MVSR Engineering College

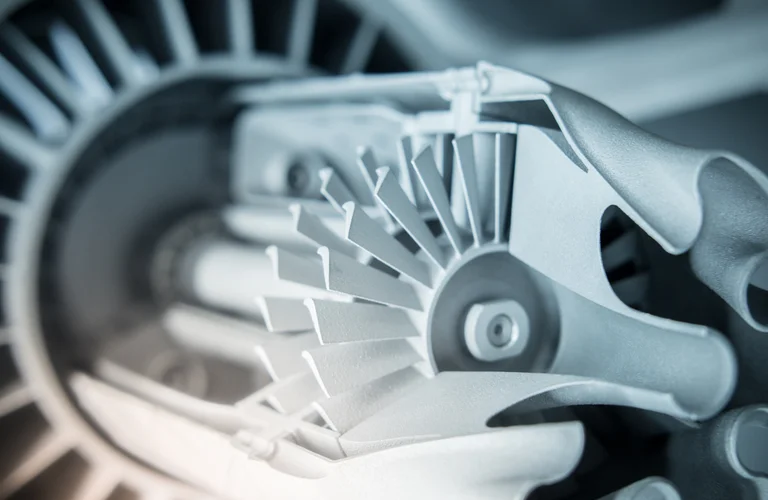

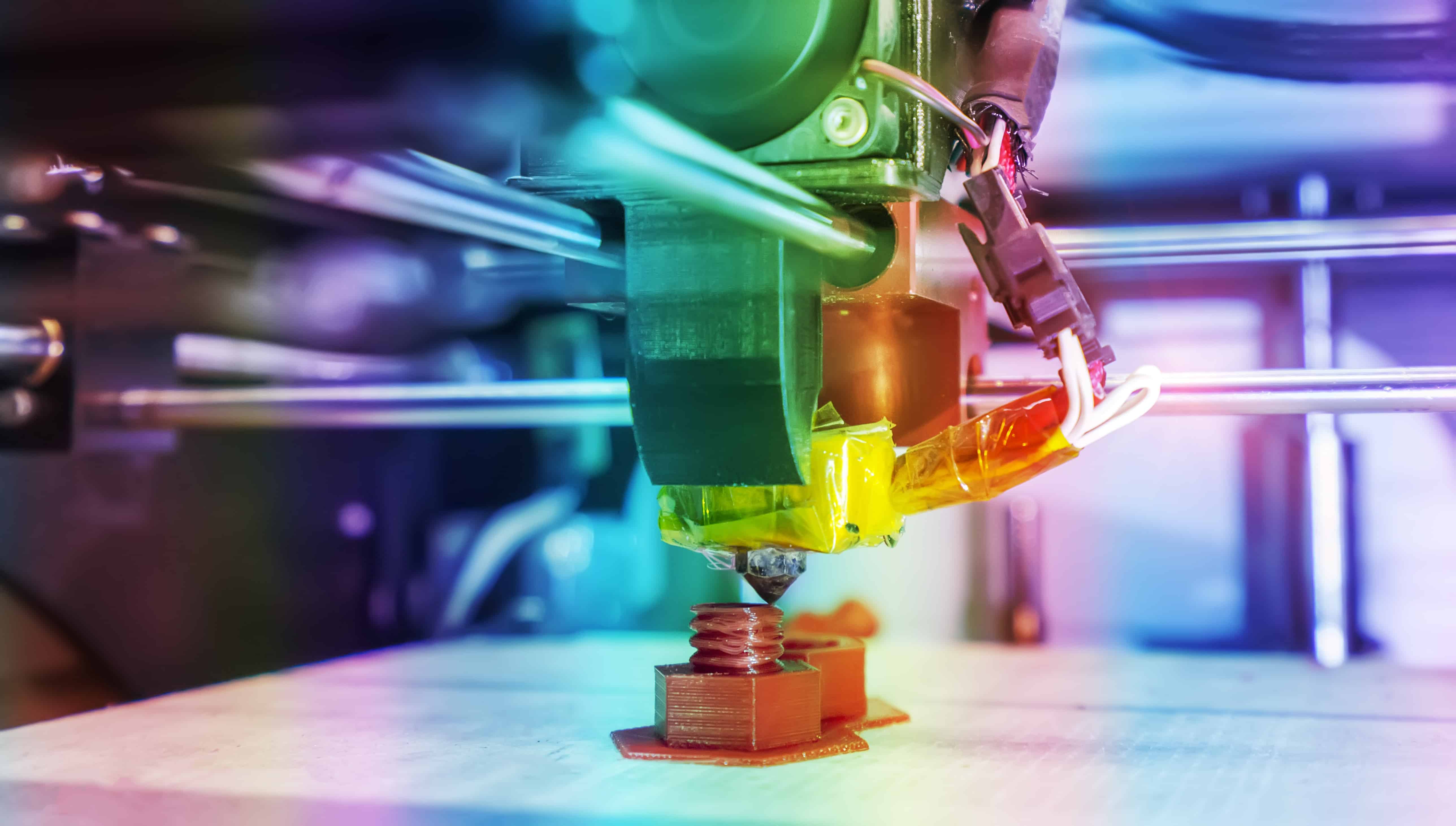

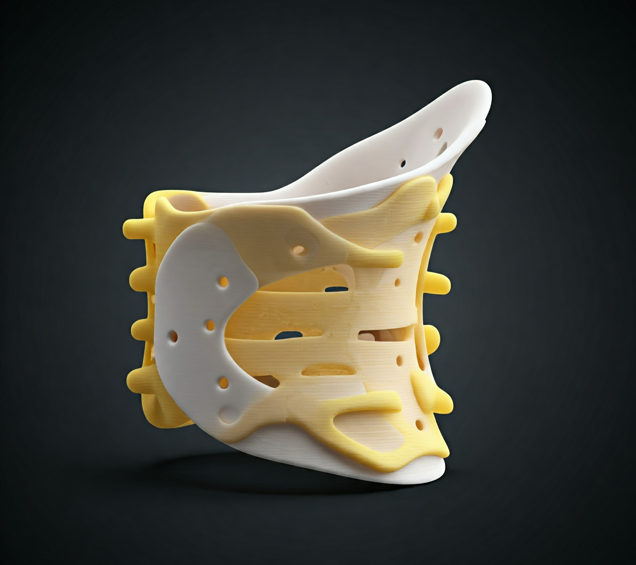

Sintratec 3D printer uses Selective Laser Sintering technology to print functional prototypes. With the advanced 3D printing technology in the lab, students and researchers get hands-on practice and do live projects which prepares them for the industry.