Other trends

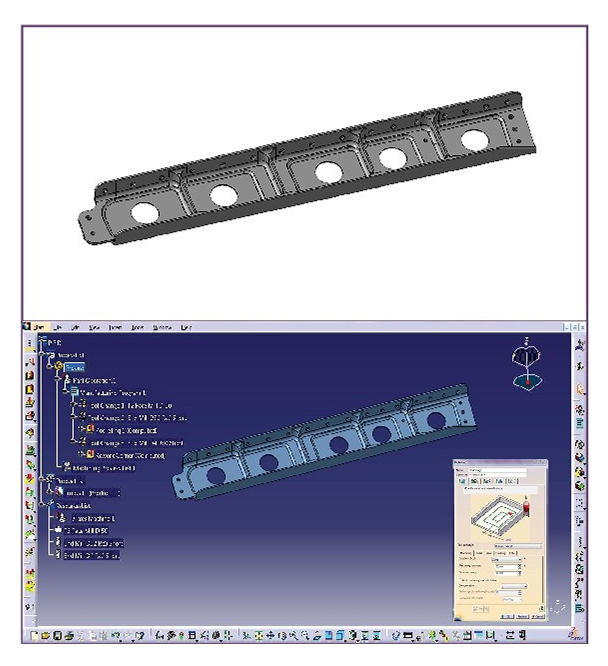

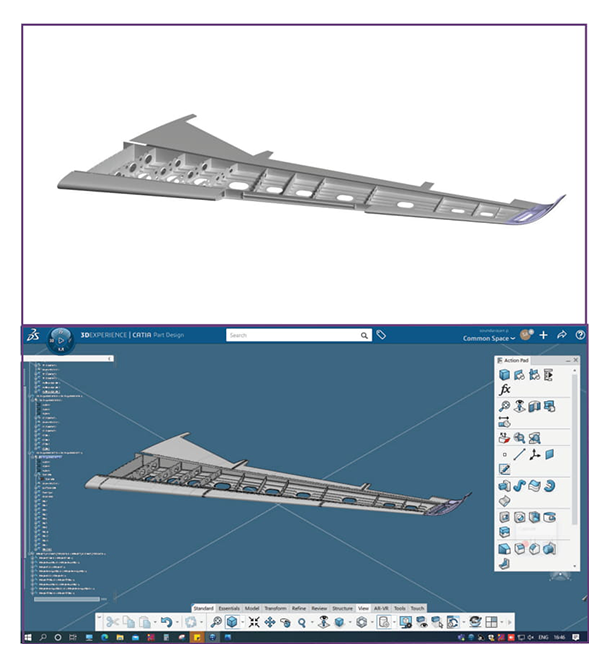

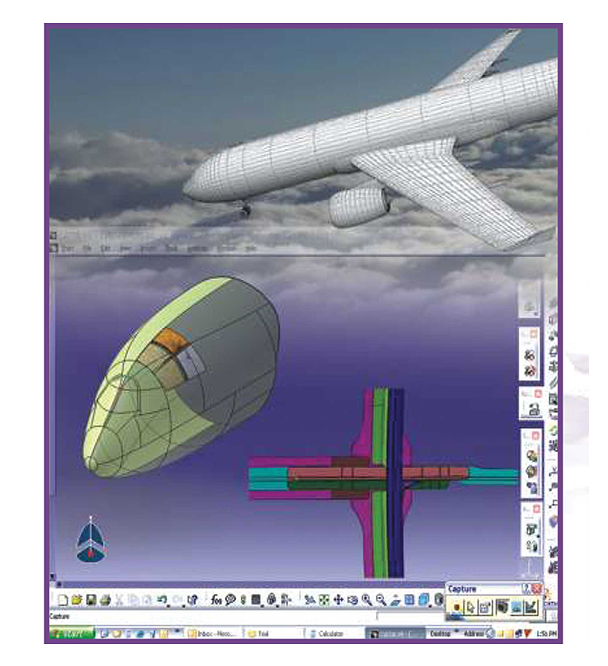

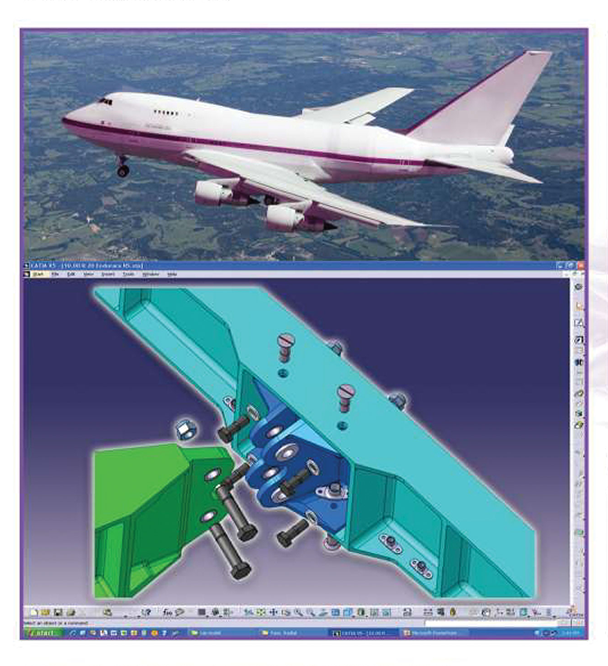

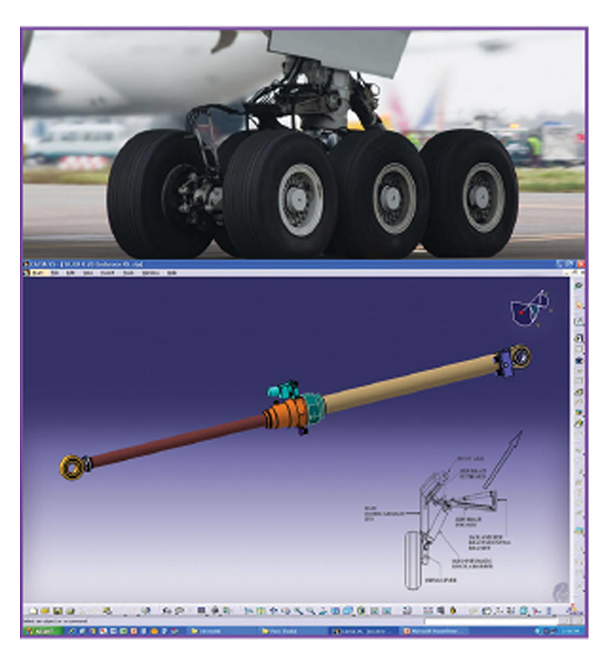

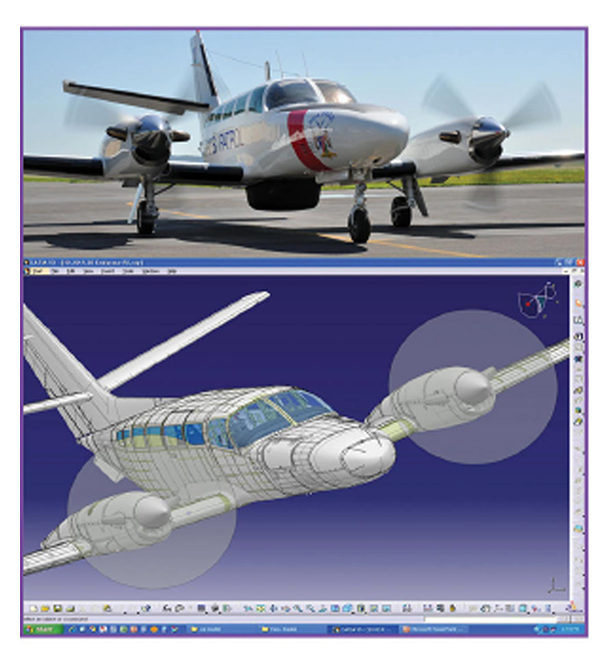

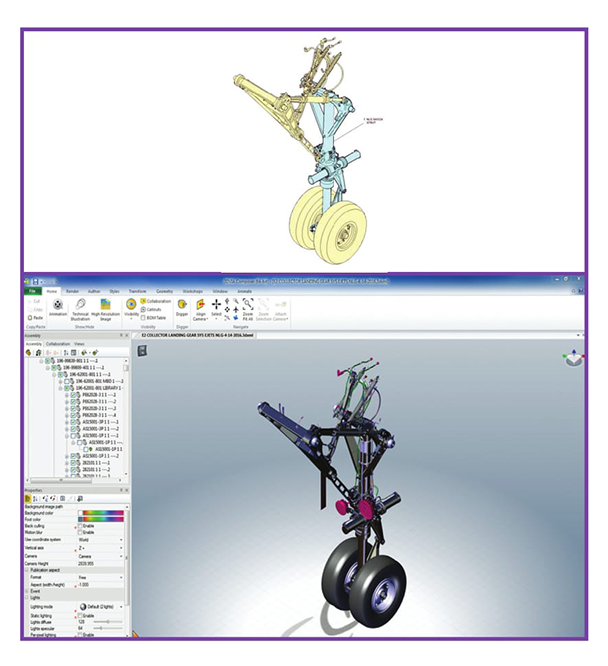

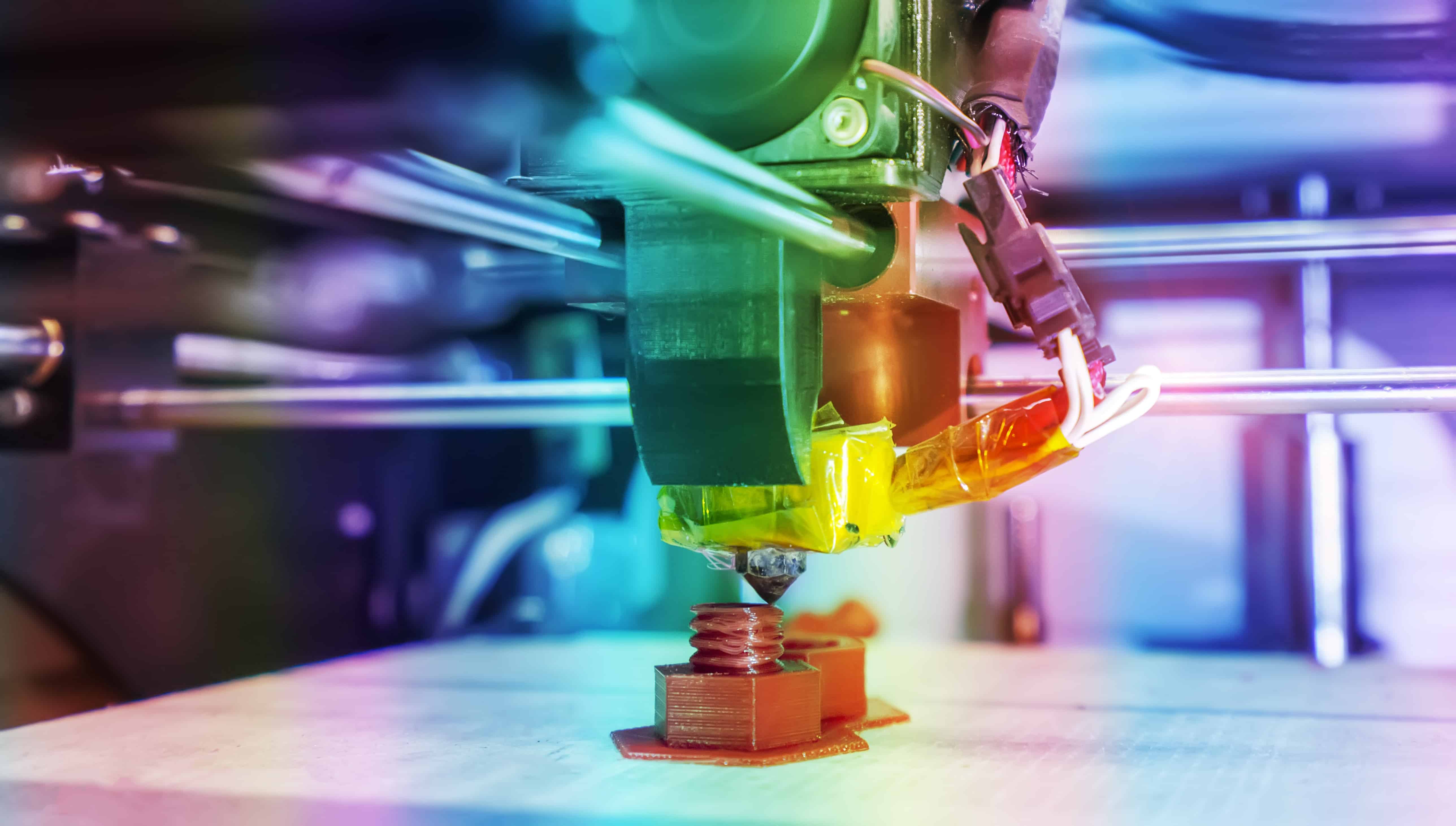

Enhance Aerospace and Drone Performance Through Advanced Lightweight Materials

In the aerospace and drone industries, improving performance and fuel efficiency while maintaining safety and durability requires the use of advanced lightweight materials. These materials help reduce weight, increase payload capacity, and enhance overall efficiency. However, designing components with these materials and ensuring their manufacturability can be complex. EOS, a leader in 3D printing technology, enables the production of high-performance lightweight parts using additive manufacturing. CATIA, Dassault Systèmes' design software, provides powerful tools for designing these components with precision and optimizing them for performance. By combining EOS for 3D printing and CATIA for design, aerospace and drone manufacturers can create innovative, lightweight structures that boost performance, reduce costs, and ensure sustainability, all while maintaining the necessary strength and reliability.

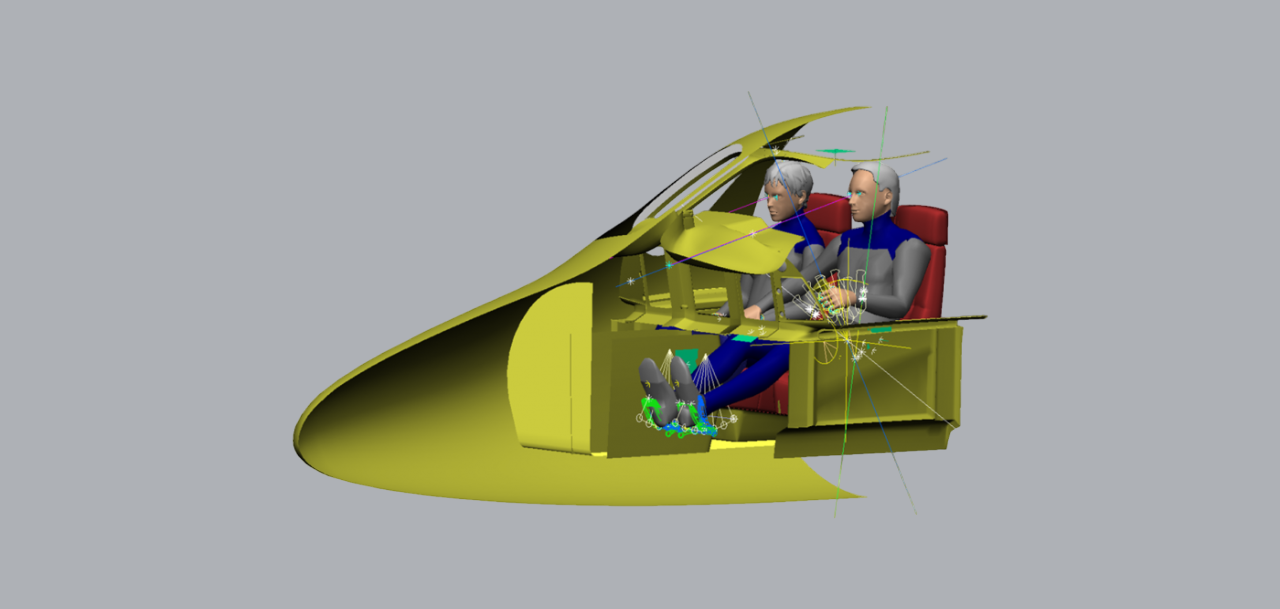

Revolutionizing Aircraft Interior Design with Human-Centered Ergonomics

In the aerospace industry, designing aircraft interiors that prioritize passenger comfort, safety, and usability is essential to enhancing the overall flying experience. However, achieving this balance requires a deep understanding of human-centered ergonomics, as well as the ability to test and optimize designs for various body types and seating configurations. RAMSIS, an advanced human simulation software, empowers designers to create ergonomic, comfortable, and functional aircraft interiors by simulating real-world human interactions with cabin spaces. Using RAMSIS, aerospace manufacturers can analyze seating arrangements, aisle space, and emergency evacuation scenarios to ensure optimal comfort and safety for passengers and crew. This human-centered approach revolutionizes interior design by making it more adaptable, user-friendly, and efficient, ultimately improving the passenger experience and meeting the evolving demands of modern air travel.

Reduce Risk and Enhance Quality with Integrated Lifecycle Management

In the aerospace industry, managing the complexity of product development, from design to manufacturing and maintenance, is critical to reducing risks and ensuring the highest standards of quality. Traditional processes can lead to inefficiencies, errors, and costly delays. ENOVIA, a leading product lifecycle management (PLM) solution, integrates every phase of the aerospace product lifecycle, enabling real-time collaboration, data sharing, and complete visibility across teams. By providing a unified platform for design, manufacturing, and maintenance, ENOVIA helps aerospace manufacturers identify and address potential risks early, streamline workflows, and ensure compliance with industry regulations. This integrated approach enhances product quality, reduces development time, and ensures a more efficient, reliable, and safe end product, ultimately contributing to greater operational success and customer satisfaction.