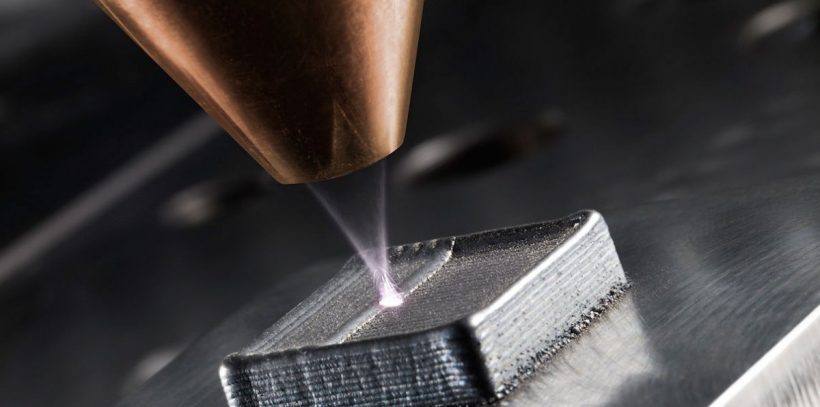

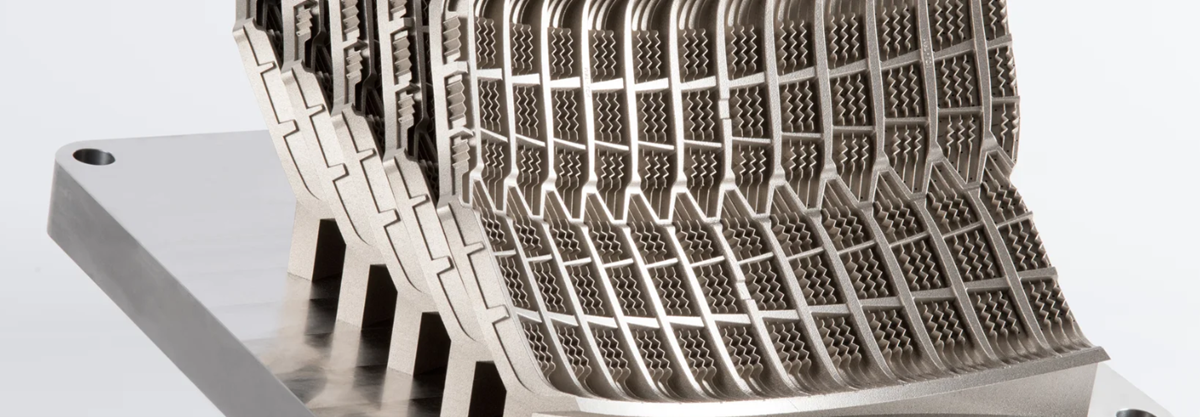

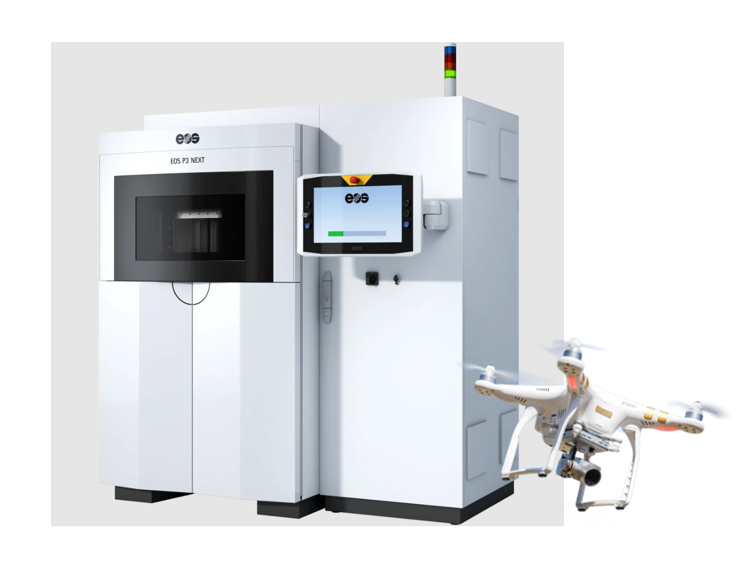

The nickel alloy family (IN625, IN718, IN939, HX, HAYNES® 282®) is optimized for EOS metal systems, with each powder shipped with an inspection certificate (EN 10204, Type 3.1 or Type 2.2) confirming quality. EOS offers validated processes for each alloy, ensuring consistent material properties in 3D printed parts. These alloys are ideal for applications in gas turbines, aerospace, energy, oil & gas, and shipbuilding.

Properties:

- Excellent strength at high temperature: Maintains strength even in elevated temperatures.

- Heat and corrosion resistant: Resistant to both heat and environmental degradation.

- High tensile, creep, and rupture strength: Can withstand stretching, long-term stress, and breakage under pressure.

All Grades

EOS NickelAlloy HAYNES® 282®

This material is a precipitation-strengthened nickel-based superalloy, offering a unique combination of high-temperature strength, thermal stability, and excellent fabricability. It was specifically developed for high-temperature…

EOS NickelAlloy IN625

EOS NickelAlloy IN625 is a heat- and corrosion-resistant nickel alloy powder, optimized specifically for processing on DMLS systems. Parts made from this alloy are known…

EOS NickelAlloy IN718

Parts demonstrate excellent tensile, fatigue, creep, and rupture strength at temperatures up to 700°C, making them ideal for a wide range of high-temperature applications, including…

EOS NickelAlloy IN939

Parts exhibit high tensile, fatigue, creep, and rupture strength at temperatures up to 850°C (1560°F), along with outstanding corrosion and oxidation resistance. They remain crack-free…

EOS NickelAlloy HX

EOS NickelAlloy HX is a nickel-based alloy powder designed for processing on EOS DMLS systems. Parts made from this material exhibit high strength and excellent…

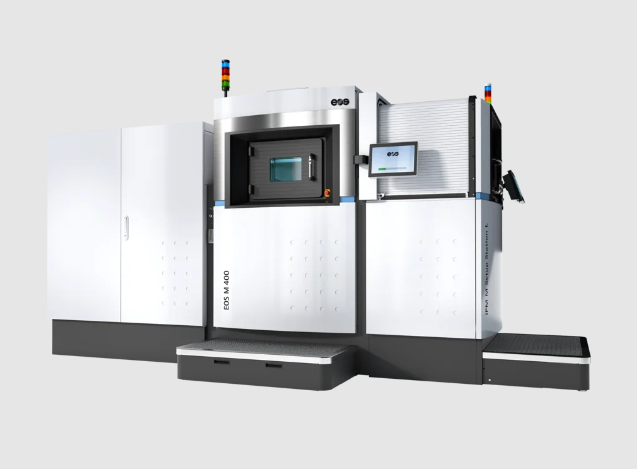

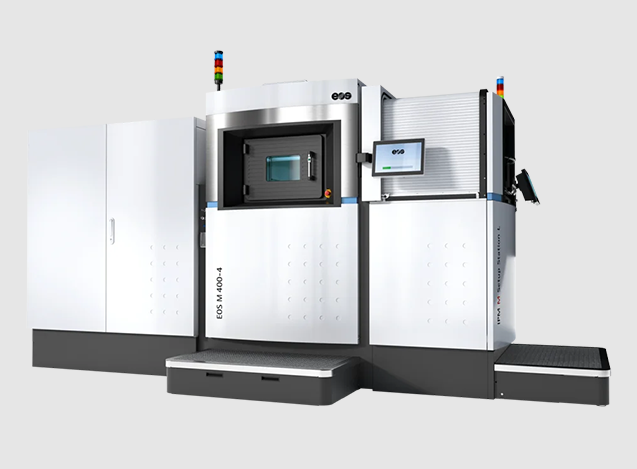

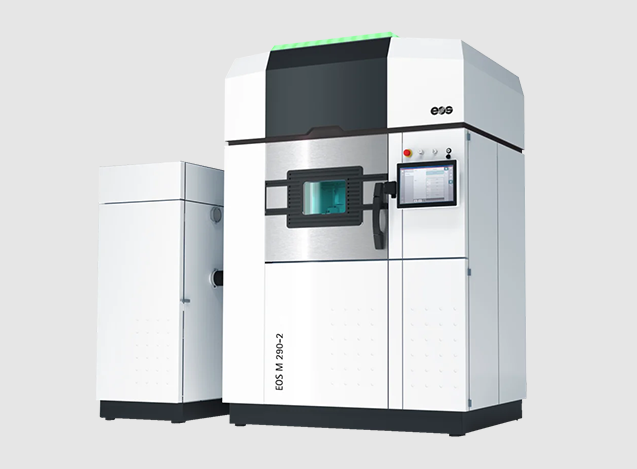

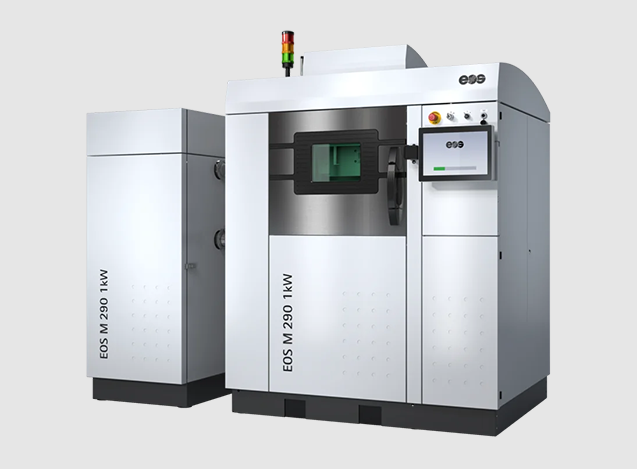

Compatible Printers

References

Latest Blog Posts

Resources

Subscribe to our newsletter

Get all the latest information on Events, Sales and Offers.