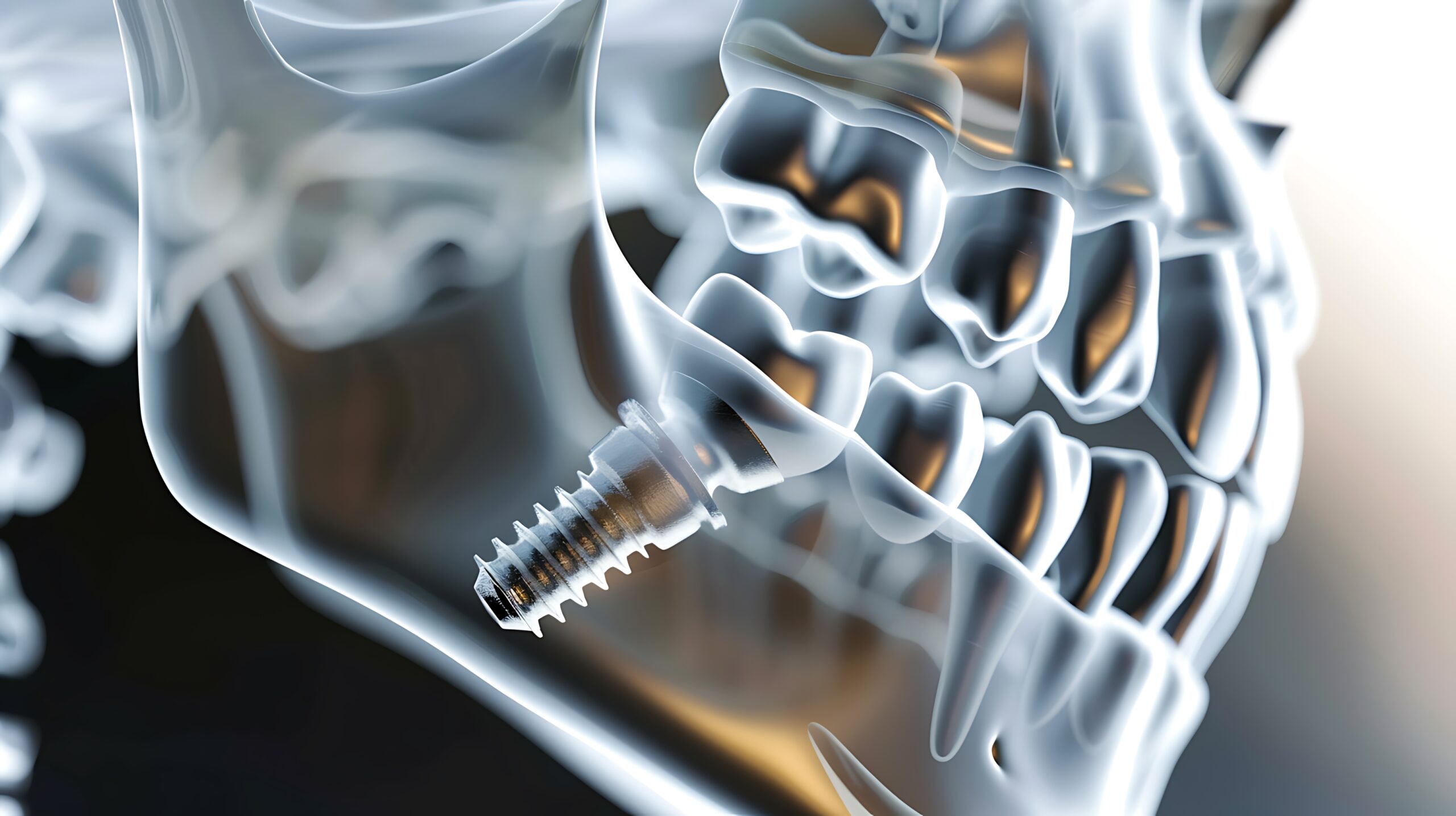

Implants and Prosthetics

Optimize the design and fit of implants and prosthetics using advanced structural and biomechanical simulations, while enabling patient-specific solutions through high-performance additive manufacturing, resulting in improved outcomes and faster recovery times. This approach enhances customization, ensuring a perfect match for each patient’s unique anatomy.

Solutions for Implants and Prosthetics

Ensuring Design Reliability for Consistent Performance

Design reliability is a key factor in ensuring that products perform as expected throughout their lifecycle, with minimal risk of failure. In industries ranging from automotive to aerospace, electronics to consumer goods, the ability to design products that can withstand real-world conditions while maintaining performance and durability is crucial.

Advanced Composite Design for High-Performance Applications

Composite materials are increasingly being used across industries like automotive, aerospace, and defense due to their exceptional strength-to-weight ratio and ability to withstand harsh conditions. However, designing composites requires specialized tools to optimize material usage, ensure structural integrity, and meet performance standards. Advanced composite design involves not only sele

Streamlining Project Management with Data-Driven Insights and Collaboration

In today’s fast-paced environment, data-driven project management is essential for ensuring projects are delivered on time and within budget. By leveraging real-time data, teams can track progress, manage resources efficiently, and identify risks early. This approach enables quick decision-making, reduces delays, and optimizes project outcomes.

Products

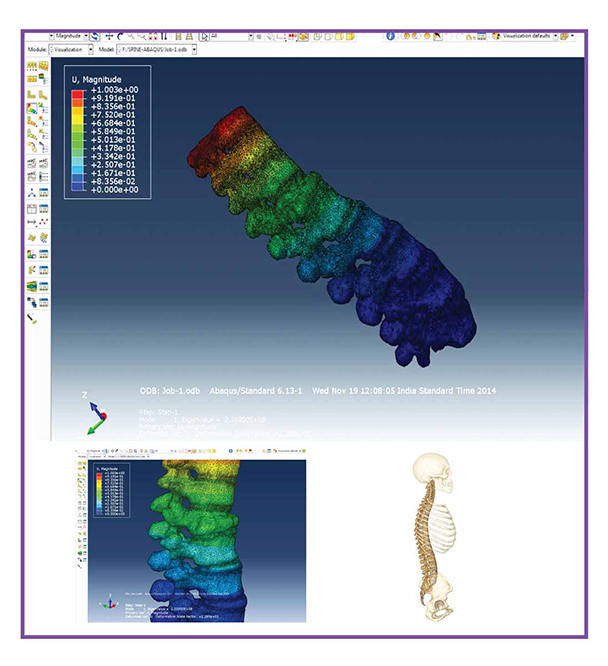

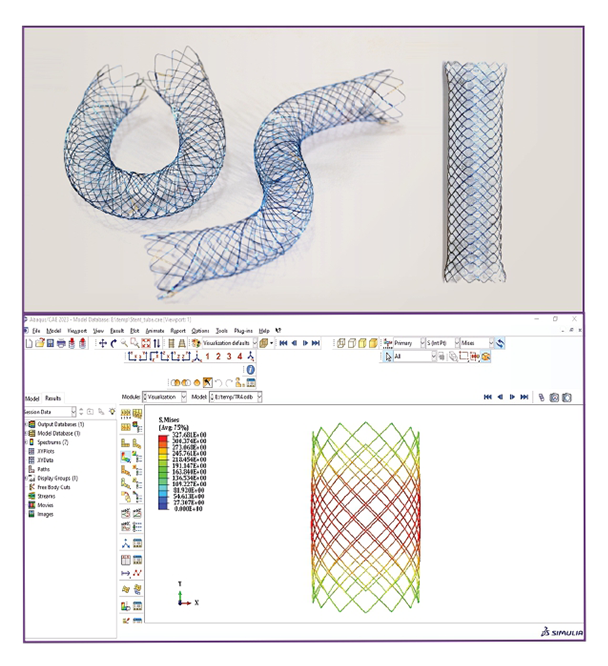

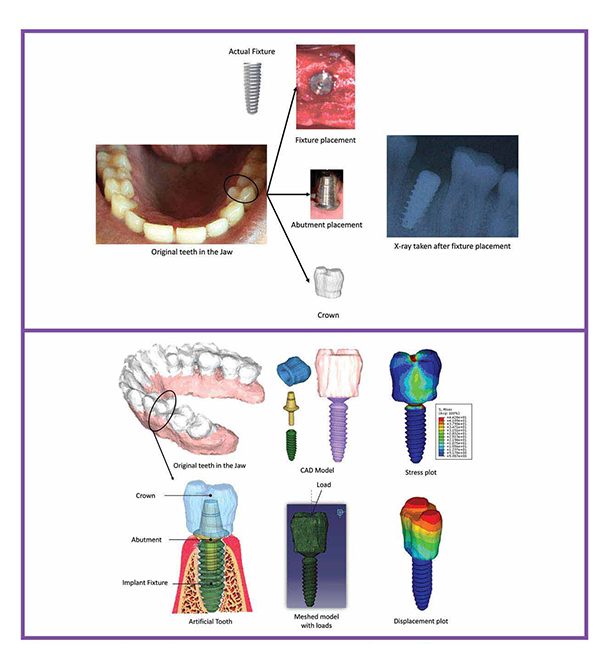

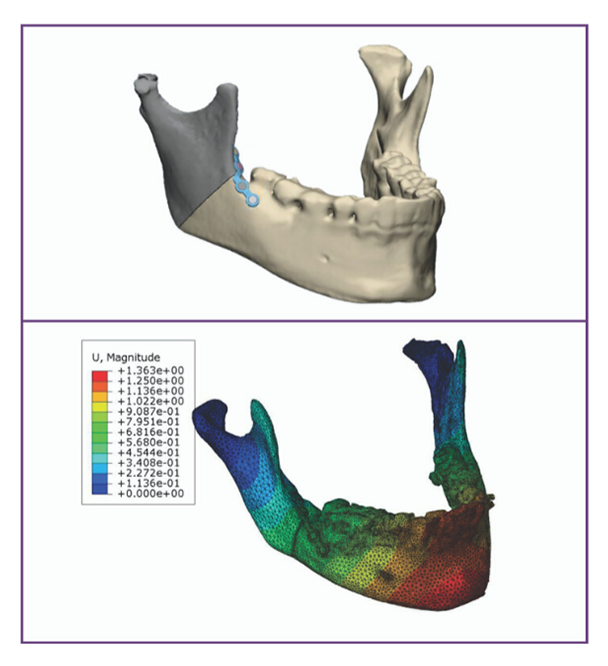

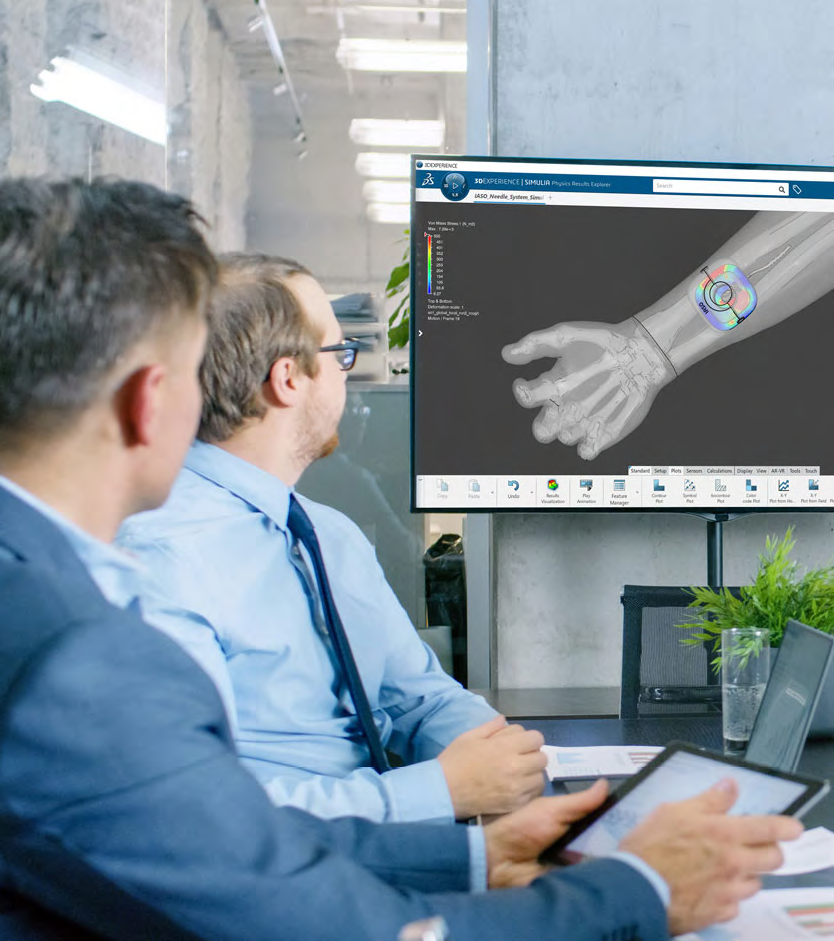

SIMULIA

Accelerate innovation in medical devices, implants, and prosthetics with advanced simulation and testing

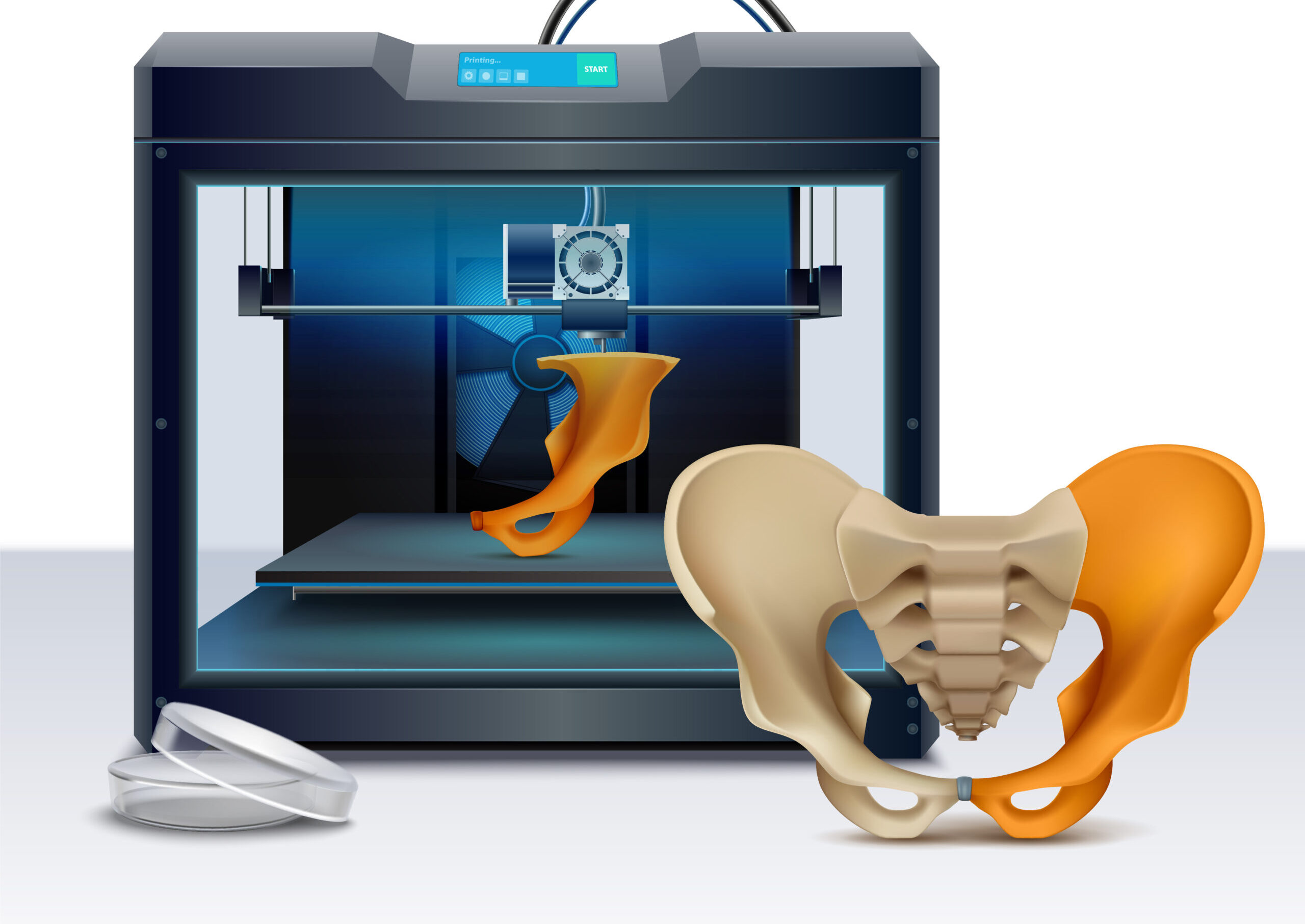

EOS 3D Printers

Revolutionize healthcare solutions with precision 3D printing for medical devices and implants

Optomec 3D Printers

Optomec specializes in advanced 3D printing technologies, enabling the additive manufacturing of high-performance materials such as metals and functional inks for electronics and coatings

Trends

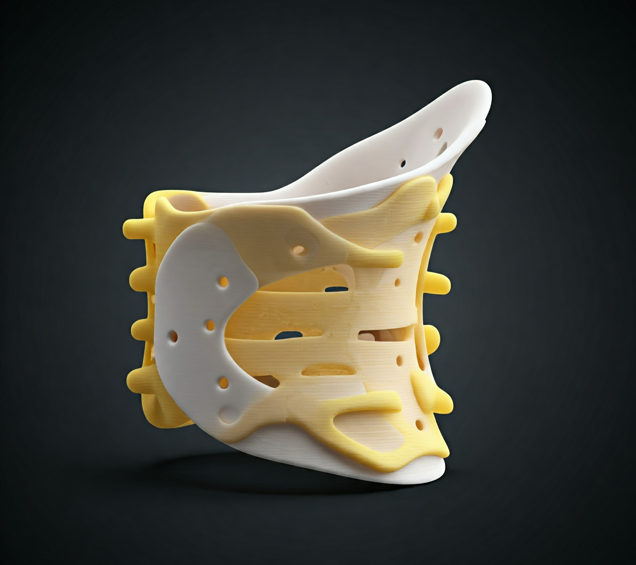

Enable Personalized Healthcare Solutions with 3D Printing for Custom Implants and Prosthetic

Personalized healthcare solutions are transforming the implants and prosthetics industry by enabling the creation of custom devices that are tailored to each patient's unique needs. However, challenges such as achieving precise fit, optimizing material properties, and ensuring regulatory compliance can hinder the development of high-quality custom implants and prosthetics. EOS and Optomec 3D Printers address these issues by offering advanced additive manufacturing technology that allows for the production of highly accurate, customized devices using biocompatible materials. With their ability to create complex geometries, fine-tune material properties, and ensure precise fit, these 3D printers improve the functionality, comfort, and performance of implants and prosthetics, while accelerating the production process and enhancing patient outcomes.

Enhance Patient Comfort and Functionality with 3D Printed Prosthetics

Enhancing patient comfort and functionality is critical in the prosthetics industry, where the goal is to create devices that not only fit well but also improve the quality of life for users. However, challenges such as achieving the right fit, ensuring durability, and personalizing prosthetics to meet individual needs can complicate the design and manufacturing process. EOS and Optomec 3D Printers address these challenges by enabling the creation of custom prosthetics with precise geometries and personalized features. These 3D printers use

From Standardization to Personalization in Patient Care Solutions

The shift from standardization to personalization in patient care solutions is transforming healthcare by providing treatments and devices tailored to individual patient needs. However, challenges such as the limitations of mass-produced solutions, achieving precise customization, and ensuring both functionality and comfort can hinder this shift. EOS and Optomec 3D Printers help overcome these challenges by enabling the production of personalized medical devices, such as prosthetics and implants, using adva

Optimize Orthotic Performance with EOS 3D Printing for Lightweight, Durable Designs

Optimizing orthotic performance is essential for improving patient comfort, mobility, and overall quality of life. However, challenges such as achieving the right balance between lightweight design and durability, as well as ensuring a precise fit for individual patients, can make the production of high-performance

Latest Blog Posts

Discover our most recent posts across all industries, branchs and topics.

Revolutionize Medical Device Industry with Sustainable Innovation

The healthcare industry, alternatively referred to as the medical industry or the health economy, encompasses a diverse range of economic sectors dedicated to providing products…