Digital Manufacturing: A Sustainable Future in Manufacturing for You

- Radhakrishnan Jayapal

- October 31, 2019

For the past decade, Digital Economy is transforming the traditional manufacturing process with modern digital systems. Digital Manufacturing has improved the Quality, Efficiency, and Sustainability of Manufacturing. Manufacturers are now open to new and improved business practices to start their digital transformation journey.

Traditional manufacturing has worked well so far for mass production by being cost-effective with short cycle times. However, extensive manufacturing equipment generates more waste with inventory overflow and high energy consumption. Whereas, digital manufacturing is sustainable, efficient, and flexible with boundless manufacturing opportunities.

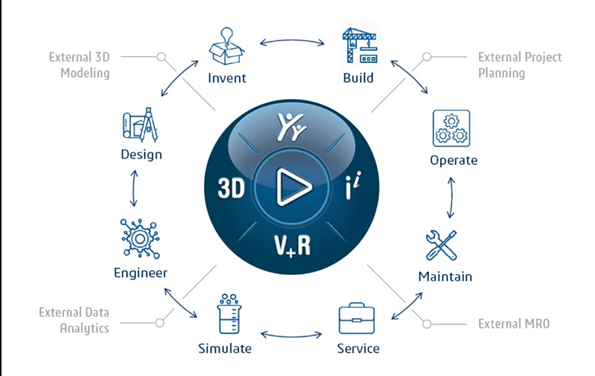

Digital Manufacturing is modern manufacturing with end-to-end technology including hardware and software integration. Manufacturers have realized the need to optimize their business model to align with the modern market and start their digital transformation journey.

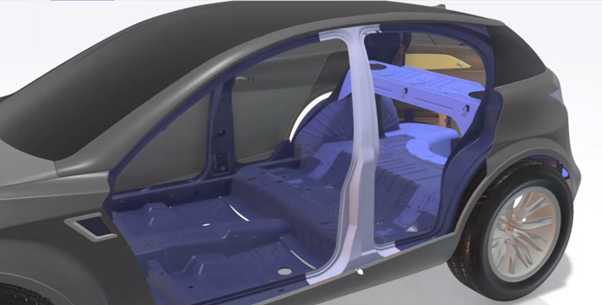

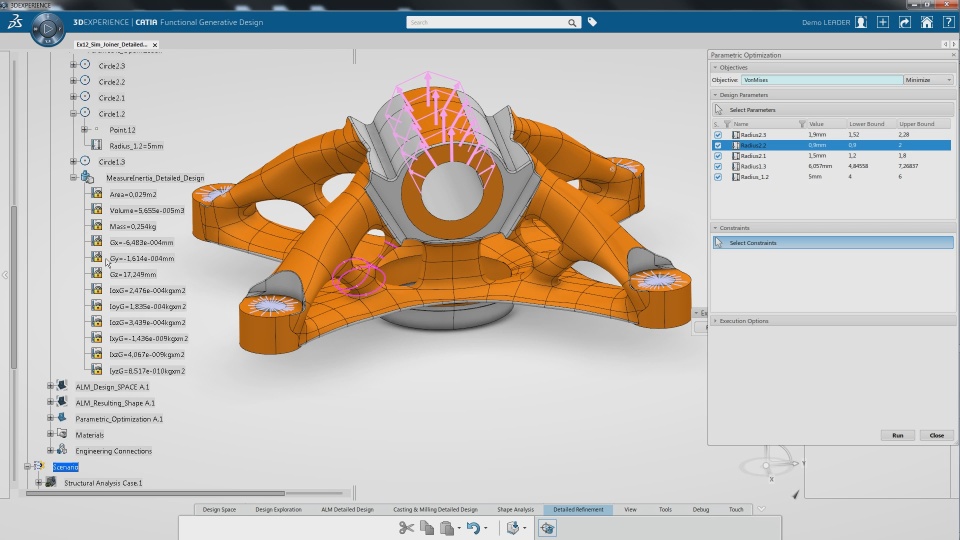

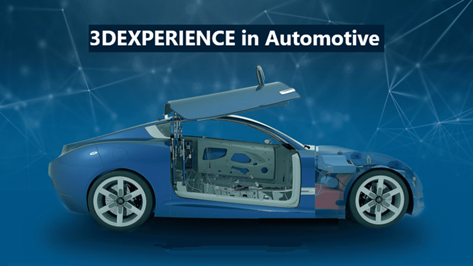

Each stage of the digital systems is connected, aligned, and improved. The digital simulations of 3D CAD models generated by PLM software enable product feedback and corrections. The design is digitally refined by addressing the issues and updating the product without affecting the time and cost of production. The product blueprint is finalized only after complete quality control and then sent for production.

Customers now seek customizable and unique products for their needs. It is easy to customize the product design as per customer requirements with reduced time consumption and manual labor.

Product testing is another important process in product manufacturing. Digital manufacturing enables the production of small batches for product testing and also provides better inventory control. This ensures further refining of the product to deliver better and more quality products in an efficient automated system. Also, it enables the ability to switch production and product design with the change in market trends and product demand. Digital transformation in manufacturing ensures a reduction in waste generation, time, and fuel consumption reinforces sustainability in the whole manufacturing process.

According to ‘Investing for a Sustainable Future,’ an MIT report, Sustainable Business Models are likely to generate twice the profit. By adopting Digital Manufacturing technology practices, manufacturers are saving time, cost, and conserving natural resources. Digital Manufacturing creates an automated process that helps project managers make informed decisions for efficient and faster production.

The future of digital manufacturing is bright and beaming with numerous opportunities for a sustainable world. At EDS Technologies, we strive to be part of the Movement for Global Sustainability in Business with our solutions. We also encourage our customers who are manufacturing companies to start their digital transformation journey with our engineering solutions such as DELMIA, CATIA, SIMULIA, ENOVIA and 3DEXPERIENCE for a better world.

- Radhakrishnan Jayapal

- October 31, 2019

Digital Manufacturing: A Sustainable Future in Manufacturing for You

For the past decade, Digital Economy is transforming the traditional manufacturing process with modern digital systems. Digital Manufacturing has improved the Quality, Efficiency, and Sustainability of Manufacturing. Manufacturers are now open to new and improved business practices to start their digital transformation journey.

Traditional manufacturing has worked well so far for mass production by being cost-effective with short cycle times. However, extensive manufacturing equipment generates more waste with inventory overflow and high energy consumption. Whereas, digital manufacturing is sustainable, efficient, and flexible with boundless manufacturing opportunities.

Digital Manufacturing is modern manufacturing with end-to-end technology including hardware and software integration. Manufacturers have realized the need to optimize their business model to align with the modern market and start their digital transformation journey.

Each stage of the digital systems is connected, aligned, and improved. The digital simulations of 3D CAD models generated by PLM software enable product feedback and corrections. The design is digitally refined by addressing the issues and updating the product without affecting the time and cost of production. The product blueprint is finalized only after complete quality control and then sent for production.

Customers now seek customizable and unique products for their needs. It is easy to customize the product design as per customer requirements with reduced time consumption and manual labor.

Product testing is another important process in product manufacturing. Digital manufacturing enables the production of small batches for product testing and also provides better inventory control. This ensures further refining of the product to deliver better and more quality products in an efficient automated system. Also, it enables the ability to switch production and product design with the change in market trends and product demand. Digital transformation in manufacturing ensures a reduction in waste generation, time, and fuel consumption reinforces sustainability in the whole manufacturing process.

According to ‘Investing for a Sustainable Future,’ an MIT report, Sustainable Business Models are likely to generate twice the profit. By adopting Digital Manufacturing technology practices, manufacturers are saving time, cost, and conserving natural resources. Digital Manufacturing creates an automated process that helps project managers make informed decisions for efficient and faster production.

The future of digital manufacturing is bright and beaming with numerous opportunities for a sustainable world. At EDS Technologies, we strive to be part of the Movement for Global Sustainability in Business with our solutions. We also encourage our customers who are manufacturing companies to start their digital transformation journey with our engineering solutions such as DELMIA, CATIA, SIMULIA, ENOVIA and 3DEXPERIENCE for a better world.