Other trends

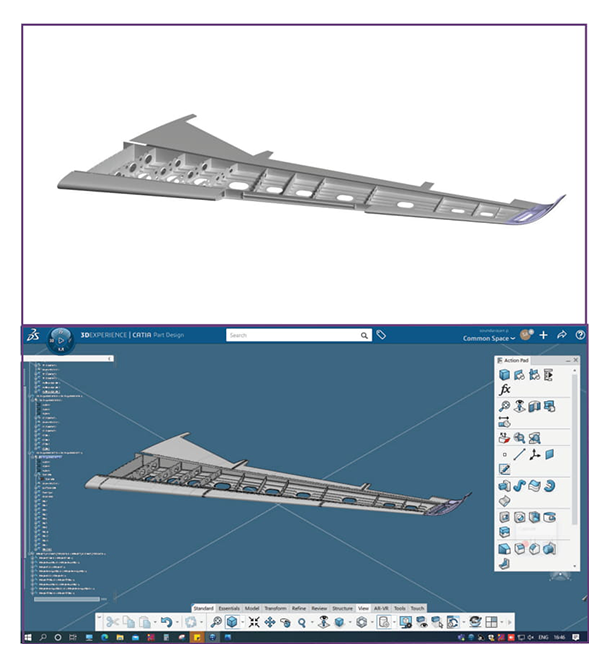

Increase Fuel Efficiency and Payload with Lightweighting in Space Exploration

In space exploration, maximizing fuel efficiency and payload capacity is critical to mission success. One of the most effective ways to achieve this is through lightweighting—reducing the weight of spacecraft components while maintaining their strength and durability. CATIA, Dassault Systèmes' advanced design software, allows engineers to create optimized, lightweight structures with precise geometry, while EOS, a leader in additive manufacturing, enables the production of these parts using high-performance materials through 3D printing. By combining CATIA’s powerful design capabilities with EOS’s additive manufacturing technology, space agencies and manufacturers can produce lightweight yet strong components, significantly reducing fuel consumption and increasing payload capacity. This approach enhances the efficiency and sustainability of space exploration missions, enabling more cost-effective and successful space programs.

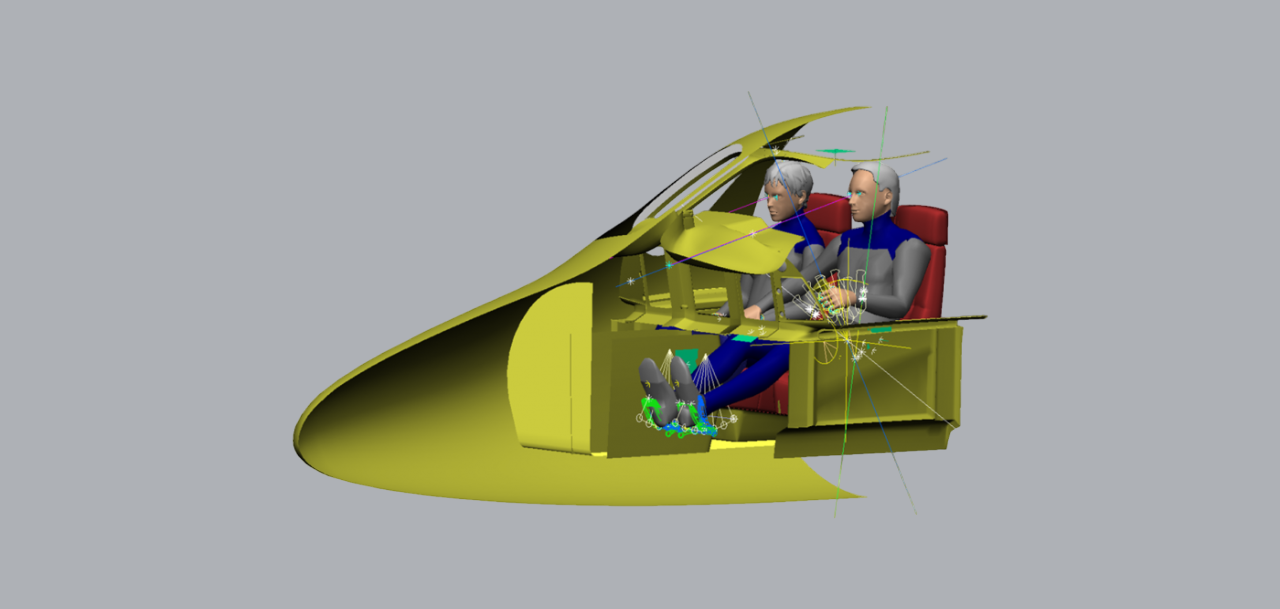

Collaborative Mechatronics Engineering for Space Systems

In the space industry, developing complex space systems requires seamless collaboration across multiple engineering disciplines, particularly in mechatronics, which combines mechanical, electrical, and software systems. The integration of these systems must be precise to ensure the reliability and performance of spacecraft, satellites, and other space technologies. ENOVIA, a leading product lifecycle management (PLM) solution, fosters this collaboration by providing a unified platform for engineers to manage the design, simulation, and production processes of mechatronic systems. With ENOVIA, teams from different domains can work together in real-time, ensuring alignment, reducing errors, and streamlining workflows. This collaborative approach accelerates development, enhances innovation, and ensures that space systems are engineered for maximum efficiency, safety, and performance.

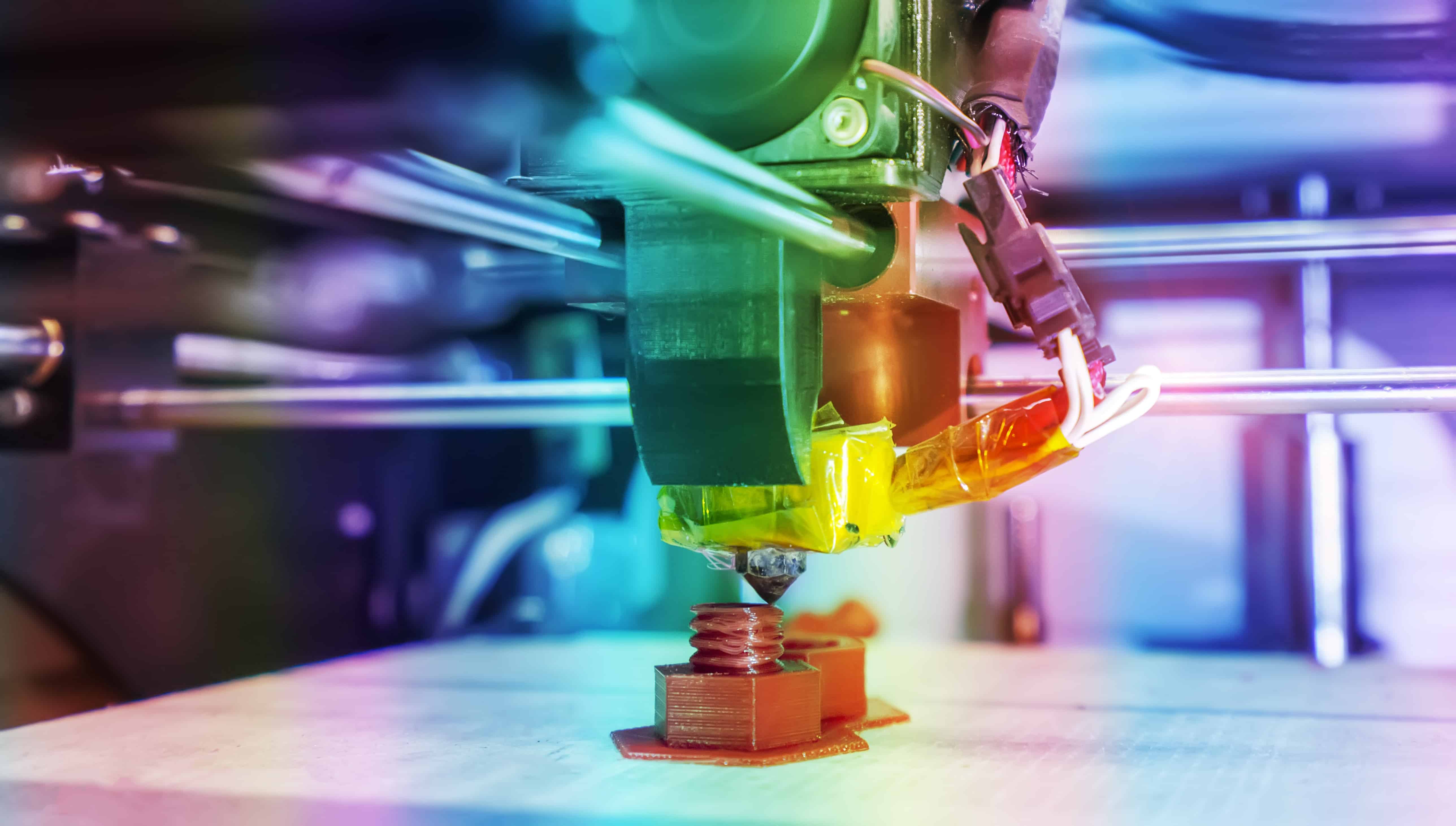

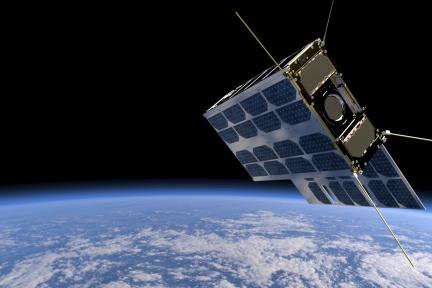

Advancing Spacecraft and Satellite Development with Additive Manufacturing

In the development of spacecraft and satellites, the demand for lightweight, high-performance components is crucial to ensuring mission success and reducing costs. Additive manufacturing (AM) offers a transformative solution by enabling the creation of complex, optimized parts with reduced weight and enhanced functionality.