Transforming Business Operations with Mining Intelligence

- Surendiran R

- October 14, 2024

Data is the backbone of the mining industry. Every mine must have reliable, up-to-date information to make the best possible decisions, from first dig to end of life.

Historically, mining data has been confined to departmental silos, limiting its utility for mining organizations at large. Mining data helps gain an understanding of the “what” in data. Mining Intelligence answers the “how” and “why” to provide a comprehensive view of data. Together they enable mining companies to perform, test, and interpret sophisticated analyses quickly.

Miners can at once respond to worldwide and mine-specific challenges with evidence-based decisions, cutting through silos and interlinking various departments. This enables enhanced collaboration and knowledge sharing, while ensuring knowledge is retained across the organization even during multiple staff changes.

In the current scenario, more and more technological advancements are made in data collection. It is easy to become overwhelmed by the sheer volume of new, incredibly detailed information arriving every day. And to be confused about exactly how you are going to collect, store, and analyze it all. The reality is that not every mine has the expertise and experience it needs to complete a complex data analytics project. Yet in the current mining environment, it is becoming increasingly vital that mines use all the data at their disposal in order not just to maintain the status quo, but to get ahead in a competitive industry.

Need for Data Intelligence in Mining Industry

Data intelligence plays a crucial role in the mining industry for enhanced decision-making, optimizing operations, and improving safety and sustainability. Data converted into valuable information is particularly useful in key areas such as predictive maintenance, resource estimation & optimization, risk assessment, incident analysis, waste management, environmental impact monitoring, inventory management, logistics & transportation, exploration, transparency & reporting.

Embracing data intelligence in the mining industry not only drives efficiency and profitability but also fosters a safer and more sustainable approach to resource extraction. As technology continues to evolve, the potential for leveraging right data and information will only increase.

Big Data – A Fact of Life for Mining Companies

Mines must gather a vast amount of information and verify it against economic calculations and regulatory compliance. During mine design and planning, engineers must add information about how the site will be rehabilitated and relinquished. Later, once the mine is in operation, mine-to-mill optimisation demands up-to-date data from every stage of the process – such as data on the effectiveness of blast design, or on recovery rate, co-product valorisation, water recirculation, waste dewatering, etc. at the processing plant to make each stage more productive and therefore more profitable. At the same time other data such as data related to the effect of fleet powering choices (fossil fuel, natural gas or electricity) on the mine’s carbon footprint, is required to ensure sustainability.

A lot of mining data today is what is known as “big data.” Potentially many terabytes in size, most big data is “soft”, or unstructured (qualitative) data as opposed to “hard” or structured (quantitative) data.

Hard data is directly observed and measured and easily put into searchable rows and columns. Soft data includes text, video, photographs, scans, etc., as well as metadata – in other words, data without structure that cannot be put into rows and columns. To understand and take advantage of all your data, your soft data must be able to work with and be stored, viewed, and analysed alongside – your traditional hard data, such as the lithologies, assays, and other physical drilling information used in resource estimations.

Why Virtual Twin Experiences are Key to Mining Intelligence

Modern mining operations are intricate systems of systems, surpassing the capabilities of industry solutions to analyze them. To fully harness the potential of big data, it’s important to identify the different systems generating it, understand their functions, and delineate their boundaries and interconnections. This enables effective management of data flow between these systems.

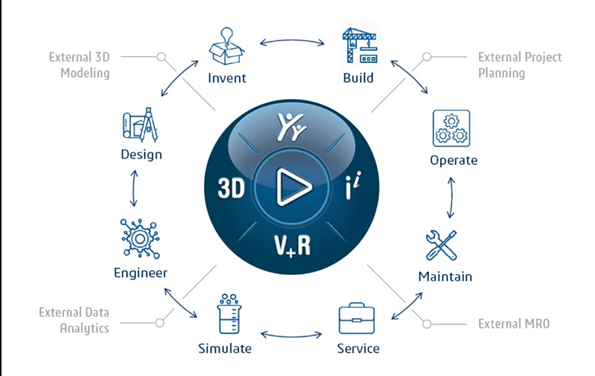

This level of interconnected data management is achievable through virtual twin experiences. Unlike standard digital twins, virtual twin experiences offer a dynamic, live virtual representation of the real world.

The applications linked to this system of systems incorporate smart algorithms that empower AI techniques to suggest decision options based on past data, current behaviour, and possible simulated outcomes based on those decision options.

Having a digital continuity between financial assumptions based on commodity prices, energy cost and so on as well as geology, terrain, and in-field operational information enables mining companies to achieve consistency in planning from short-term to long-term and vice-versa. This also helps avoid having contradicting decisions implemented at the same time in different parts of the mine, which can hurt Net Present Value.

The virtual twin enables three levels of data analytics:

- Descriptive: Examining what happened

- Predictive: Examining possible outcomes based on what happened

- Prescriptive: Prescribing roadmaps based on possible decision options to adjust to various evolving factors on the go, thereby permanently pursuing value in all operations

This approach minimizes waste and risk and maximizes productivity by reducing unnecessary material re-handling.

How can Mining Industries turn Data into Valuable Business Insights

Turning data into valuable business insights through data analytics involves several key steps. Here’s a structured approach that is required for business transformation:

- Identify your issues

- Collect, store, and integrate your data

- Analyze your data/define your dashboards

- Publish your data

- Share your data

Once all the data is in a single repository, it can be well organized and integrated using the most appropriate GEOVIA Mining Intelligence applications on the 3DEXPERIENCE platform as detailed below:

Exploration Intelligence

- Index all geological data, both structured and unstructured, from various source systems

- Create a visual overview of all exploration data

- Measure, analyze, display, and share data, and

- Develop detailed, drilldown views of specific exploration activities, such as drilling sampling results sorted by their campaign code, status and period

Geology Intelligence

- Index, analyze and report tonnages, grade, volume, material type and other metrics

- Compare multiple versions of the block model

- Share results internally with other teams or stakeholders across the mine

- Display and share specific analytics, such as an analysis of the estimated weight of ore, waste and average grade for various cut-off grades, or a comparison of the mathematical (spherical) model and variogram curve from the drill hole

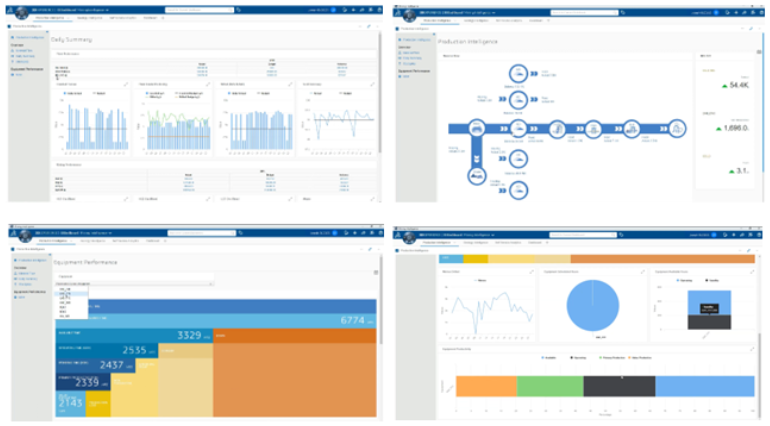

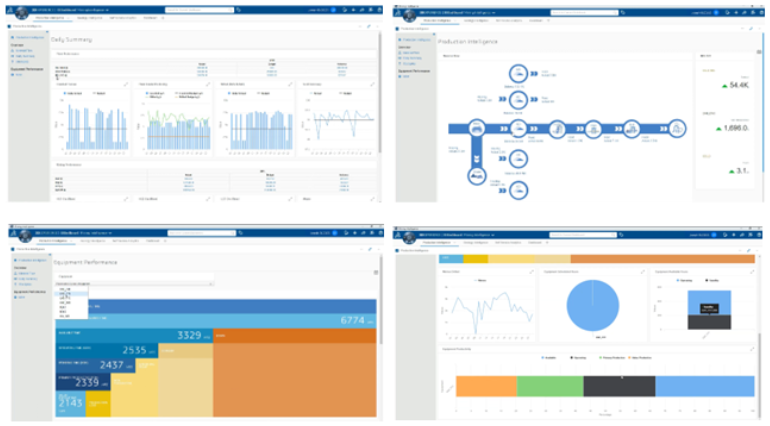

Production Intelligence

Index production data at source, analyze it and visualize the results using a range of standard dashboards, including dashboards that

- Monitor production actuals against targets, ore processing metrics and equipment performance

- Review stockpile balances and equipment fuel consumption

- Reveal material flow and key performance indicators

Traditionally, mining processes were manual, with strategic planning conducted by engineers across various disciplines using Excel while managing data in silos. The Dassault Systèmes’ 3DEXPERIENCE platform leverages the existing mining engine to introduce a cloud-based data analytics layer on top of it to democratize data.

The platform integrates and automates mining processes, dismantles silos and enables executives to focus on higher-value areas and optimized geotechnical, economic, productivity and ESG parameters. The optimization ensures positive cash flow or net present value (NPV) while adhering to sustainability and compliance goals.

Overall, GEOVIA Mining Intelligence on the 3DEXPERIENCE platform represents a leap forward in the quest to gain a competitive edge.

Its four powerful applications provide efficient and effective methods for:

- Gathering all your big data into one place

- Indexing it so it is immediately ready to retrieve and analyze as required, and

- Understanding it more deeply than you ever thought possible through multiple visualizations, leading to Better-informed decisions and greater productivity.

To get more information & insights on how the 3DEXPERIENCE Platform drives business transformation in the mining industry, please reach out to us at marketing@edstechnologies.com

- Surendiran R

- October 14, 2024

Transforming Business Operations with Mining Intelligence

Data is the backbone of the mining industry. Every mine must have reliable, up-to-date information to make the best possible decisions, from first dig to end of life.

Historically, mining data has been confined to departmental silos, limiting its utility for mining organizations at large. Mining data helps gain an understanding of the “what” in data. Mining Intelligence answers the “how” and “why” to provide a comprehensive view of data. Together they enable mining companies to perform, test, and interpret sophisticated analyses quickly.

Miners can at once respond to worldwide and mine-specific challenges with evidence-based decisions, cutting through silos and interlinking various departments. This enables enhanced collaboration and knowledge sharing, while ensuring knowledge is retained across the organization even during multiple staff changes.

In the current scenario, more and more technological advancements are made in data collection. It is easy to become overwhelmed by the sheer volume of new, incredibly detailed information arriving every day. And to be confused about exactly how you are going to collect, store, and analyze it all. The reality is that not every mine has the expertise and experience it needs to complete a complex data analytics project. Yet in the current mining environment, it is becoming increasingly vital that mines use all the data at their disposal in order not just to maintain the status quo, but to get ahead in a competitive industry.

Need for Data Intelligence in Mining Industry

Data intelligence plays a crucial role in the mining industry for enhanced decision-making, optimizing operations, and improving safety and sustainability. Data converted into valuable information is particularly useful in key areas such as predictive maintenance, resource estimation & optimization, risk assessment, incident analysis, waste management, environmental impact monitoring, inventory management, logistics & transportation, exploration, transparency & reporting.

Embracing data intelligence in the mining industry not only drives efficiency and profitability but also fosters a safer and more sustainable approach to resource extraction. As technology continues to evolve, the potential for leveraging right data and information will only increase.

Big Data – A Fact of Life for Mining Companies

Mines must gather a vast amount of information and verify it against economic calculations and regulatory compliance. During mine design and planning, engineers must add information about how the site will be rehabilitated and relinquished. Later, once the mine is in operation, mine-to-mill optimisation demands up-to-date data from every stage of the process – such as data on the effectiveness of blast design, or on recovery rate, co-product valorisation, water recirculation, waste dewatering, etc. at the processing plant to make each stage more productive and therefore more profitable. At the same time other data such as data related to the effect of fleet powering choices (fossil fuel, natural gas or electricity) on the mine’s carbon footprint, is required to ensure sustainability.

A lot of mining data today is what is known as “big data.” Potentially many terabytes in size, most big data is “soft”, or unstructured (qualitative) data as opposed to “hard” or structured (quantitative) data.

Hard data is directly observed and measured and easily put into searchable rows and columns. Soft data includes text, video, photographs, scans, etc., as well as metadata – in other words, data without structure that cannot be put into rows and columns. To understand and take advantage of all your data, your soft data must be able to work with and be stored, viewed, and analysed alongside – your traditional hard data, such as the lithologies, assays, and other physical drilling information used in resource estimations.

Why Virtual Twin Experiences are Key to Mining Intelligence

Modern mining operations are intricate systems of systems, surpassing the capabilities of industry solutions to analyze them. To fully harness the potential of big data, it’s important to identify the different systems generating it, understand their functions, and delineate their boundaries and interconnections. This enables effective management of data flow between these systems.

This level of interconnected data management is achievable through virtual twin experiences. Unlike standard digital twins, virtual twin experiences offer a dynamic, live virtual representation of the real world.

The applications linked to this system of systems incorporate smart algorithms that empower AI techniques to suggest decision options based on past data, current behaviour, and possible simulated outcomes based on those decision options.

Having a digital continuity between financial assumptions based on commodity prices, energy cost and so on as well as geology, terrain, and in-field operational information enables mining companies to achieve consistency in planning from short-term to long-term and vice-versa. This also helps avoid having contradicting decisions implemented at the same time in different parts of the mine, which can hurt Net Present Value.

The virtual twin enables three levels of data analytics:

- Descriptive: Examining what happened

- Predictive: Examining possible outcomes based on what happened

- Prescriptive: Prescribing roadmaps based on possible decision options to adjust to various evolving factors on the go, thereby permanently pursuing value in all operations

This approach minimizes waste and risk and maximizes productivity by reducing unnecessary material re-handling.

How can Mining Industries turn Data into Valuable Business Insights

Turning data into valuable business insights through data analytics involves several key steps. Here’s a structured approach that is required for business transformation:

- Identify your issues

- Collect, store, and integrate your data

- Analyze your data/define your dashboards

- Publish your data

- Share your data

Once all the data is in a single repository, it can be well organized and integrated using the most appropriate GEOVIA Mining Intelligence applications on the 3DEXPERIENCE platform as detailed below:

Exploration Intelligence

- Index all geological data, both structured and unstructured, from various source systems

- Create a visual overview of all exploration data

- Measure, analyze, display, and share data, and

- Develop detailed, drilldown views of specific exploration activities, such as drilling sampling results sorted by their campaign code, status and period

Geology Intelligence

- Index, analyze and report tonnages, grade, volume, material type and other metrics

- Compare multiple versions of the block model

- Share results internally with other teams or stakeholders across the mine

- Display and share specific analytics, such as an analysis of the estimated weight of ore, waste and average grade for various cut-off grades, or a comparison of the mathematical (spherical) model and variogram curve from the drill hole

Production Intelligence

Index production data at source, analyze it and visualize the results using a range of standard dashboards, including dashboards that

- Monitor production actuals against targets, ore processing metrics and equipment performance

- Review stockpile balances and equipment fuel consumption

- Reveal material flow and key performance indicators

Traditionally, mining processes were manual, with strategic planning conducted by engineers across various disciplines using Excel while managing data in silos. The Dassault Systèmes’ 3DEXPERIENCE platform leverages the existing mining engine to introduce a cloud-based data analytics layer on top of it to democratize data.

The platform integrates and automates mining processes, dismantles silos and enables executives to focus on higher-value areas and optimized geotechnical, economic, productivity and ESG parameters. The optimization ensures positive cash flow or net present value (NPV) while adhering to sustainability and compliance goals.

Overall, GEOVIA Mining Intelligence on the 3DEXPERIENCE platform represents a leap forward in the quest to gain a competitive edge.

Its four powerful applications provide efficient and effective methods for:

- Gathering all your big data into one place

- Indexing it so it is immediately ready to retrieve and analyze as required, and

- Understanding it more deeply than you ever thought possible through multiple visualizations, leading to Better-informed decisions and greater productivity.

To get more information & insights on how the 3DEXPERIENCE Platform drives business transformation in the mining industry, please reach out to us at marketing@edstechnologies.com