Other Trends

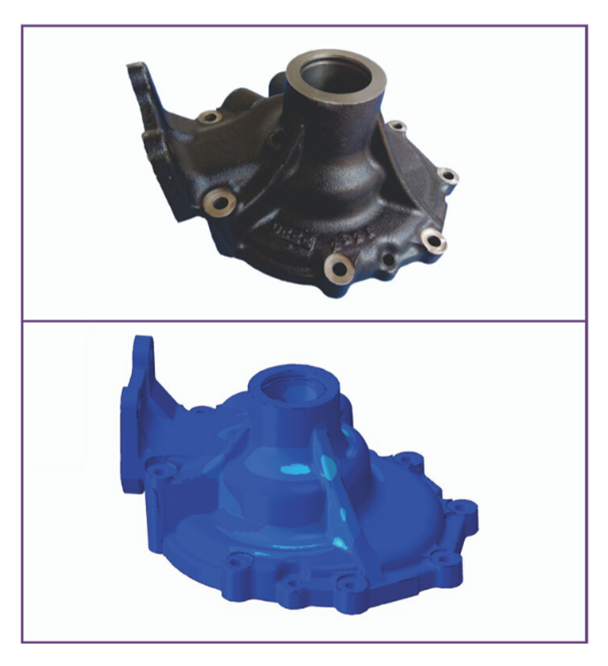

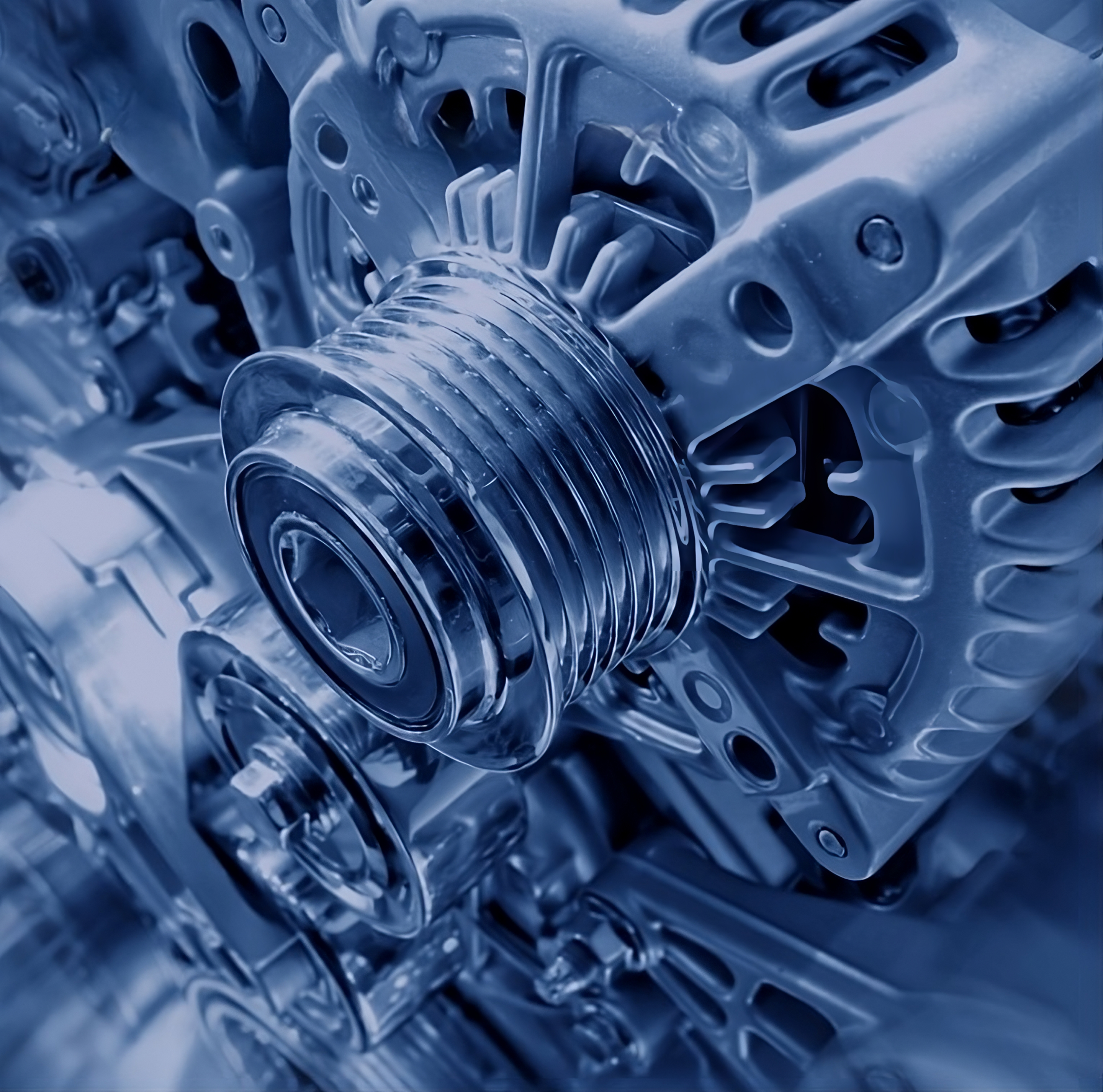

Elevate Quality Management in Metal and Plastic Manufacturing

Elevating quality management in metal and plastic manufacturing is crucial for ensuring product consistency and meeting stringent industry standards. In the fabricated metal and plastic products industry, companies often face challenges such as inconsistent quality control processes, difficulty tracking defects, and managing complex compliance requirements. ENOVIA addresses these issues by providing a comprehensive product lifecycle management (PLM) solution that integrates quality data across the entire ma

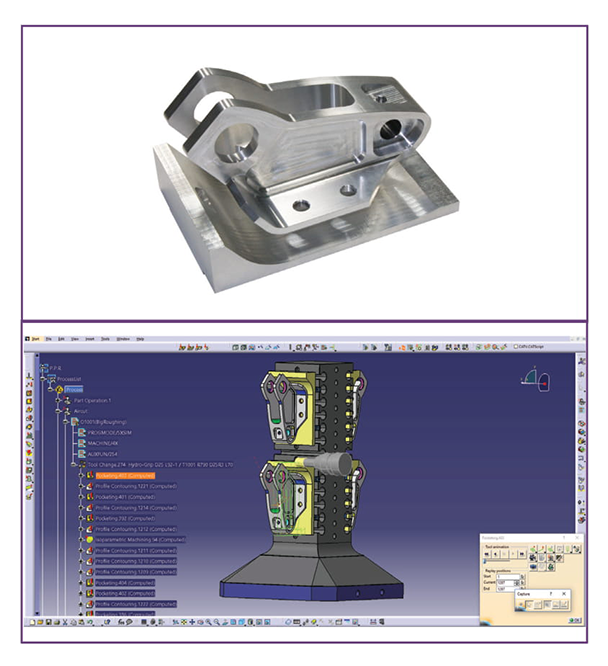

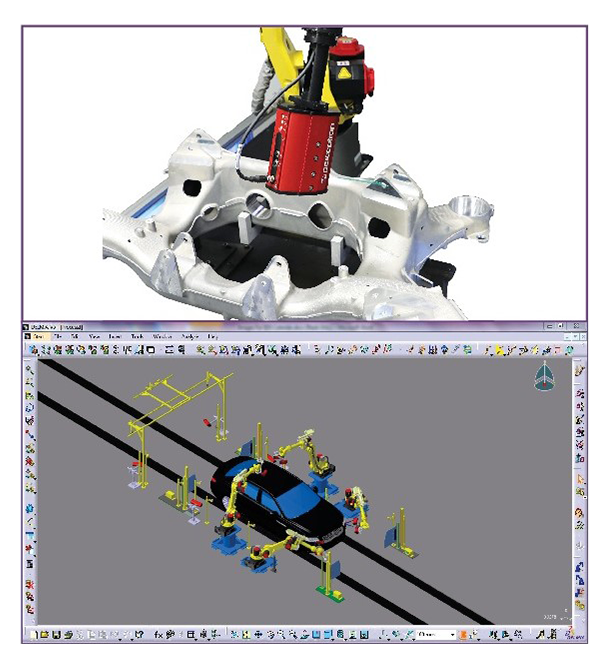

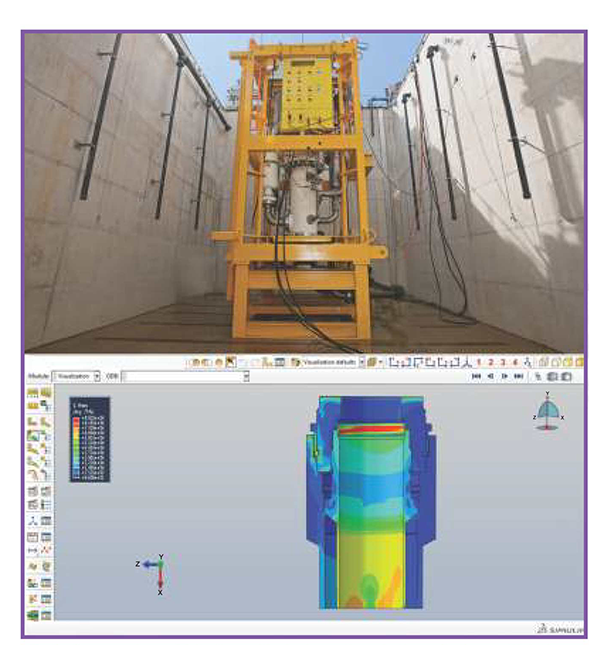

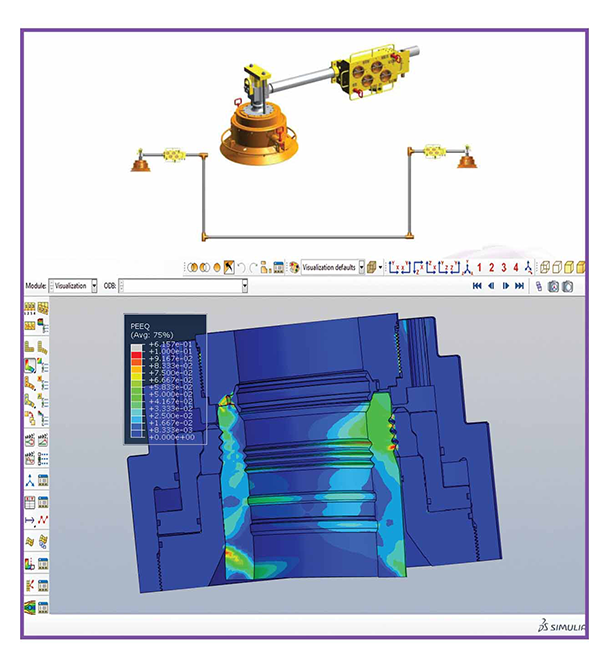

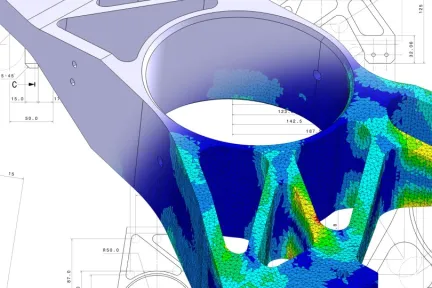

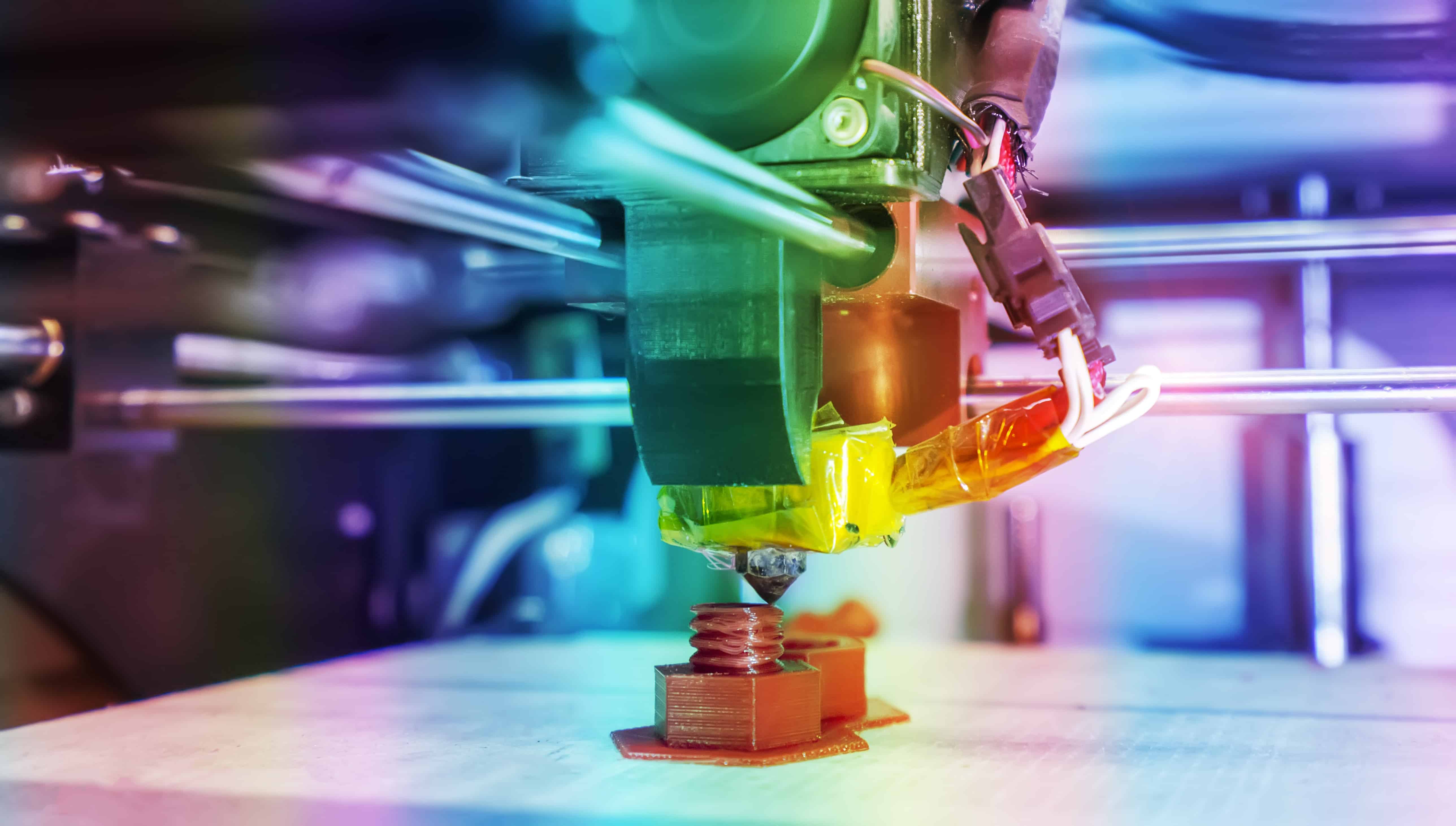

Streamline Engineering to Manufacturing for Advanced Product Solutions

Streamlining engineering to manufacturing for advanced product solutions is crucial in the fabricated metal and plastic products industry to enhance efficiency and ensure high-quality outcomes. However, manufacturers often face challenges such as siloed teams, miscommunication, and difficulties in managing complex product data across the development lifecycle. ENOVIA addresses these issues by providing a robust product lifecycle management (PLM) solution that connects design, engineering, and manufacturing teams on a single platform. It enables real-time collaboration, centralized data management, and seamless transition from engineering to production, ensuring consistency, reducing errors, and accelerating the time-to-market for advanced product solutions.

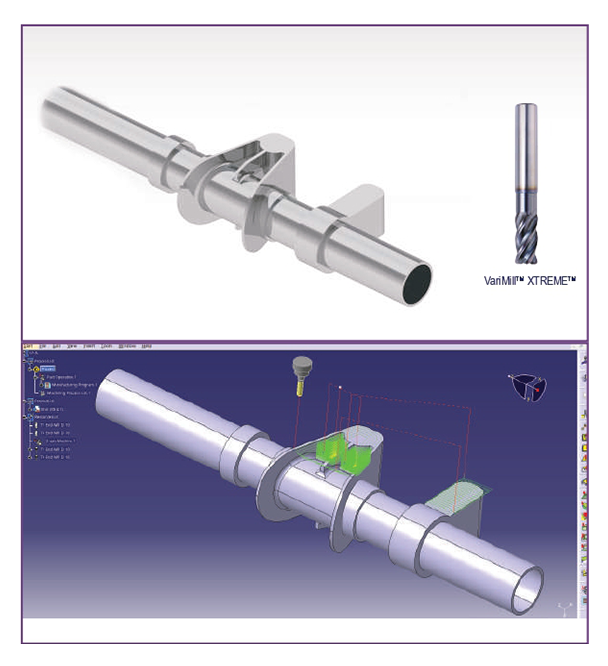

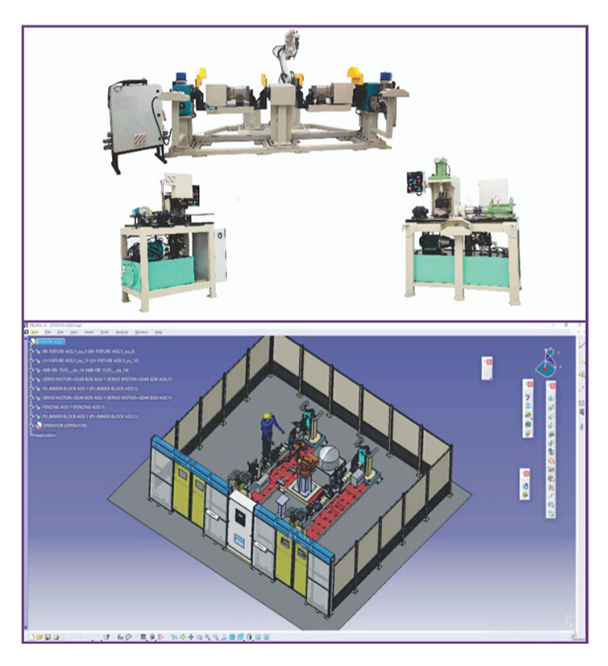

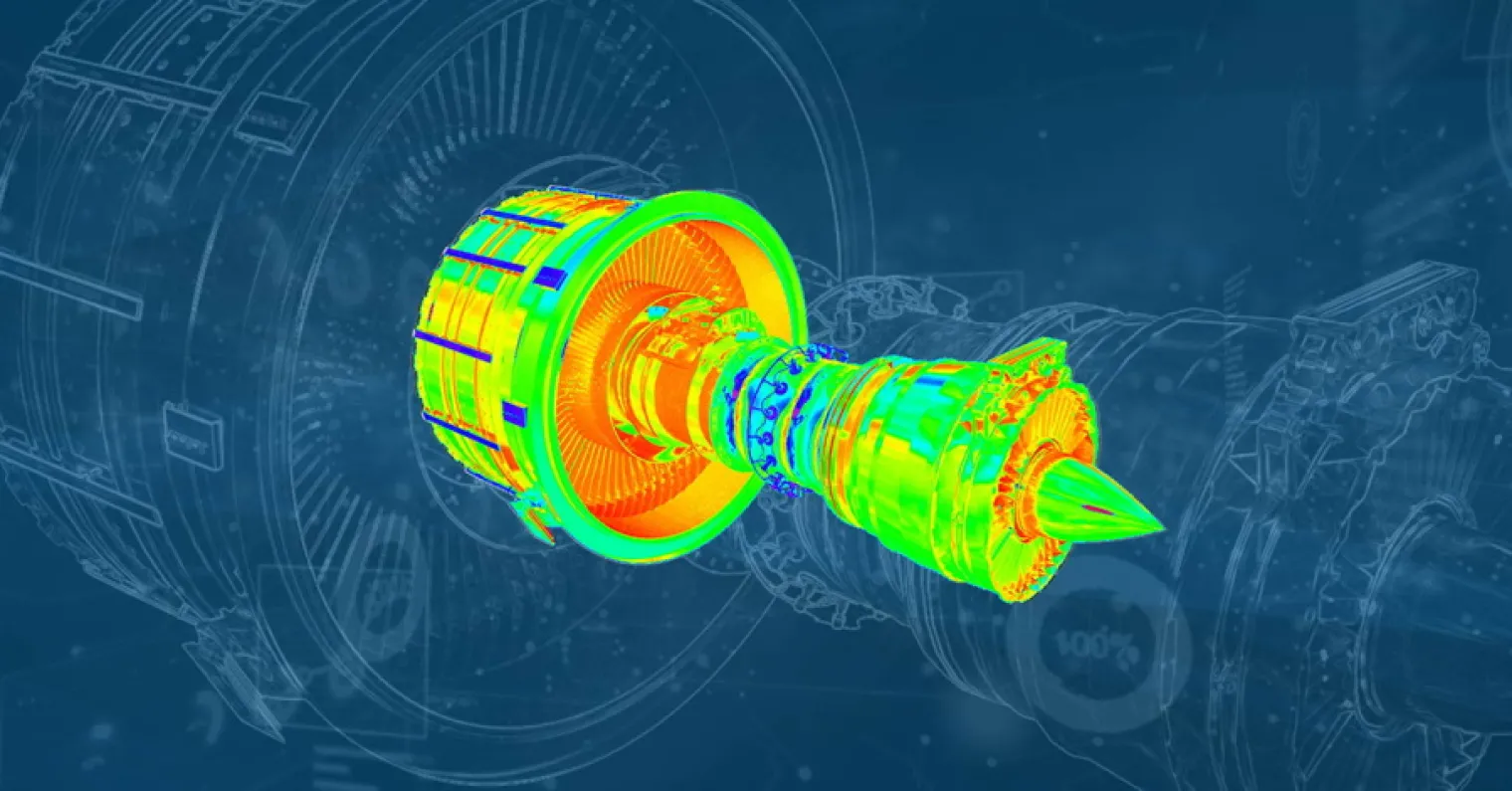

Maximizing operational efficiency in the fabricated metal and plastic products

Maximizing operational efficiency in the fabricated metal and plastic products industry is essential for staying competitive and meeting growing demand. However, manufacturers often face challenges such as siloed data, inefficient workflows, and difficulty in coordinating between design, engineering, and production teams. ENOVIA addresses these challenges by providing a robust product lifecycle management (PLM) platform that centralizes data, enhances collaboration, and streamlines processes across