Other trends

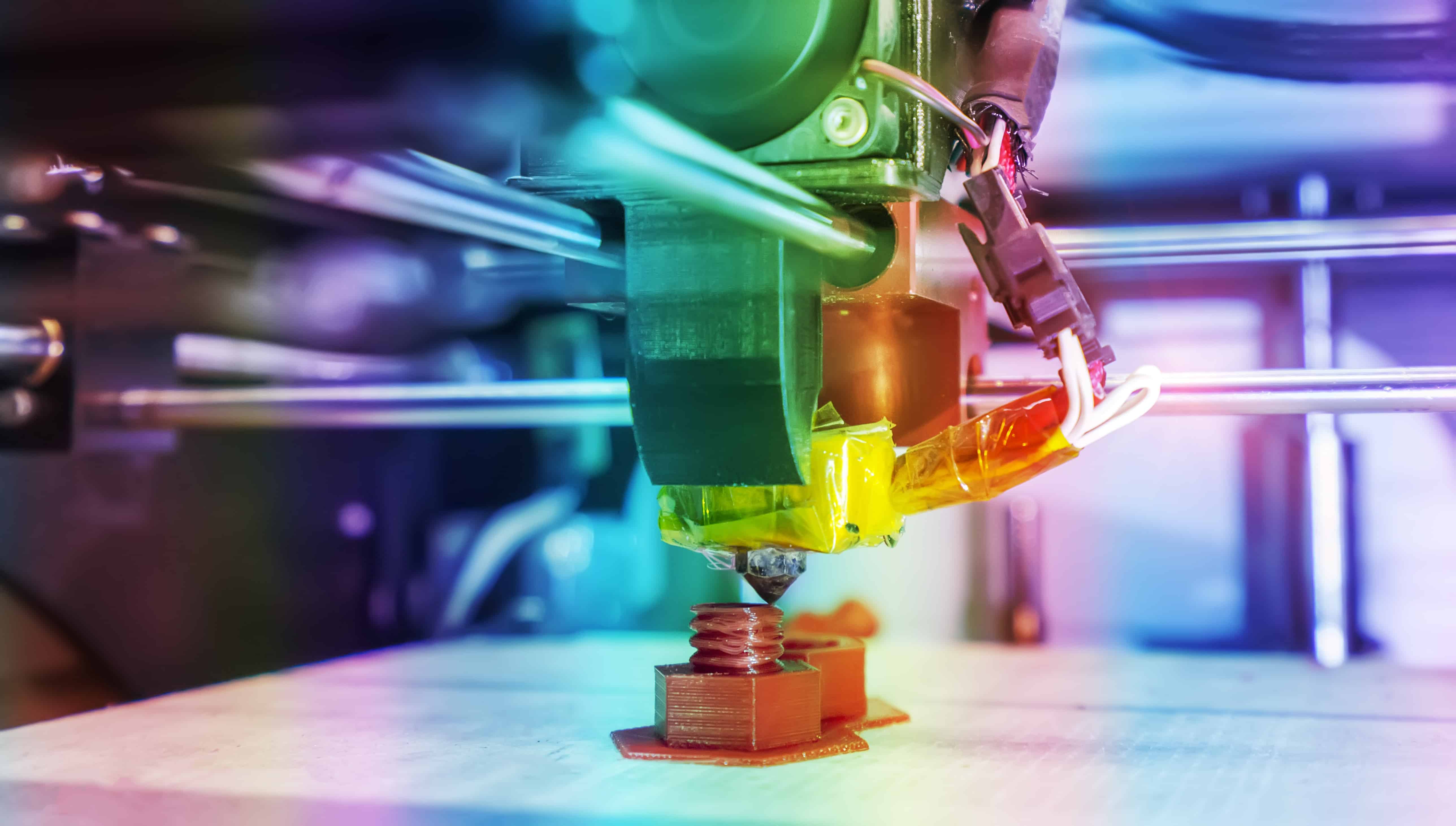

Increase Fuel Efficiency and Payload with Lightweighting in Space Exploration

In space exploration, maximizing fuel efficiency and payload capacity is critical to mission success. One of the most effective ways to achieve this is through lightweighting—reducing the weight of spacecraft components while maintaining their strength and durability. CATIA, Dassault Systèmes' advanced design software, allows engineers to create optimized, lightweight structures with precise geometry, while EOS, a leader in additive manufacturing, enables the production of these parts using high-performance materials through 3D printing. By combining CATIA’s powerful design capabilities with EOS’s additive manufacturing technology, space agencies and manufacturers can produce lightweight yet strong components, significantly reducing fuel consumption and increasing payload capacity. This approach enhances the efficiency and sustainability of space exploration missions, enabling more cost-effective and successful space programs.

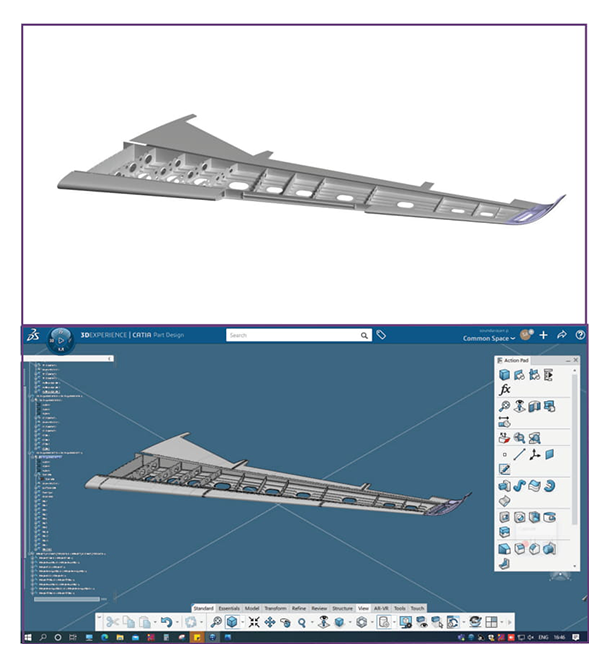

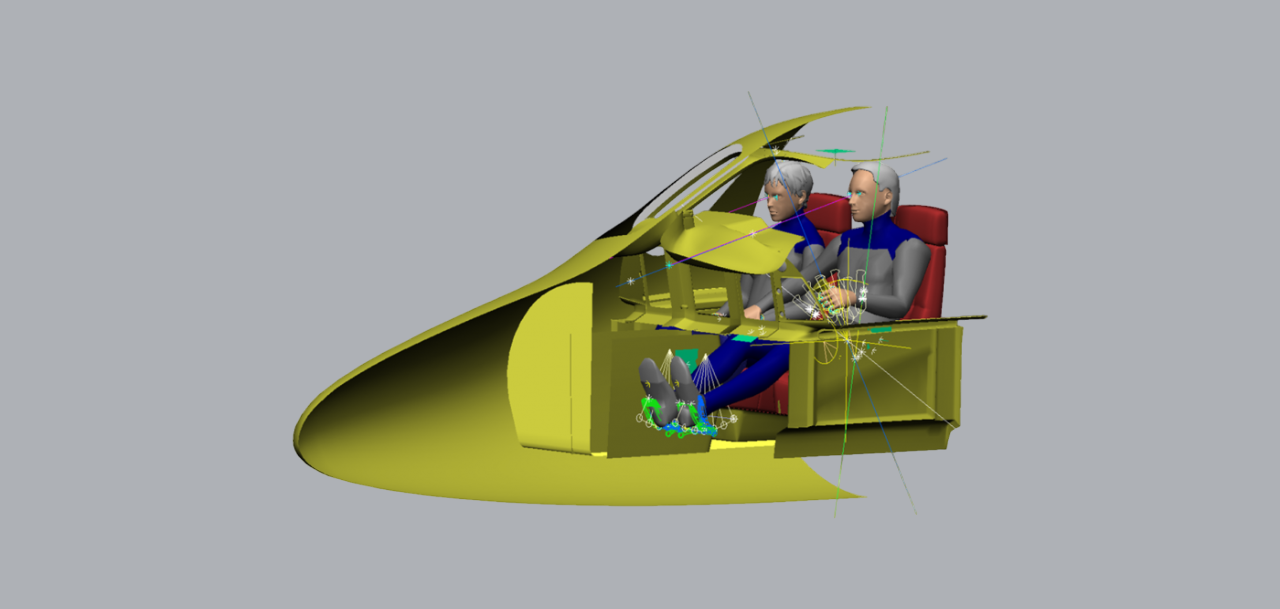

Enhance Space Systems Design with Advanced Systems Engineering Solutions

Designing space systems requires the integration of complex subsystems, including propulsion, avionics, power, and communication, all of which must function seamlessly together in extreme environments. CATIA, Dassault Systèmes’ advanced systems engineering software, enables engineers to create, simulate, and optimize these intricate systems with precision. By offering powerful tools for multi-disciplinary design, simulation, and collaboration, CATIA ensures that each component of the space system is efficiently integrated and performs optimally. With CATIA, space agencies and manufacturers can streamline the development process, reduce risk, and improve the performance and reliability of space systems, ensuring mission success in challenging conditions.

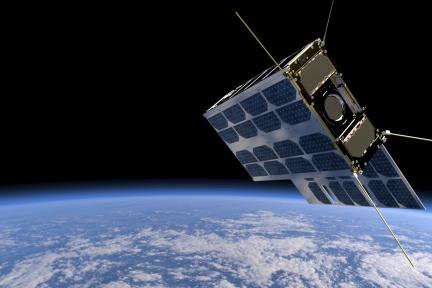

Advancing Spacecraft and Satellite Development with Additive Manufacturing

In the development of spacecraft and satellites, the demand for lightweight, high-performance components is crucial to ensuring mission success and reducing costs. Additive manufacturing (AM) offers a transformative solution by enabling the creation of complex, optimized parts with reduced weight and enhanced functionality.