CATIA empowers the Industrial Equipment industry by offering a comprehensive platform for design, engineering, simulation, and manufacturing. Its parametric design capabilities enable rapid customization and modification, while its precision tools ensure accurate and efficient creation of complex machinery and equipment. Through integration and collaboration, CATIA helps manufacturers innovate faster, improve product quality, and streamline production to meet evolving market demands and maintain competitiveness.

Product Capabilities for Industrial Equipment

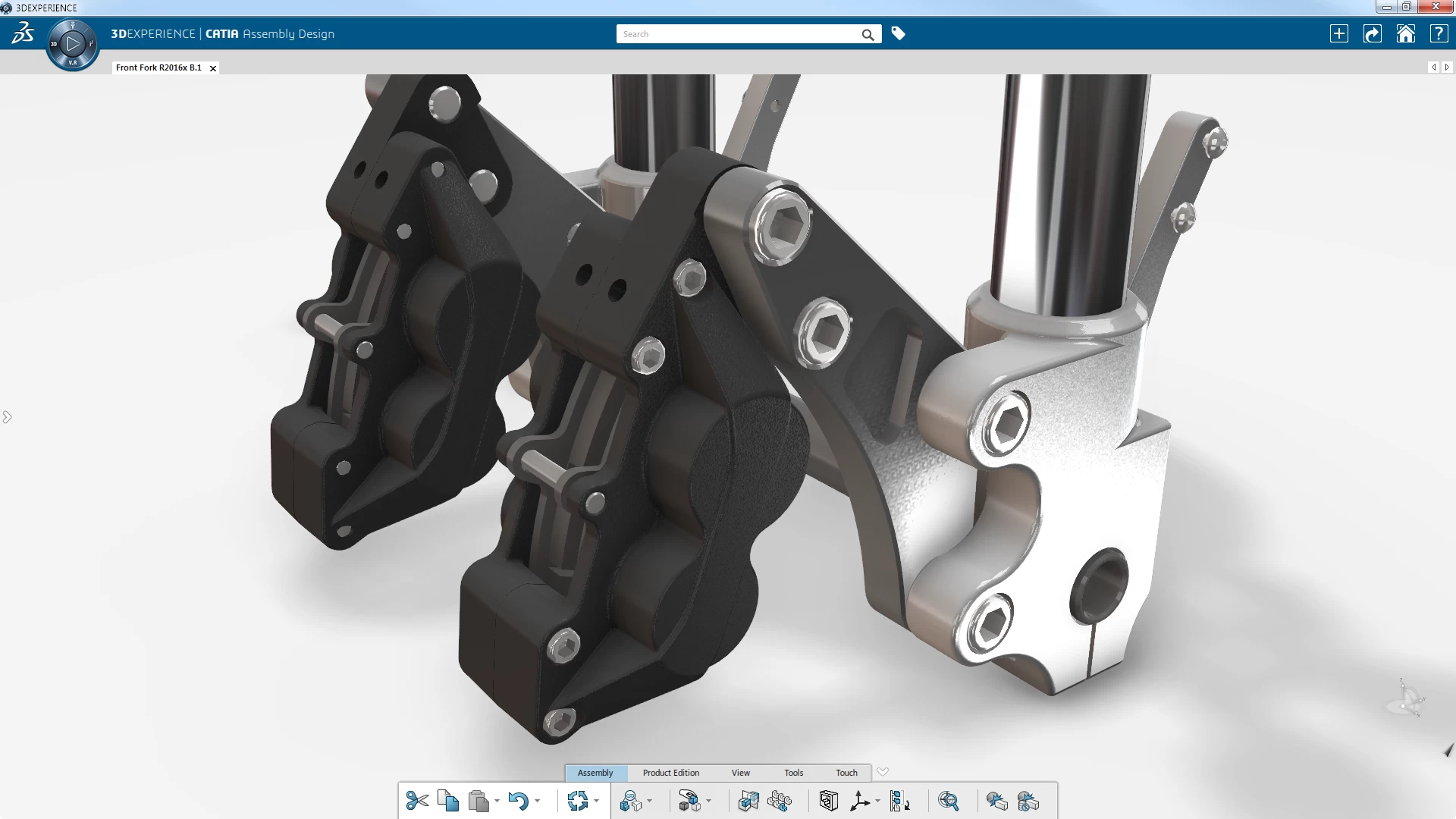

Equipment Mechanical Engineering

The Equipment Mechanical Engineering process allows complete mechanical design and engineering of very complex equipment in a multi-discipline environment leveraging instant collaboration across the company. this process includes simulation for designers and engineers allowing structural simulation to be carried over without the need to get simulation analysts assistance.

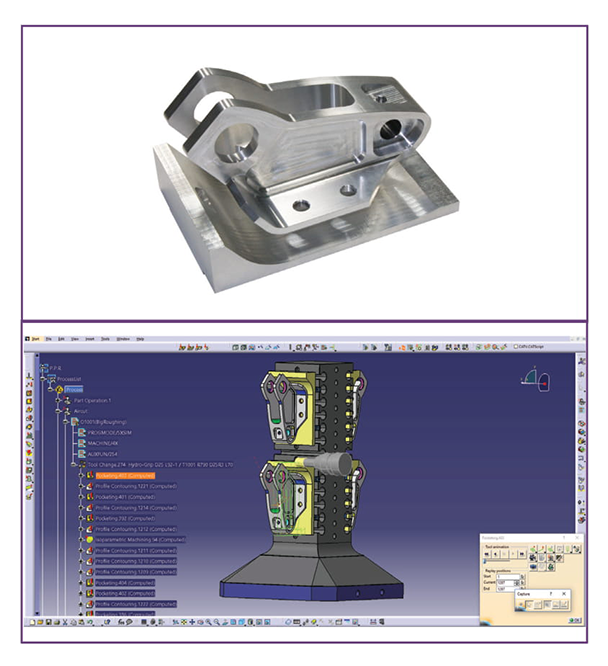

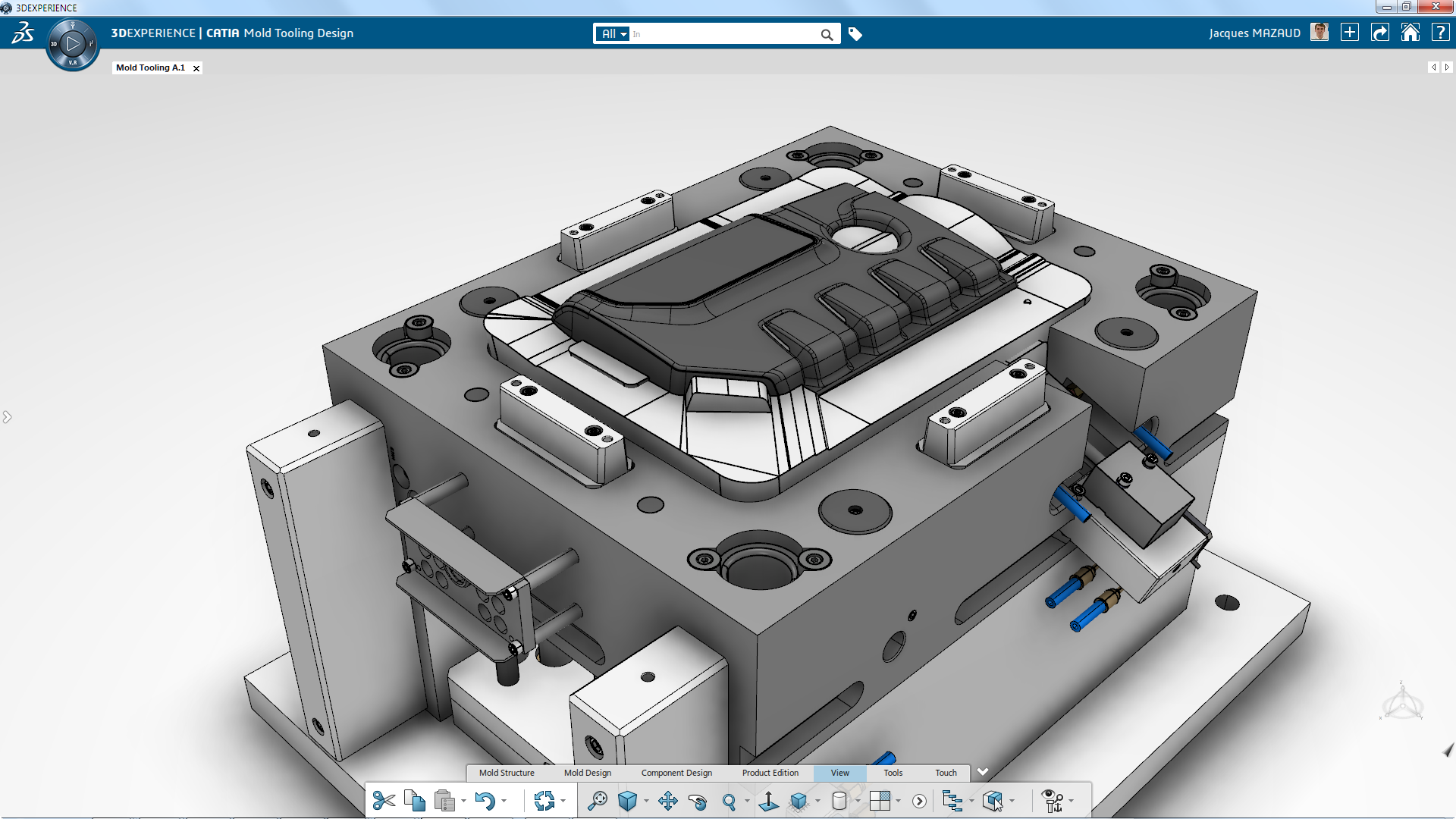

Mold Engineering and Machining

The Mold & Tooling process enables a flexible and highly customizable approach from conceptual and detailed mold tooling design to machining. It enables the user to automate design tasks and assist user decision-making at any step of a complex mold design. It enables also capabilities to validate and optimize plastic parts and mold tooling designs by simulating the filling, packing, warpage & mold cooling.

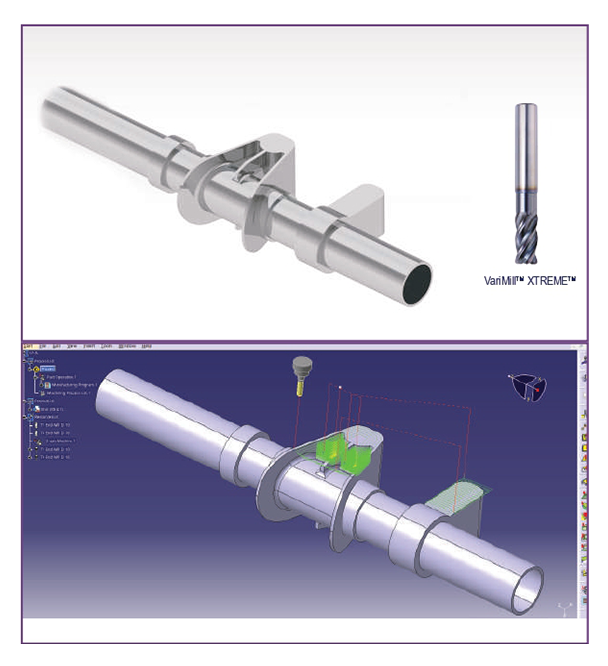

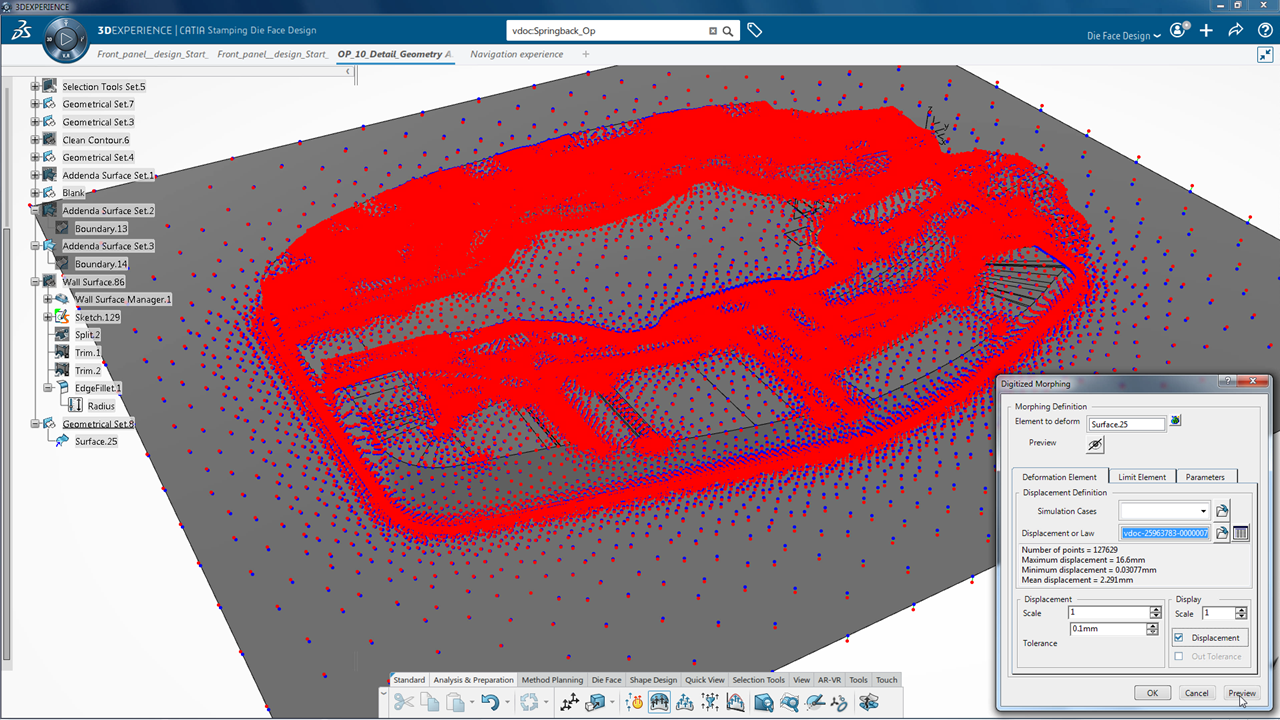

Stamping Die Engineering and Machining

A complete coverage of the stamping die manufacturing process from Engineering to Machining in a single digital thread, Enables a complete coverage of the stamping die manufacturing process from Engineering to Machining in a single digital thread without any geometry transfer

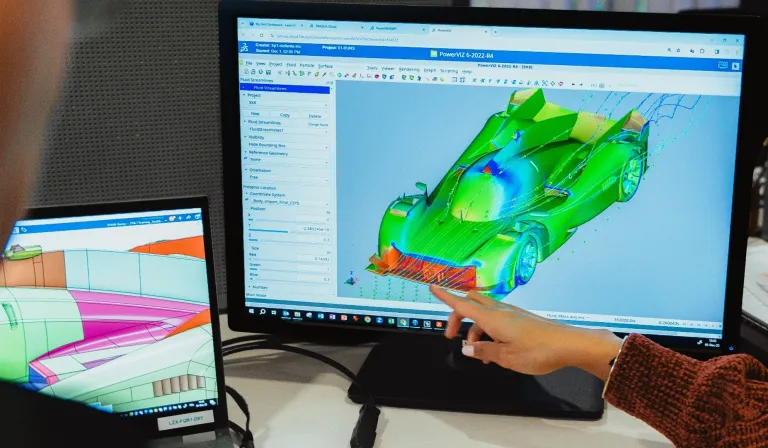

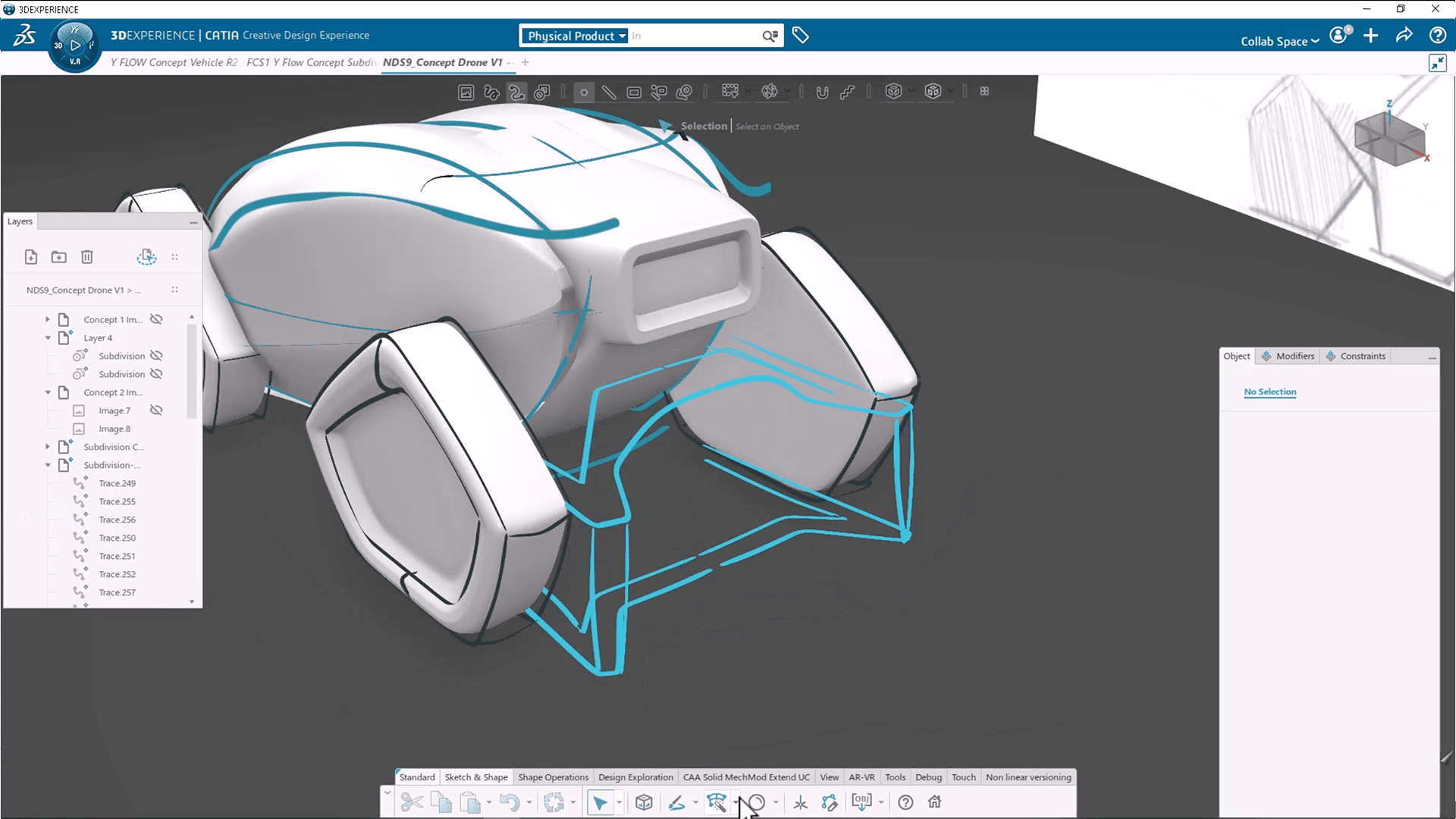

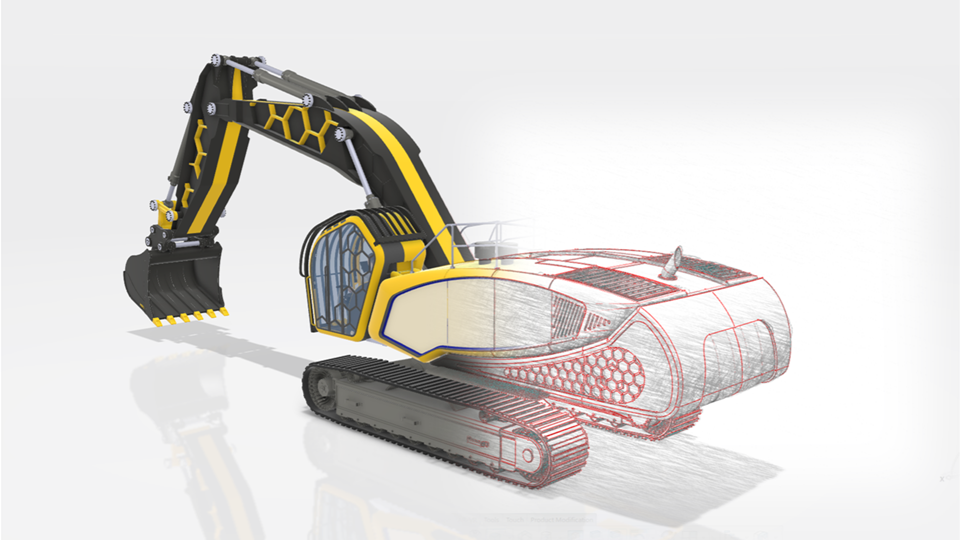

Heavy machinery creative design and styling

A complete and unified Industrial Design process to boost collaborative innovation and design experience thinking. A unified Industrial Design workflow solution, addressing the Industrial Equipment design development process with an integrated and complete solution. The process

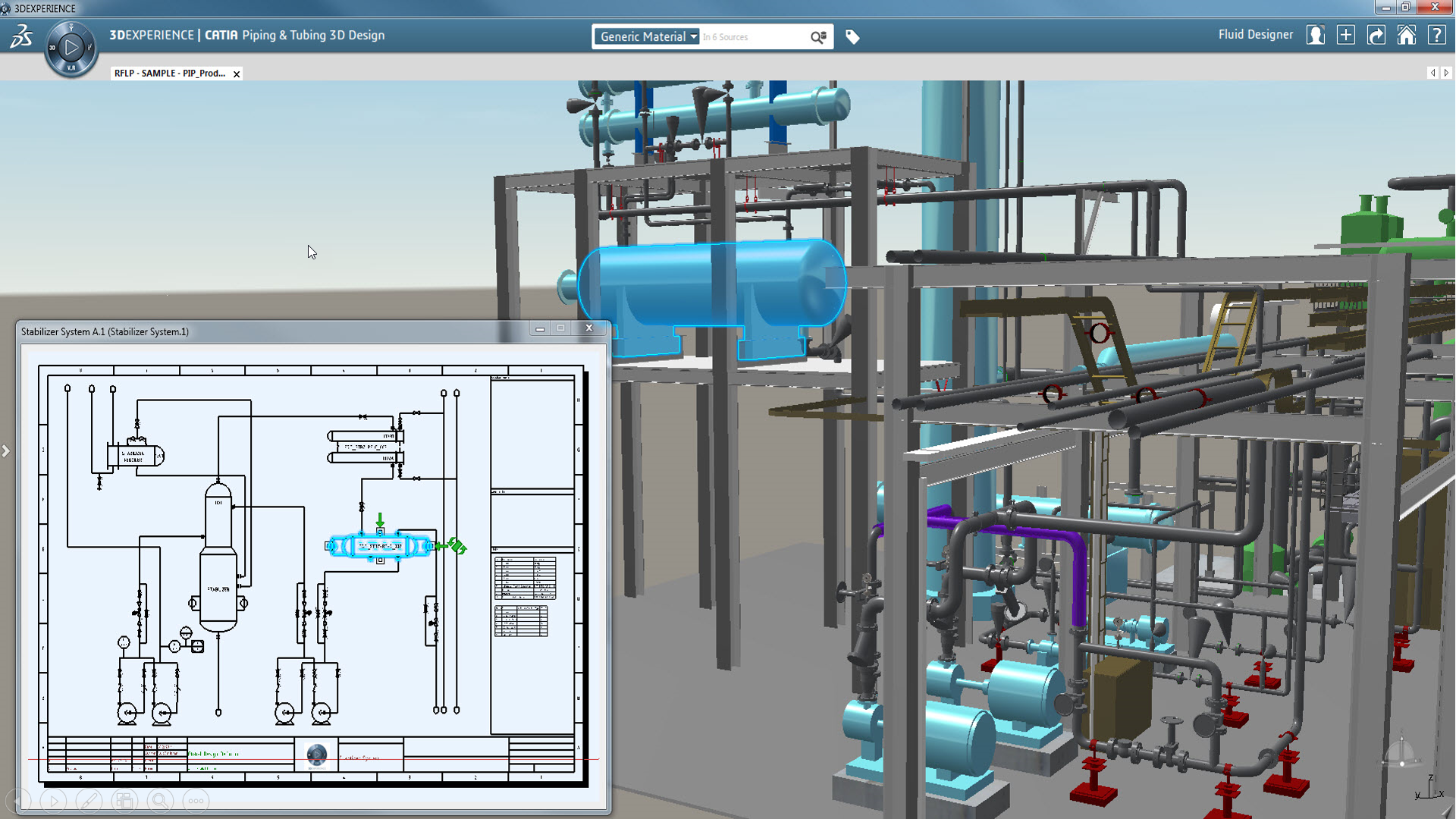

Piping, Tubing and HVAC System Design

Improve Piping & Tubing engineering while reducing time and cost in an end- to-end process from requirements to manufacturing

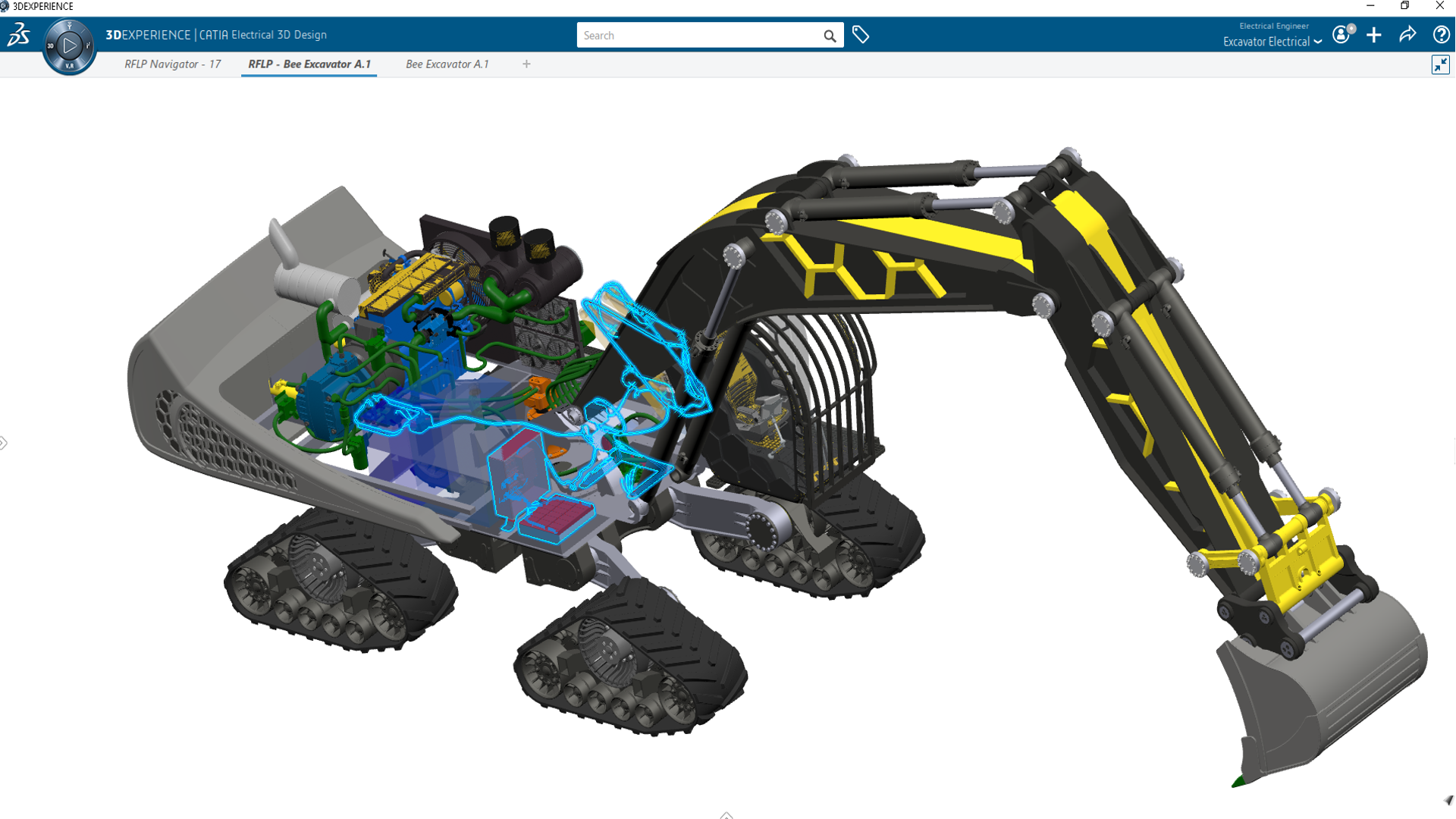

Heavy Machinery Electrical and Control Systems

An integrated End-to-End electrical development process from schematics through 3D design up to manufacturing preparation, to ensure regulatory compliance to electromagnetic standards with EMC/EMI integrated simulations.

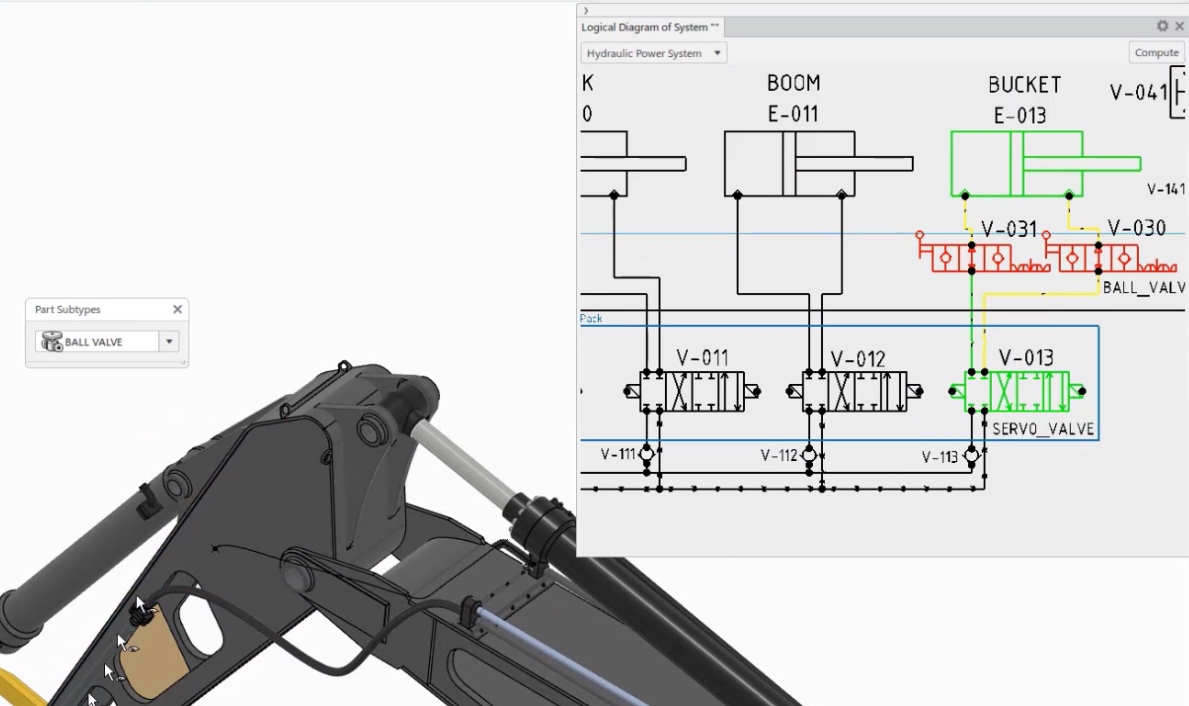

Heavy Machinery Hydraulic Systems

This process provides an integrated End to End Piping, Tubing and HVAC systems development environment which enables the complete design of fluid systems

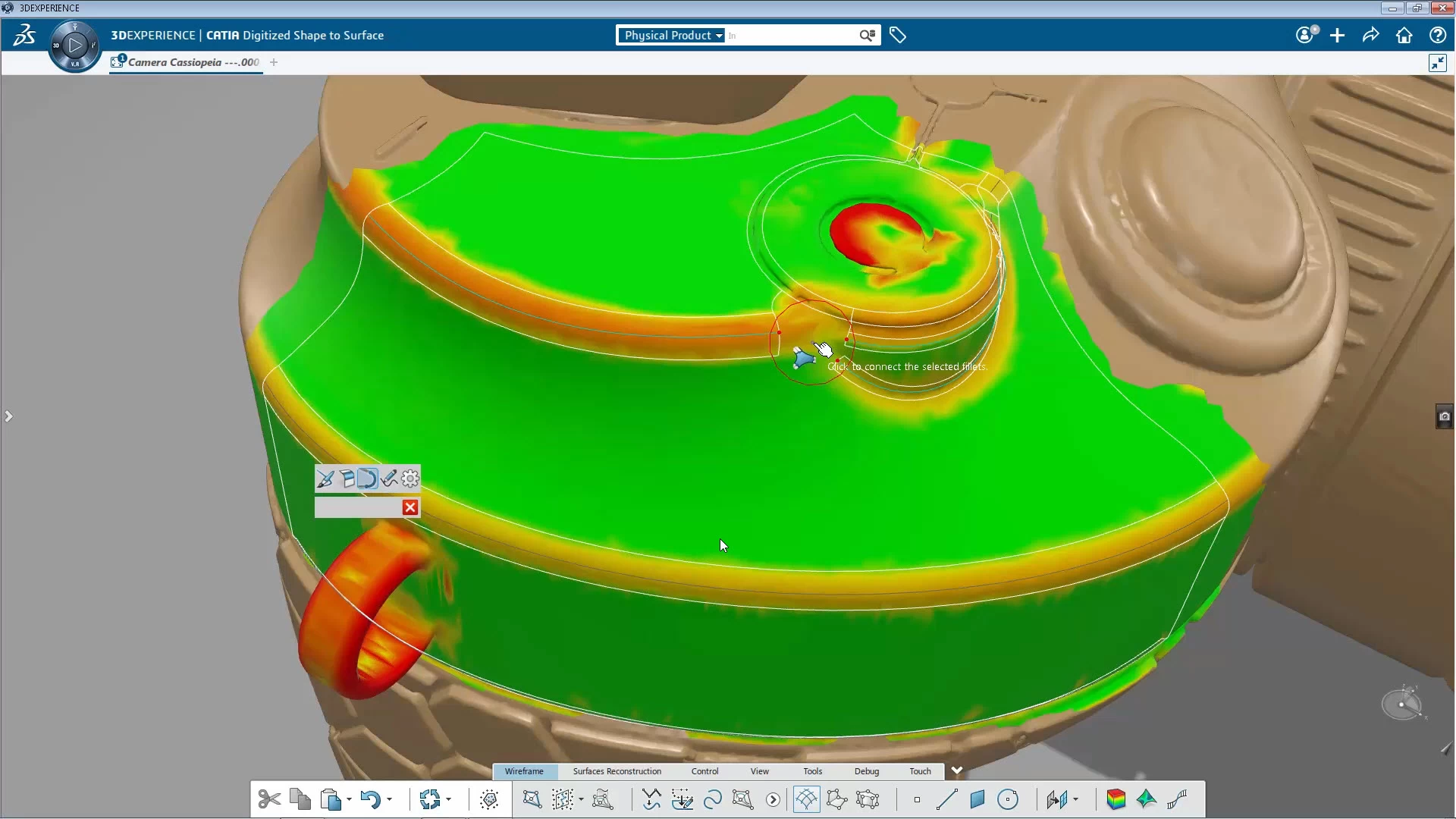

Reverse Engineering

Digital 3D design data of a piece of equipment is often not available, especially on legacy products