Integrate Mold and Tooling with 3DEXPERIENCE Platform for first-time-right design

- Kiran Makam Setty

- December 27, 2019

Major challenge for tool makers is the quick turn around and reduce design to manufacturing cycle time as required in every industry. Every manufacturer’s goal is constant innovation to manufacture products with ever improving quality at the right cost. Maximizing efficiency and reliability of tooling regardless of human and resource related contingencies will accelerate the product delivery.

Tool makers work as a collaborative team and the latest product data is misplaced with the collect, exchange, translate and duplicate of data. Tool makers also collaborate with designers. There are multiple iterations of product data from designer to toolmaker and vice versa. With numerous collaborators, there is bound to be numerous iterations due to defects from manufacturability issues. It is necessary to have various iterations to reach at a refined final product but leads to delays in the tooling delivery.

Other challenges faced by tool makers are:

- Collaborators use different software for design, simulation and manufacturing leading to high data translation cost.

- Significant amount of time is spent in integrating product design changes due to excessive engineering and poor standardization.

Integrate Mold and Tooling with 3DEXPERIENCE Platform for first-time-right design

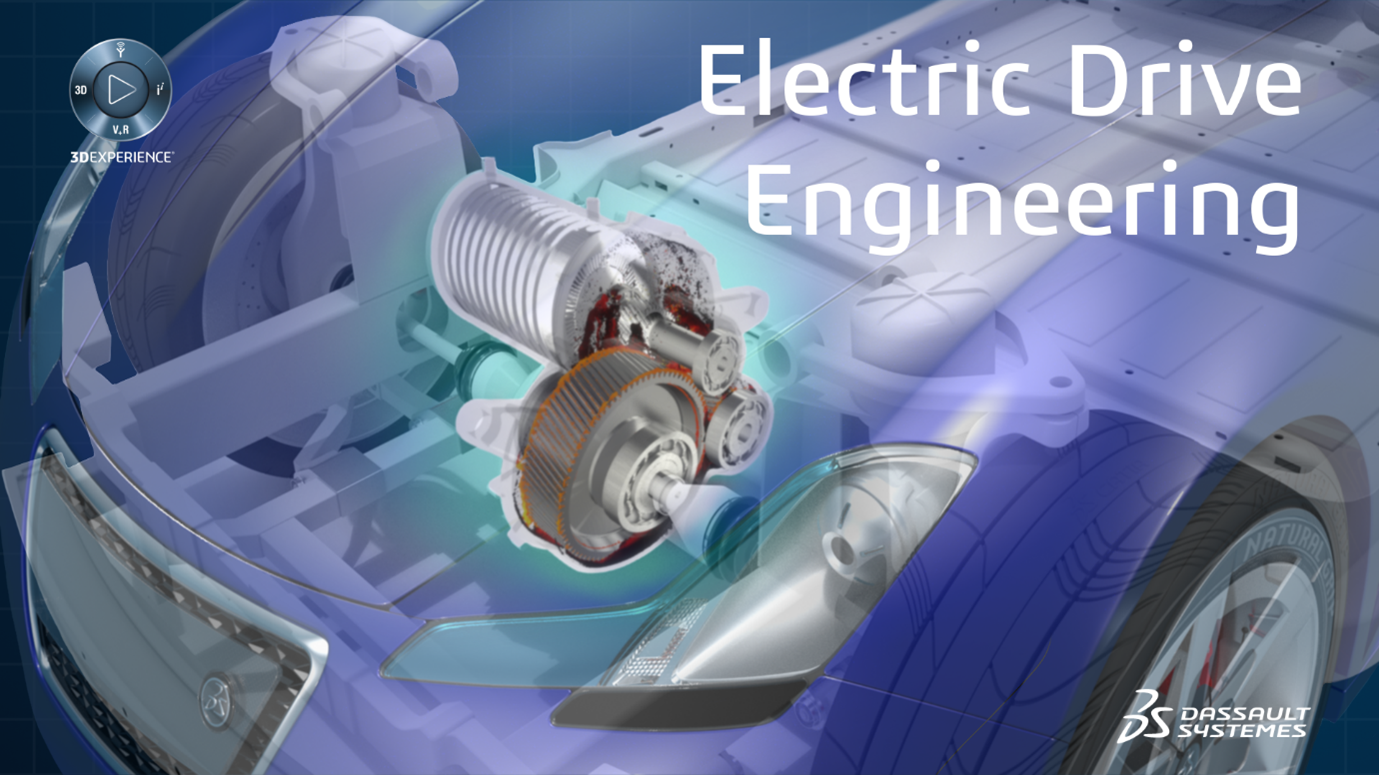

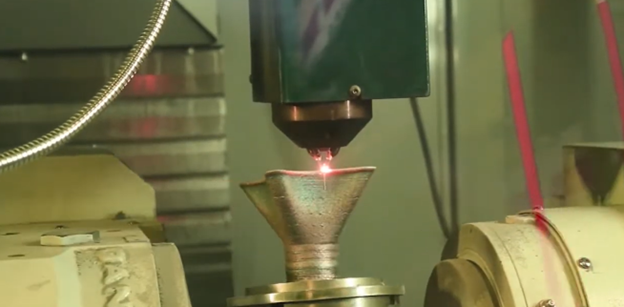

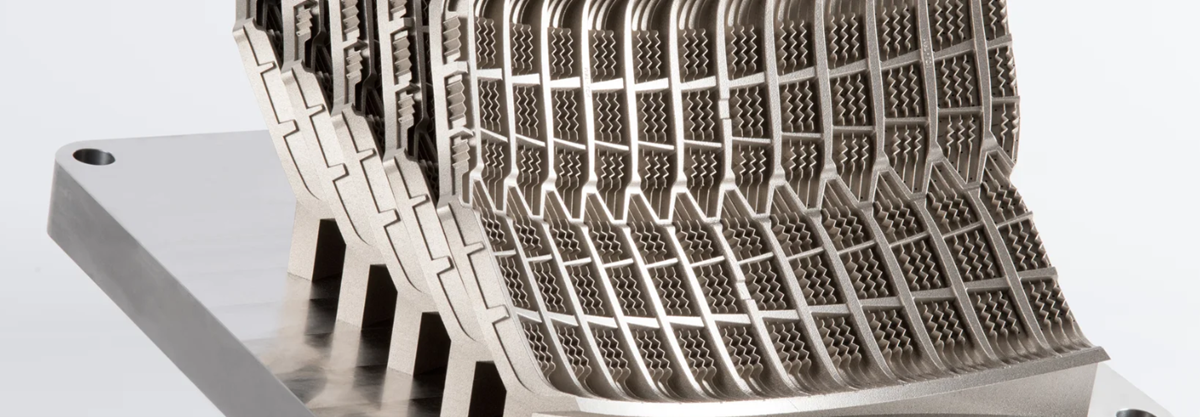

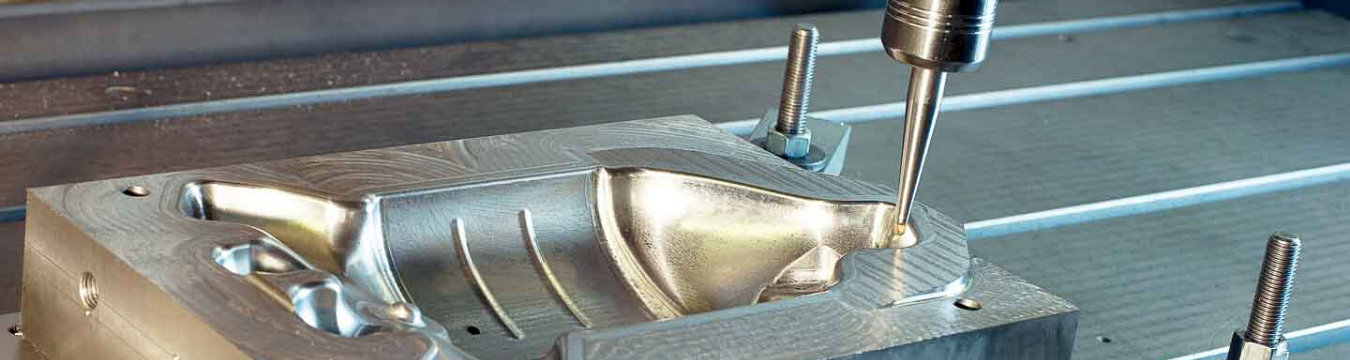

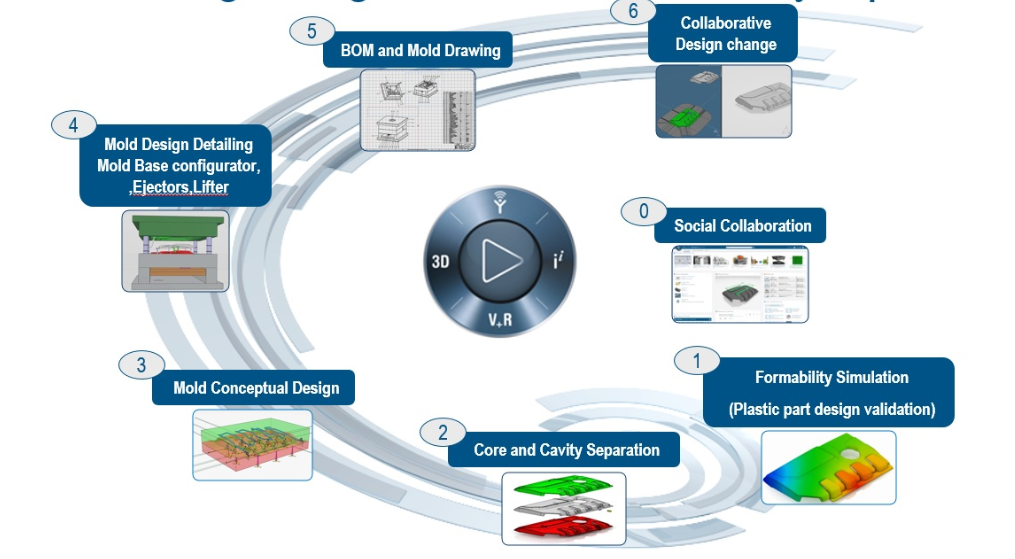

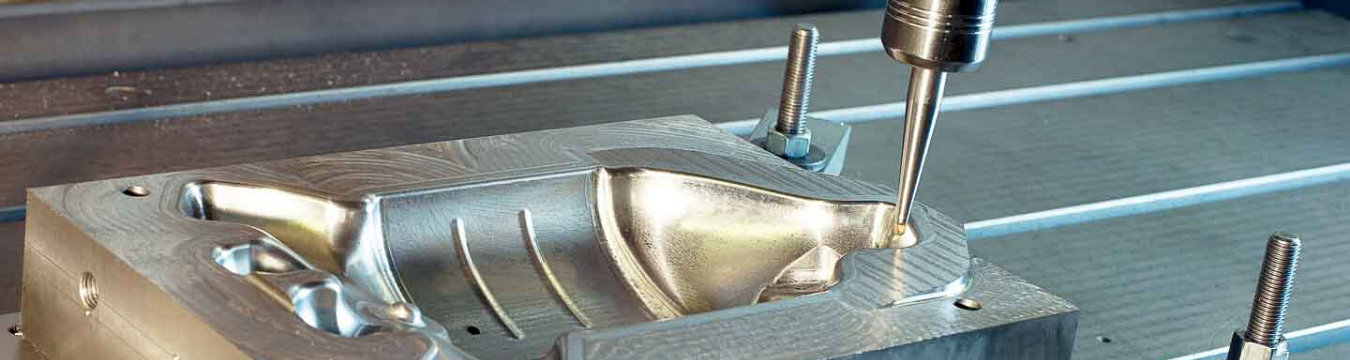

With CATIA Mold and Tooling solution, companies are able to create first-time-right collision-free tool paths through the fully integrated and collaborative 3DEXPERIENCE platform. Easy access to designs to create the appropriate tooling in a single environment is helpful to interact with collaborators, eliminating the need for data translation and to easily freeze product design.

Features of CATIA Mold and Tooling solution

- Powerful, flexible, and highly customizable experience to address the mold making requirements and challenges

- Increased design productivity, standardize tooling design practices, automate design tasks and assist decision-making from simple to complex projects

- Added value to manufacturing companies to produce high quality products

- Avoid modification cycles and attached costs with design right the first time

- Consistently deliver high quality tooling

- Minimize risk of critical situations

- Increase competitive edge

Key Benefits of CATIA Mold and Tooling solution

Increase productivity and reduce cycle time:

- Dedicated capabilities addressing toolmakers’ specific needs

- Ease to capture, reuse and grow company resource

Promote standardization and ensure lifecycle integrity:

- Single software platform for integrated tooling design and manufacturing

- Full 3D visual simulation for reference throughout the process

Enhance quality and bolster innovation:

- Automate tasks and assist user decision and enable collaborative engineering

Contact us to know more about how CATIA 3DEXPERIENCE can aid your team for first-time-right design.

- Kiran Makam Setty

- December 27, 2019

Integrate Mold and Tooling with 3DEXPERIENCE Platform for first-time-right design

Major challenge for tool makers is the quick turn around and reduce design to manufacturing cycle time as required in every industry. Every manufacturer’s goal is constant innovation to manufacture products with ever improving quality at the right cost. Maximizing efficiency and reliability of tooling regardless of human and resource related contingencies will accelerate the product delivery.

Tool makers work as a collaborative team and the latest product data is misplaced with the collect, exchange, translate and duplicate of data. Tool makers also collaborate with designers. There are multiple iterations of product data from designer to toolmaker and vice versa. With numerous collaborators, there is bound to be numerous iterations due to defects from manufacturability issues. It is necessary to have various iterations to reach at a refined final product but leads to delays in the tooling delivery.

Other challenges faced by tool makers are:

- Collaborators use different software for design, simulation and manufacturing leading to high data translation cost.

- Significant amount of time is spent in integrating product design changes due to excessive engineering and poor standardization.

Integrate Mold and Tooling with 3DEXPERIENCE Platform for first-time-right design

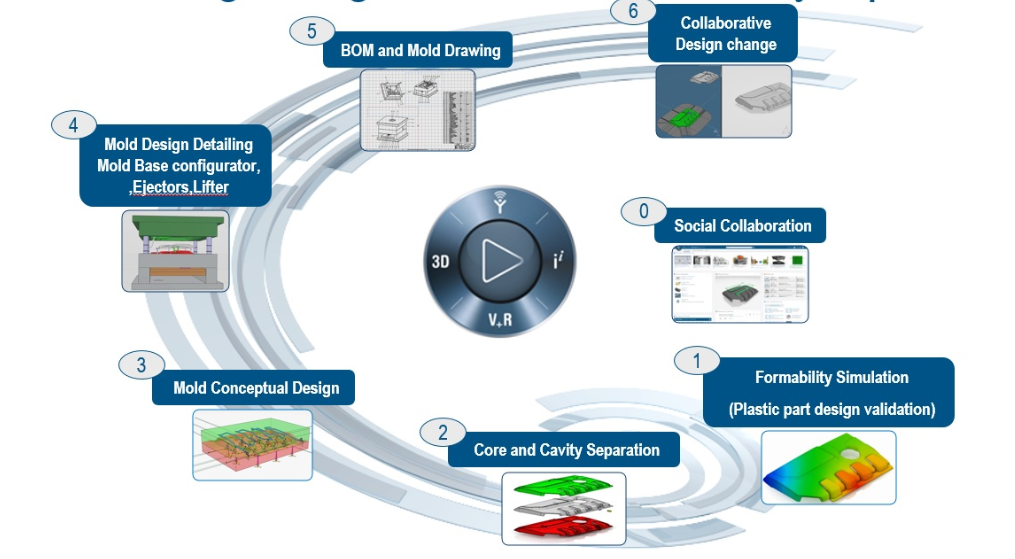

With CATIA Mold and Tooling solution, companies are able to create first-time-right collision-free tool paths through the fully integrated and collaborative 3DEXPERIENCE platform. Easy access to designs to create the appropriate tooling in a single environment is helpful to interact with collaborators, eliminating the need for data translation and to easily freeze product design.

Features of CATIA Mold and Tooling solution

- Powerful, flexible, and highly customizable experience to address the mold making requirements and challenges

- Increased design productivity, standardize tooling design practices, automate design tasks and assist decision-making from simple to complex projects

- Added value to manufacturing companies to produce high quality products

- Avoid modification cycles and attached costs with design right the first time

- Consistently deliver high quality tooling

- Minimize risk of critical situations

- Increase competitive edge

Key Benefits of CATIA Mold and Tooling solution

Increase productivity and reduce cycle time:

- Dedicated capabilities addressing toolmakers’ specific needs

- Ease to capture, reuse and grow company resource

Promote standardization and ensure lifecycle integrity:

- Single software platform for integrated tooling design and manufacturing

- Full 3D visual simulation for reference throughout the process

Enhance quality and bolster innovation:

- Automate tasks and assist user decision and enable collaborative engineering

Contact us to know more about how CATIA 3DEXPERIENCE can aid your team for first-time-right design.