Other Trends

Enable Personalized Healthcare Solutions with 3D Printing for Custom Implants and Prosthetic

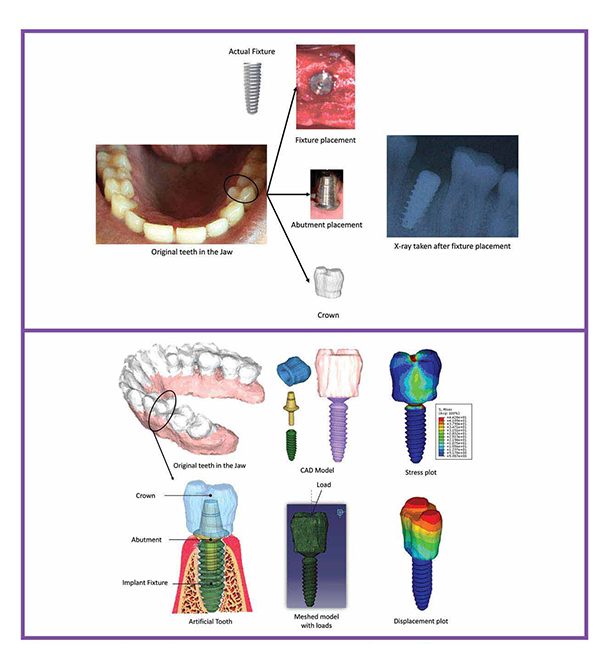

Personalized healthcare solutions are transforming the implants and prosthetics industry by enabling the creation of custom devices that are tailored to each patient's unique needs. However, challenges such as achieving precise fit, optimizing material properties, and ensuring regulatory compliance can hinder the development of high-quality custom implants and prosthetics. EOS and Optomec 3D Printers address these issues by offering advanced additive manufacturing technology that allows for the production of highly accurate, customized devices using biocompatible materials. With their ability to create complex geometries, fine-tune material properties, and ensure precise fit, these 3D printers improve the functionality, comfort, and performance of implants and prosthetics, while accelerating the production process and enhancing patient outcomes.

Enhance Patient Comfort and Functionality with 3D Printed Prosthetics

Enhancing patient comfort and functionality is critical in the prosthetics industry, where the goal is to create devices that not only fit well but also improve the quality of life for users. However, challenges such as achieving the right fit, ensuring durability, and personalizing prosthetics to meet individual needs can complicate the design and manufacturing process. EOS and Optomec 3D Printers address these challenges by enabling the creation of custom prosthetics with precise geometries and personalized features. These 3D printers use

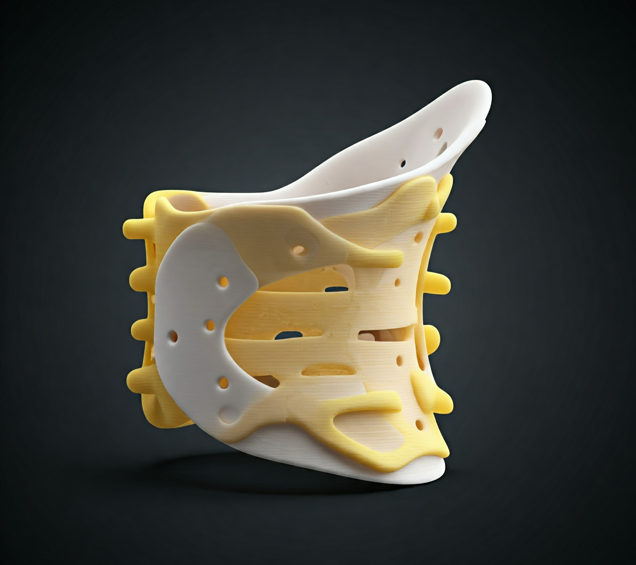

Optimize Orthotic Performance with EOS 3D Printing for Lightweight, Durable Designs

Optimizing orthotic performance is essential for improving patient comfort, mobility, and overall quality of life. However, challenges such as achieving the right balance between lightweight design and durability, as well as ensuring a precise fit for individual patients, can make the production of high-performance