Automate your CAD using CATIA V5 Macros

- Mohit Aggarwal

- March 23, 2022

Performing repetitive tasks manually leads to a loss of productivity. This is one of the major reasons why organizations are increasingly trying to automate processes which helps to reduce manual labour, design time and increase productivity. In CATIA V5, repetitive manual tasks can be automated using CATIA V5 Macros.

There are two ways to create CATIA V5 Macros:

- Recording a macro.

- Writing a macro.

How to Record a Macro in CATIA V5

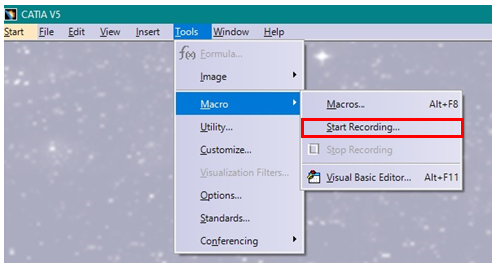

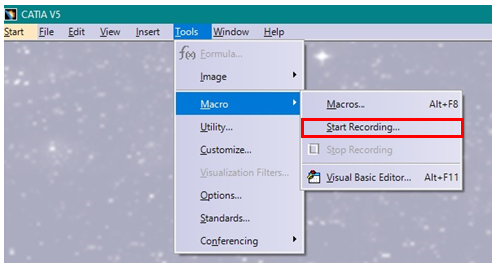

- Launch CATIA V5 & Go to Tools ? Macro ? Start Recording.

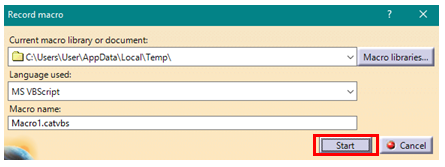

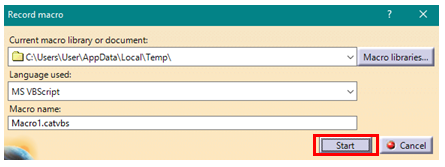

- Now, you can specify the macro library in which you want to save the recorded macro, specify the name you want to give to the recorded macro & click Start.

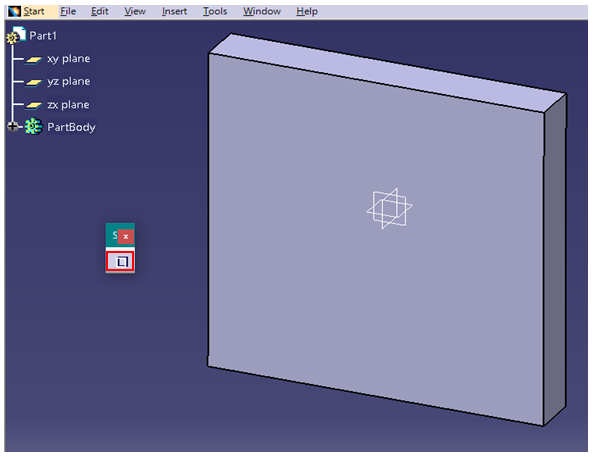

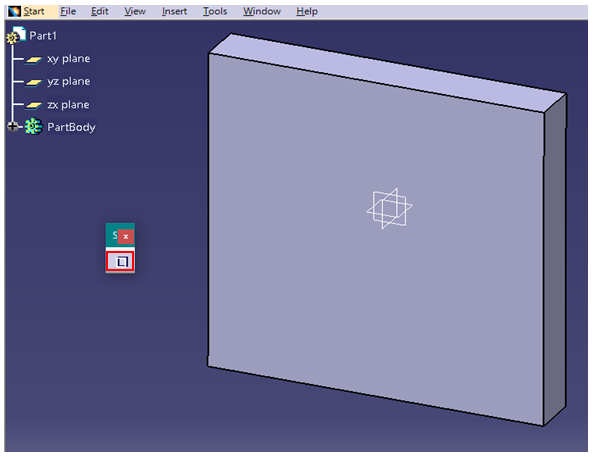

- Now, perform the operations which you want to automate in CATIA V5 e.g., Open Part Design Workbench ? Create A Sketch ? Create Pad.

- Once all the operations that you want to automate are completed, click on Stop Macro Recording.

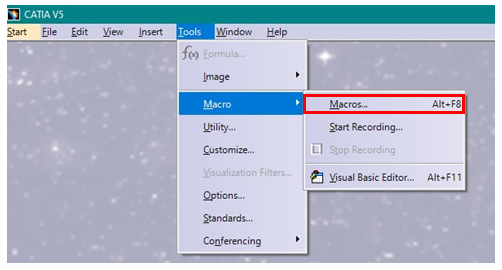

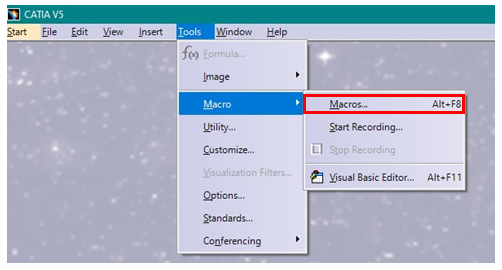

- Now, to perform the task automatically, run the recorded macro by clicking Tools ? Macro ? Macros or simply by pressing Alt+F8 keys.

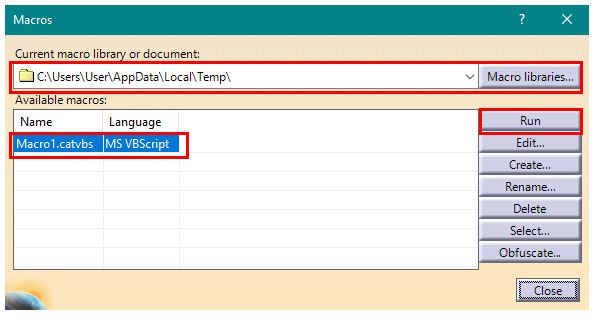

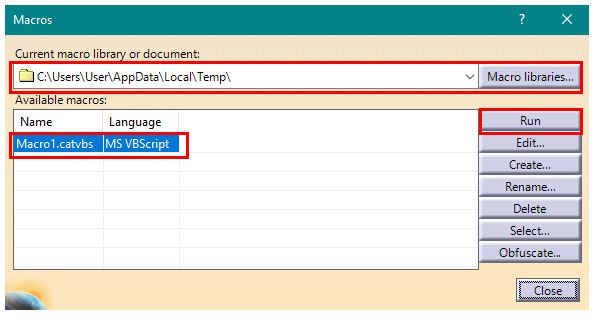

- Now, select the Macro Library, the macro which you want to run & click on Run.

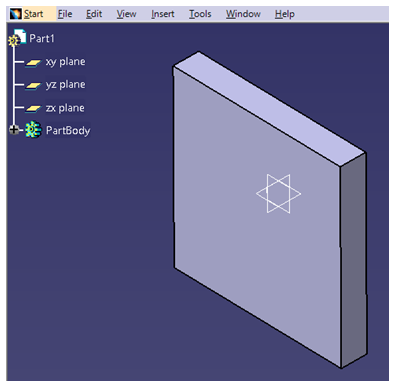

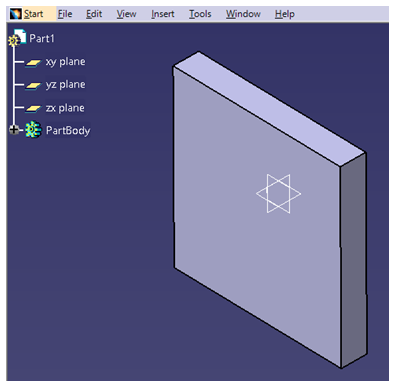

- The task will now be performed automatically e.g.; pad is created automatically.

You can modify the recorded macro and use that macro to create all the variants of a product.

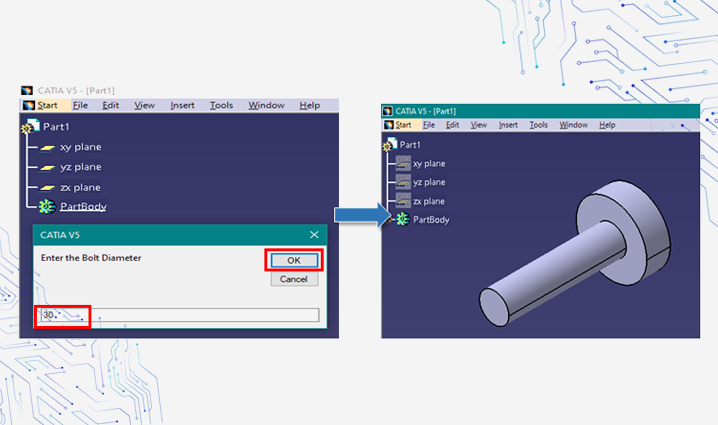

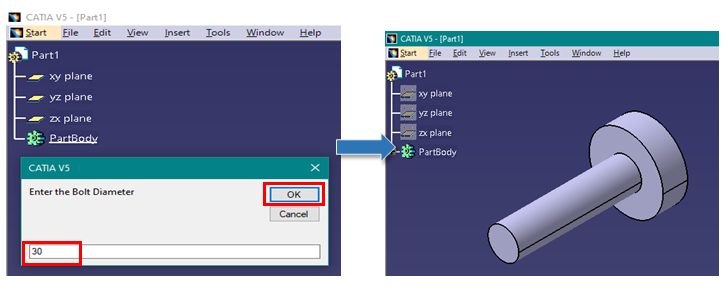

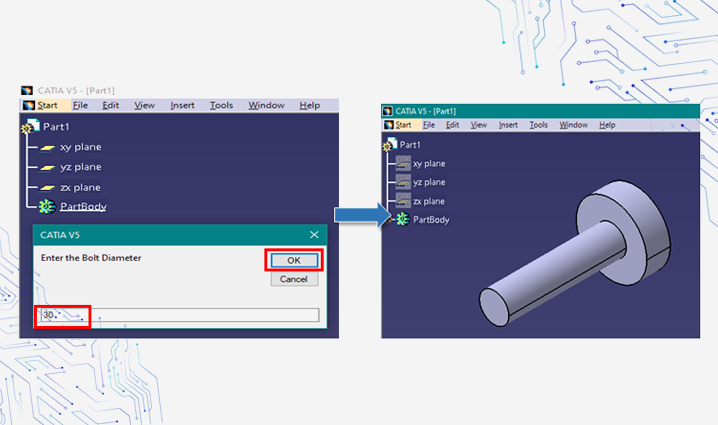

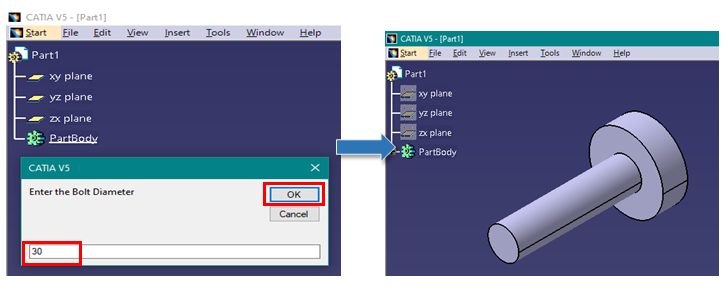

For example, if you need to create multiple bolts which are having different diameters then you don’t need to create all the bolts manually, you can automate the bolts creation process and the parameters can be entered using “input-box”.

How to Write a Macro in CATIA V5

CATIA V5 Macro can be written in three languages:

- Visual Basic 6

- VBA

- VB Script / CATScript

Applications of CATIA V5 Macros

Macros can be used for Automating the Below set of Scenarios:

- Repeated Set of Tasks: Create/Insert customised title block, saving images of annotation views to PowerPoint, extract BOM table to excel, etc.

- Create Templates & Standardise the Company Workflow: For example, you have a standard template of part in which only few parameters might vary. The part can be created using automation and the parameters can be put in by the user.

- Quality Checking Process: Macros can be used to automate the predefined quality checks like checking whether material is applied, font style in drawing, proper tree structure in assembly etc. Based on the check results, we can perform additional tasks.

Advantages of CATIA V5 Macros

- Faster Completion: 90% of the time can be saved in product design using CATIA V5 Macros.

- Error-free: As there is no human interaction while performing the repeated set of tasks, there are minimal chances of error.

- Run the Automation During Non-Working Hours: As macros can work automatically, repeated set of tasks can be performed during non-working hours which ultimately increases productivity by reducing design time.

- Mohit Aggarwal

- March 23, 2022

Automate your CAD using CATIA V5 Macros

Performing repetitive tasks manually leads to a loss of productivity. This is one of the major reasons why organizations are increasingly trying to automate processes which helps to reduce manual labour, design time and increase productivity. In CATIA V5, repetitive manual tasks can be automated using CATIA V5 Macros.

There are two ways to create CATIA V5 Macros:

- Recording a macro.

- Writing a macro.

How to Record a Macro in CATIA V5

- Launch CATIA V5 & Go to Tools ? Macro ? Start Recording.

- Now, you can specify the macro library in which you want to save the recorded macro, specify the name you want to give to the recorded macro & click Start.

- Now, perform the operations which you want to automate in CATIA V5 e.g., Open Part Design Workbench ? Create A Sketch ? Create Pad.

- Once all the operations that you want to automate are completed, click on Stop Macro Recording.

- Now, to perform the task automatically, run the recorded macro by clicking Tools ? Macro ? Macros or simply by pressing Alt+F8 keys.

- Now, select the Macro Library, the macro which you want to run & click on Run.

- The task will now be performed automatically e.g.; pad is created automatically.

You can modify the recorded macro and use that macro to create all the variants of a product.

For example, if you need to create multiple bolts which are having different diameters then you don’t need to create all the bolts manually, you can automate the bolts creation process and the parameters can be entered using “input-box”.

How to Write a Macro in CATIA V5

CATIA V5 Macro can be written in three languages:

- Visual Basic 6

- VBA

- VB Script / CATScript

Applications of CATIA V5 Macros

Macros can be used for Automating the Below set of Scenarios:

- Repeated Set of Tasks: Create/Insert customised title block, saving images of annotation views to PowerPoint, extract BOM table to excel, etc.

- Create Templates & Standardise the Company Workflow: For example, you have a standard template of part in which only few parameters might vary. The part can be created using automation and the parameters can be put in by the user.

- Quality Checking Process: Macros can be used to automate the predefined quality checks like checking whether material is applied, font style in drawing, proper tree structure in assembly etc. Based on the check results, we can perform additional tasks.

Advantages of CATIA V5 Macros

- Faster Completion: 90% of the time can be saved in product design using CATIA V5 Macros.

- Error-free: As there is no human interaction while performing the repeated set of tasks, there are minimal chances of error.

- Run the Automation During Non-Working Hours: As macros can work automatically, repeated set of tasks can be performed during non-working hours which ultimately increases productivity by reducing design time.