Other Trends

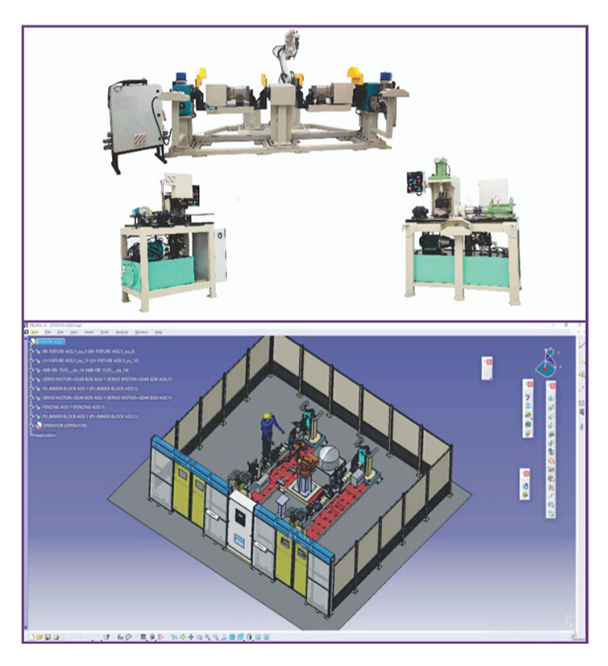

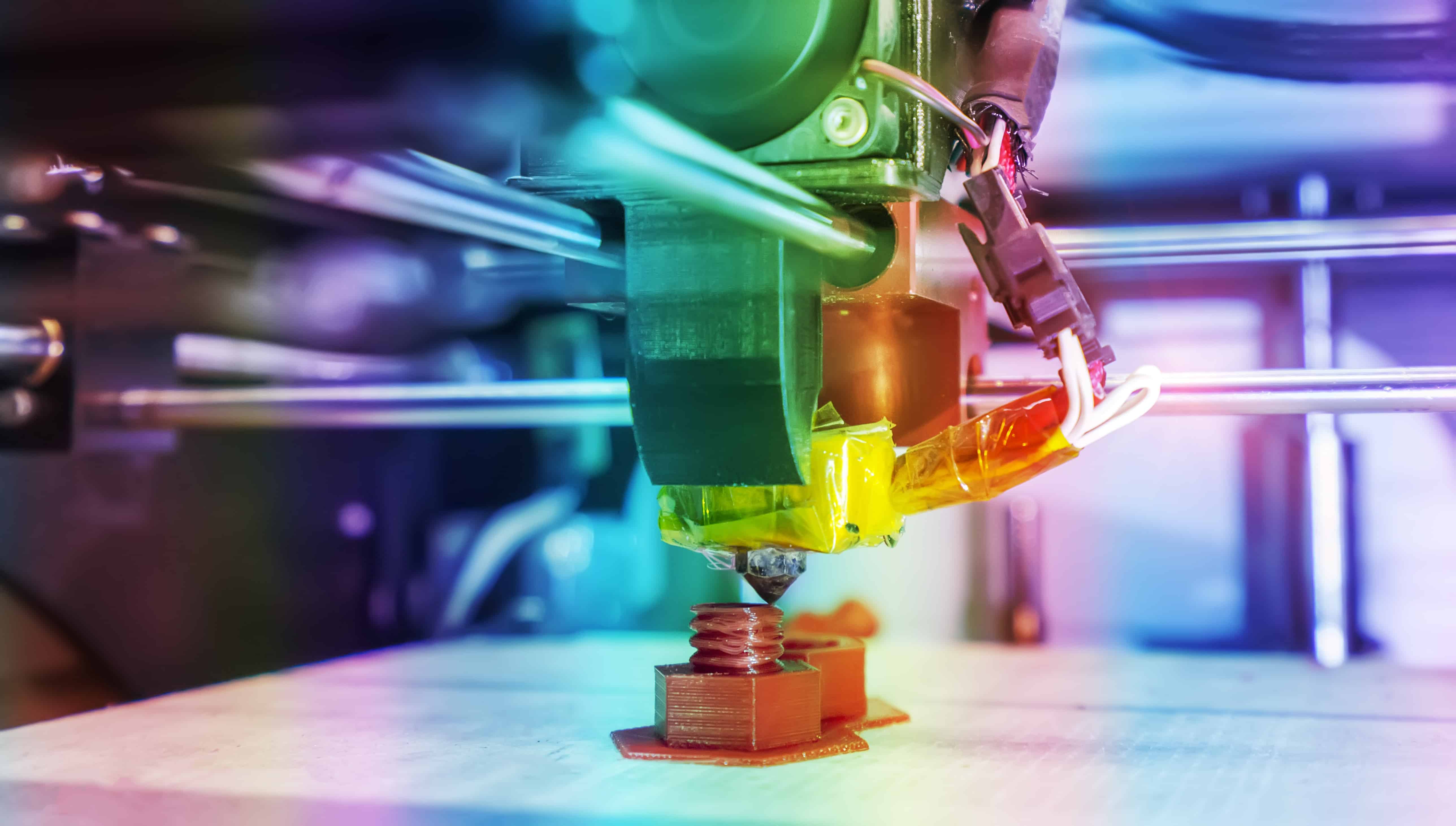

The Future of Operations with Advanced Manufacturing Technologies

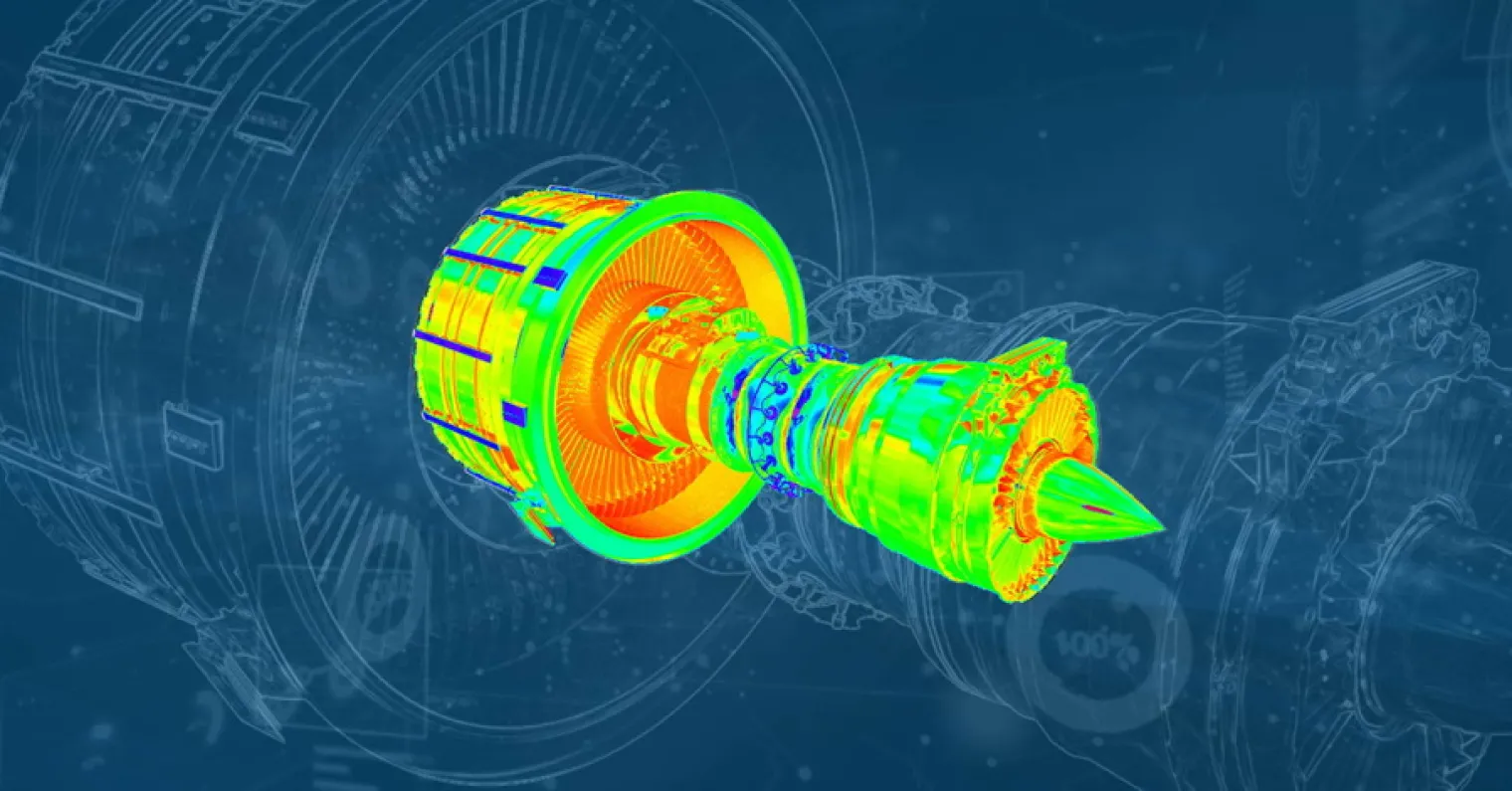

The future of operations in the specialized manufacturing machinery industry is being shaped by advancements in automation, artificial intelligence, and data analytics. As industries push for higher efficiency, precision, and flexibility, manufacturers are faced with challenges such as managing complex supply chains, optimizing production processes, and ensuring product quality at scale. DELMIA, a leading digital manufacturing solution, addresses these challenges by offering cutting-edge tools for virtual manufacturing, production planning, and real-time monitoring. By integrating AI-driven insights, DELMIA helps manufacturers streamline operations, reduce downtime, and enhance overall productivity, enabling them to stay competitive in a rapidly evolving market.

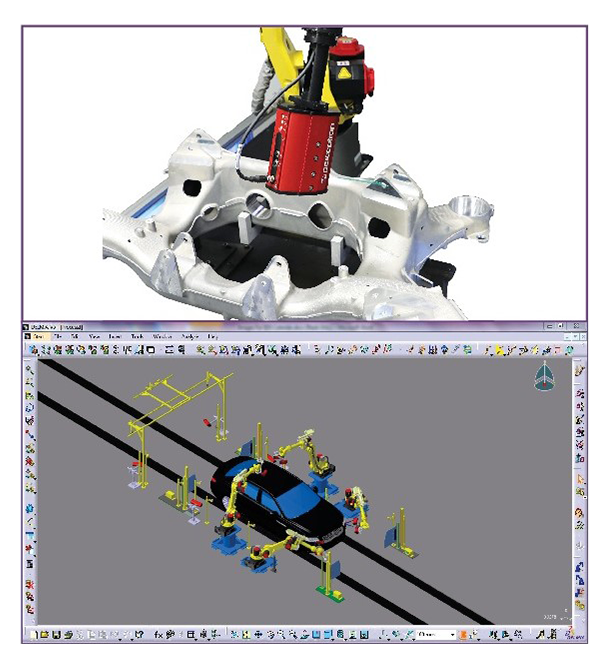

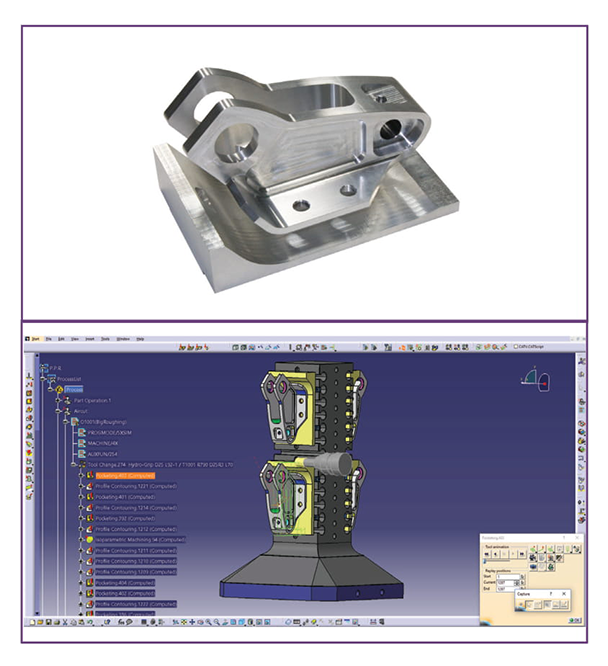

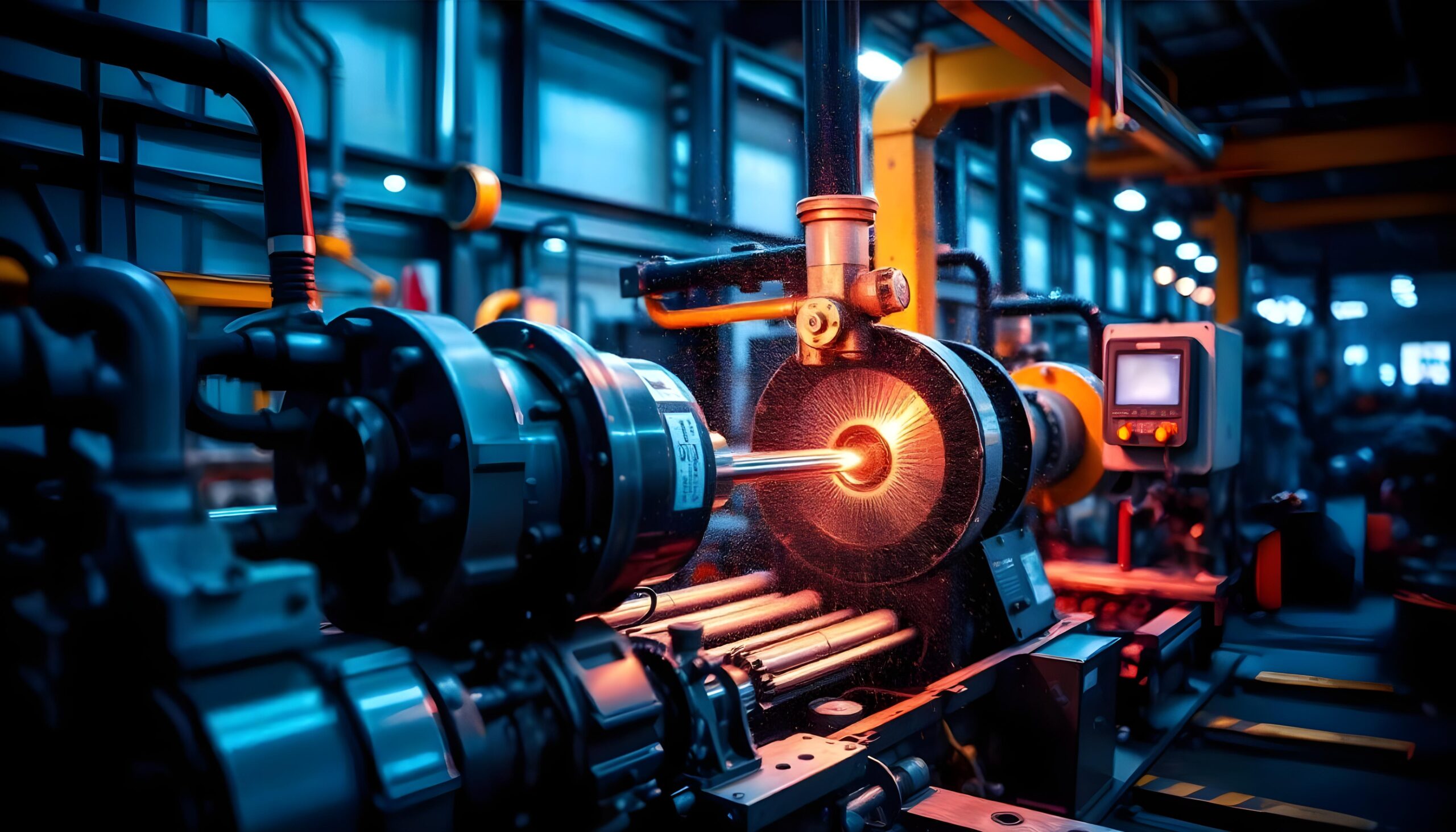

Maximizing operational efficiency in specialized machinery production

Maximizing operational efficiency in specialized machinery production is crucial for meeting growing market demands and maintaining competitiveness. However, manufacturers face challenges such as complex design processes, inefficient collaboration, and difficulty managing product lifecycle data across multiple teams. ENOVIA, a robust product lifecycle management (PLM) solution, tackles these issues by providing a unified platform for managing design, engineering, and manufacturing data. By enhancing collaboration and ensuring real-time access to critical information, ENOVIA streamlines workflows, reduces errors, and accelerates time-to-market. This empowers manufacturers to optimize their operations, improve product quality, and drive efficiency throughout the entire production cycle.

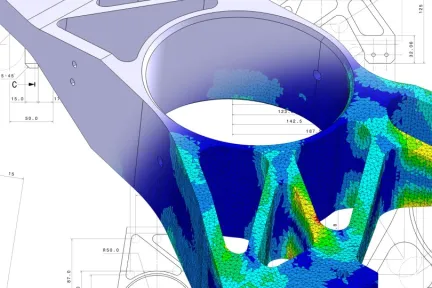

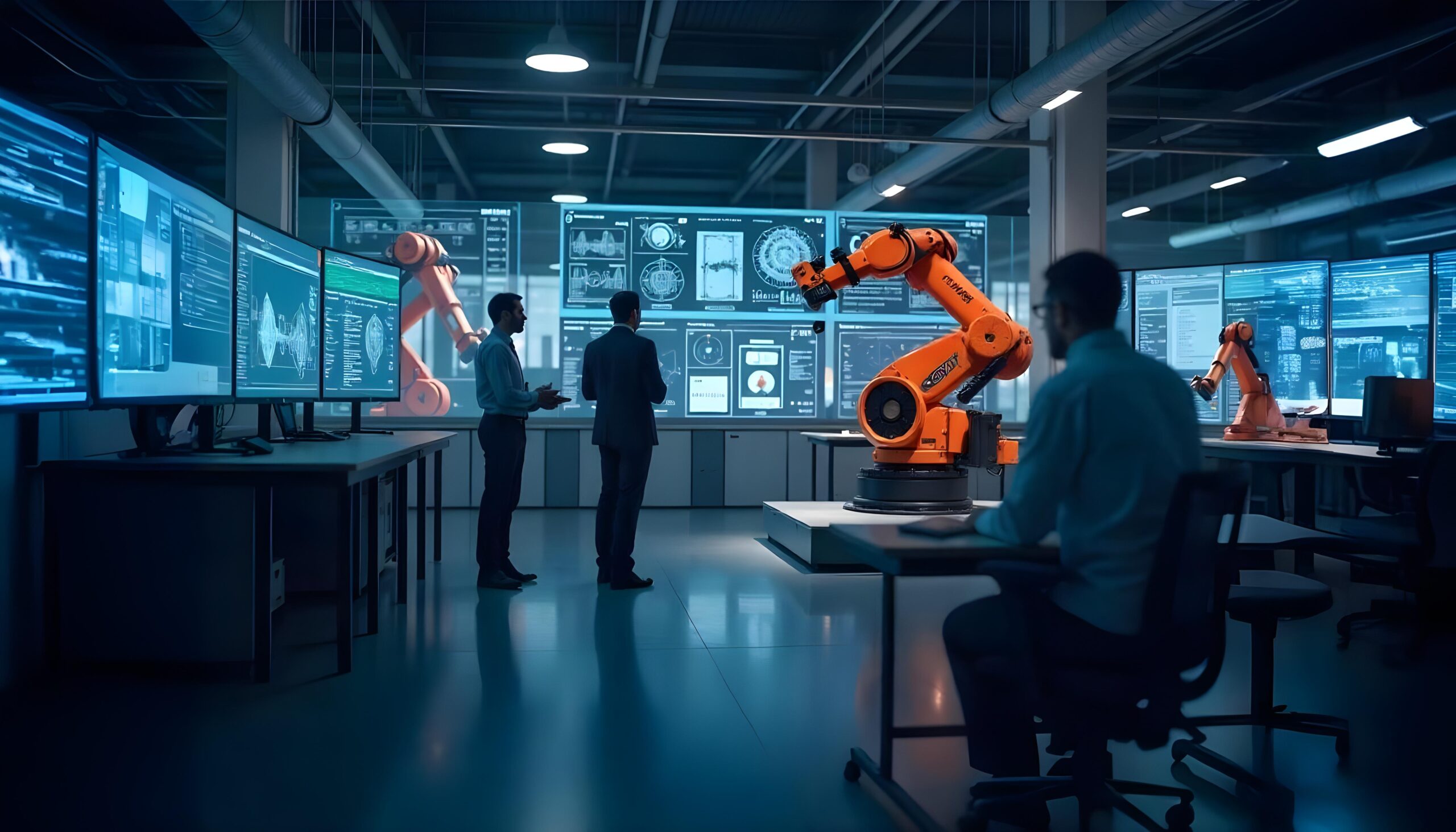

Drive efficiency in machinery design and manufacturing with integrated life cycle management

Driving efficiency in machinery design and manufacturing requires seamless integration across the entire product lifecycle. In the specialized manufacturing machinery industry, companies often face challenges like fragmented data, inefficient collaboration, and difficulty managing complex design revisions. ENOVIA addresses these issues by offering an integrated life cycle management solution that connects all stages of product development—from design and engineering to manufacturing and maintenance. By providing a single platform for data management and real-time collaboration, ENOVIA streamlines processes, improves accuracy, reduces errors, and accelerates time-to-market, ultimately driving greater efficiency and innovation in machinery design and production.