It specializes in advanced additive manufacturing (AM) technologies, particularly in the areas of 3D printing and direct energy deposition (DED). These cutting-edge technologies are used in aerospace and defence applications to enable more efficient manufacturing processes, enhance part performance, and reduce costs. By leveraging these innovations, industries can create more complex and durable components, streamline production workflows, and achieve higher precision, ultimately driving advancements in both performance and sustainability.

Product Capabilities for Aerospace and Defence

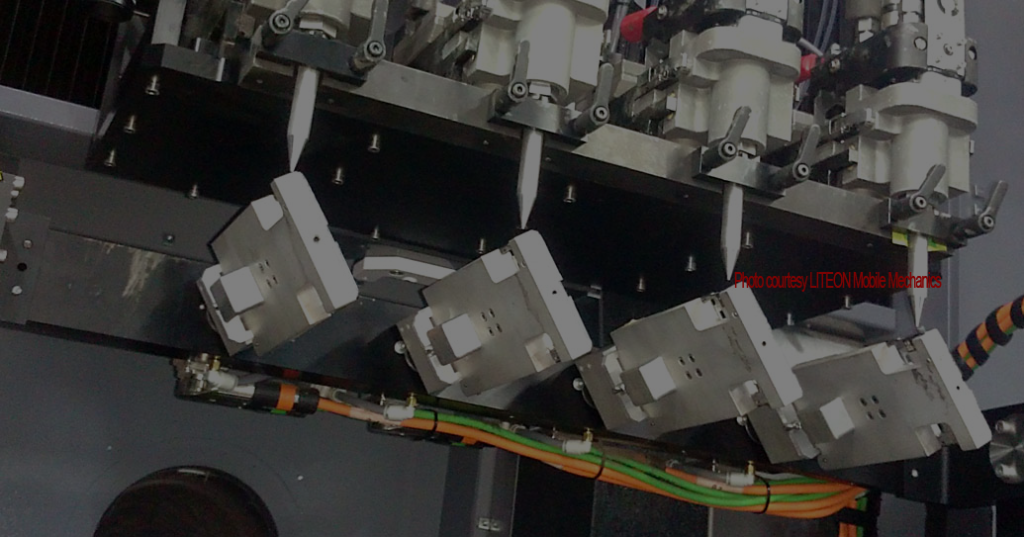

Blisk Repairing

LENS additive manufacturing technology is an ideal solution for blisk repairs because it offers precise, efficient, and high-quality restoration of damaged parts. By using laser-based metal deposition, this technology can restore the intricate geometries, materials, and mechanical properties of the blisk, ensuring its continued high performance in turbine and jet engine applications. The technology also reduces costs, waste, and downtime, making it a valuable solution for the aerospace and power generation industries. With its ability to deliver reliable, on-demand repairs, this approach helps extend the life of critical components, improve operational efficiency, and reduce the need for expensive replacements.

Aircraft Blade Repairing

LENS 3D printing technology is revolutionizing aircraft blade repair by enabling precision restoration of turbine blades using additive manufacturing. The technology provides cost-effective, efficient, and high-quality repairs that restore the blades to their original strength and performance. By reducing material waste, minimizing downtime, and improving the durability of repaired parts, this solution helps extend the lifespan of critical aircraft components, ensuring safe and efficient operation in the aviation industry. This approach not only enhances operational reliability but also contributes to significant cost savings and sustainability in aircraft maintenance. Furthermore, it allows for on-site repairs, reducing the need for costly part replacements and improving overall fleet availability.

Additive repair of Turbine Parts

Additive manufacturing technologies, especially the LENS® system, offer significant benefits for the repair of turbine parts. By using precision metal deposition to restore damaged areas, this technology enables fast, cost-effective, and high-quality repairs that extend the life of expensive turbine components like blades, vanes, and other high-stress parts. Overall, additive repair technology for turbines provides a precise, efficient, and sustainable way to extend the life of critical turbine parts, reducing the need for costly replacements and improving the reliability and performance of turbines. This approach not only enhances operational efficiency but also supports long-term cost savings and sustainability in industrial applications.

Explore Optomec 3D Printers

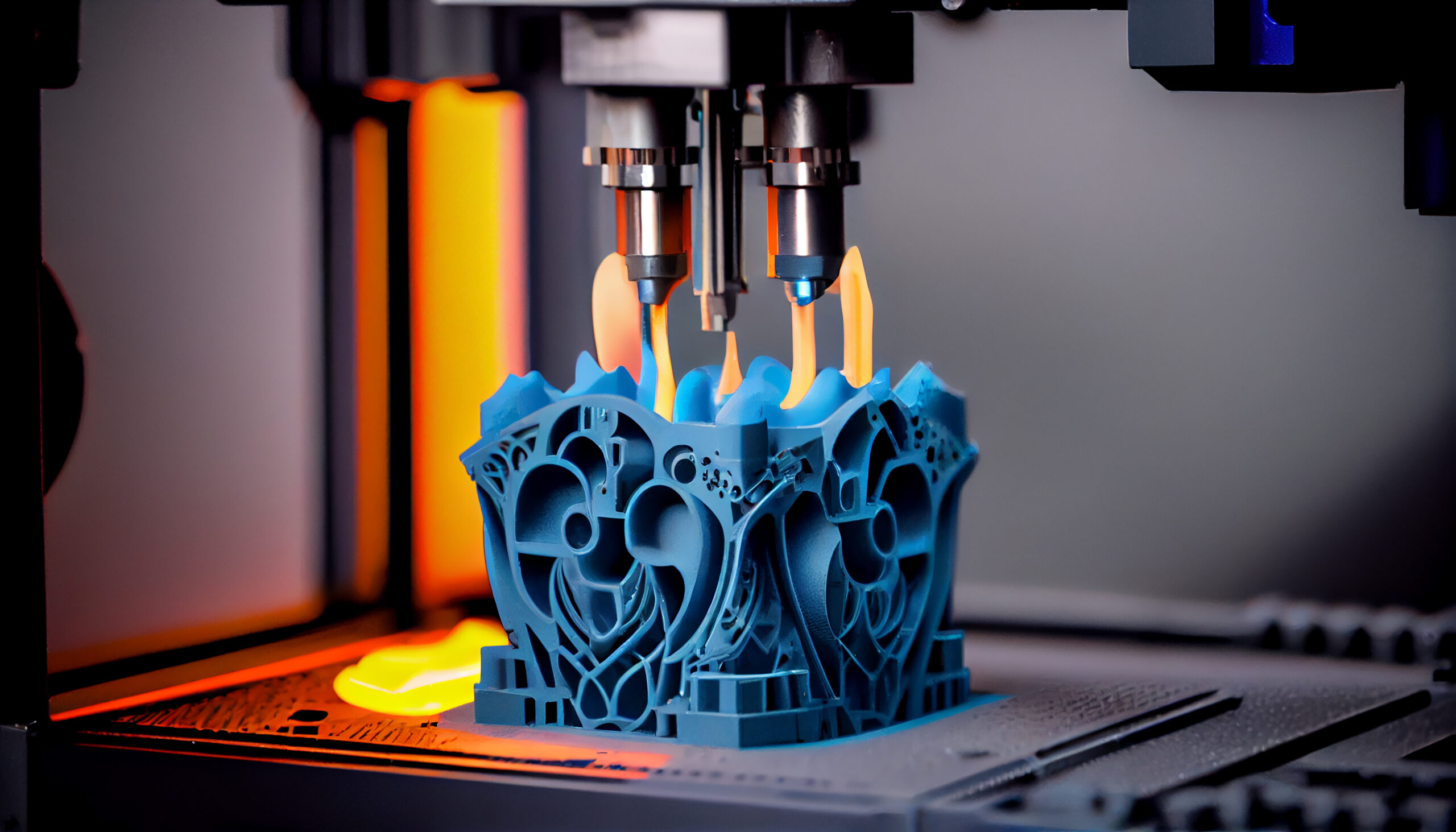

3D Metal Printer

Unleashing precision and power- 3D Metal Printer transforms metal powder into complex, high-performance parts with laser precision, layer by layer

3D Electronic Printer

Precision in every print- 3D Electronic Printer delivers fine-featured circuits and components directly onto substrates with unmatched accuracy