Other Trends

Aerosol Jet Printing for High-Resolution Circuitry

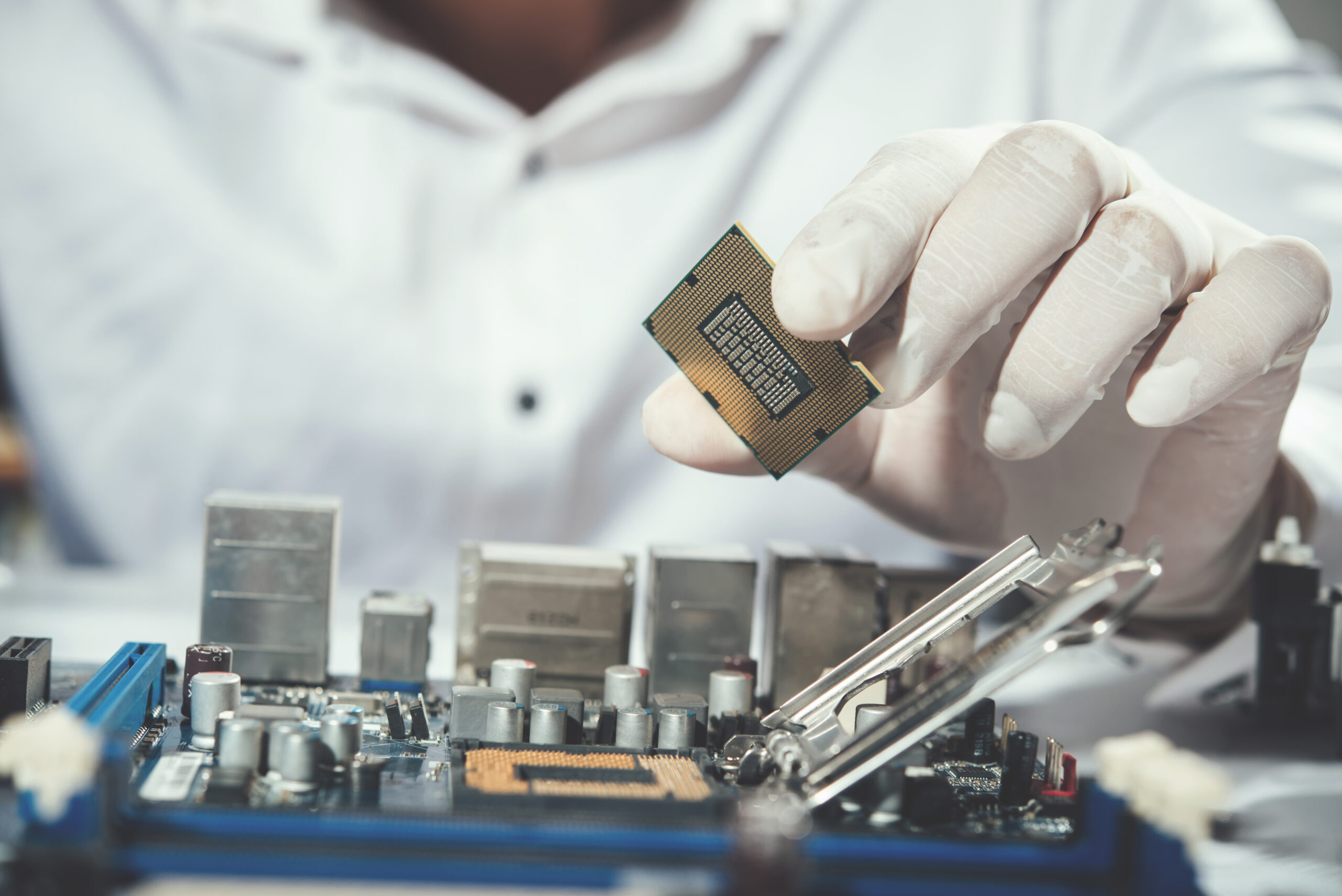

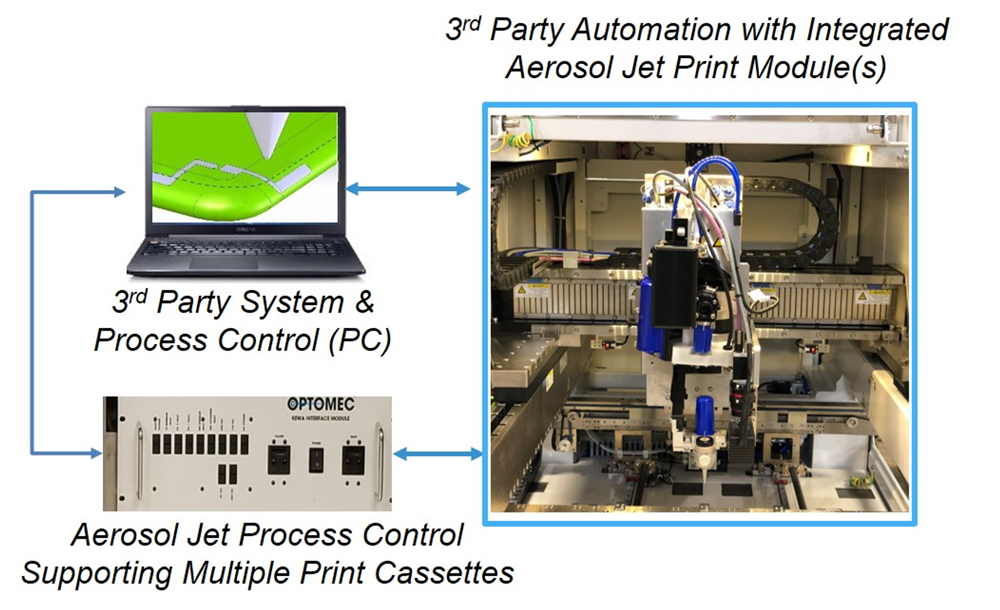

Aerosol Jet Printing for high-resolution circuitry is transforming the semiconductor industry by enabling precise and flexible production of complex electronic components. However, key challenges include achieving the required resolution for fine features, ensuring material consistency, and maintaining high throughput in a cost-effective manner. OPTOMEC 3D Printers address these challenges by using advanced Aerosol Jet Printing technology, which enables the deposition of conductive materials with micron-level precision. This technology allows semiconductor manufacturers to print high-resolution circuitry directly onto various substrates, reducing the need for traditional photolithography and accelerating the prototyping and production processes, ultimately enhancing efficiency and reducing costs.

The Future of Printed Electronics for Flexible Devices

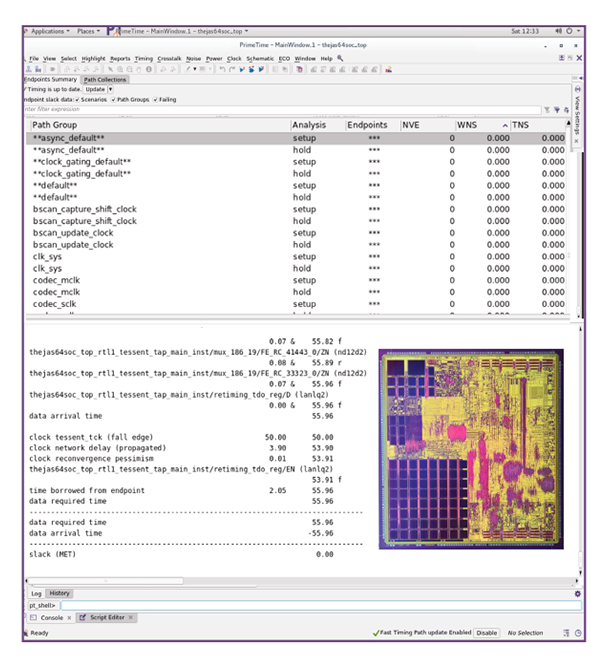

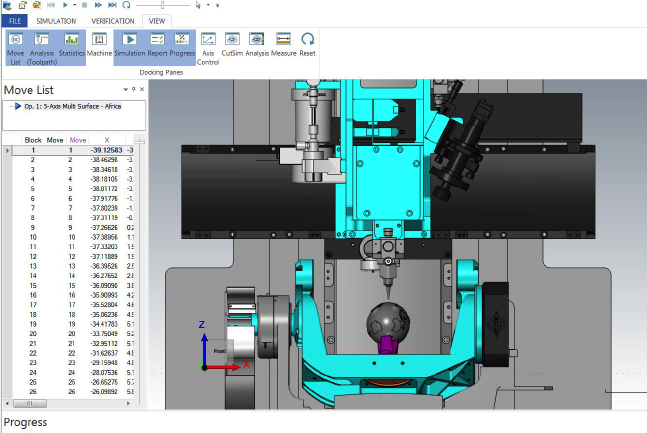

The future of printed electronics for flexible devices in the semiconductor industry presents exciting possibilities, but challenges such as achieving high-performance circuitry on flexible substrates, ensuring fine resolution, and optimizing designs for manufacturability persist. OPTOMEC 3D Printers and Synopsys EDA tool