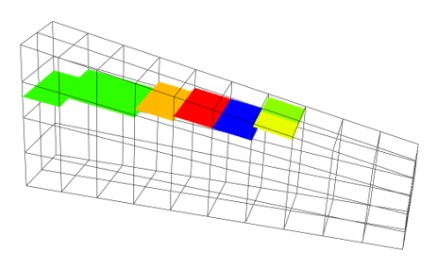

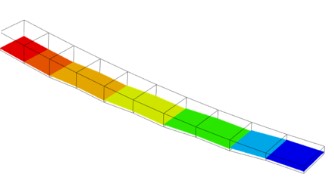

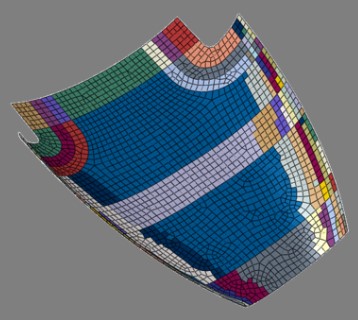

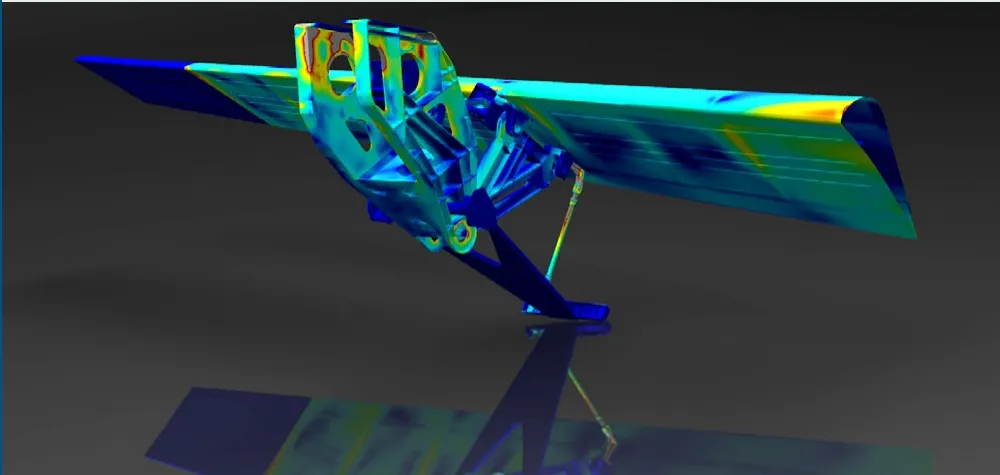

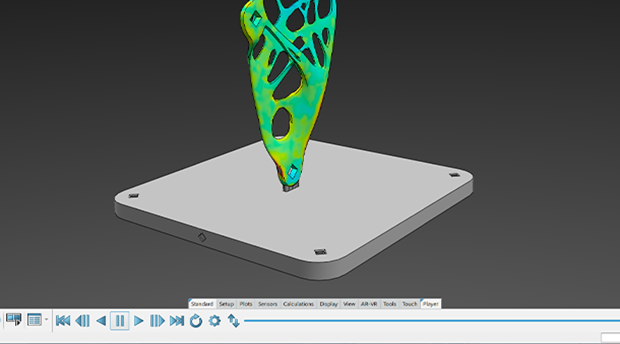

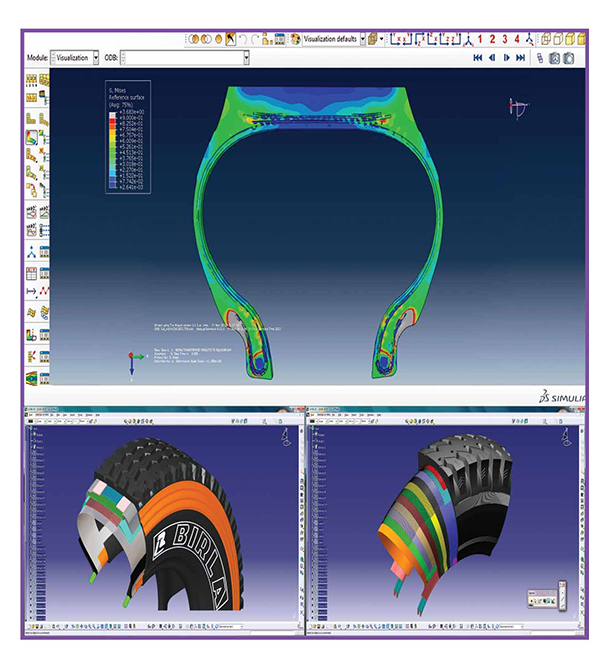

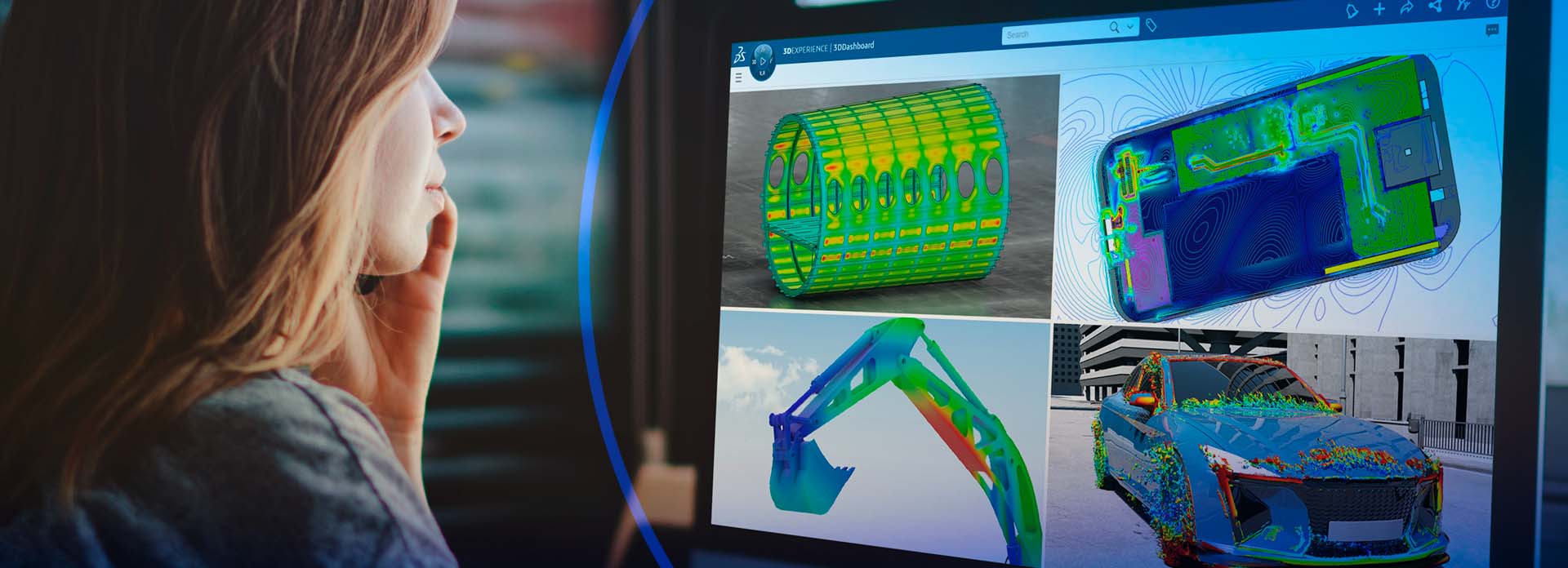

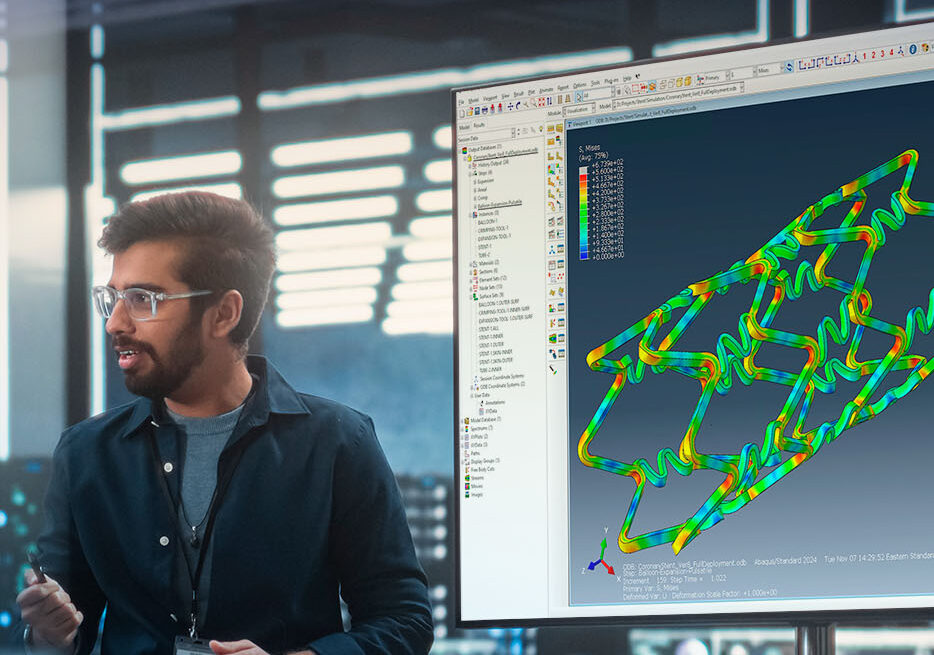

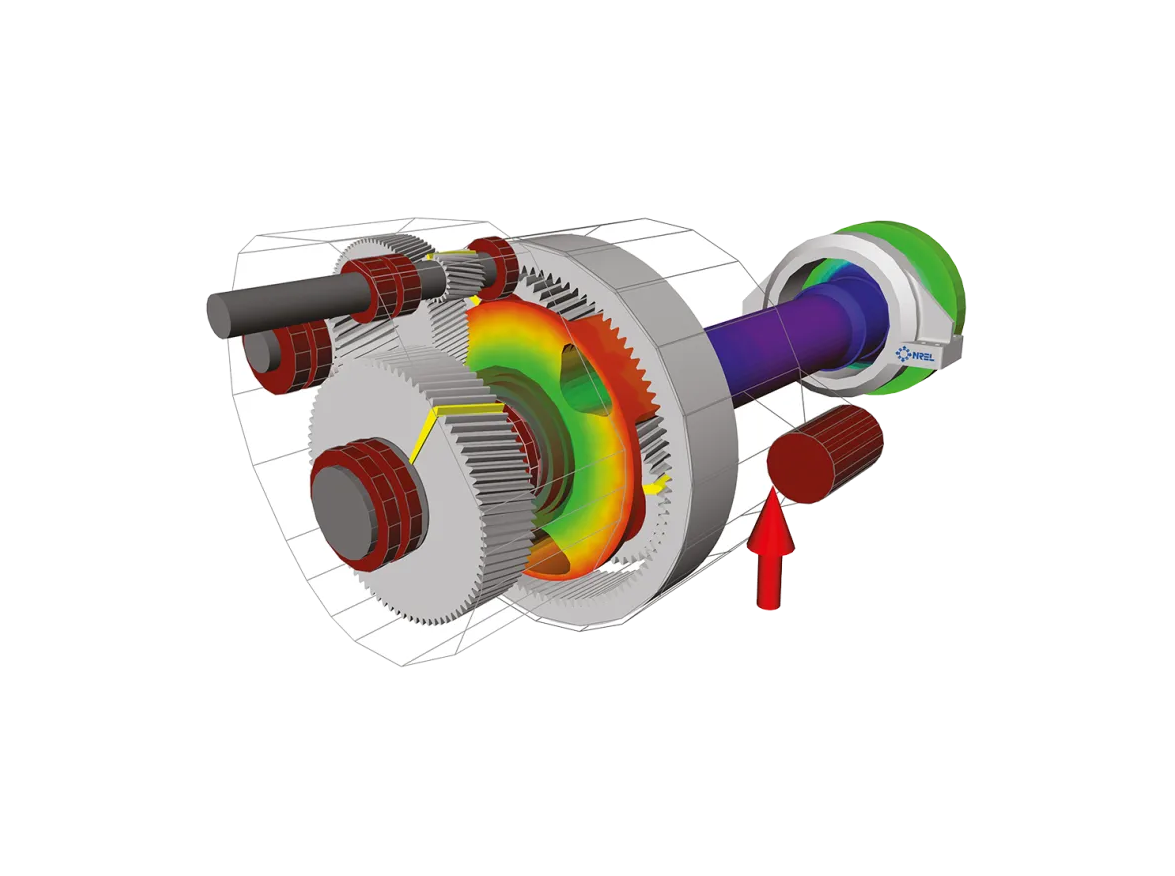

The Composites Modeler for Abaqus/CAE enhances and expands upon the advanced ply modeling features within Abaqus/CAE. It offers proven fiber simulation capabilities and sophisticated model-building tools, all integrated into the Abaqus/CAE environment. The Composites Modeler directly transfers precise fiber angles and ply thicknesses to Abaqus simulations, ensuring exceptional accuracy. It facilitates quick review and modification of the composites model, enabling rapid design improvements. Additionally, it generates manufacturing data to verify that the analyzed model aligns with the final structure and provides direct integration with Simulayt’s Layup Pipeline for improved communication across the enterprise.

Applications

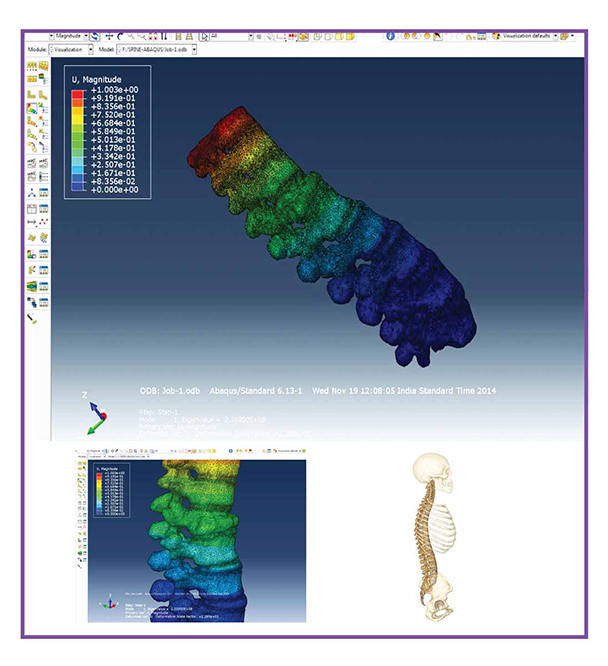

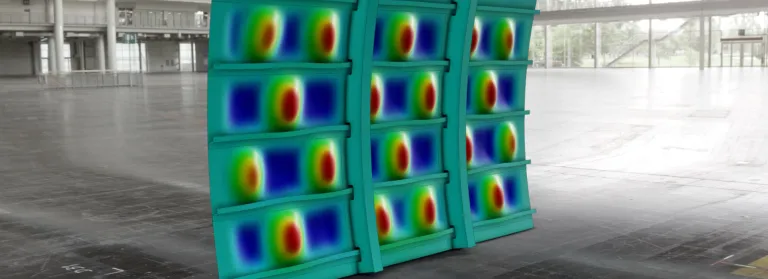

- Multi-Layered Structures: Capable of modeling complex multi-layered composites used in various engineering fields.

- Material Variability: Supports a wide range of composite materials, including fiber-reinforced plastics, metal matrix composites, and natural fibers.

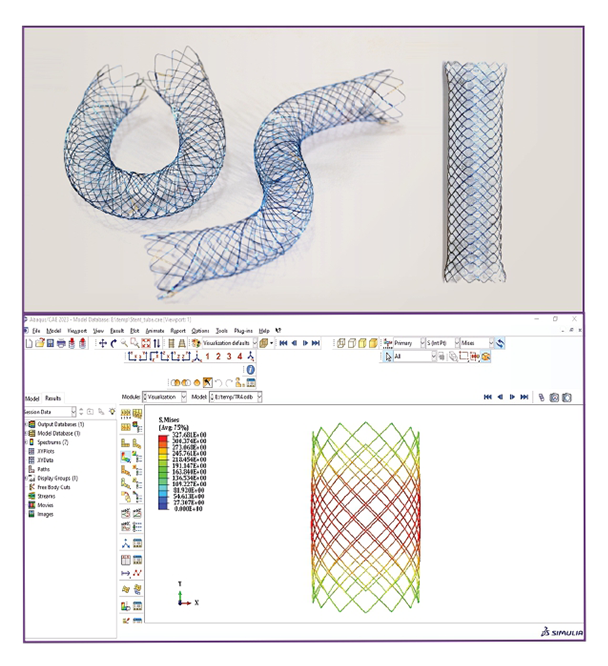

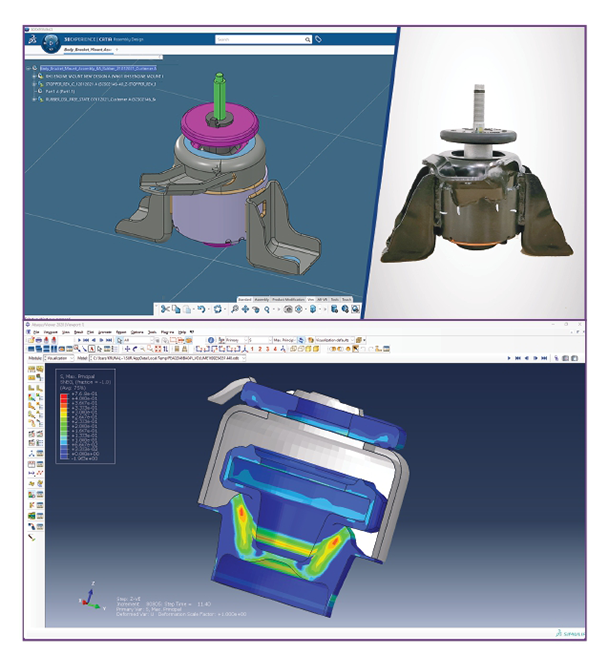

- Failure Analysis: Includes capabilities for analyzing various failure modes specific to composite materials.

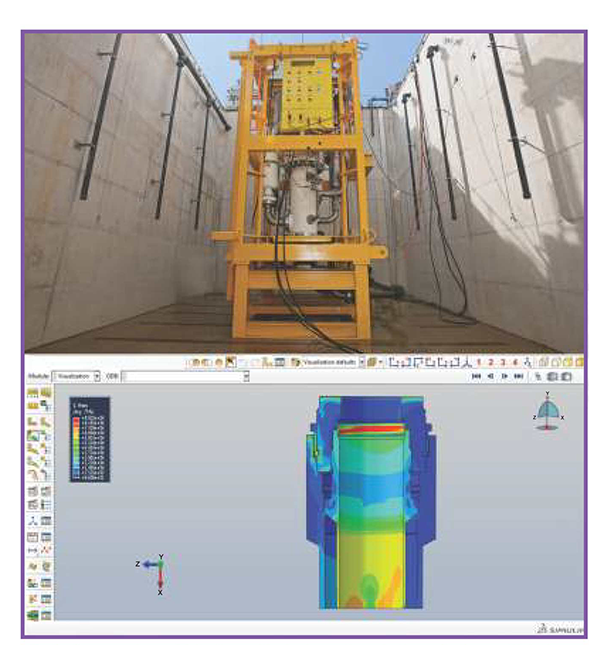

- Thermal and Mechanical Loads: Can simulate the effects of different loading conditions, including thermal, mechanical, and dynamic loads.

- Design Optimization: Useful in the design optimization of composite components for performance and weight reduction.

Applications

- Aerospace Engineering: Used for designing lightweight and strong components in aircraft and spacecraft.

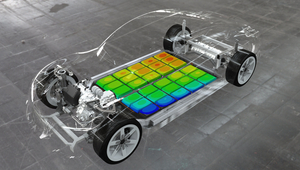

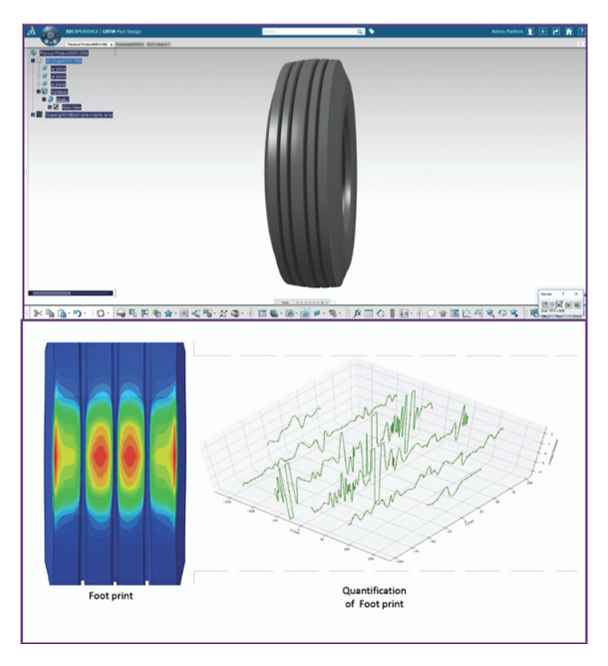

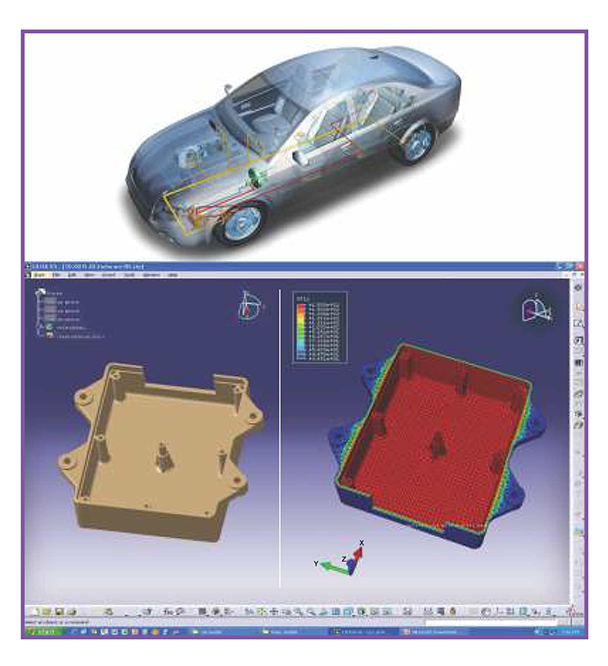

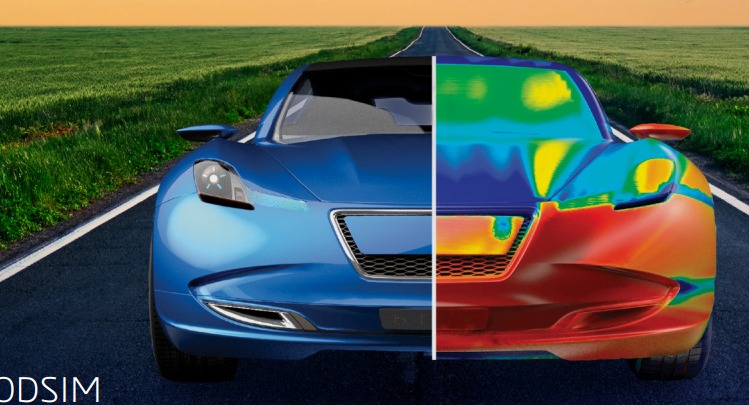

- Automotive Industry: Applied in the development of high-performance parts that reduce vehicle weight and enhance fuel efficiency.

- Marine Engineering: Utilized for constructing hulls and components in boats and ships, focusing on durability and performance.

- Civil Engineering: Employed in designing structures that require high strength-to-weight ratios, such as bridges and high-rise buildings.

- Sports Equipment: Used in the design of high-performance sports gear, including bicycles, skis, and racquets.

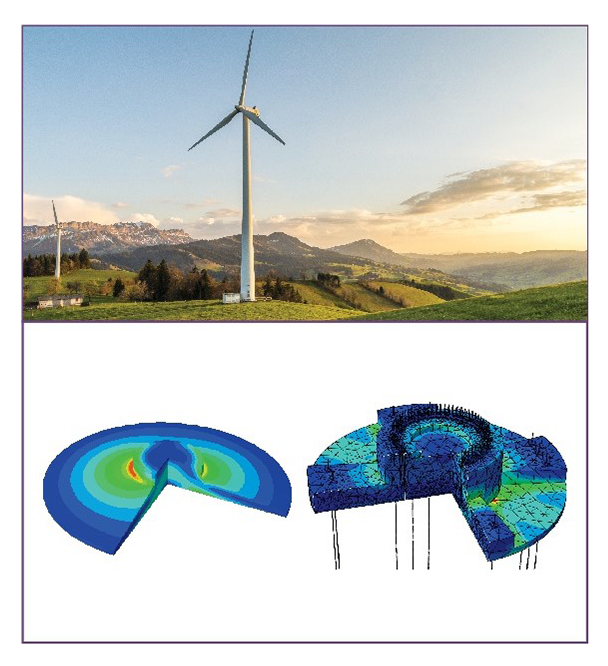

- Wind Energy: Important for designing turbine blades that need to withstand extreme conditions while maintaining light weight.

Benefits

- User-Friendly Interface: Simplifies the design and modeling of composite structures with an intuitive graphical interface.

- Material Customization: Allows for detailed definition of composite materials, including properties, orientations, and stacking sequences.

- Enhanced Accuracy: Supports advanced material behavior modeling, improving the reliability of simulation results.

- Flexibility: Enables easy modifications of layups and material properties, facilitating optimization and iterative design processes.

- Integration: Seamlessly works with other Abaqus modules, streamlining workflows from design to analysis.

Discover Abaqus Modules

Abaqus/Standard

Solution Technology for Linear and Nonlinear Finite Element Analysis

Abaqus/Explicit

Solution Technology for Highly Nonlinear Transient Events

Abaqus Multiphysics

Complete Solutions for Realistic Simulation

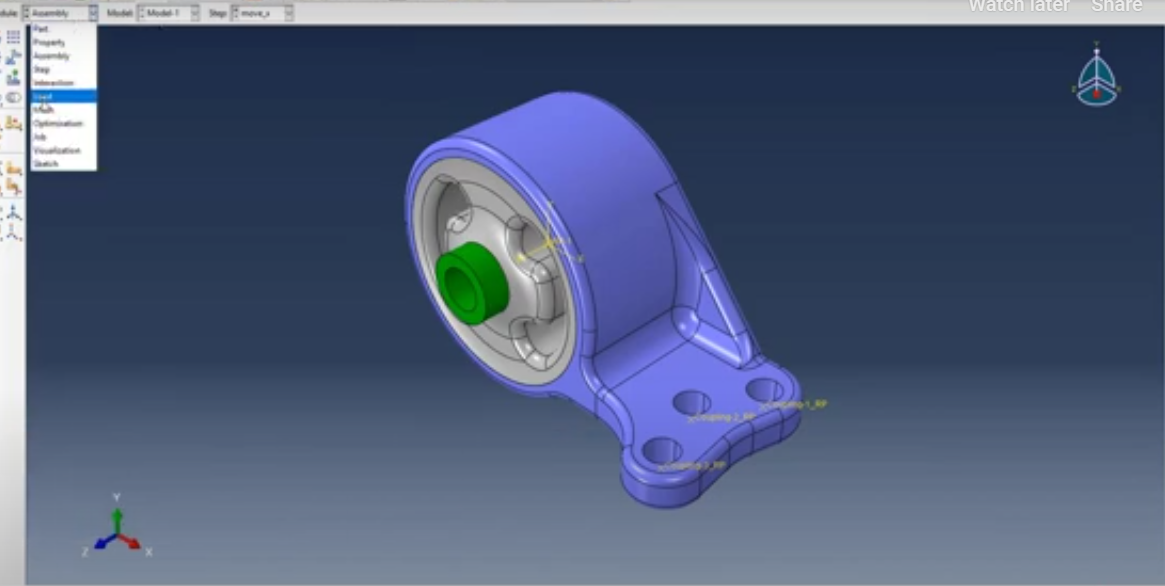

Abaqus/CAE

Complete Solution for Abaqus Finite Element Modeling, Visualization, and Process Automation

Abaqus CAD Associative Interface

Associative Interfaces Between Abaqus and CAD Systems

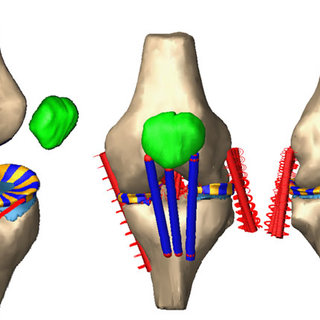

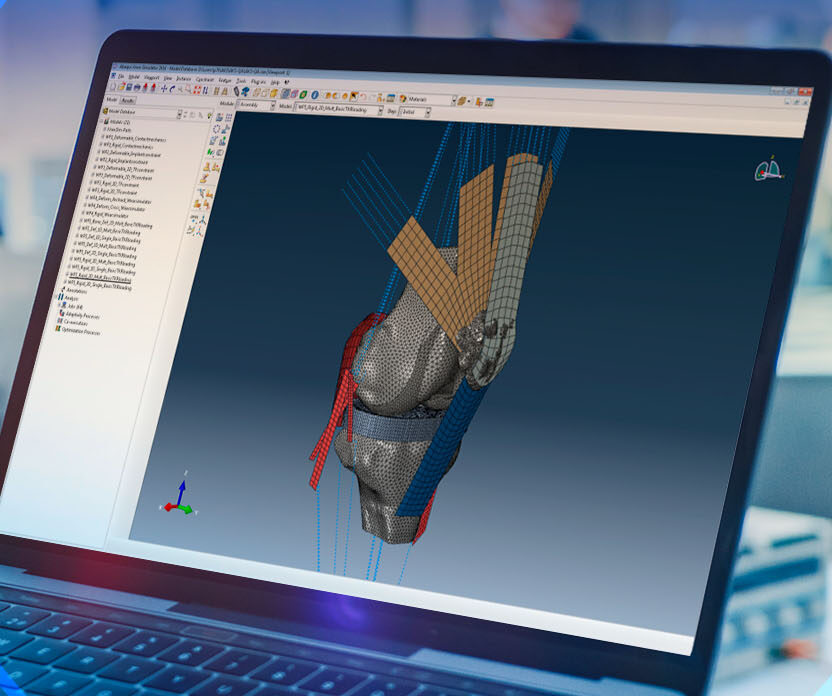

Abaqus Knee Simulator

Advanced Knee Implant Analyses and Simulation

Czone for Abaqus

Crush Simulation for Laminated Composites

Explore Other Apps

Abaqus

Finite Element Analysis for Mechanical and Civil Engineering Excellence

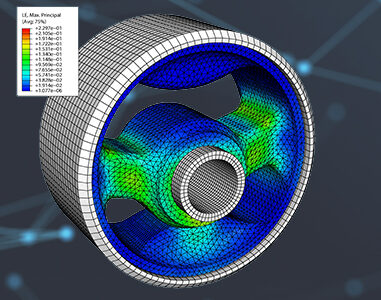

Fe-safe

Durability Analysis Software for Finite Element Models

Tosca

Unlocking Efficiency: Optimization Through Advanced FEA and CFD Simulations

Isight

Transforming Innovation Through Process Automation and Design Exploration

Simpack

Powerful Multibody System Simulation Software for Comprehensive Dynamic Analysis