The Transportation & Mobility (T&M) industry is undergoing a rapid transformation. Driven by factors like evolving customer preferences, disruptive technologies, and stringent regulations, companies must adapt to stay competitive. Digital engineering, powered by virtual testing and simulation, offers a strategic solution. By leveraging multiscale-multidisciplinary modeling, organizations can streamline product development, reduce costs, and deliver innovative solutions that meet market demands.

Product Capabilities for Transportation & Mobility

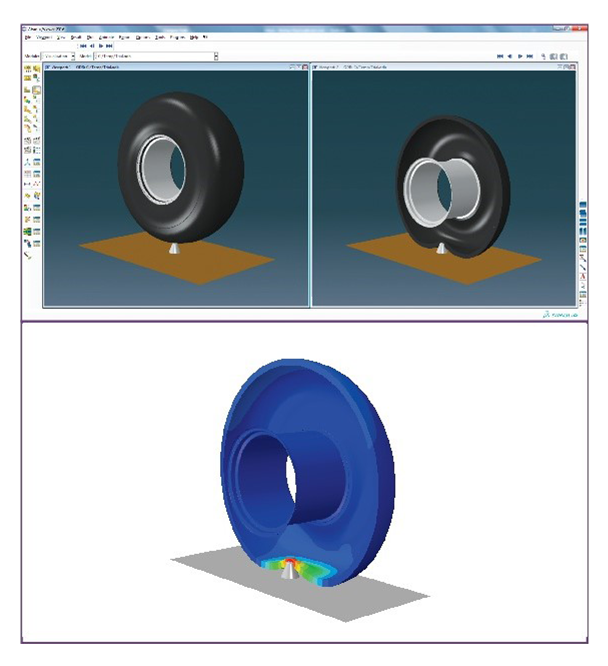

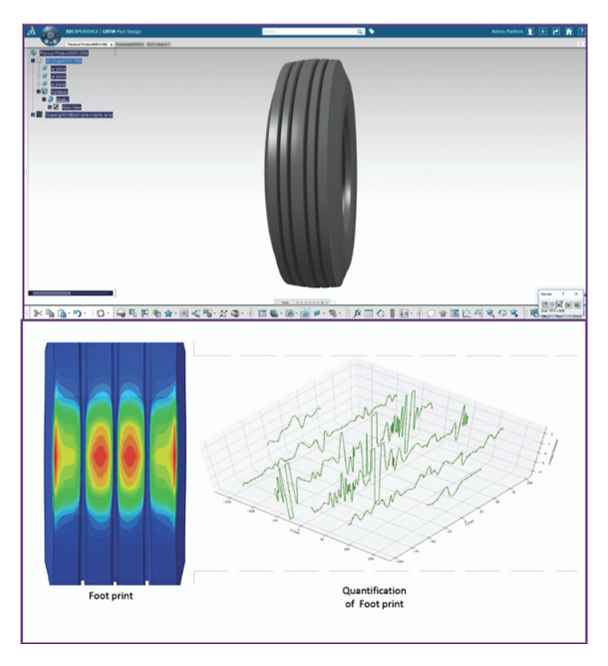

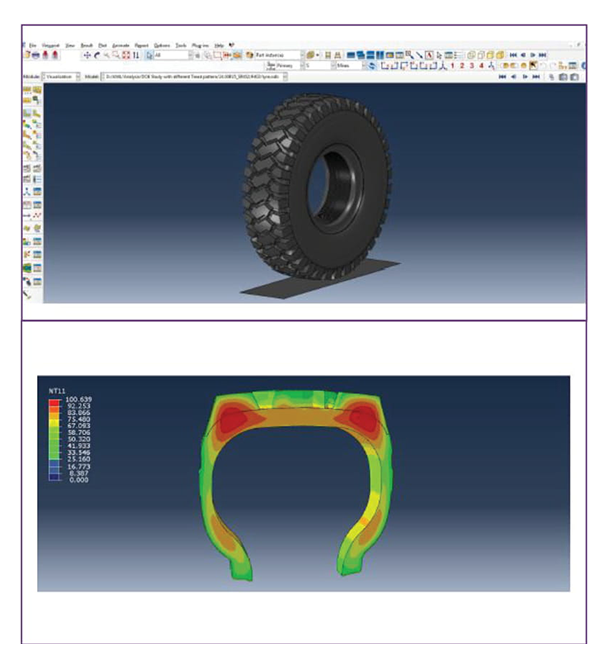

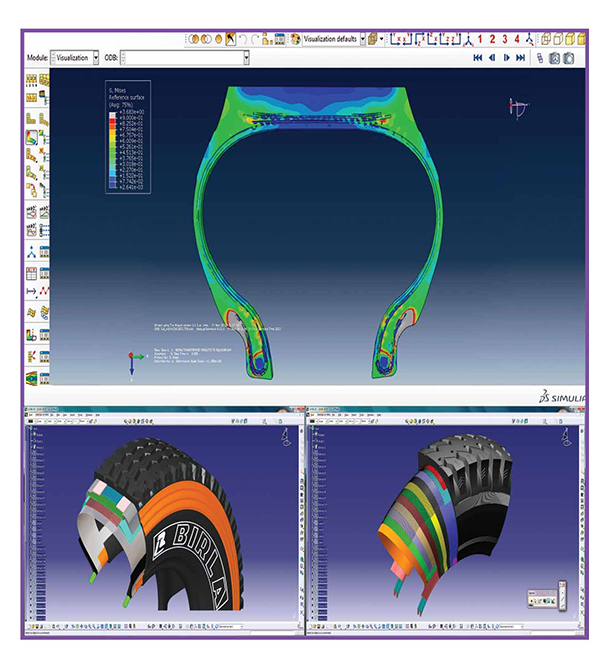

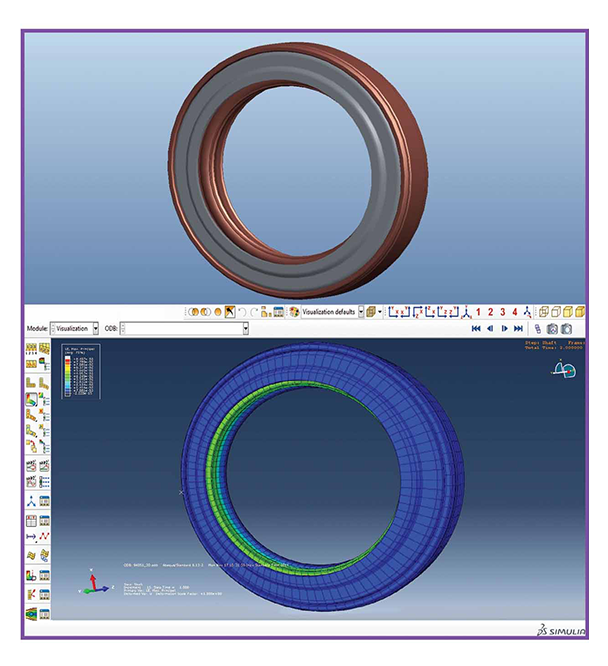

Tyres

The main goals of improving chassis and suspension strength, durability, and vibration are to ensure structural integrity, enhance ride quality, and comply with regulations. Reducing unsprung mass while maintaining stiffness improves steering and handling.

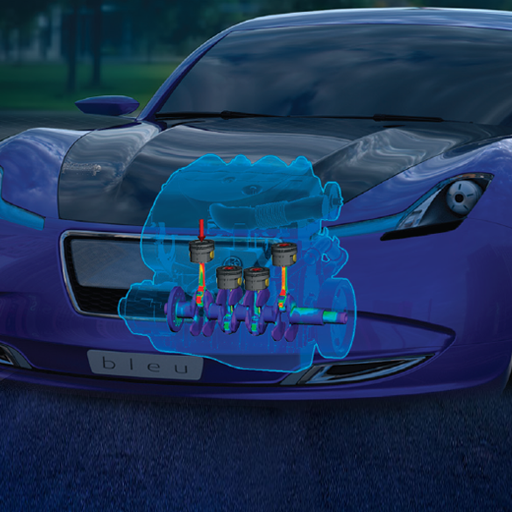

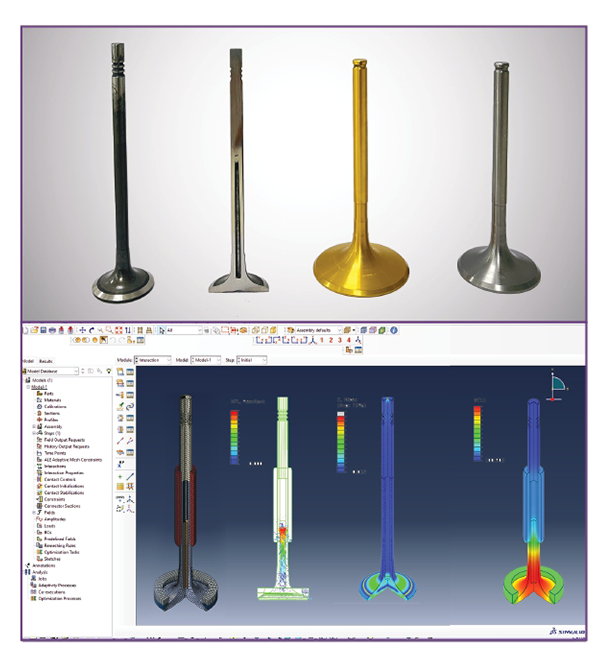

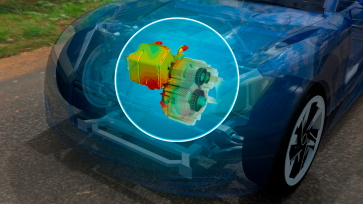

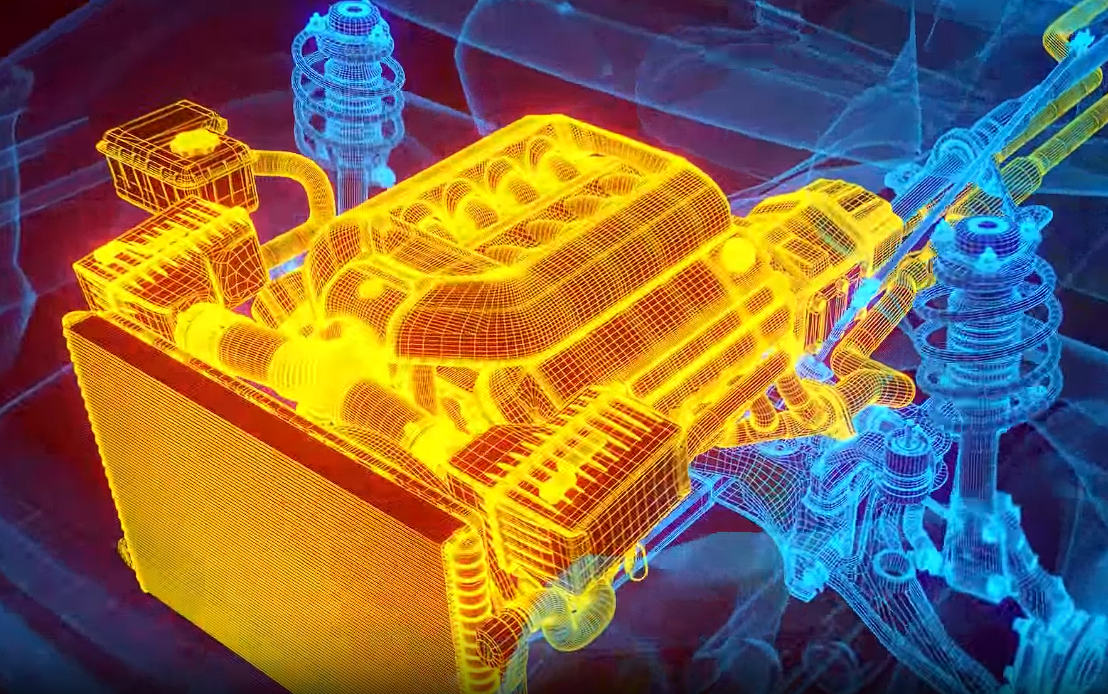

Powertrain

SIMULIA Abaqus FEA ensures reliable powertrain simulations with accurate thermal, mechanical, and lifespan predictions. Robust and efficient solvers for solving detailed large-scale powertrain models Accurate and robust contact algorithms for bolt-down and sealing analyses Integrated thermal-stress analysis models powertrain behavior across all operating temperatures

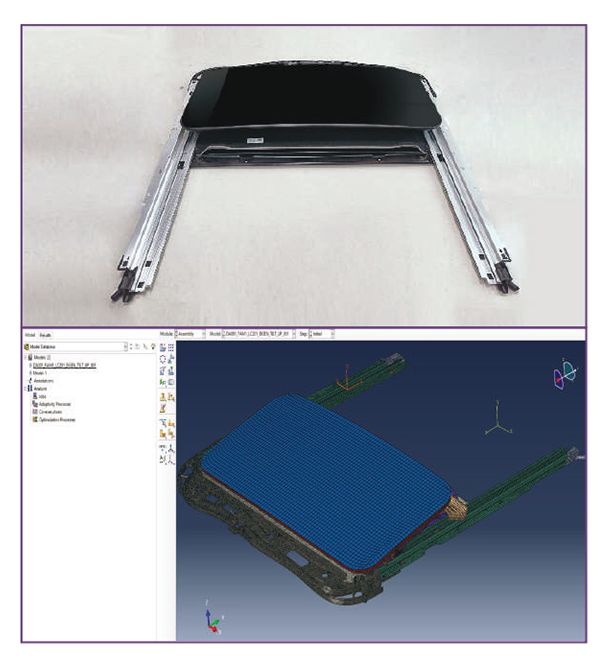

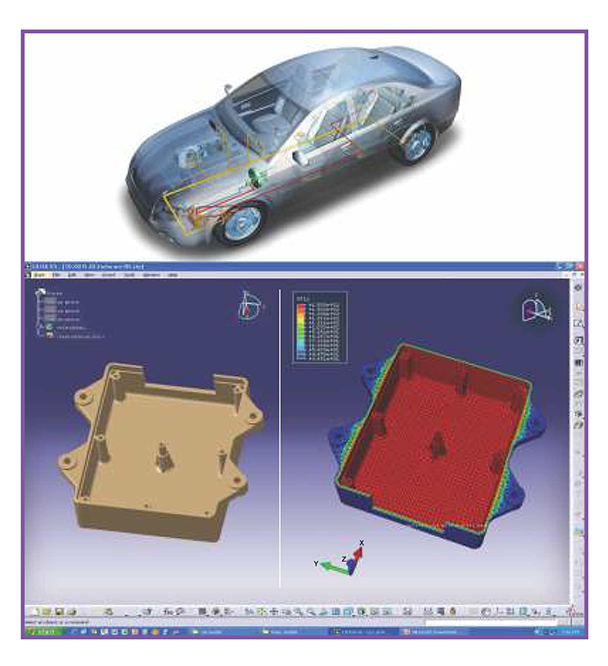

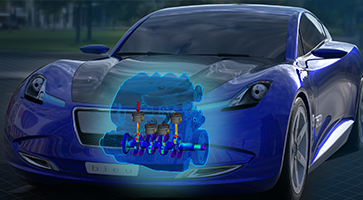

Mechanisms

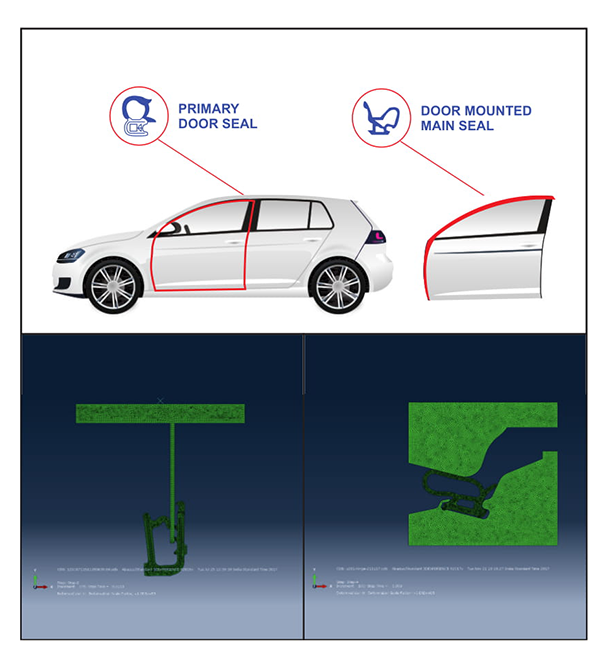

Vehicle mechanisms require careful analysis. Our solutions analyze components like powertrains and convertible roofs, incorporating linear and nonlinear effects.

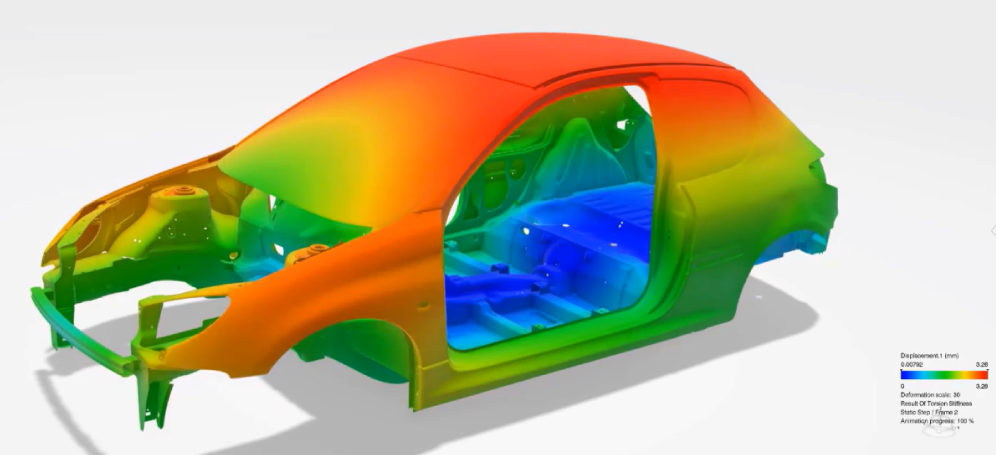

Body in White

The automotive body is vital for integrity, noise reduction, and safety. SIMULIA’s Abaqus FEA suite integrates Body in White (BIW) and Trimmed Body analysis, streamlining workflows for crash safety and stiffness.

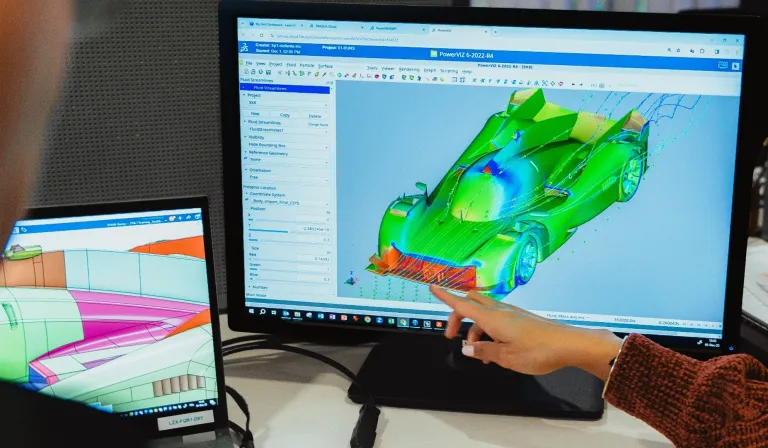

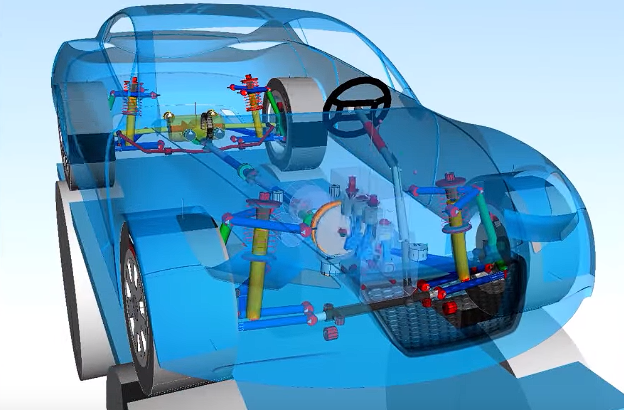

Vehicle Dynamics

Vehicle Dynamics uses Multi Body System (MBS) simulations to optimize and validate vehicle performance, incorporating Software in the Loop (SIL) and SIMULA/Simpack for Hardware in the Loop (HIL) and Man in the Loop (MIL) applications, supporting ADAS and autonomous driving.

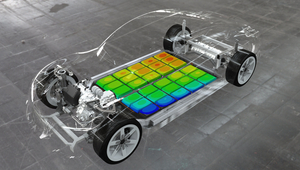

Battery Engineering

In electric vehicles, batteries act as modern fuel tanks, storing energy to address range concerns while ensuring safety. Dassault Systèmes offers comprehensive battery solutions, including BIOVIA for chemistry modeling to enhance battery longevity and CATIA libraries for 1D simulations of cells, modules, and packs. This system-level approach integrates the aging, thermal, and electrical characteristics of cells.

Electric Drive Engineering

The electric drive is essential for vehicle electrification and integrates into the electric powertrain and vehicle architecture. Early understanding of system interdependencies through Model-Based Systems Engineering (MBSE) is crucial for optimizing performance and balancing design objectives, aligning system-level and physics-based simulations.

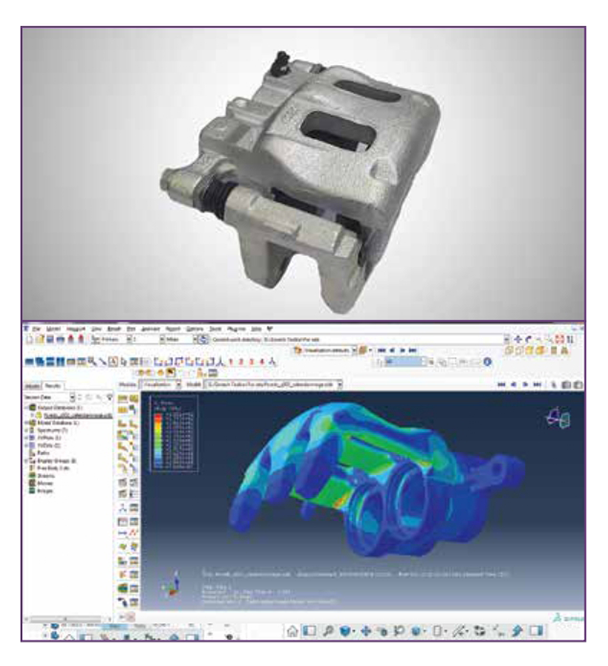

Brake System Engineering

The brake system is essential for vehicle safety and performance, ensuring reliable, durable, and efficient operation. Customers expect quiet operation and predictable maintenance, making effective design critical.

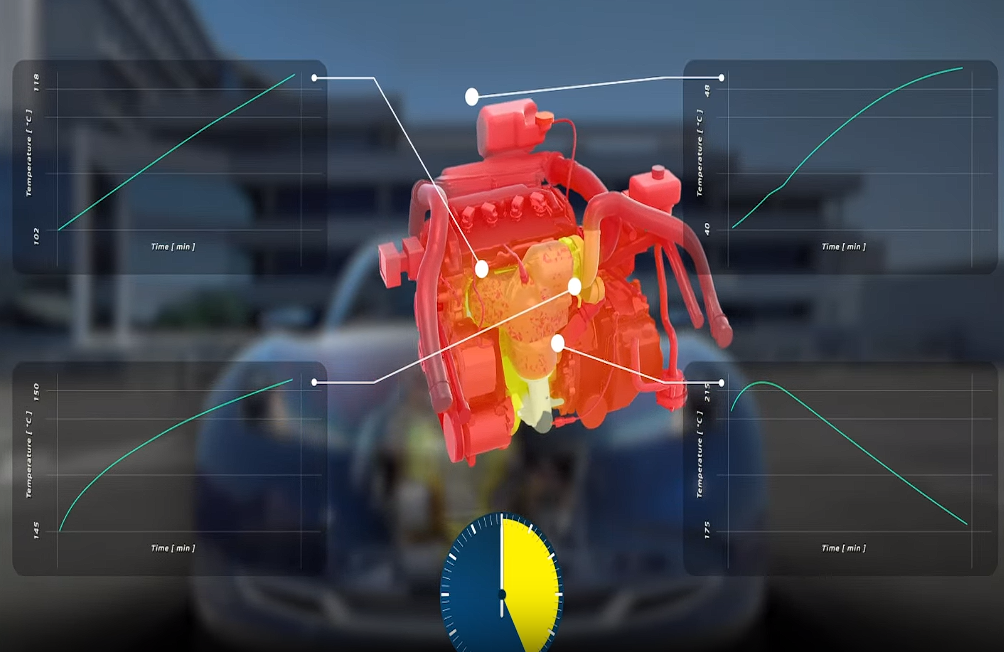

Vehicle Thermal Management

Designing energy-efficient vehicles involves addressing conflicting goals while meeting stringent environmental regulations. Effective thermal management is crucial for reducing emissions and enhancing vehicle performance, contributing significantly to compliance with evolving standards.

Performance Driven Architecture

The success of a vehicle program hinges on selecting the right concepts for development. As the number of models and architectural options increases, decision-making becomes complex for concept engineers facing tight timelines and conflicting requirements. Insufficient collaboration among architects and domain experts often results in isolated efforts and suboptimal outcomes.

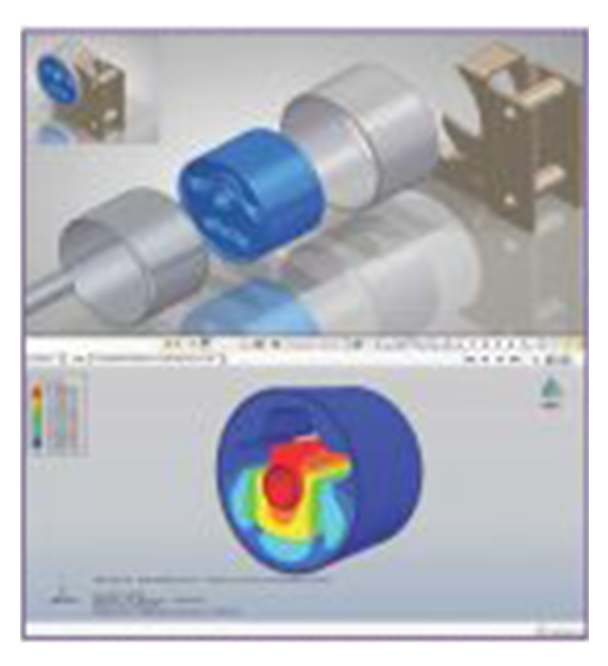

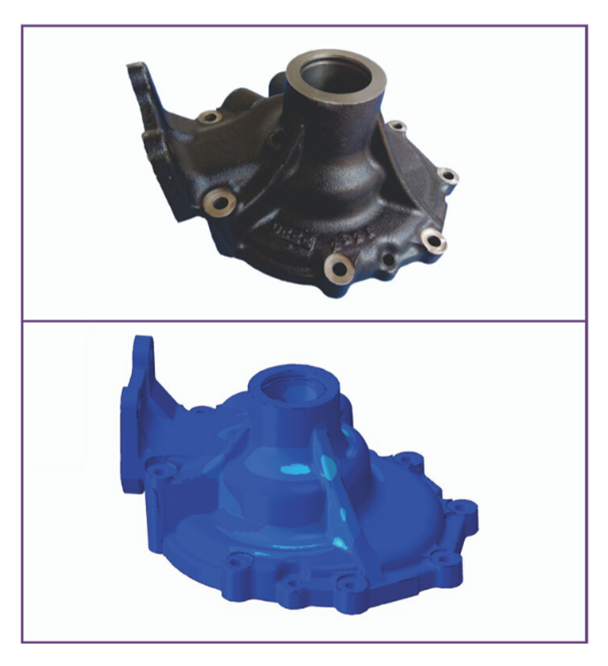

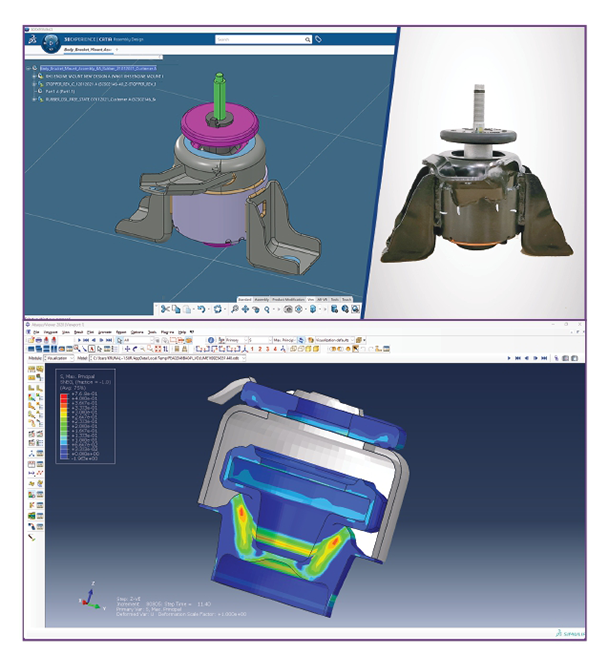

Powertrain Strength, Durability & Vibration

Effective powertrain design is essential for a vehicle's reliability, durability, efficiency, performance, and safety. Structural simulations enable quicker and more cost-effective insights than physical testing, addressing bore distortion, bending stiffness, load distributions, and fatigue safety factors through realistic elements like non-linearity and Multiphysics.

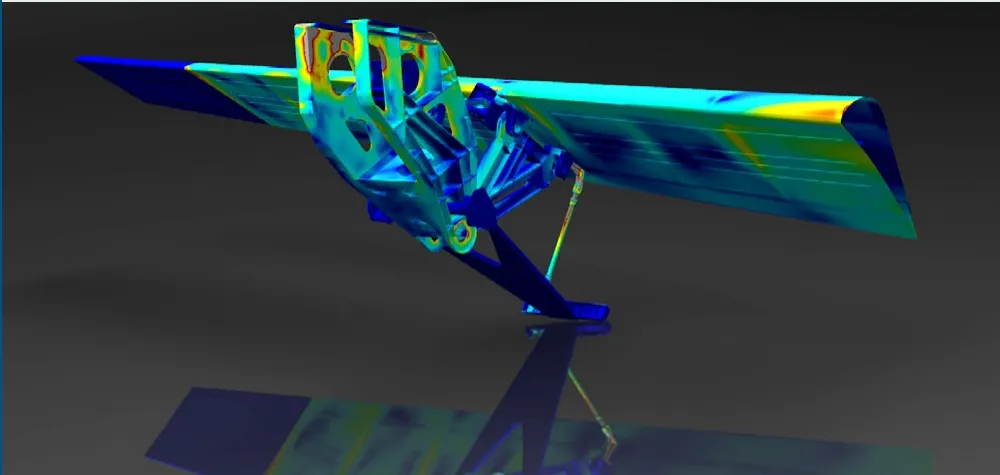

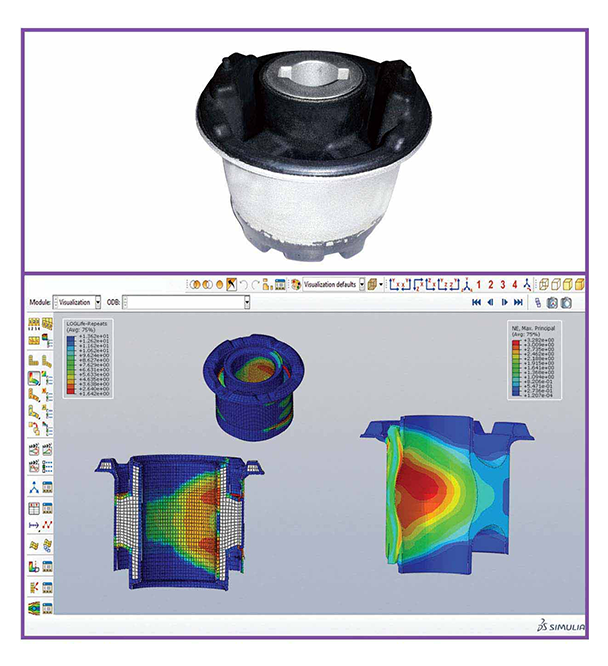

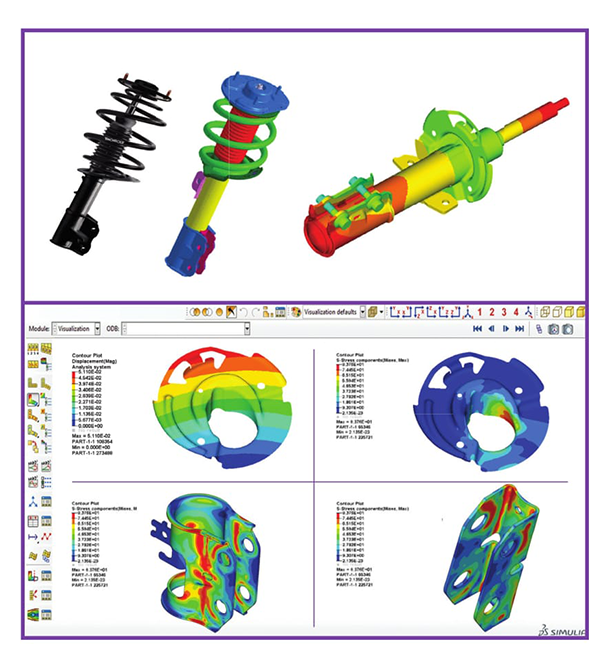

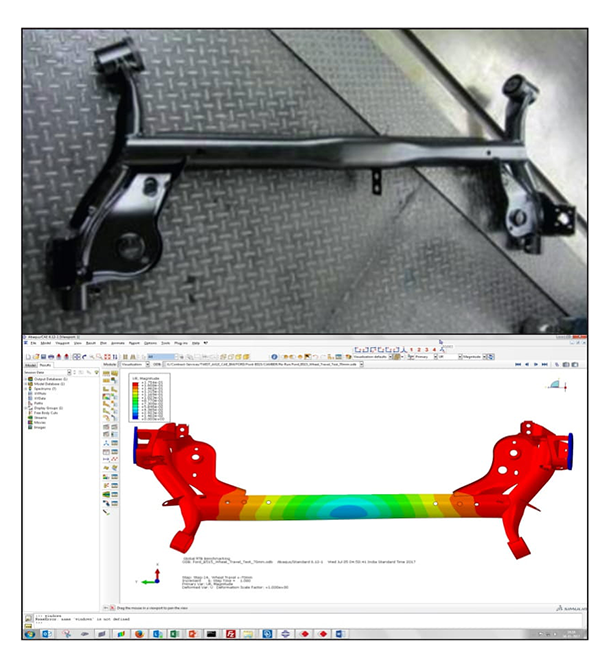

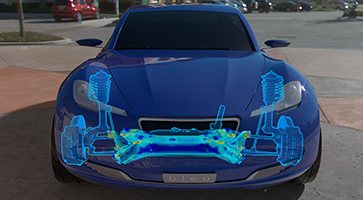

Chassis & Suspension Strength, Durability & Vibration

The main goals of improving chassis and suspension strength, durability, and vibration are to ensure structural integrity, enhance ride quality, and comply with regulations. Reducing unsprung mass while maintaining stiffness improves steering and handling.