Other Trends

Revolutionizing Wind Turbine Maintenance with 3D Printing for On-Demand Replacement Parts

Maintaining wind turbines involves challenges like costly downtime and delays in sourcing custom parts. Optomec's 3D printing technology is transforming this by enabling on-demand production of replacement parts directly at turbine sites. This reduces inventory needs, shortens repair times, and cuts operational costs. The precision and durability of Optomec's 3D printers allow for complex, custom parts, impro

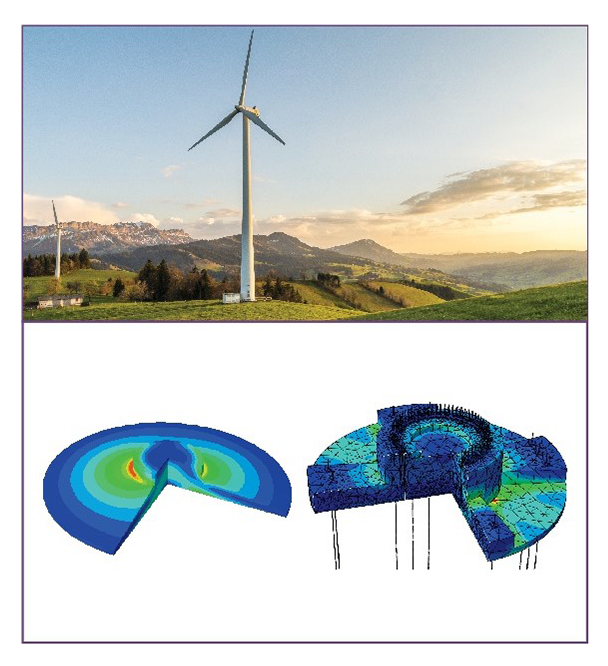

Enhancing Wind Turbine Blade Performance with Advanced Composite Materials Simulation

Wind turbine blades are crucial for maximizing energy capture, but designing them for optimal performance involves overcoming challenges like material fatigue, structural integrity, and weight optimization. The use of advanced composite materials has become essential in addressing these challenges, but simulating their behavior under real-world conditions is complex. EOS 3D printers are revolutionizing this process by enabling the creation of high-performance composite parts with unmatched precision. These printers allow for accurate simulation and testing of new materials, helping engineers refine designs and improve the strength, efficiency, and lifespan of turbine blades. By integrating EOS technology into the design and manufacturing process, wind turbine performance is significantly enhanced, reducing maintenance costs and boosting energy production.