Motor Sports

Additive Manufacturing in Motor Sports

Motorsports, known for driving technological innovation and safety, have greatly benefited from additive manufacturing. No other manufacturing technology enables such bold, out-of-the-box thinking when bringing ideas to the racetrack.

- Easy integration of lightweight structures

- Simplified implementation of functional components

- Significantly reduced lead times and faster iterations

Lightweight Design and Topology Optimization of a Brake Pedal

- Use Titanium material for enhanced strength

- Create hollow designs for weight reduction

- Leverage Materialise software for topology optimization

- Perform rapid iterations to achieve the optimal result

Additive Manufacturing of a Footrest

Making complex lightweight components quickly without compromising safety is a key challenge. With EOS additive manufacturing solutions, various iterations of topology-optimized motorsport parts have been successfully realized.

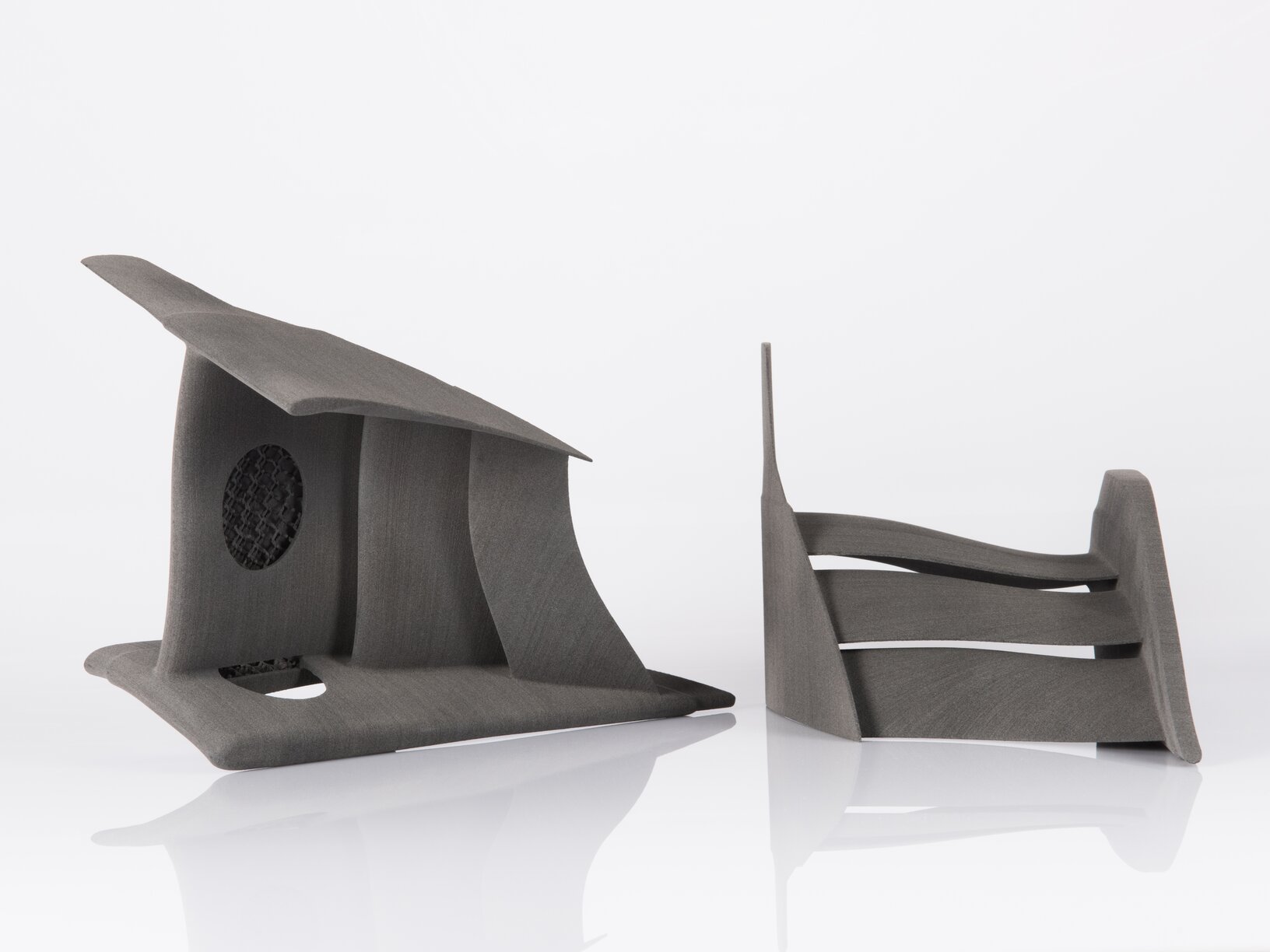

EOS Solutions for the Formula 1 Team

Formula 1 teams seek simple, fast, and cost-efficient solutions to build design prototypes for their race car front wings. Additive manufacturing by EOS offers the ideal complement to development and manufacturing processes. Using the EOSINT P 760, teams can quickly produce various iterations, reducing production times and lowering costs.

Other Applications

Serially Produced Vehicles

Efficient, high-performance, and cost-optimized parts for streamlined manufacturing

Resources

Design for Additive Manufacturing with FDR

Fine Detail Resolution (FDR) functions like Selective Laser Sintering (SLS) but at a much greater level of precision.

10 Essential Rules of Additive Manufacturing (3D Printing)

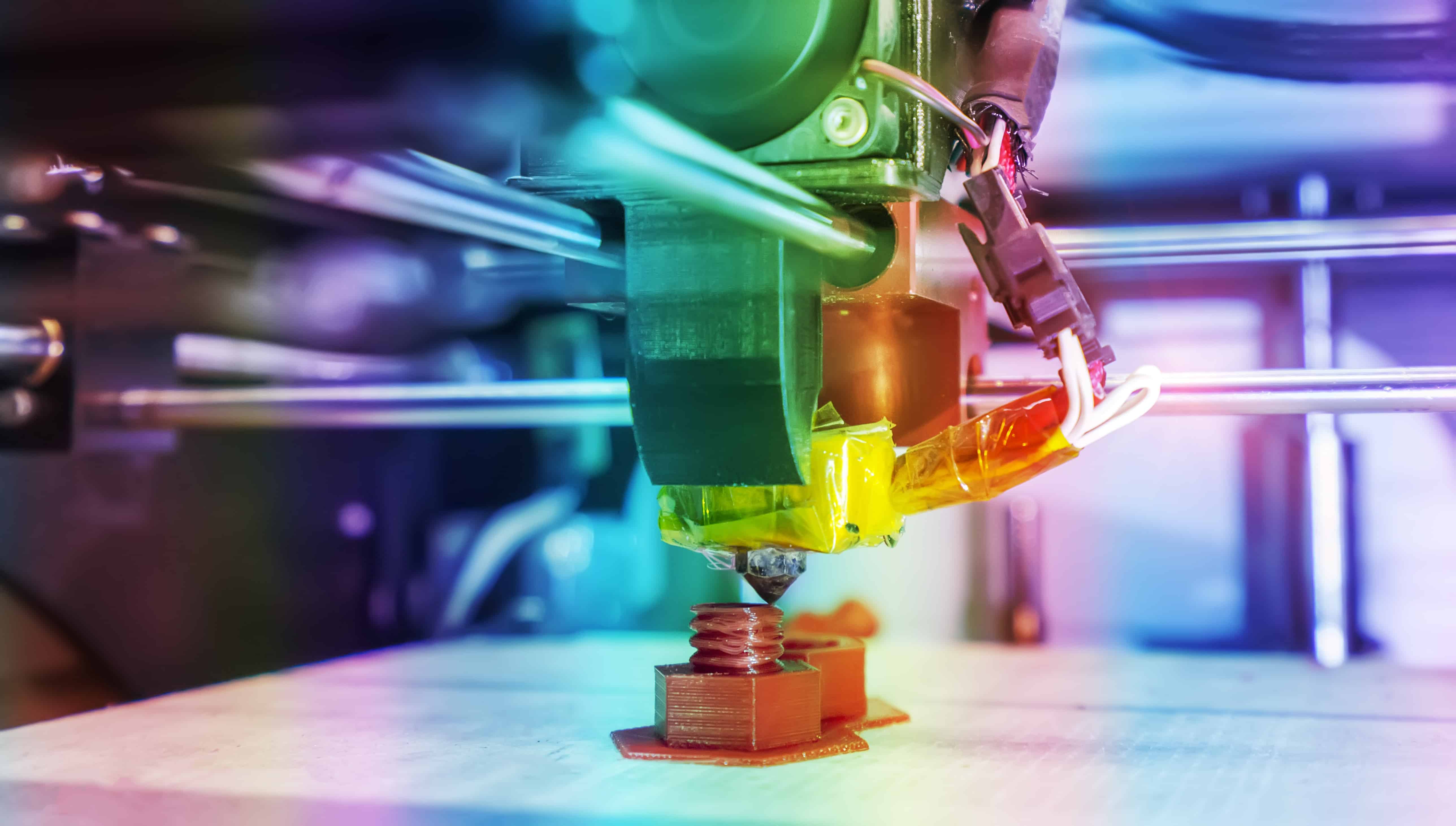

Are you new to 3D printing, also known as additive manufacturing (AM)?

Effectively Prepare and Validate your 3D Printing Process

Highlights of the Webinar, save time and energy by archiving best practices for reuse. Create supports to allow for developing different strategies for the additive…

The Hitchhiker’s Guide to Smart Fusion

This white paper showcases the principle of Smart Fusion, EOS’ qualification methodology and different applications and how this groundbreaking technology was used.

Support-Free Printing of Closed Impellers

There are a wide variety of applications that could potentially manage with fewer supports. In recent years, supportless building has enabled the development of applications…

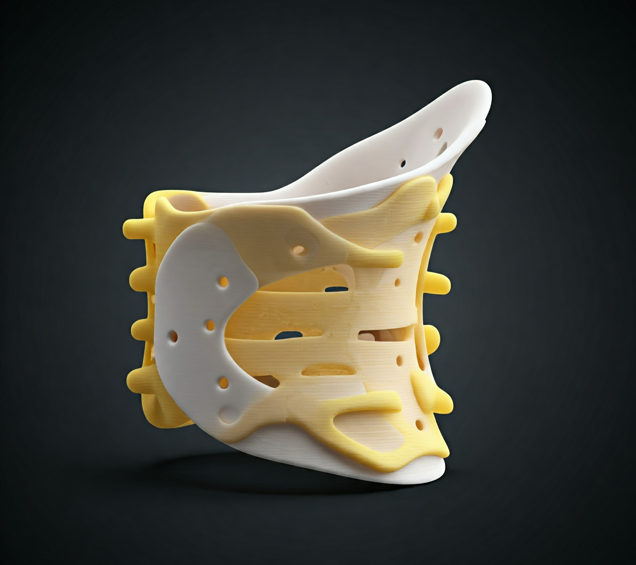

3D Printed Personalized Spinal Bracing: Transforming Healthcare

Discover how additive manufacturing is transforming the medical device industry, particularly in the realm of spinal bracing. This video delves into the innovative 3D design…

The Ideal 3D Printer for your Lab Requirements

Explore the benefits of modern, scalable additive manufacturing with a user-friendly 3D printing solution designed to bring your ideas and designs to life quickly and…

Custom Bike Design with 3D Printing

Explore the revolutionary impact of 3D printing on custom bike design. Bike enthusiasts know the value of quality welds, dynamic suspensions, and low-maintenance features. In…