The 3D printing technologies, particularly the Aerosol Jet and LENS (Laser Engineered Net Shaping) systems, are widely used in the high-tech industry for a variety of advanced applications. These technologies allow for the production of highly complex, precise, and functional components that are critical to high-tech industries such as electronics, aerospace, automotive, and renewable energy. Their ability to work with a wide range of materials, including metals, polymers, and ceramics, enables innovation across multiple sectors. As industries demand faster production times and more customized solutions, these advanced 3D printing systems continue to play a key role in shaping the future of manufacturing.

Product Capabilities for High Tech

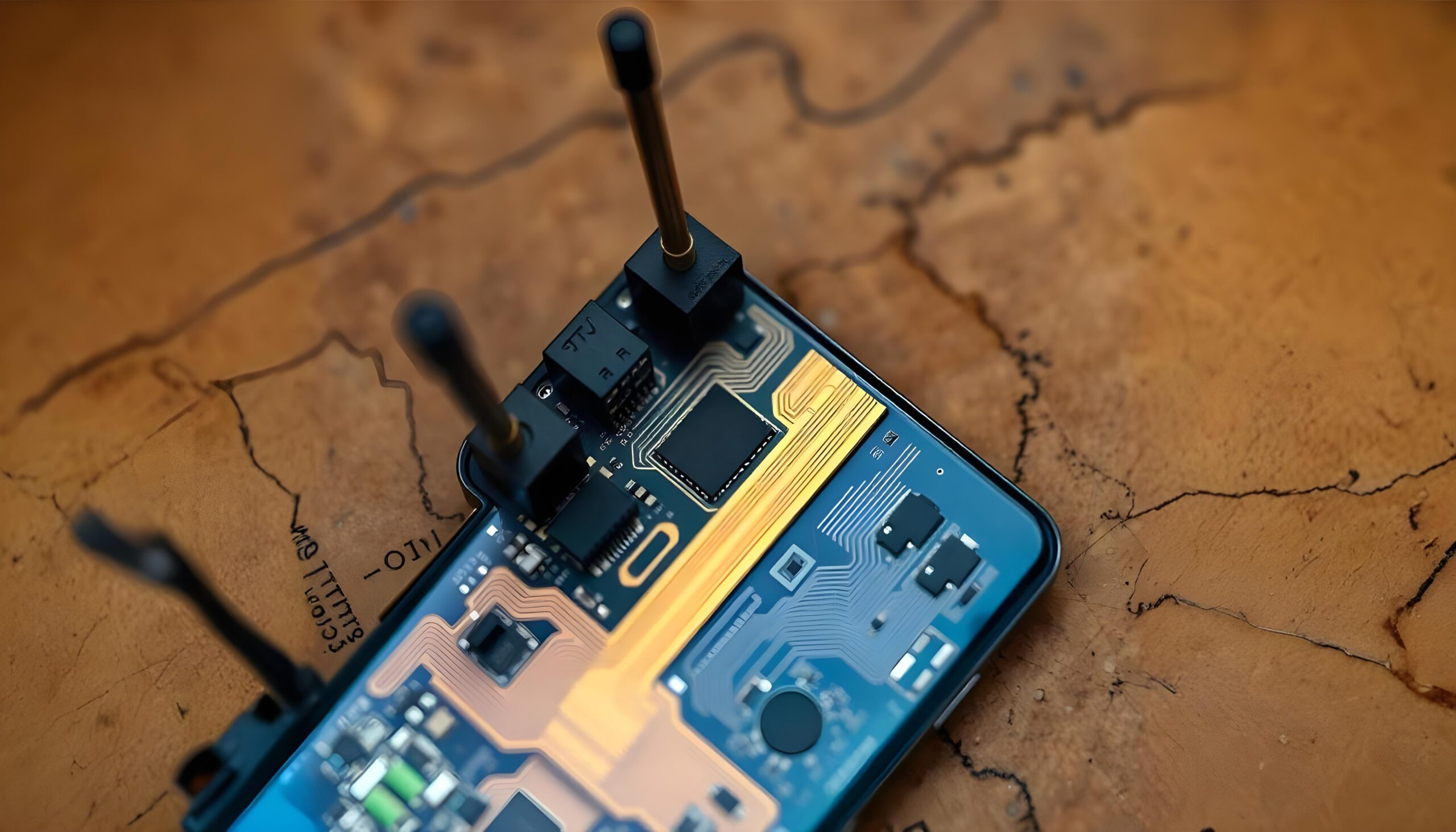

Printed Antenna

Aerosol Jet Printing technology is revolutionizing the design and manufacturing of printed antennas. By offering high-precision printing, material flexibility, and conformal capabilities, it enables the creation of customized, high-performance antennas for a wide range of applications, from 5G communications to wearable devices. Its ability to create intricate designs, minimize material waste, and facilitate rapid prototyping makes it a powerful tool for the next generation of wireless technology.

High Frequency RF Connects

As RF package frequencies exceed 60 GHz, traditional interconnect techniques face limitations due to decreasing line widths and substrate thickness. Aerosol Jet printing of 3D interconnects provides a solution, allowing precise customization of impedance for transition interconnects. This approach minimizes signal degradation and reflection by eliminating impedance mismatch. The printed interconnects can be designed in any shape or thickness, with line widths as small as 10 microns, supporting frequencies beyond 100 GHz. Their conformal design integrates seamlessly into the package, reducing trace length and eliminating air gaps, lowering transition loss by up to 50%.

Print on Un-Packaged Die

Aerosol Jet Printing provides significant advantages in the direct printing of interconnects on un-packaged semiconductor dies. It allows for high-precision, low-loss, and customizable interconnects essential for RF, high-frequency, and advanced semiconductor applications. By enabling design flexibility, eliminating the need for wire bonding, and improving overall device performance, this technology supports the development of smaller, more efficient, and higher-performing electronics.

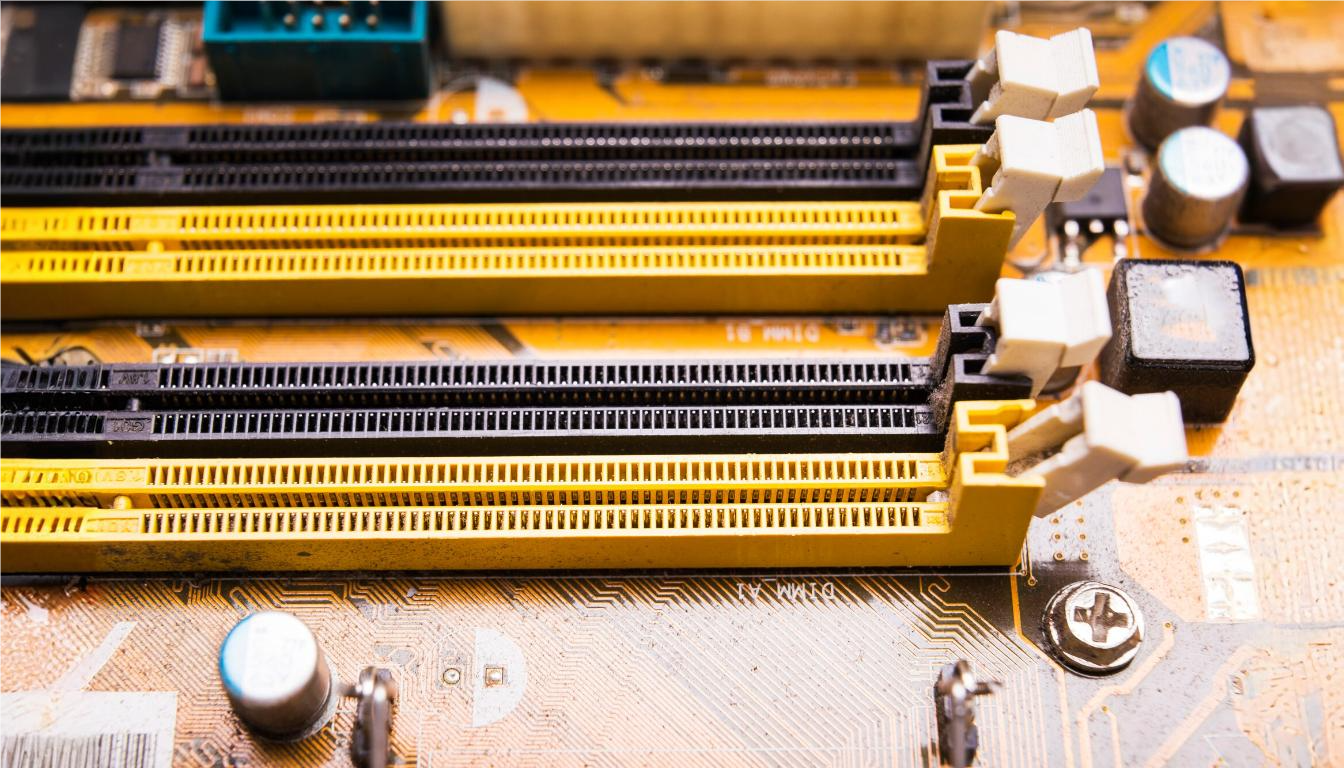

Stacked Die DRAM

Aerosol Jet Printing technology plays a key role in advancing the manufacturing of stacked die DRAM by enabling precise interconnects, customizable impedance, and high-density packaging. The ability to directly print fine interconnects on semiconductor dies helps reduce complexity, improve performance, and lower costs in the production of stacked die DRAM, making it a crucial technology for next-generation memory devices used in high-performance computing, mobile devices, and beyond.

Touch Screen Display

Aerosol Jet technology is being utilized to enhance performance and lower manufacturing costs of touchscreen displays. By printing interconnects as narrow as 30 microns, this technology reduces the space needed for edge circuits, increasing the usable area of the display. Additionally, it shows promise in improving the quality and reducing the cost of capacitive touchscreen displays. The process involves applying a base layer of dielectric material, followed by a printed 10-micron wide conductor to create bridge or jumper circuits on pre-patterned ITO. This approach streamlines the process and reduces the steps and costs of traditional manufacturing methods.

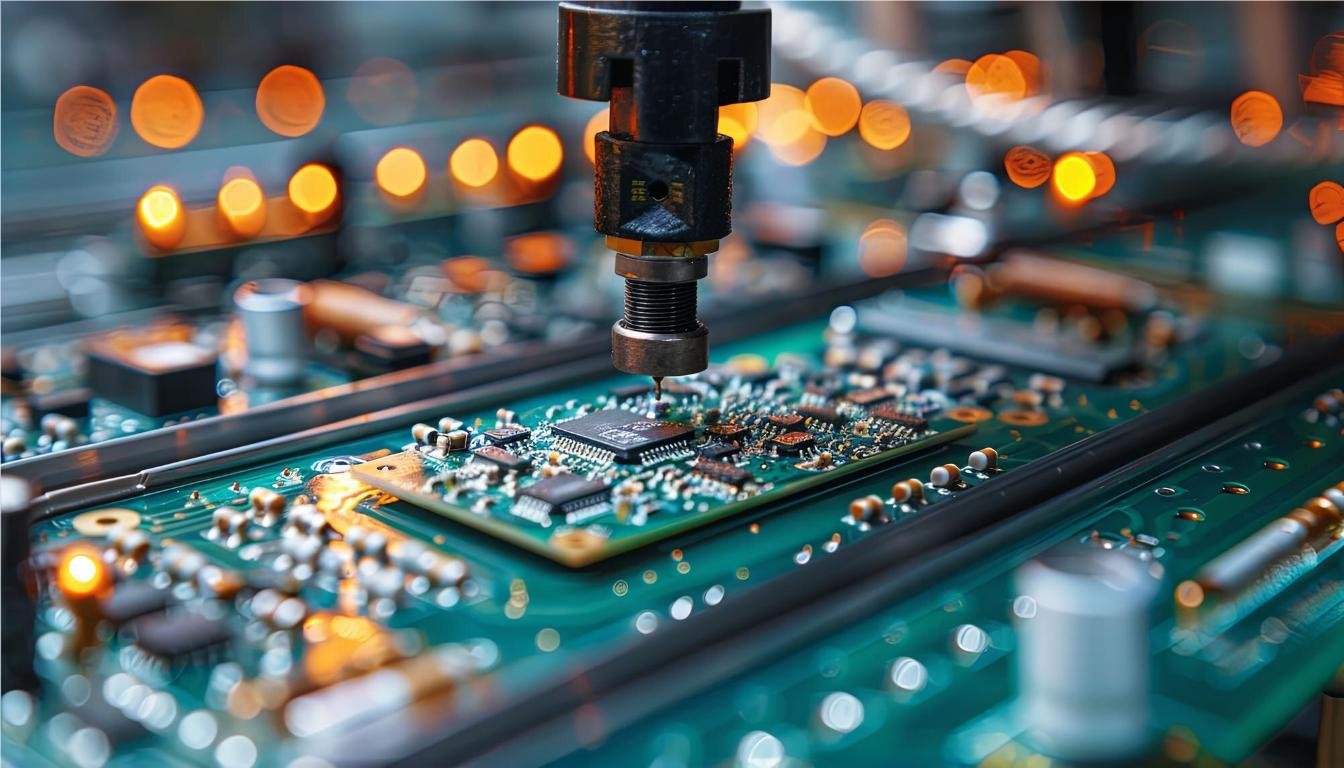

Semiconductor Packaging

Aerosol Jet Printing technology is revolutionizing semiconductor packaging by providing precise, efficient, and customizable solutions for creating interconnects, reducing manufacturing costs, and enabling advanced packaging techniques. It supports the production of high-performance, miniaturized, and cost-effective semiconductor packages, driving innovation in areas like 3D ICs, system-in-package, flexible electronics, and RF communication systems. This helps meet the increasing demand for smaller, faster, and more powerful electronic devices.

Explore Optomec 3D Printers

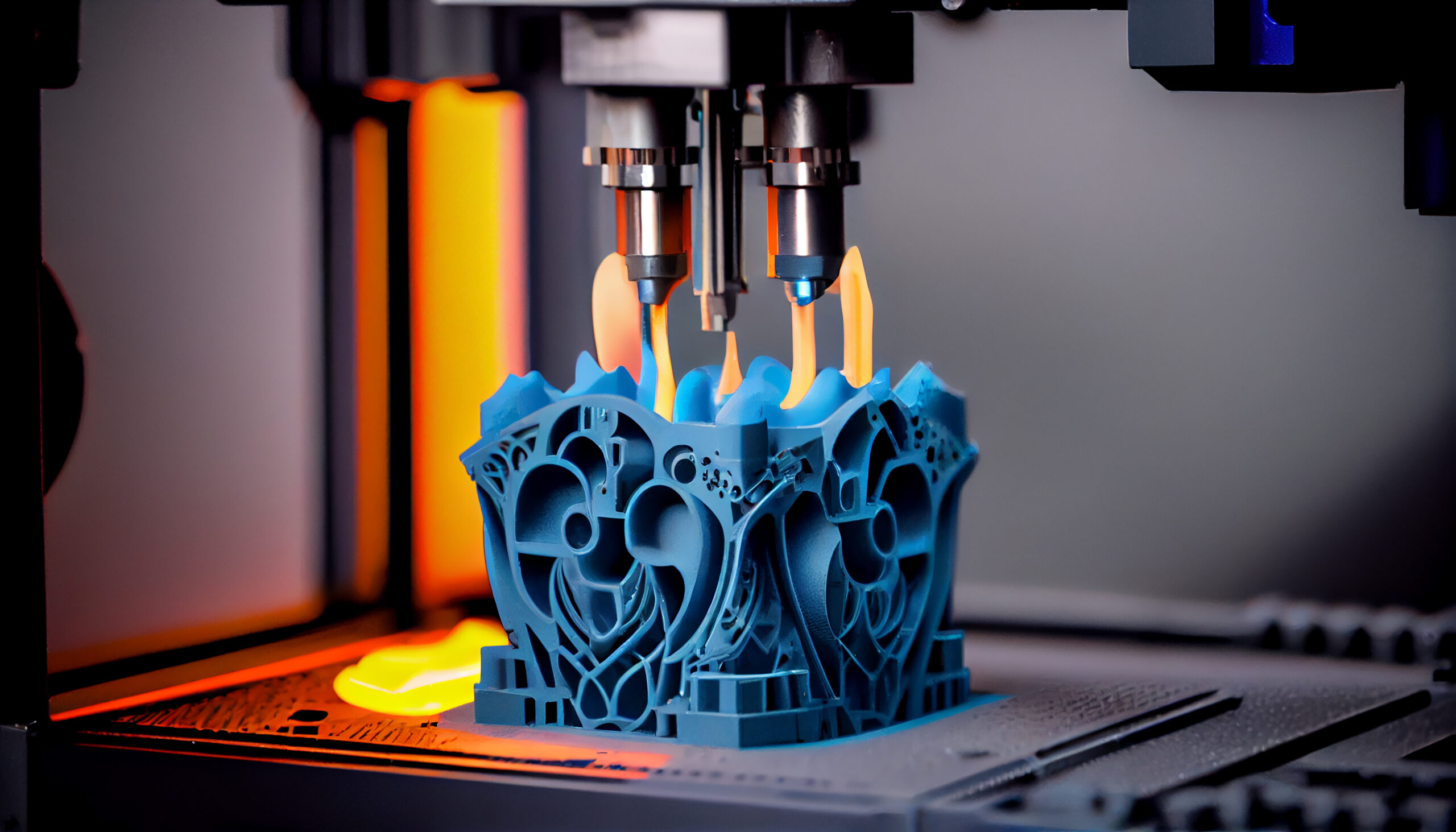

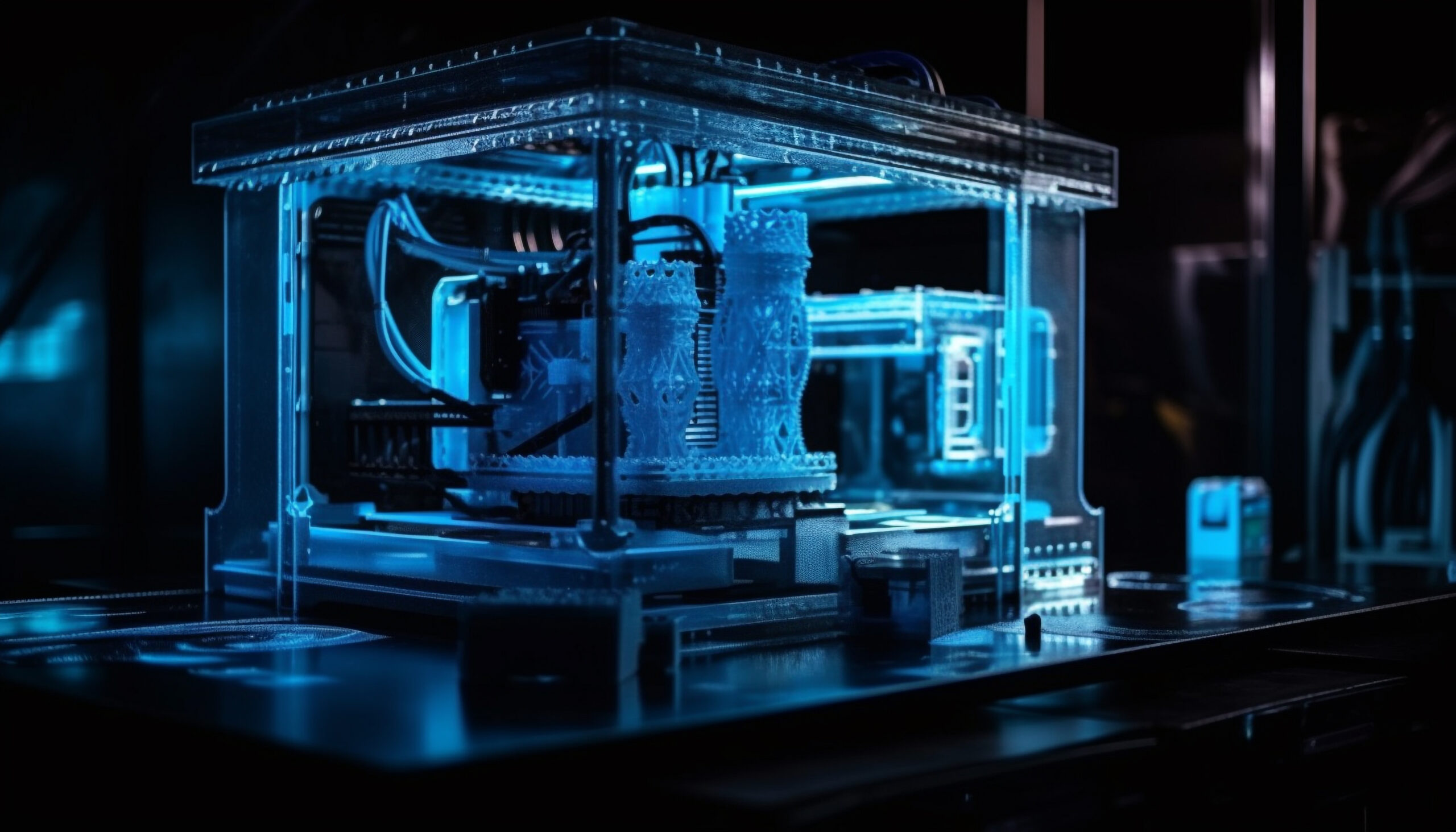

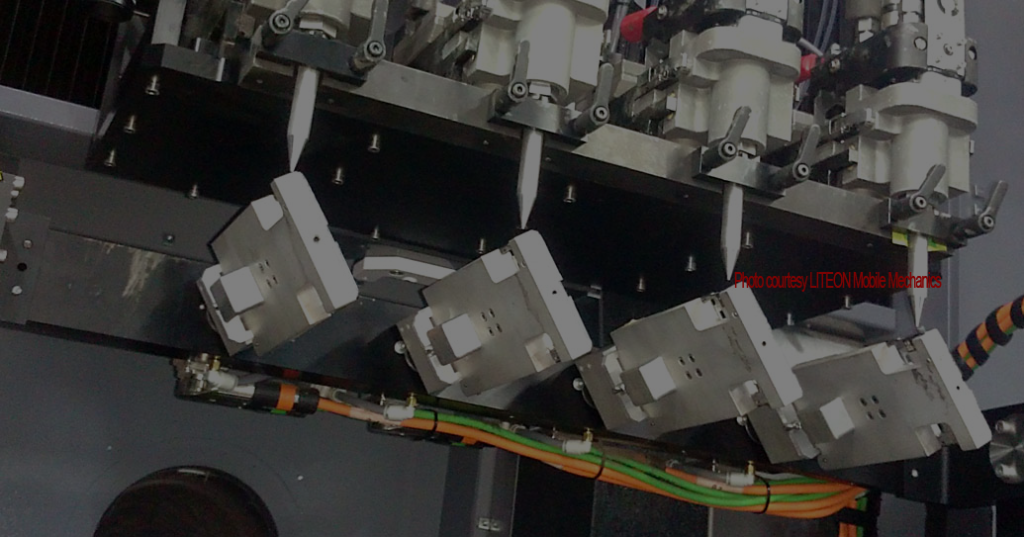

3D Metal Printer

Unleashing precision and power- 3D Metal Printer transforms metal powder into complex, high-performance parts with laser precision, layer by layer

3D Electronic Printer

Precision in every print- 3D Electronic Printer delivers fine-featured circuits and components directly onto substrates with unmatched accuracy