Accelerating the Digital Transformation of Semiconductor Development with 3DEXPERIENCE

- Karthik Gopal

- December 26, 2024

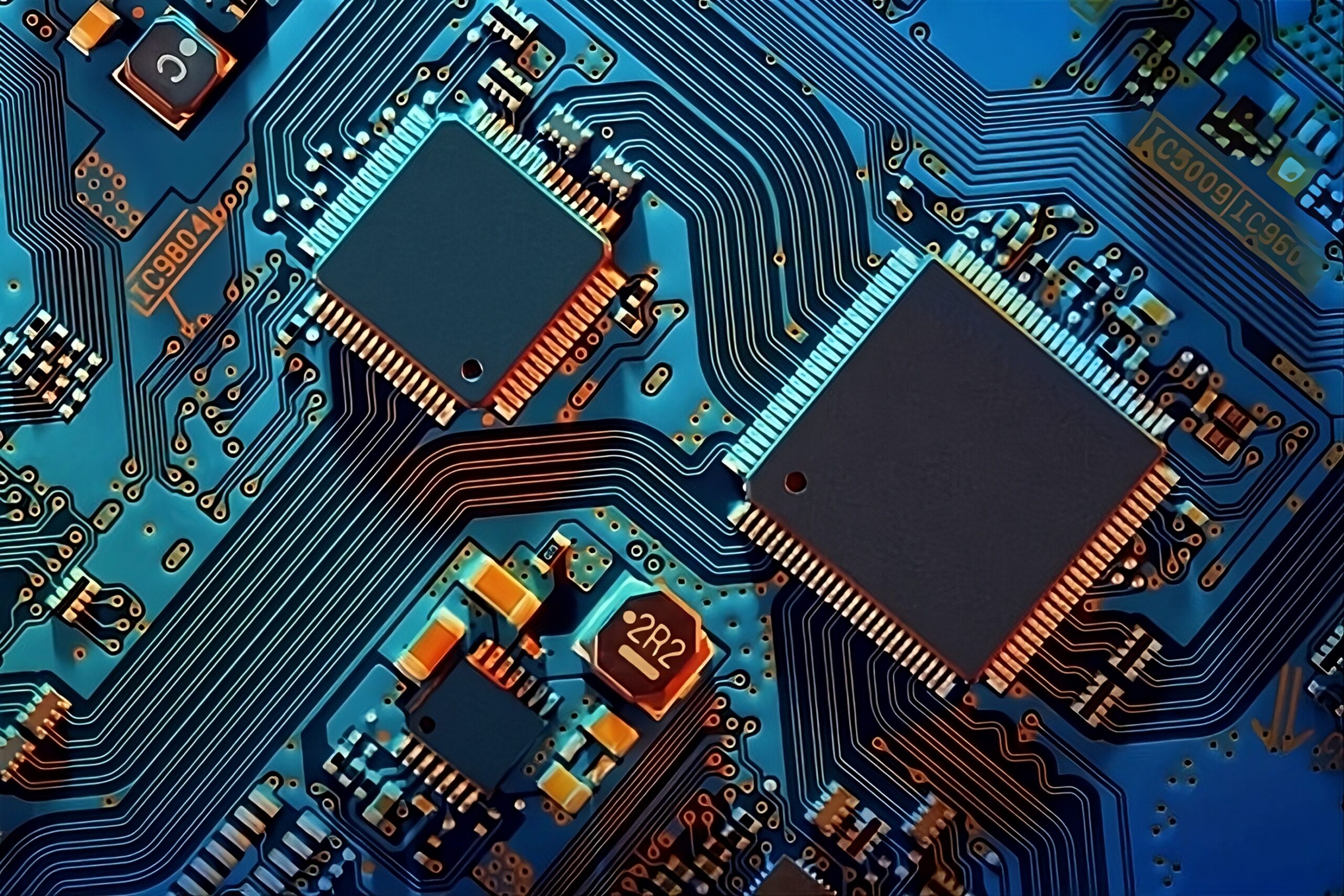

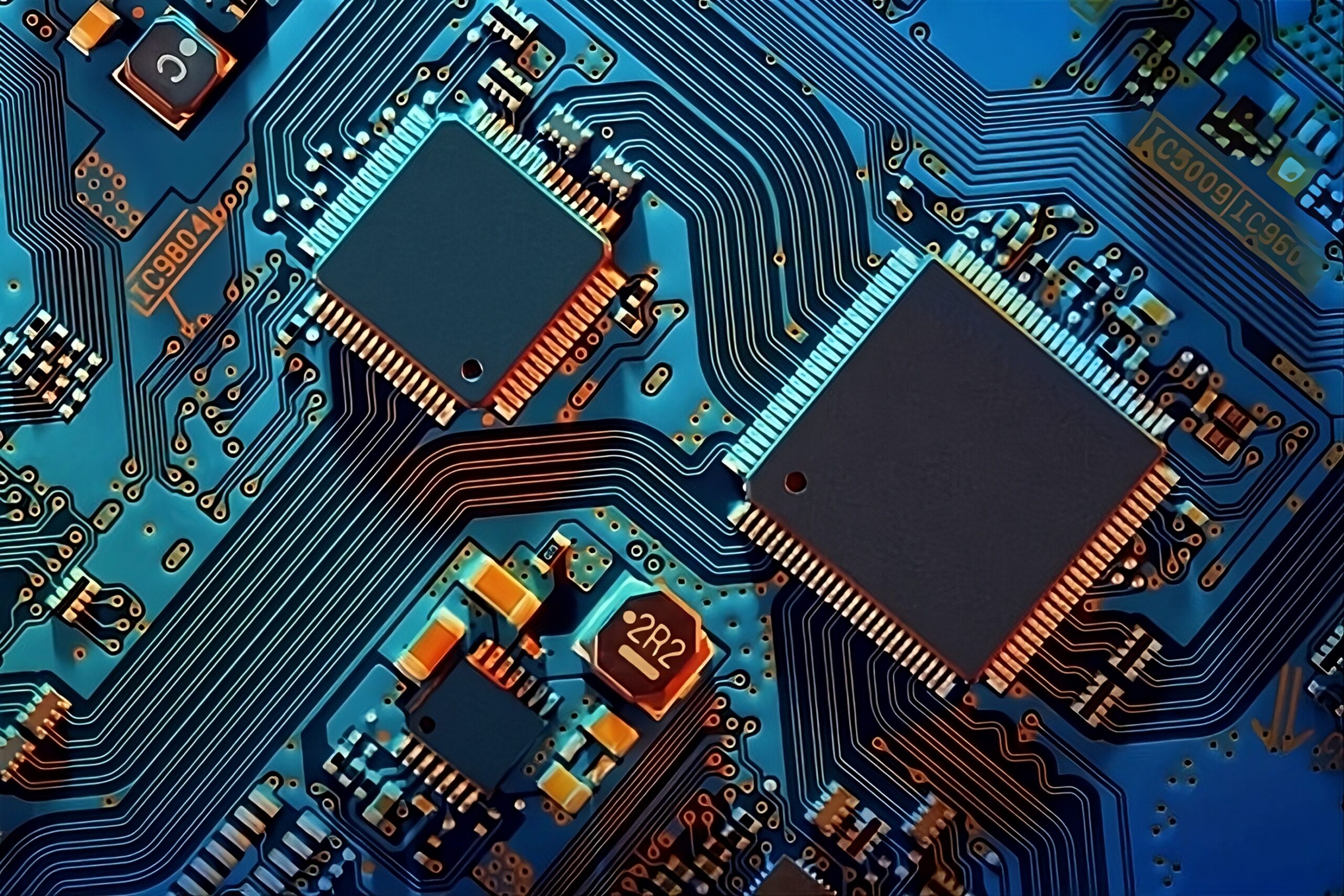

Semiconductors are among the simplest electronic components, yet they perform some of the most intricate functions conceivable. These components are produced from silicon, which is one of the most plentiful elements found in the Earth’s crust.

Semiconductors serve as fundamental components of electronic technology. They play a crucial role in regulating electrical currents within devices such as televisions, smartphones, and computers, thereby facilitating their speed, power, and compactness. Given their numerous applications, they’re a foundational piece of technology in our lives today.

Today’s Status of Digital Twin

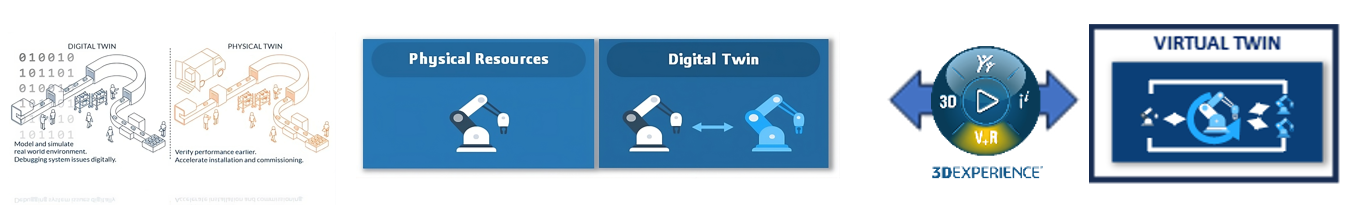

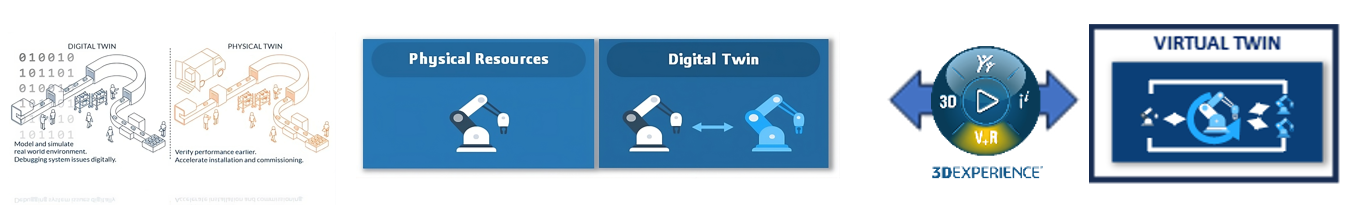

The DIGITAL TWIN is a static or a semi-dynamic digital model of objects where engineers can simulate the design/manufacturing process virtually to develop and validate systems using simulation without impacting the physical world first.

In the same way that digital twins mimic physical items, virtual twins go one step further and simulate the interactions and processes that occur inside a whole ecosystem or system. With a more comprehensive approach to comprehending and resolving complicated problems, this might revolutionize the semiconductor industry and beyond. Virtual twins may be able to predict future disruptions and offer insights into supply chain dynamics and production processes by integrating real-world data in real-time. This would provide a more complete solution to the shortage of semiconductors and other pressing problems facing the technology industry today.

Why Virtual Twin Over Digital Twin?

![]()

Digital twin serve as three-dimensional representations of tangible objects. These models are static and possess a relatively narrow range of functionalities. Users can manipulate the 3D visualization, reposition it, examine its components, and perform simulations. However, this type of model operates in isolation. It does not provide insights into its interactions with other objects or the potential impacts of various changes, such as temperature or pressure. Essentially, it functions in a self-contained environment. Virtual twin extends beyond merely representing a digital model of an object or process; they encapsulate the complete environment surrounding that entity. As a more advanced alternative, virtual twin can be as comprehensive as desired. This encompasses not only the soccer ball and a simulation of its being kicked but also an intricate overview of its production journey, from the supply chain that procures its raw materials to the manufacturing techniques employed in its creation. The potential applications of virtual twin are extensive, offering significantly more possibilities for utilization.

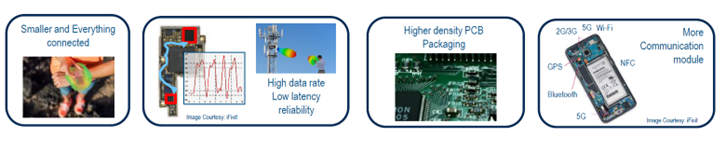

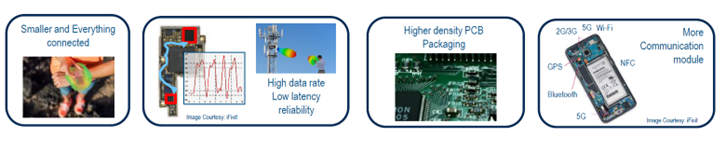

Semiconductor Industry: Technical Trends and Challenges

Business Challenges

- Keep pace with OEM Adoption of Technology

- Move up the value chain

- Shift from single product to systems

- New regulations from functional safety and cyber security

- IP Management, promotion and reuse

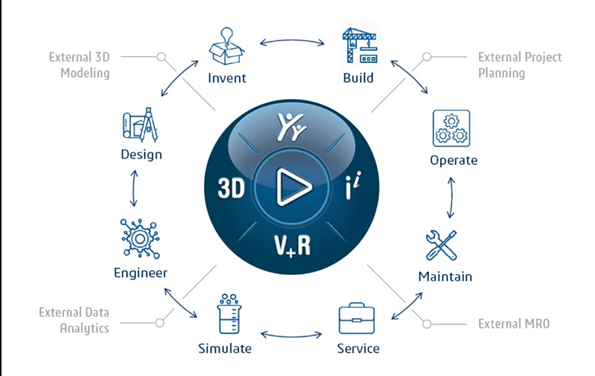

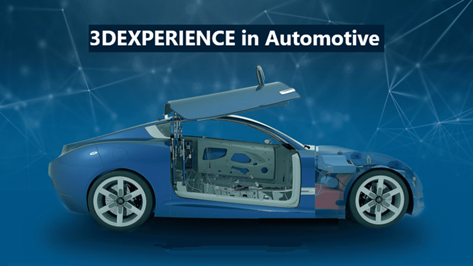

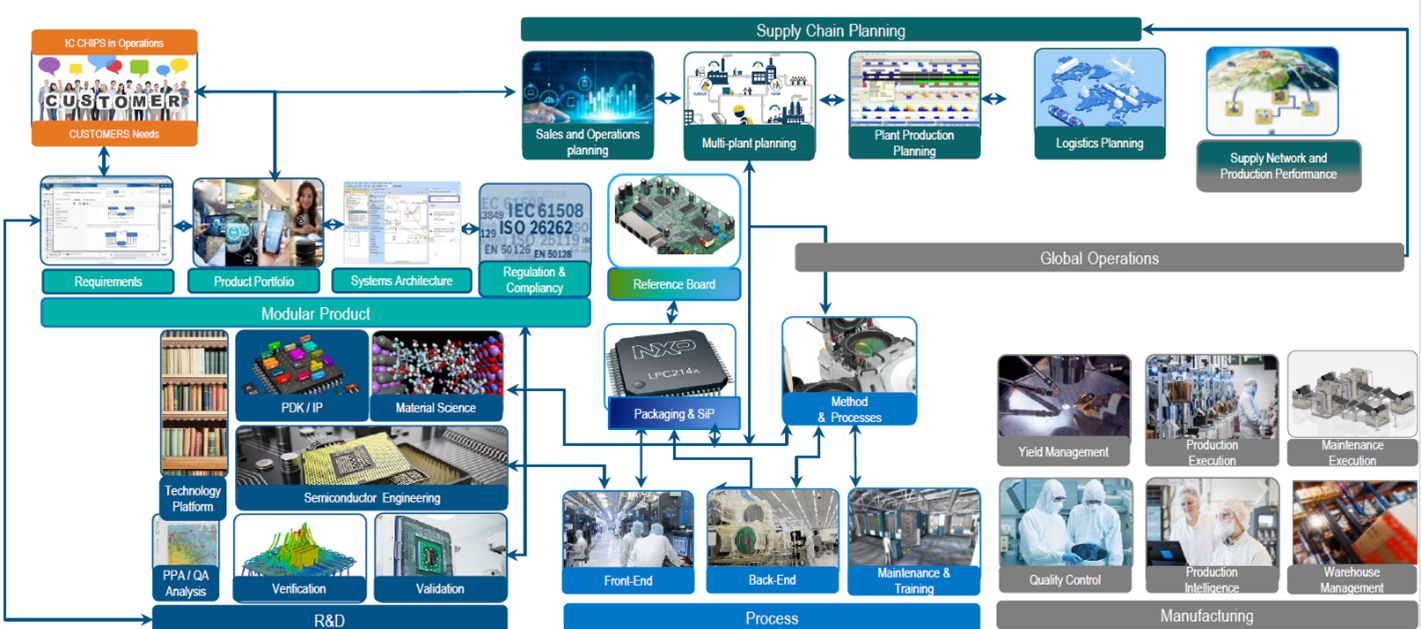

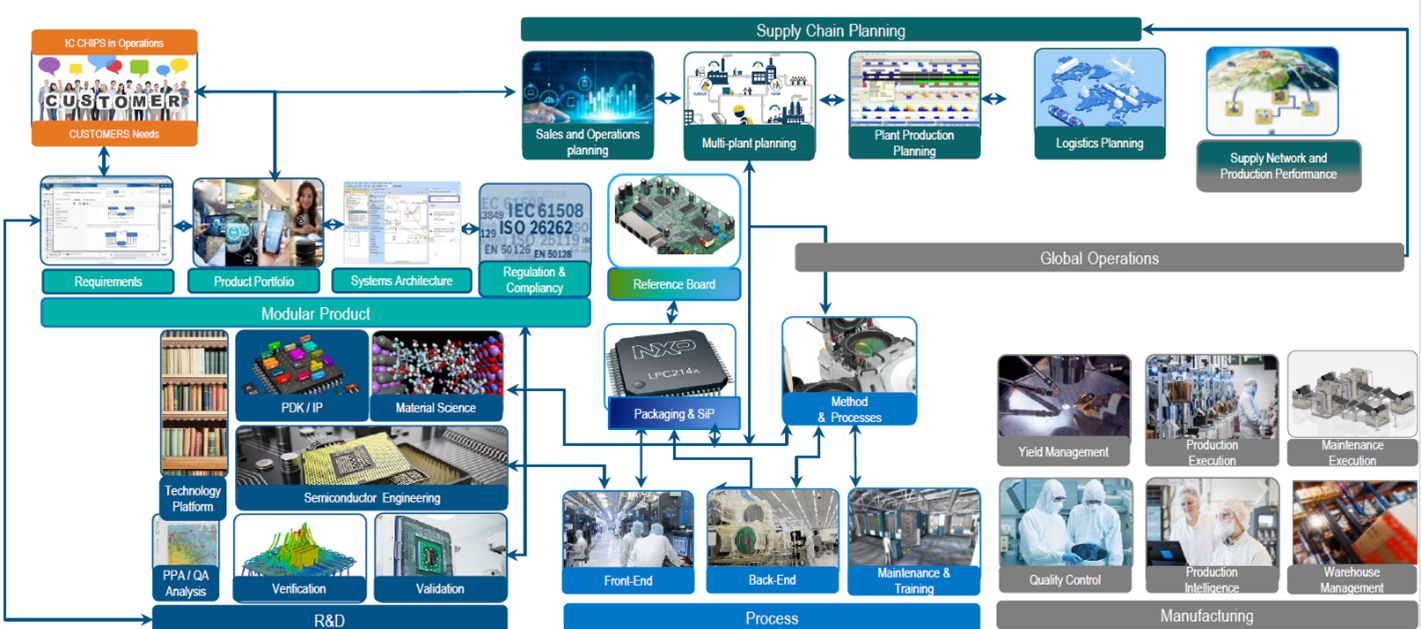

3DEXPERIENCE: A Catalyst for End-to-End Digital Continuity

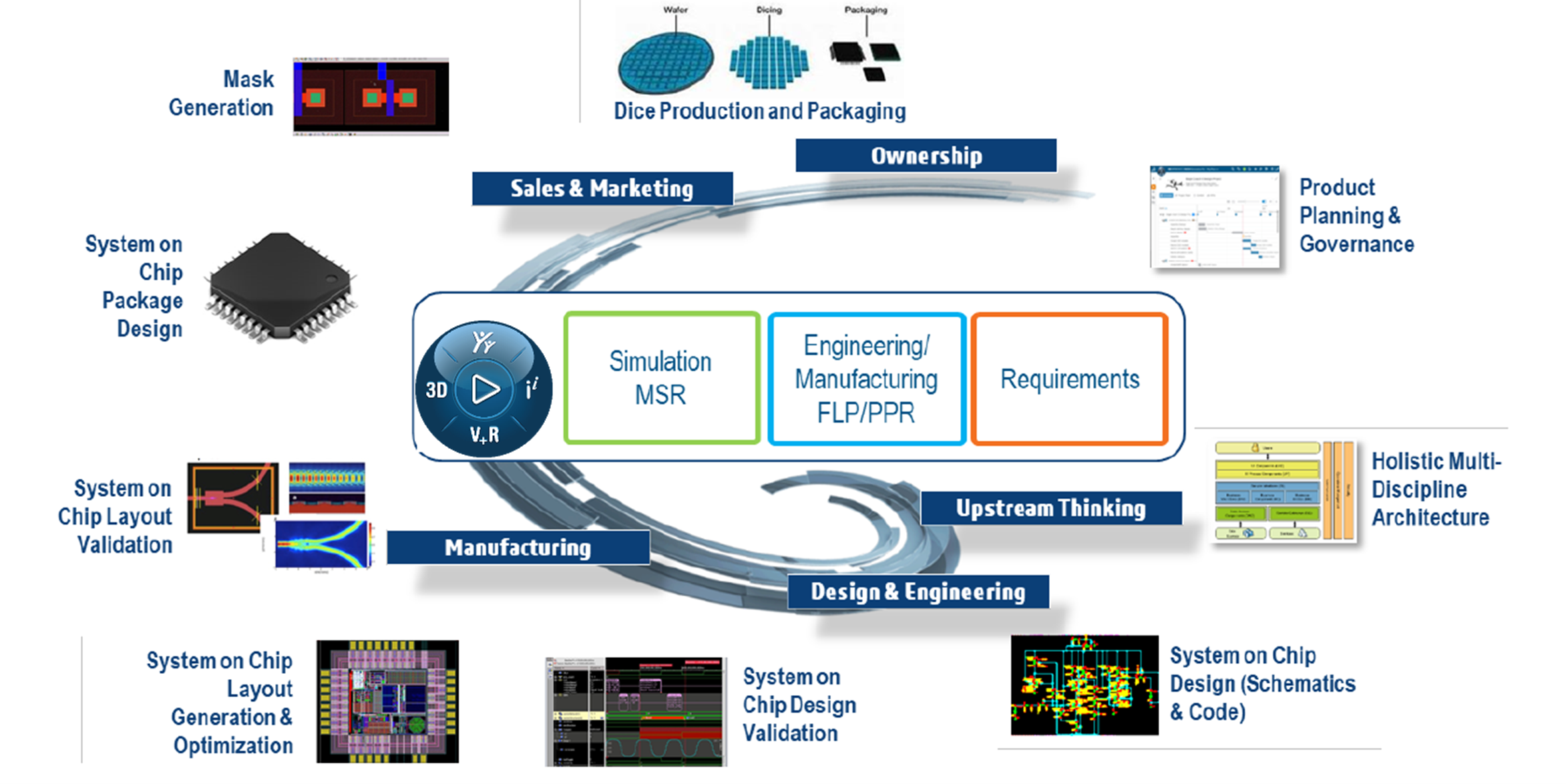

Simplifying Chip Development: Holistic Digital Transformation

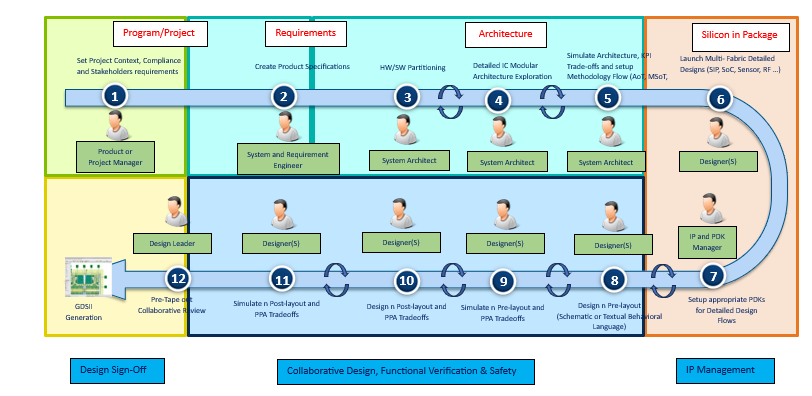

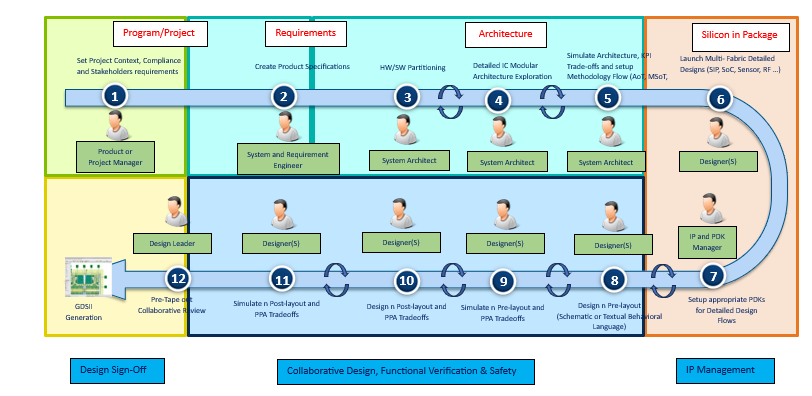

Holistic Level View Chip Development

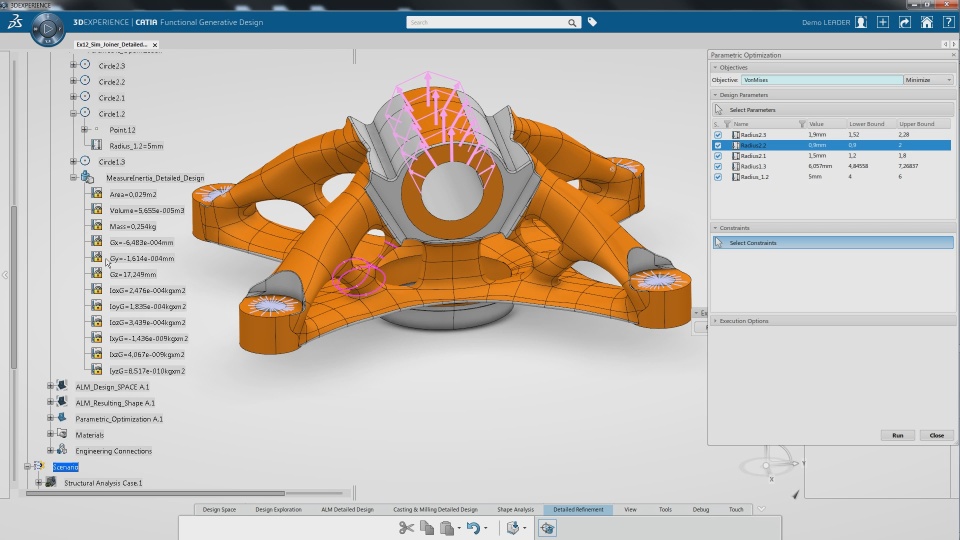

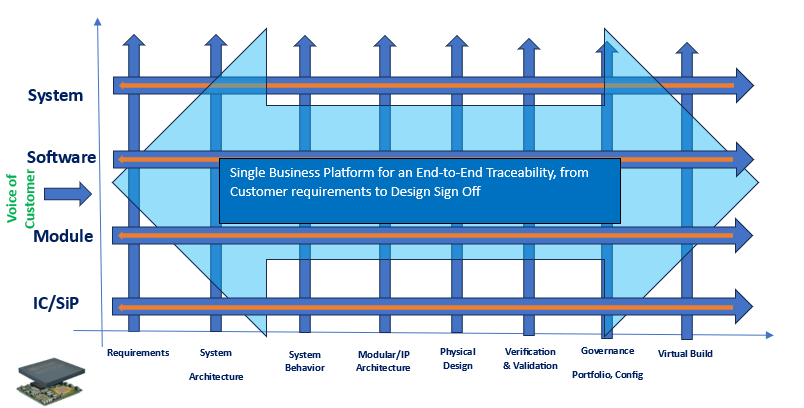

3DEXPERIENCE Digital Transformation

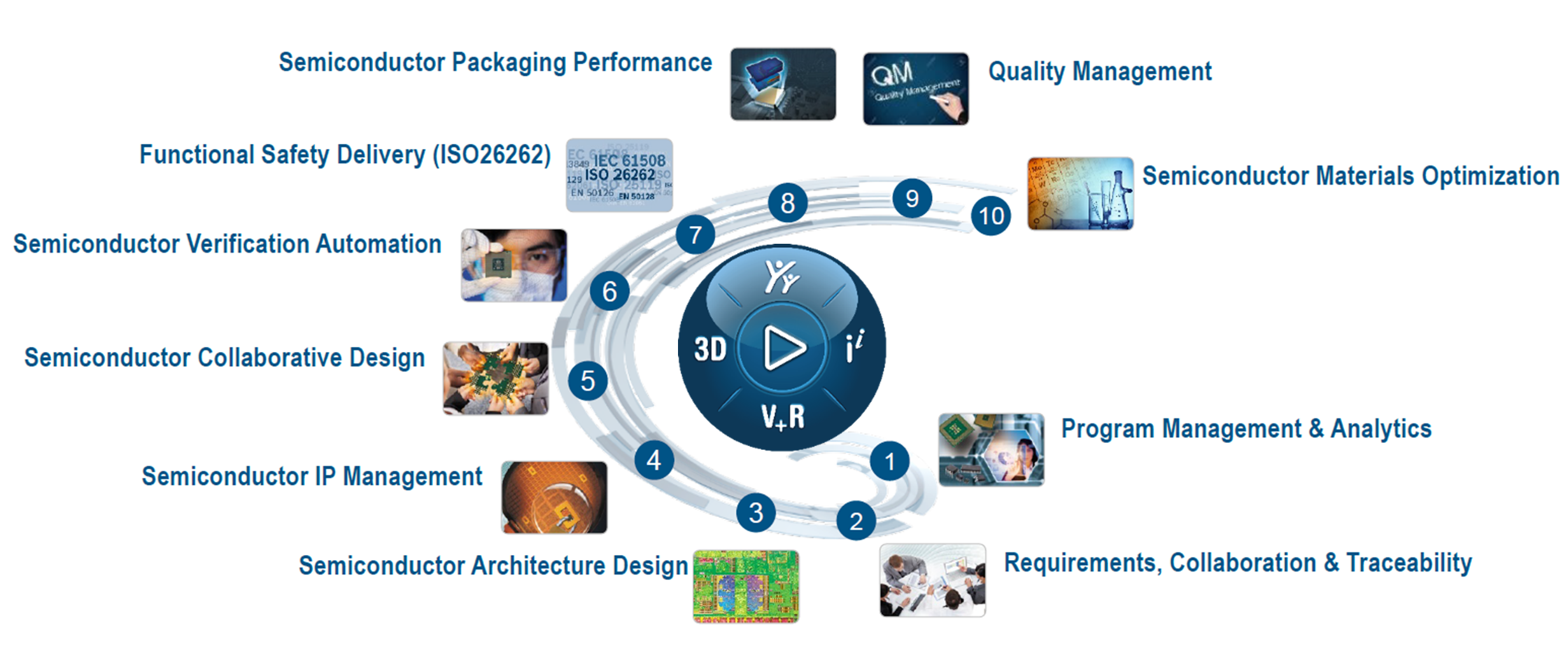

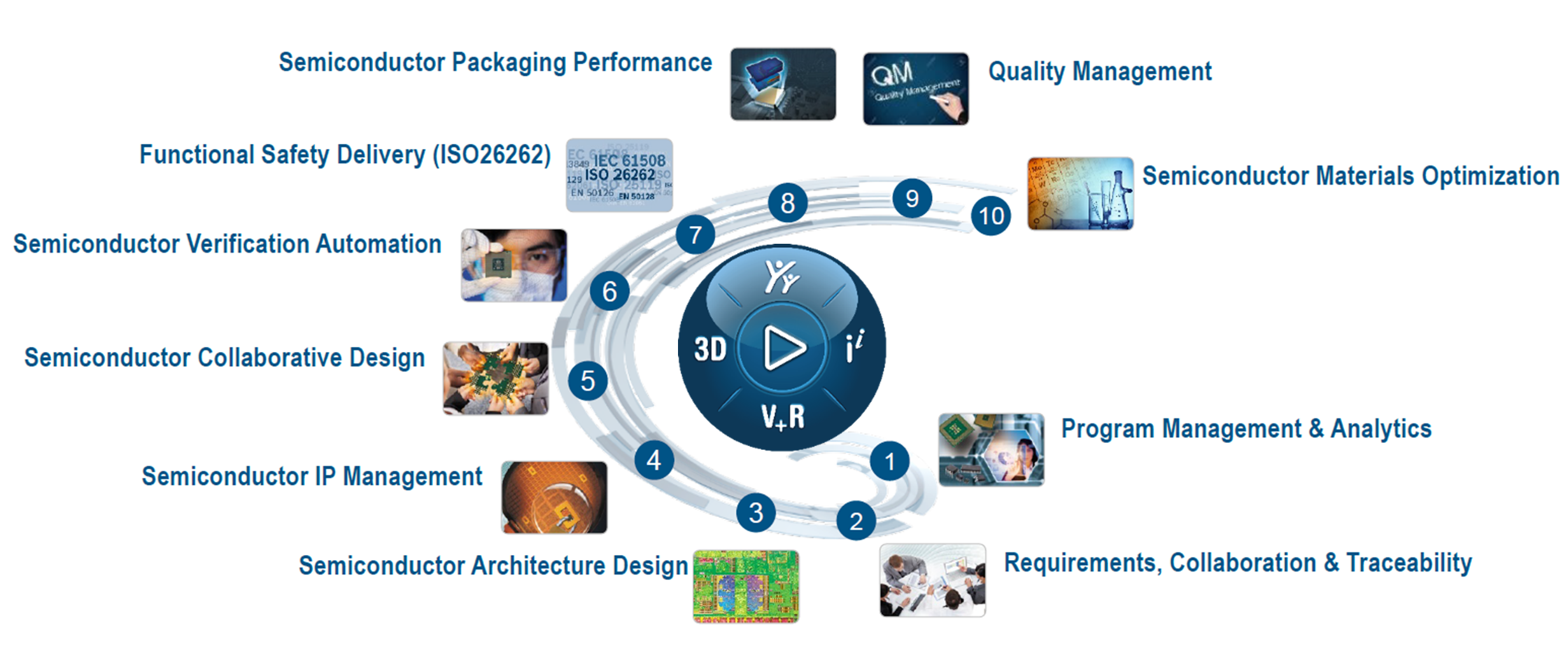

3DEXPERIENCE Solutions at a Glance

Benefits of the 3DEXPERIENCE Platform

- Entire enterprise connected/working on the same model

- Concurrent product and Manufacturing Definition

- Agility and Collaboration – Innovate & React Changes

- Accelerate Development and NPI Effort

- Maximize Data reuse

- Minimize rework

In essence, a commitment to advancing virtual twin technology, combined with a strong focus on semiconductor innovation, reflects a forward-thinking approach that paves the way for a thriving and technologically advanced future.

To learn more about how the 3DEXPERIENCE Platform enables digitalization by streamlining end-to-end digital continuity for semiconductor development, please reach out to us at marketing@edstechnologies.com.

- Karthik Gopal

- December 26, 2024

Accelerating the Digital Transformation of Semiconductor Development with 3DEXPERIENCE

Semiconductors are among the simplest electronic components, yet they perform some of the most intricate functions conceivable. These components are produced from silicon, which is one of the most plentiful elements found in the Earth’s crust.

Semiconductors serve as fundamental components of electronic technology. They play a crucial role in regulating electrical currents within devices such as televisions, smartphones, and computers, thereby facilitating their speed, power, and compactness. Given their numerous applications, they’re a foundational piece of technology in our lives today.

Today’s Status of Digital Twin

The DIGITAL TWIN is a static or a semi-dynamic digital model of objects where engineers can simulate the design/manufacturing process virtually to develop and validate systems using simulation without impacting the physical world first.

In the same way that digital twins mimic physical items, virtual twins go one step further and simulate the interactions and processes that occur inside a whole ecosystem or system. With a more comprehensive approach to comprehending and resolving complicated problems, this might revolutionize the semiconductor industry and beyond. Virtual twins may be able to predict future disruptions and offer insights into supply chain dynamics and production processes by integrating real-world data in real-time. This would provide a more complete solution to the shortage of semiconductors and other pressing problems facing the technology industry today.

Why Virtual Twin Over Digital Twin?

![]()

Digital twin serve as three-dimensional representations of tangible objects. These models are static and possess a relatively narrow range of functionalities. Users can manipulate the 3D visualization, reposition it, examine its components, and perform simulations. However, this type of model operates in isolation. It does not provide insights into its interactions with other objects or the potential impacts of various changes, such as temperature or pressure. Essentially, it functions in a self-contained environment. Virtual twin extends beyond merely representing a digital model of an object or process; they encapsulate the complete environment surrounding that entity. As a more advanced alternative, virtual twin can be as comprehensive as desired. This encompasses not only the soccer ball and a simulation of its being kicked but also an intricate overview of its production journey, from the supply chain that procures its raw materials to the manufacturing techniques employed in its creation. The potential applications of virtual twin are extensive, offering significantly more possibilities for utilization.

Semiconductor Industry: Technical Trends and Challenges

Business Challenges

- Keep pace with OEM Adoption of Technology

- Move up the value chain

- Shift from single product to systems

- New regulations from functional safety and cyber security

- IP Management, promotion and reuse

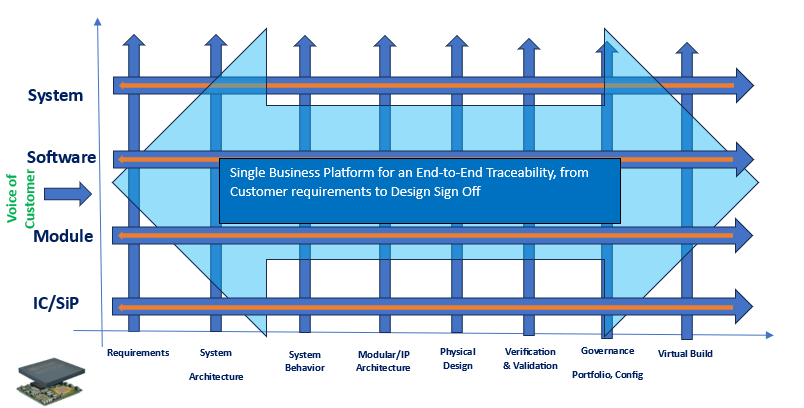

3DEXPERIENCE: A Catalyst for End-to-End Digital Continuity

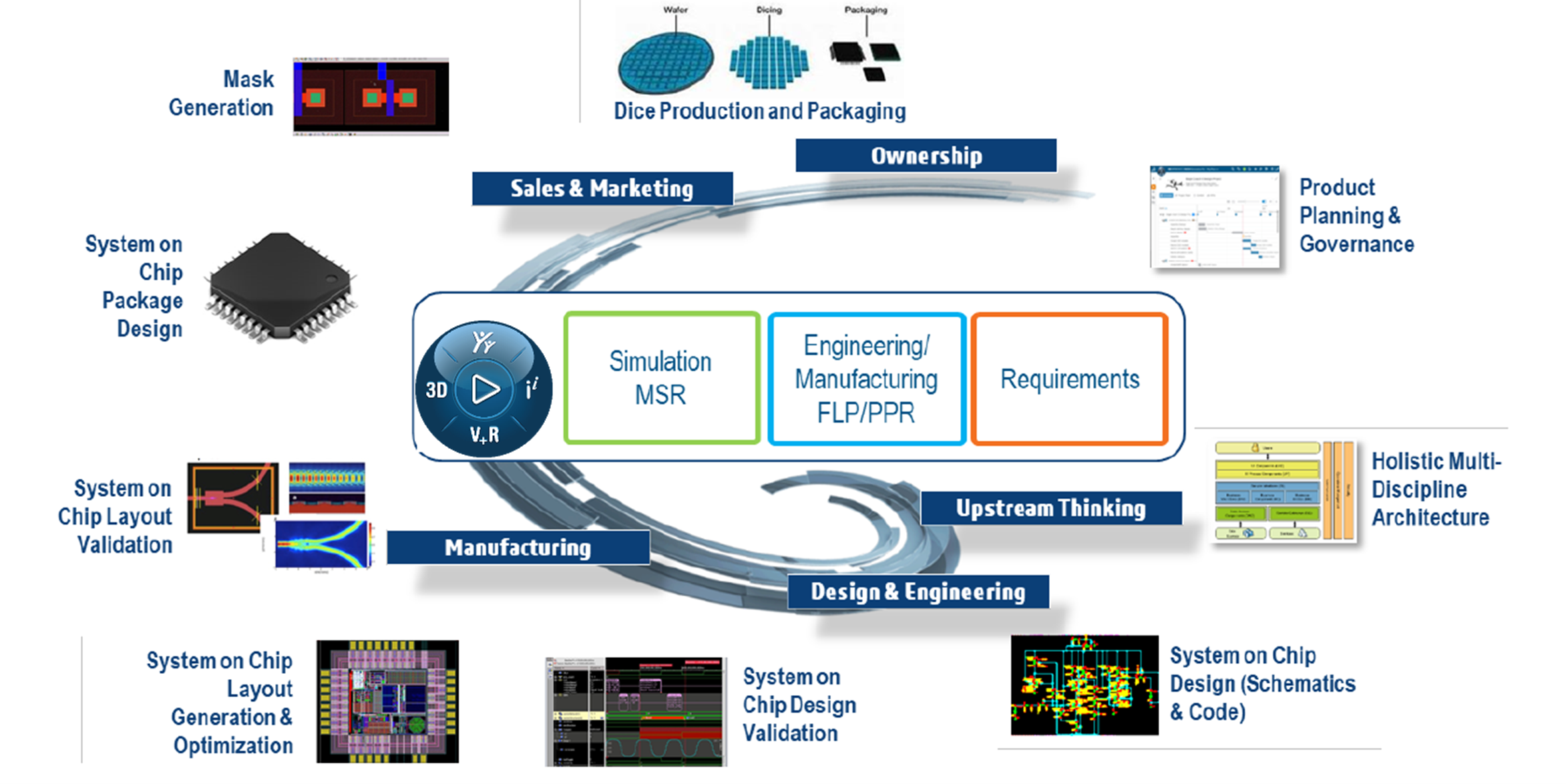

Simplifying Chip Development: Holistic Digital Transformation

Holistic Level View Chip Development

3DEXPERIENCE Digital Transformation

3DEXPERIENCE Solutions at a Glance

Benefits of the 3DEXPERIENCE Platform

- Entire enterprise connected/working on the same model

- Concurrent product and Manufacturing Definition

- Agility and Collaboration – Innovate & React Changes

- Accelerate Development and NPI Effort

- Maximize Data reuse

- Minimize rework

In essence, a commitment to advancing virtual twin technology, combined with a strong focus on semiconductor innovation, reflects a forward-thinking approach that paves the way for a thriving and technologically advanced future.

To learn more about how the 3DEXPERIENCE Platform enables digitalization by streamlining end-to-end digital continuity for semiconductor development, please reach out to us at marketing@edstechnologies.com.