An Integrated Solution for Manufacturing Complex Parts

- Goutham S R

- July 22, 2021

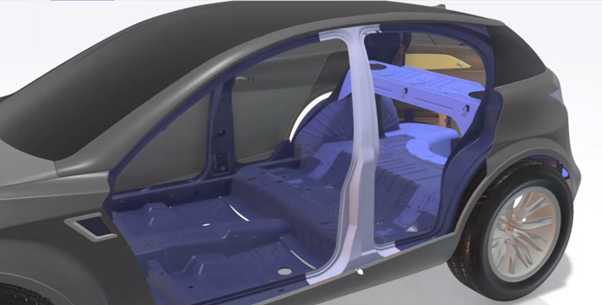

Globalization and the fluctuations in customer demand in various industries have made manufacturing companies to rethink their current manufacturing process.

The components are becoming very complex to manufacture since they have to accommodate the growing need of customers’ expectation. How can these complex parts be produced? How can manufacturing companies avoid costly errors? How can companies ensure manufacturing is carried out in the most optimized way?

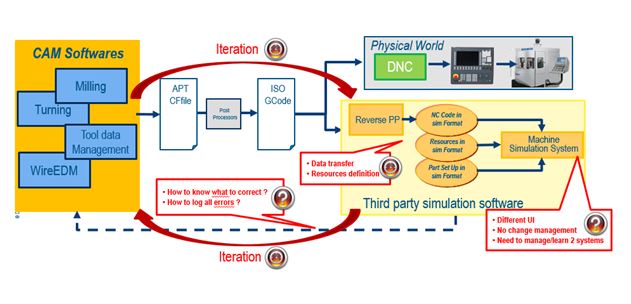

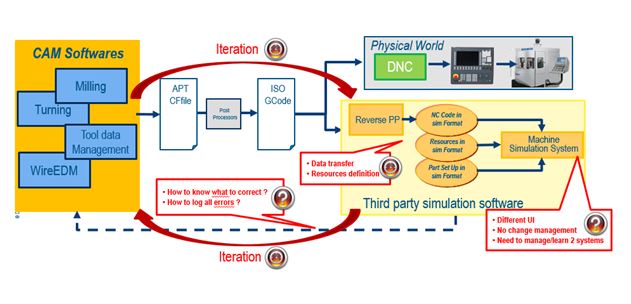

Traditionally, most of the manufacturing companies relied on conventional method which had a lot of silos. Dependency on multiple software solutions delayed the production & increased the production cost.

Traditional workflow

Let’s look at the challenges with respect to NC programming:

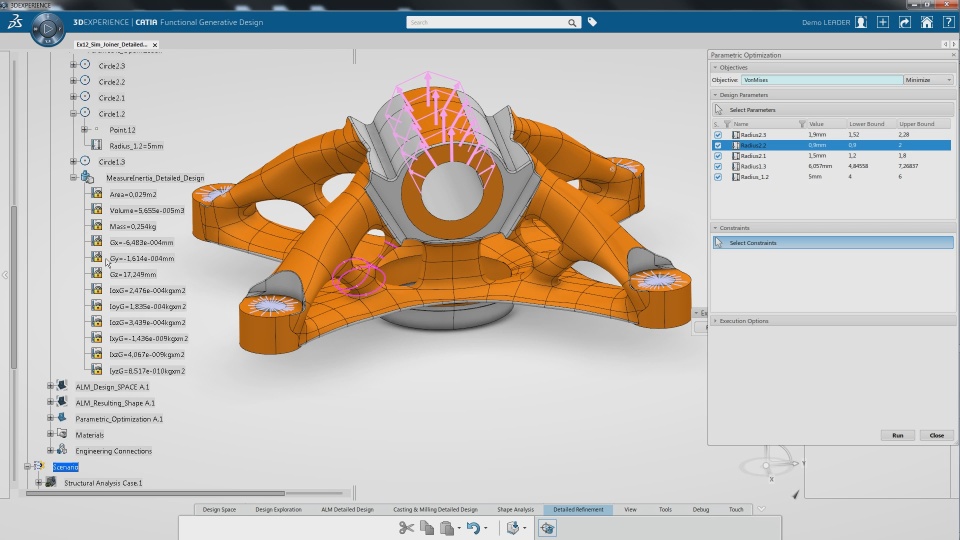

- Due to part complexity, product development cost is increased. How can companies reduce this cost?

- How to efficiently reduce programming lead-time from virtual manufacturing to actual production?

- How to reduce time-to-market?

- How to maintain quality and flexibility in a competitive environment?

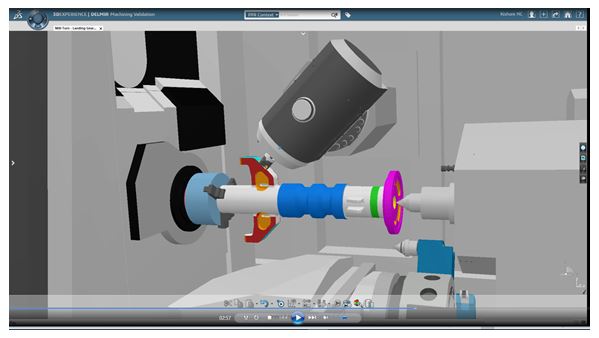

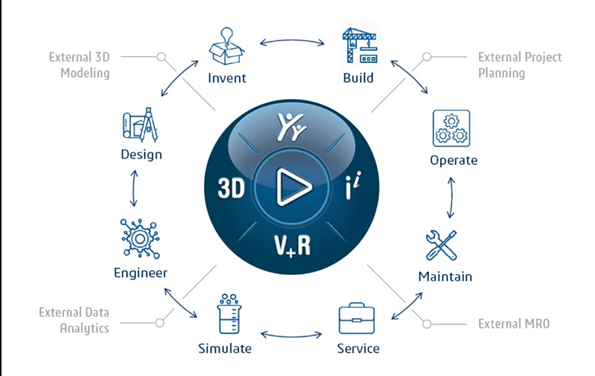

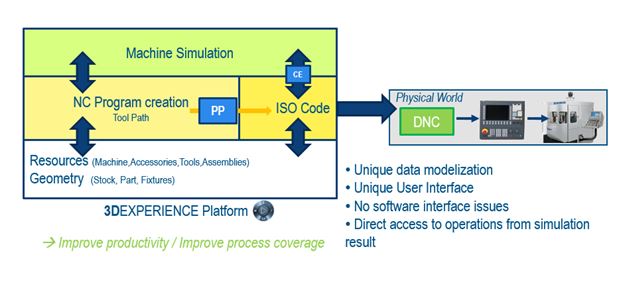

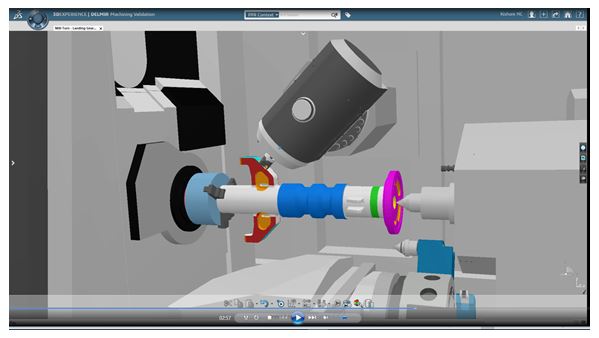

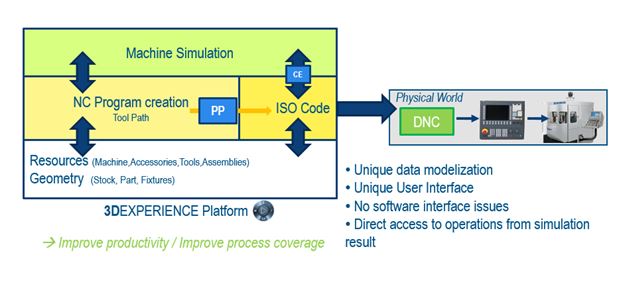

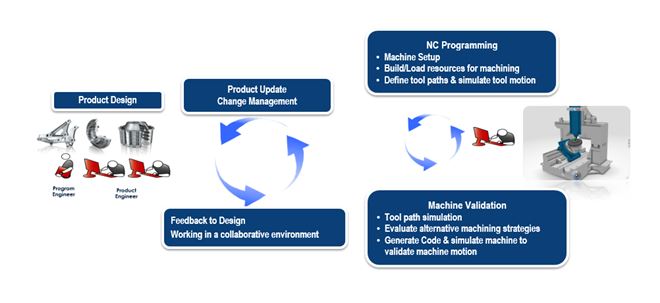

Dassault Systèmes’ NC Programming & Simulation solutions provides unified access from design to manufacturing in a collaborative environment. Dassault Systèmes’ well-known brand CATIA delivers the high-end capability with respect to design & the brand DELMIA ensures the NC code generation, validation & machine simulation under one roof.

NC Programming & Simulation solutions ensure complete work flow from design to manufacturing without the need of any third-party applications.

Benefits of NC Programming & Simulation workflow with Dassault Systèmes’ 3DEXPERIENCE platform

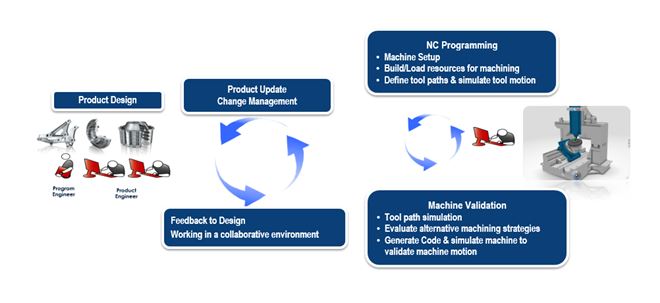

By adopting Dassault Systèmes’ NC Programming & Simulation solutions which is powered by 3DEXPERIENCE platform, manufacturing companies can address the above discussed challenges and gain the following benefits:

- Ensure the quality of NC programming, simulation and optimization

- Increase quality significantly by leveraging NC planning and programming automation

- Reuse corporate rules and standards for tools & machining process

- Improve productivity enhancements for tool management, NC setup preparation, NC program creation, NC program validation and NC program simulation

- Goutham S R

- July 22, 2021

An Integrated Solution for Manufacturing Complex Parts

Globalization and the fluctuations in customer demand in various industries have made manufacturing companies to rethink their current manufacturing process.

The components are becoming very complex to manufacture since they have to accommodate the growing need of customers’ expectation. How can these complex parts be produced? How can manufacturing companies avoid costly errors? How can companies ensure manufacturing is carried out in the most optimized way?

Traditionally, most of the manufacturing companies relied on conventional method which had a lot of silos. Dependency on multiple software solutions delayed the production & increased the production cost.

Traditional workflow

Let’s look at the challenges with respect to NC programming:

- Due to part complexity, product development cost is increased. How can companies reduce this cost?

- How to efficiently reduce programming lead-time from virtual manufacturing to actual production?

- How to reduce time-to-market?

- How to maintain quality and flexibility in a competitive environment?

Dassault Systèmes’ NC Programming & Simulation solutions provides unified access from design to manufacturing in a collaborative environment. Dassault Systèmes’ well-known brand CATIA delivers the high-end capability with respect to design & the brand DELMIA ensures the NC code generation, validation & machine simulation under one roof.

NC Programming & Simulation solutions ensure complete work flow from design to manufacturing without the need of any third-party applications.

Benefits of NC Programming & Simulation workflow with Dassault Systèmes’ 3DEXPERIENCE platform

By adopting Dassault Systèmes’ NC Programming & Simulation solutions which is powered by 3DEXPERIENCE platform, manufacturing companies can address the above discussed challenges and gain the following benefits:

- Ensure the quality of NC programming, simulation and optimization

- Increase quality significantly by leveraging NC planning and programming automation

- Reuse corporate rules and standards for tools & machining process

- Improve productivity enhancements for tool management, NC setup preparation, NC program creation, NC program validation and NC program simulation