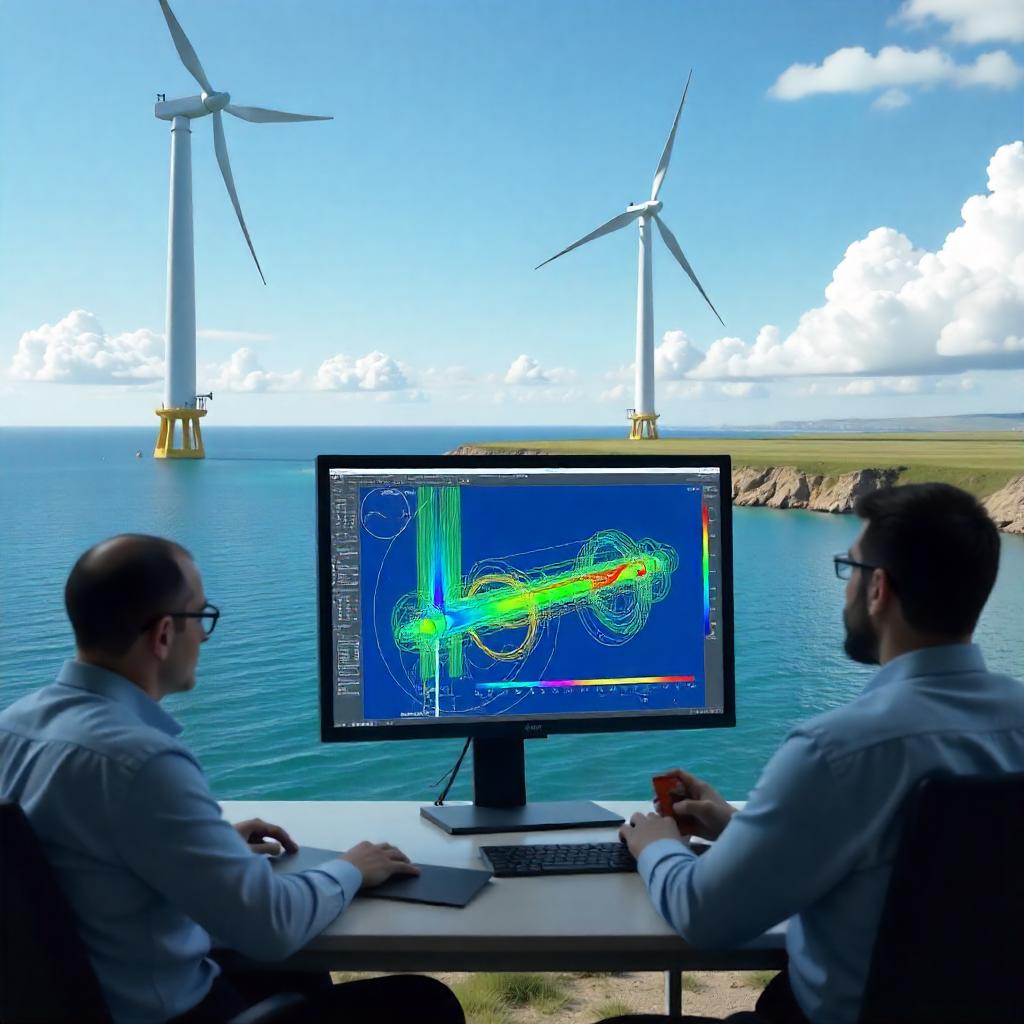

Structural reliability is a critical aspect of wind turbine design, ensuring that turbines can operate safely and efficiently over their lifetime. SIMULIA provides advanced simulation capabilities to analyze and optimize the structural integrity of wind turbine components, including towers, hubs, and drivetrains. By simulating real-world operating conditions, such as wind loads, mechanical stress, and vibration, manufacturers can predict and mitigate potential failures, enhance performance, and reduce maintenance costs.

Benefits

Increased Reliability

Ensure the structural integrity of turbines under extreme weather and operational conditions

Reduced Maintenance Costs

Identify potential issues early, minimizing downtime and repair expenses

Enhanced Safety

Validate designs to meet safety standards and withstand operational stresses

Cost Efficiency

Reduce reliance on physical prototypes by simulating real-world conditions virtually

What We Offer?

SIMULIA provides high-fidelity simulations for analyzing the structural behavior of wind turbines, offering powerful tools to evaluate the effects of wind loads, mechanical stresses, and vibrations on critical components such as blades, towers, and drivetrains. By simulating real-world conditions, SIMULIA helps engineers assess how these forces impact turbine performance over time, allowing for the refinement of designs to optimize efficiency, reliability, and safety. The platform enables manufacturers to predict potential failures, identify weak points in the structure, and make informed decisions about materials and design adjustments. This leads to more durable, cost-effective, and high-performance wind turbines, ultimately contributing to the long-term sustainability and efficiency of wind energy production.

Ensure Reliability and Efficiency in Wind Turbine Design

Enhance the structural integrity and performance of wind turbines under real-world conditions. Explore how these tools can elevate your wind energy solutions now.