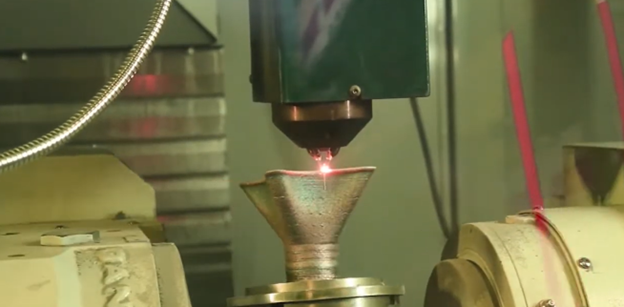

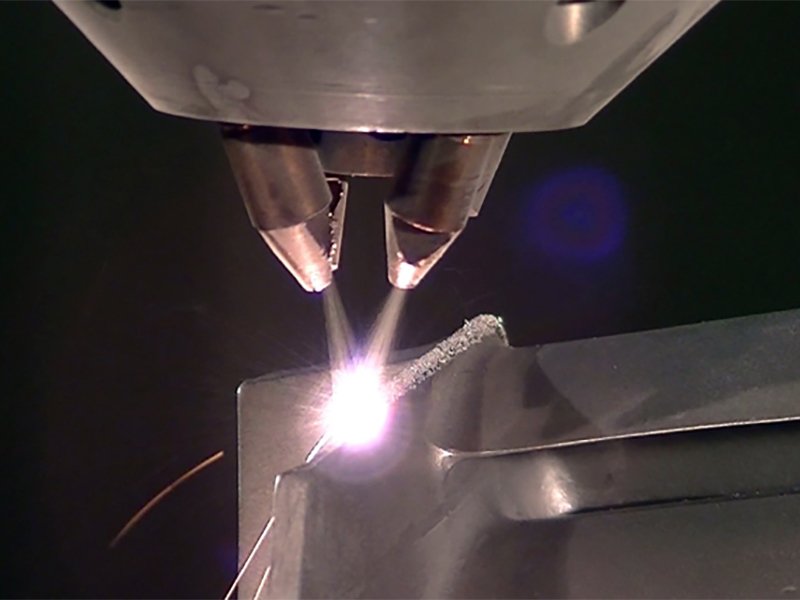

The 3D metal printer refers to advanced metal additive manufacturing technology, specifically the LENS DED system. These metal 3D printers use this technology to build complex metal parts layer by layer, utilizing a laser to melt metal powder as it is deposited. The LENS DED system is widely recognized for its ability to print high-performance metal components, which are particularly useful in industries like aerospace, defence, automotive, and medical instrumentation.

Optomec Metal Materials

LENS DED materials

Metal 3D printing with laser precision, creating strong, complex parts for aerospace, automotive, and beyond

Metal Machines

CS 250

The CS 250 system is ideal for research and development, offering additive manufacturing and repair for parts up to 250 x 250 x 250 mm

CS 558

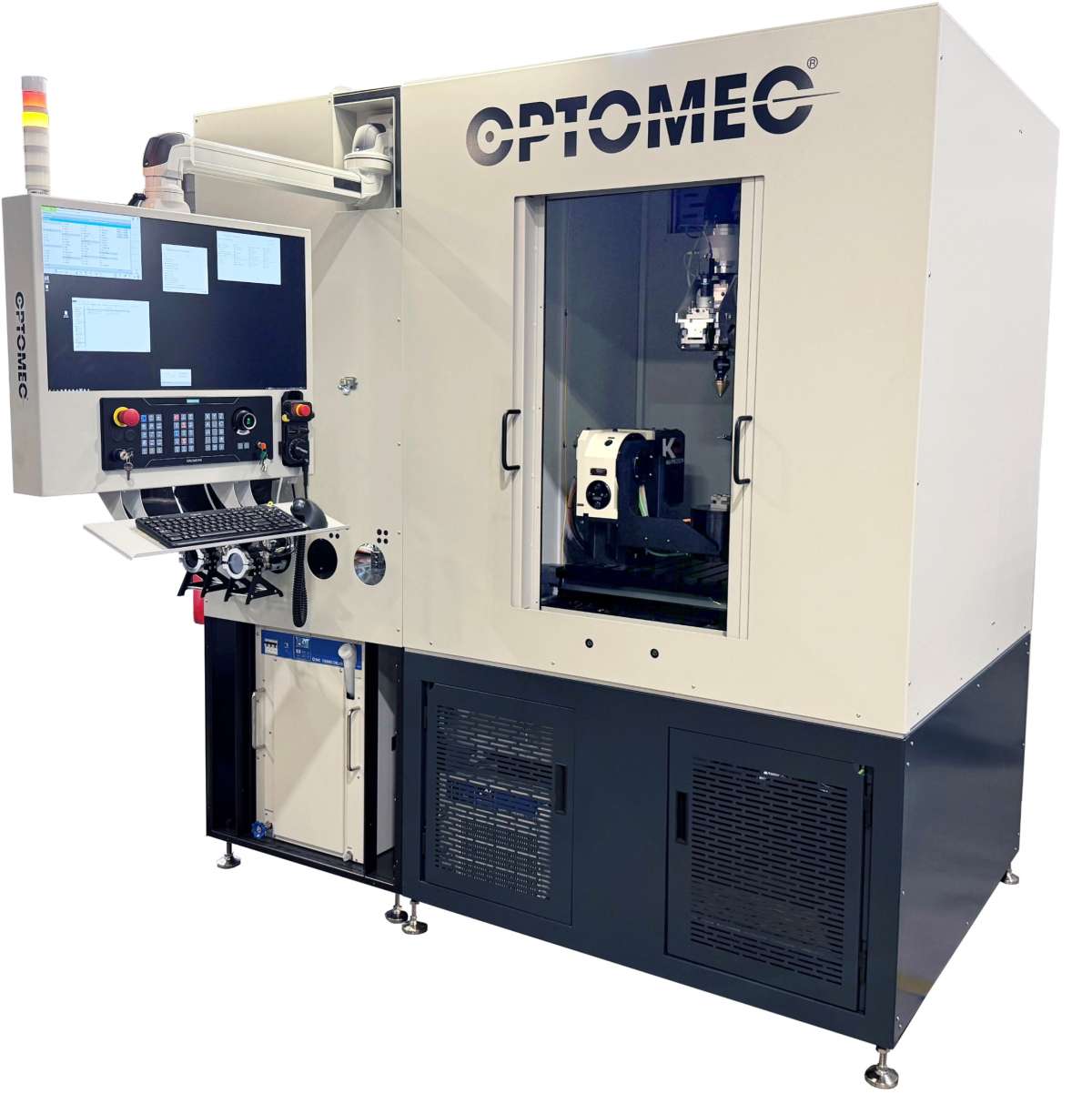

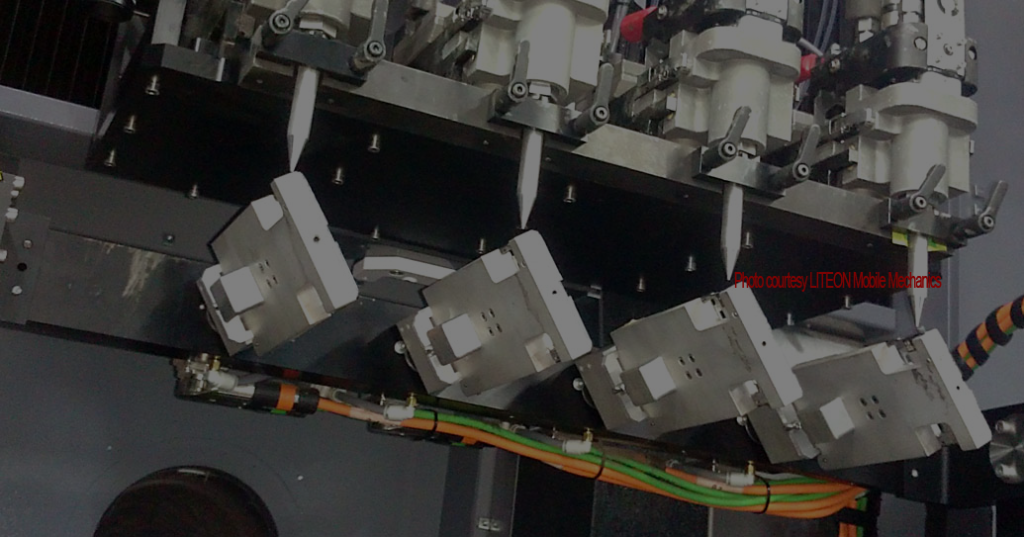

The LENS CS 558 is a DED laser cladder by Optomec for high-volume metal part repair, featuring AutoCLAD™ and machine vision

CS 800

The LENS CS 800 offers 3 kW laser power for advanced DED processing of mid to large industrial parts and high-rate cladding

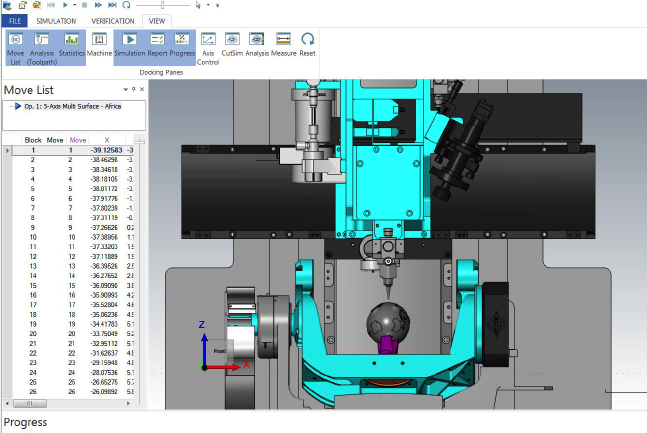

860 MTS

The LENS 860 offers larger build volumes and higher power for high-quality additive and hybrid metal manufacturing of mid to large parts

Explore Optomec 3D Printers

3D Metal Printer

Unleashing precision and power- 3D Metal Printer transforms metal powder into complex, high-performance parts with laser precision, layer by layer

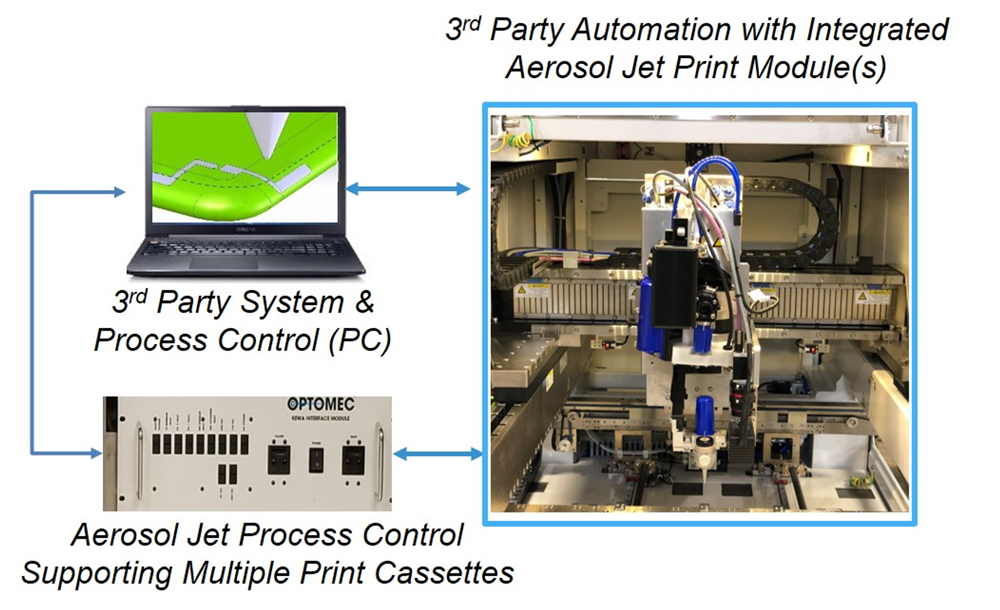

3D Electronic Printer

Precision in every print- 3D Electronic Printer delivers fine-featured circuits and components directly onto substrates with unmatched accuracy

3D Printing References

Latest Blog Posts

Discover our most recent posts across all industries, brands and topics