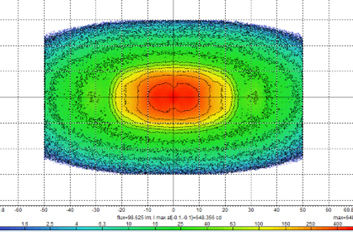

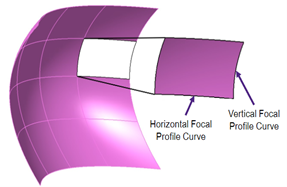

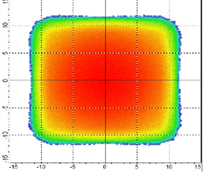

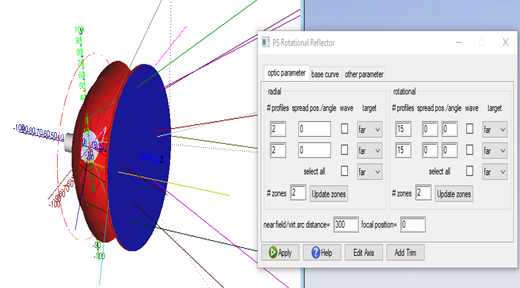

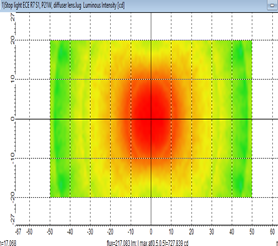

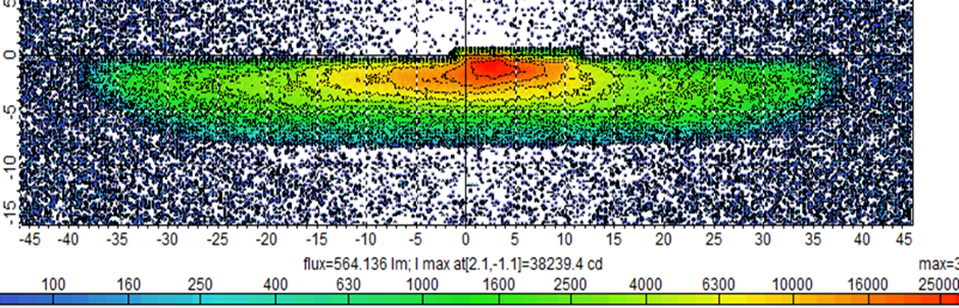

Fig 1. Depicts the two focal profile curves of the reflector that determine its curvature and the dialog box to define the spread parameters. The light distribution obtained corresponds to the specified spread parameters

A prominent trend in lighting design involves the utilization of lenses or reflectors with several small pillows or facets that allows for greater control over the light distribution. By incorporating a wider range of geometric design tools, LucidShape facilitates this design complexity.

FunGeo has 3 design tools to create reflectors and lens system based on the lamp application:

- Procedural Surface: signal lights such as stop lamps, turn lamps, and rear lamps.

- Poly Curve System: projector headlamps, LED Concentrators

- Macro Focal: Low beam and High beam lamps, interior lighting.

For a signal lamp, the PS tool allows us to set parameters like spread angles, number of profiles or the reflector size. With this technique it is also possible to create several types of lenses which are used as outer optics in automotive head lamps.

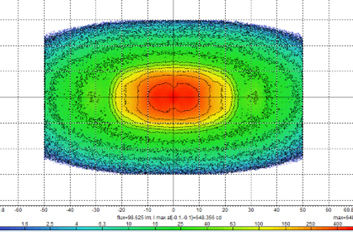

Low beam headlamps necessitate a distinct cutoff line in their light distribution. This sharp edge can be achieved using the concept of a MacroFocal (MF) object. This feature allows engineers to precisely control light distribution by defining spread for each facet, and cutoff angles essential for low beam functionality.

Collimator LED lens used to concentrate or parallelize rays from a divergent light source is based on the poly curve system design with 4 profile curves. These collimators find application in high beam lamps and motorcycle headlamps.

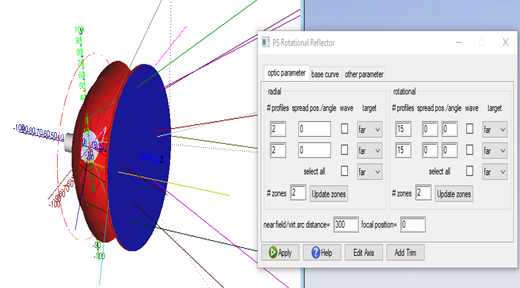

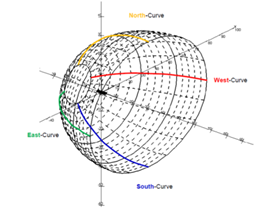

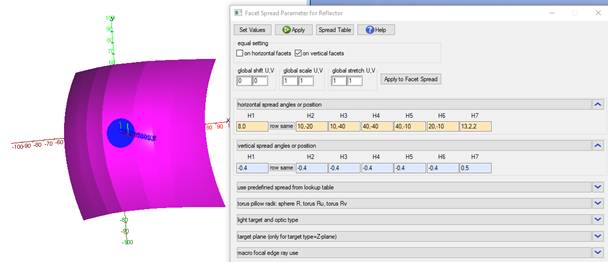

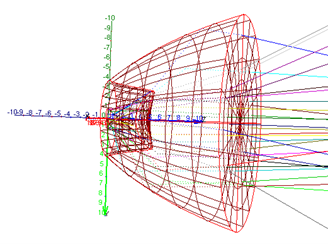

Fig 4 . Depicts the four base curves of a poly curve system that determines the reflector’s shape. A LED collimator design based on PCS tool is used to collimate light rays from a divergent source.

The goal-oriented approach of this feature helps deliver accurate, optimization-ready designs right from the first attempt. Achieving optimal light output is no longer a maze of iterations. It significantly reduces development time and empowers engineers to prioritize innovation over time-consuming refinements.

In conclusion, the innovation in lighting requires solution that balance aesthetics and functionality. LucidShape’s design features empower engineers with performance-driven design capabilities, ensuring maximum efficiency. It facilitates the creation of diverse reflector systems for a wide range of automotive lighting applications and ensures that the final product meets the stringent safety and aesthetic requirements of the modern automotive landscape.

- Niharika R K

- February 25, 2025

Shaping the Future of Automotive Lighting with Advanced Simulation

In today’s modern automotive sector, headlamps have evolved into distinctive design elements that contribute significantly to a vehicle’s overall aesthetic. Each brand strives for a unique lighting signature that reflects its identity and enhances its visual appeal while adhering to the performance standard required to ensure driver safety. One can efficiently design all exterior automotive lamps using LucidShape.

Designing a headlamp system that meets stringent regulatory requirements and delivers optimal light distribution is a complex, iterative process. Traditionally, engineers must meticulously define the geometries, curvatures, and rotations of each optical element. This involves a time-consuming cycle of input parameter adjustments, simulation, and analysis, often requiring numerous design iterations before achieving the desired output. This leads to prolonged development cycles, increased costs, and reduced efficiency.

LucidShape addresses this challenge with its innovative Functional Geometry feature where engineers can explicitly define the target light distribution they wish to achieve, instead of manually tweaking individual parameters. This represents a beneficial reverse engineering approach, streamlining the design process and enabling faster prototyping.

FunGeo Design Features

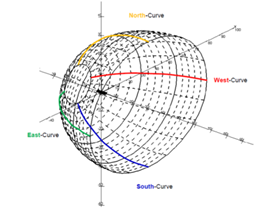

Functional geometry (FunGeo) adheres to the principle of ‘form follows function.’ Since determining precise curvatures of each facet of the reflector can be complex, LucidShape allows direct specification of desired light spread angles or distances. This approach focuses on achieving desired lighting performance by defining functional requirements rather than relying on mathematical calculation of curve shapes.

Fig 1. Depicts the two focal profile curves of the reflector that determine its curvature and the dialog box to define the spread parameters. The light distribution obtained corresponds to the specified spread parameters

A prominent trend in lighting design involves the utilization of lenses or reflectors with several small pillows or facets that allows for greater control over the light distribution. By incorporating a wider range of geometric design tools, LucidShape facilitates this design complexity.

FunGeo has 3 design tools to create reflectors and lens system based on the lamp application:

- Procedural Surface: signal lights such as stop lamps, turn lamps, and rear lamps.

- Poly Curve System: projector headlamps, LED Concentrators

- Macro Focal: Low beam and High beam lamps, interior lighting.

For a signal lamp, the PS tool allows us to set parameters like spread angles, number of profiles or the reflector size. With this technique it is also possible to create several types of lenses which are used as outer optics in automotive head lamps.

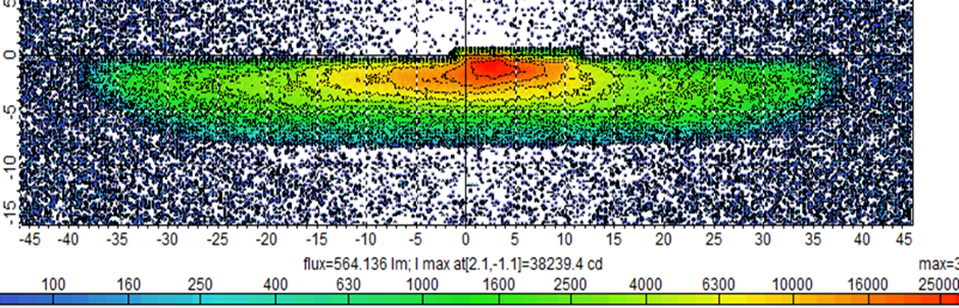

Low beam headlamps necessitate a distinct cutoff line in their light distribution. This sharp edge can be achieved using the concept of a MacroFocal (MF) object. This feature allows engineers to precisely control light distribution by defining spread for each facet, and cutoff angles essential for low beam functionality.

Collimator LED lens used to concentrate or parallelize rays from a divergent light source is based on the poly curve system design with 4 profile curves. These collimators find application in high beam lamps and motorcycle headlamps.

Fig 4 . Depicts the four base curves of a poly curve system that determines the reflector’s shape. A LED collimator design based on PCS tool is used to collimate light rays from a divergent source.

The goal-oriented approach of this feature helps deliver accurate, optimization-ready designs right from the first attempt. Achieving optimal light output is no longer a maze of iterations. It significantly reduces development time and empowers engineers to prioritize innovation over time-consuming refinements.

In conclusion, the innovation in lighting requires solution that balance aesthetics and functionality. LucidShape’s design features empower engineers with performance-driven design capabilities, ensuring maximum efficiency. It facilitates the creation of diverse reflector systems for a wide range of automotive lighting applications and ensures that the final product meets the stringent safety and aesthetic requirements of the modern automotive landscape.