Q-PLM technology is designed to integrate seamlessly with a variety of Product Data Management (PDM) systems, including leading platforms like Dassault Systèmes ENOVIA SmarTeam, ENOVIA MatrixOne, and data exchange servers such as OpenDXM, TRUfusion, and SWAN. By leveraging extensive expertise in PDM integration, Q-PLM ensures that product data quality is maintained while enhancing workflow efficiency. The technology supports continuous updates and scalability, making it adaptable to evolving PDM systems and industry requirements, allowing organizations to uphold high-quality standards throughout the product lifecycle.

Benefits

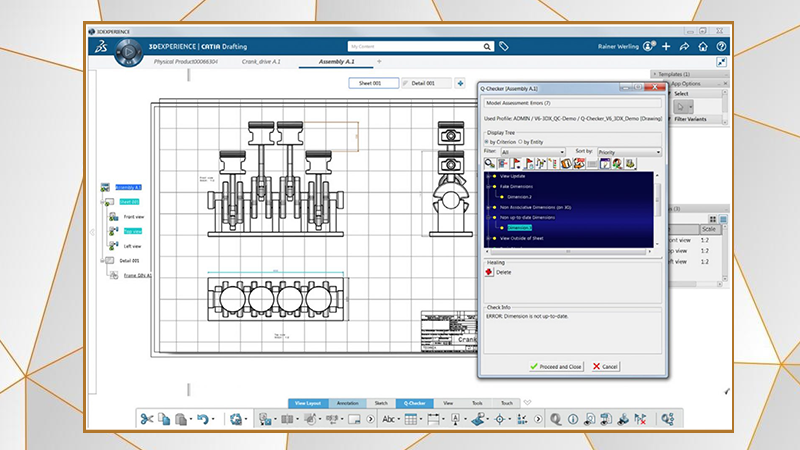

Model Data Quality

Automated checks across the PDM lifecycle enhance model data quality, reduce repairs, and ensure accuracy, minimizing errors and streamlining development. This results in fewer revisions and greater efficiency in design and manufacturing.

Quality Information

Quality information is displayed in the Product Data Management (PDM) system using PDM attributes and Q-Checker reports to ensure that product designs meet required standards, specifications, and quality checks.

Standard Components

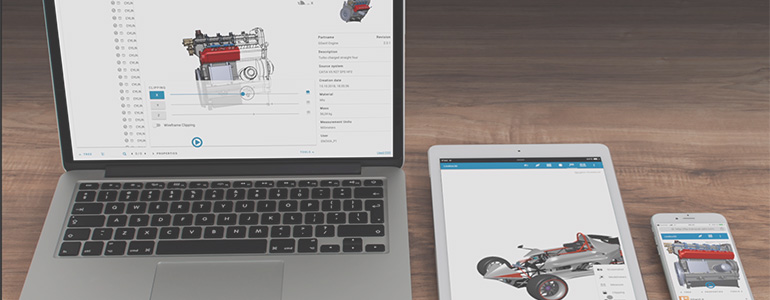

Q-PLM offers standard components for easy integration into the PLM environment, streamlining setup, improving data accuracy, and boosting collaboration across teams for faster product development.

Implementation

Low implementation effort ensures quick setup and minimal disruption to existing processes, enabling rapid adoption, seamless integration, and smooth transition with minimal downtime and reduced risk.

Compatible

Fully compatible with upcoming versions of CATIA and Q-Checker, ensuring future-proof integration, seamless updates, and sustained efficiency as new features, improvements, and enhancements are released.

Latest Blog Posts

Discover our most recent posts across all industries, brands and topics