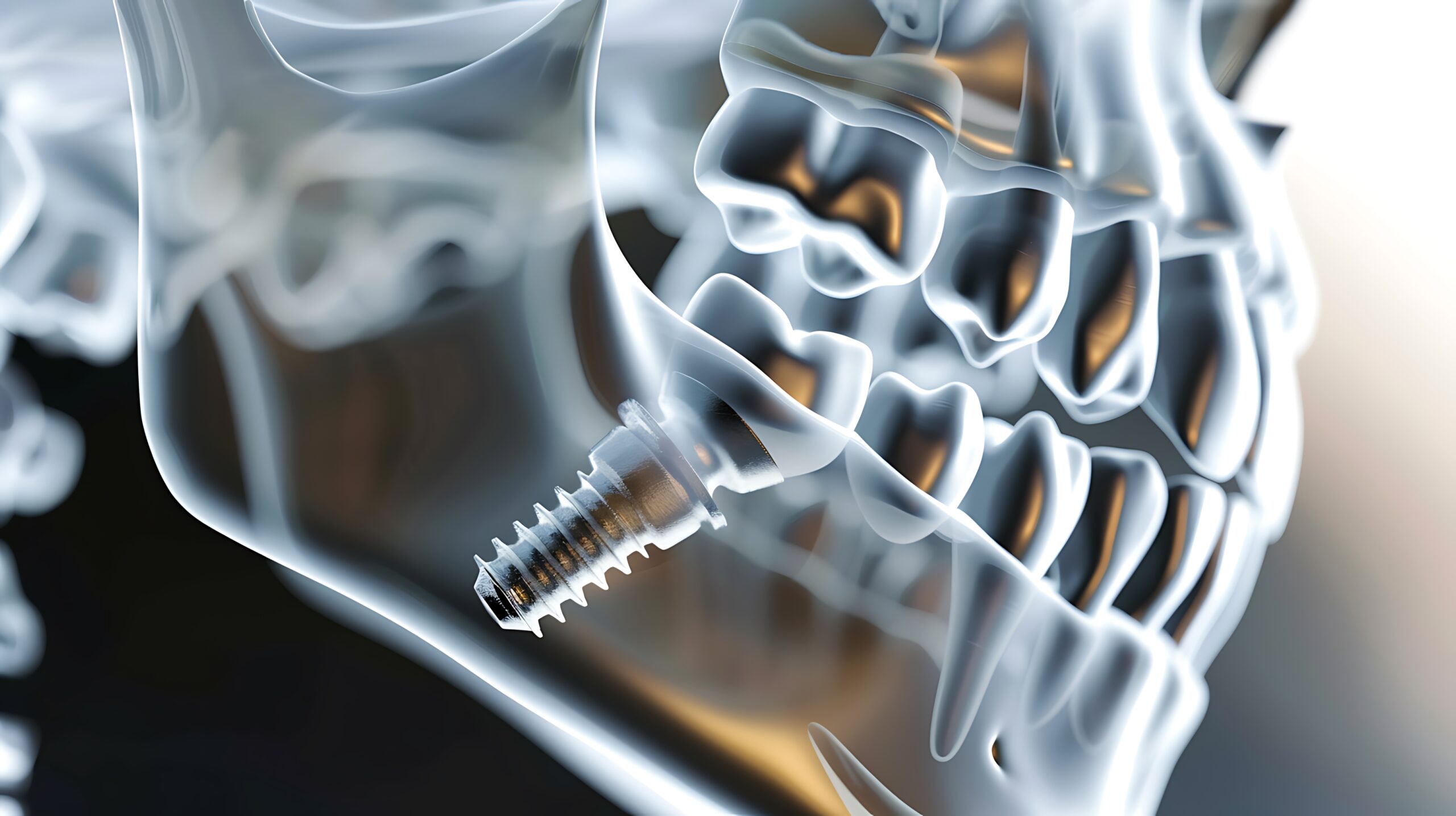

Medical Implants

Advanced additive manufacturing technologies play a crucial role in the development, repair, and customization of medical implants. Specifically, systems like Laser Engineered Net Shaping (LENS) and Aerosol Jet Printing (AJP) are used to create high-quality, patient-specific implants, as well as to enhance their functionality and biocompatibility. These innovations allow for more precise, tailored solutions in medical treatment, improving outcomes for patients and advancing the field of personalized medicine. Furthermore, they open new possibilities for repairing complex injuries and creating implants that better integrate with the body’s natural tissues.

Resources

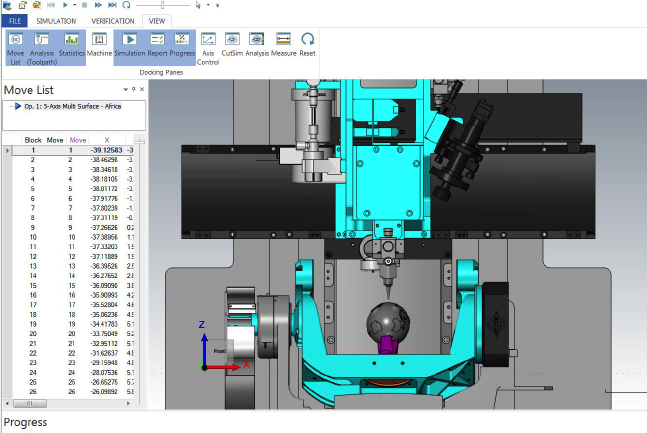

Optomec Overview: Leading 3D Printing for Metal & Electronics Manufacturing

Optomec is a leading provider of advanced 3D printing solutions, specializing in metal and functional electronics manufacturing. Their innovative technologies, including LENS (Laser Engineering Net…

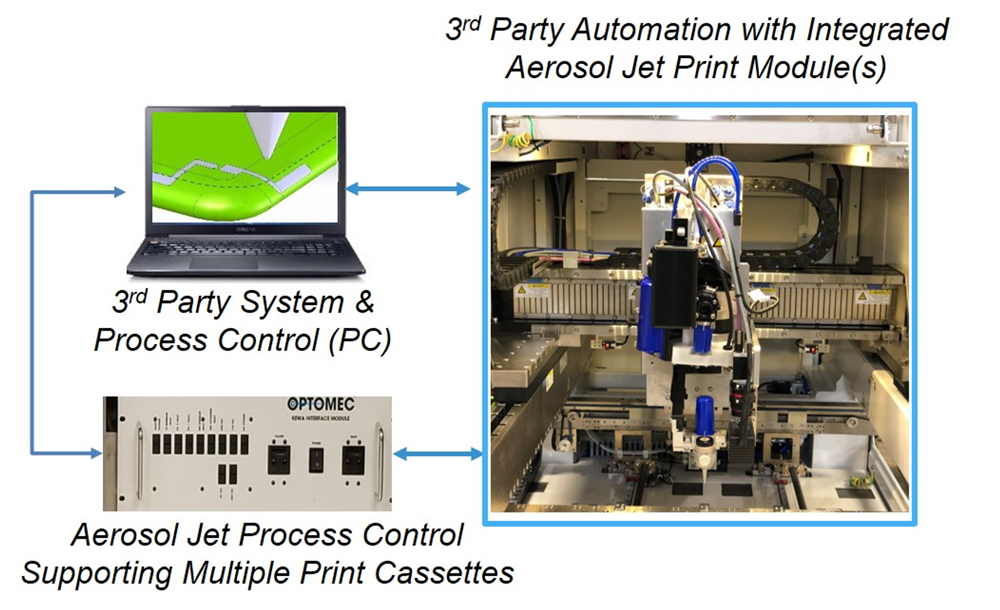

Aerosol Jet: Advanced Printing for Electronics & Biotech

Aerosol Jet systems are ideally suited to develop, fabricate, enhance and repair high performance electronic and biologic devices for Consumer Electronics, Semiconductor Packaging, Displays, Aerospace/Defense,…

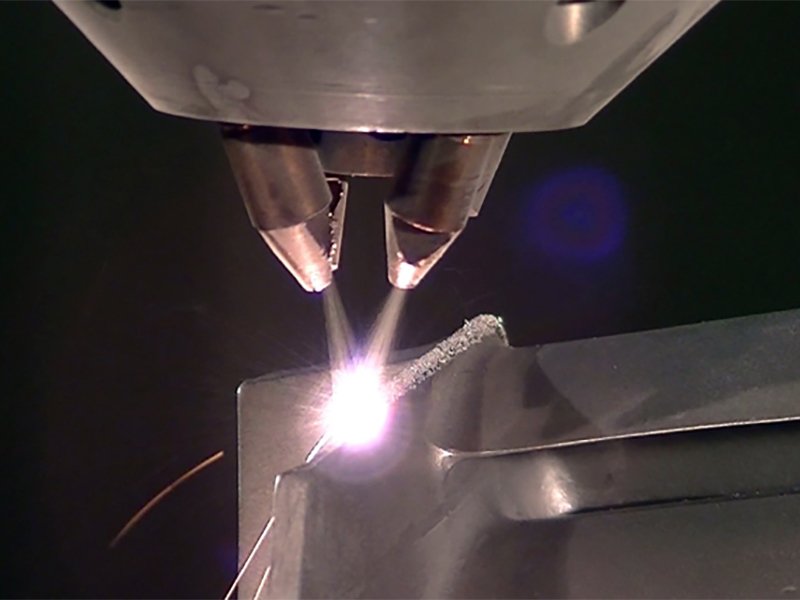

LENS Materials FAQ: Engineering Materials for Additive Manufacturing

LENS systems process common engineering materials such as stainless steels, tool steels, titanium alloys, and cobalt alloys. LENS technology can also process other materials including…

LENS Materials: Starter Recipes for Efficient Additive Manufacturing

LENS Material Starter Recipes are time saving tools helping customers speed the development of new additive manufacturing applications. Developed by Optomec LENS application engineers and…

Aerosol Jet Materials: Versatile Direct Printing for Electronics and Biology

Aerosol Jet systems have the unique ability to directly print a wide range of electronic and biological materials onto almost any substrate. The AEROSOL JET…

Aerosol Jet Material Recipes: Fast-Track Printed Electronics Development

Aerosol Jet Material Starter Recipes enable customers to save time and speed development of new printed electronic processes and applications. Developed by Optomec applications engineers…