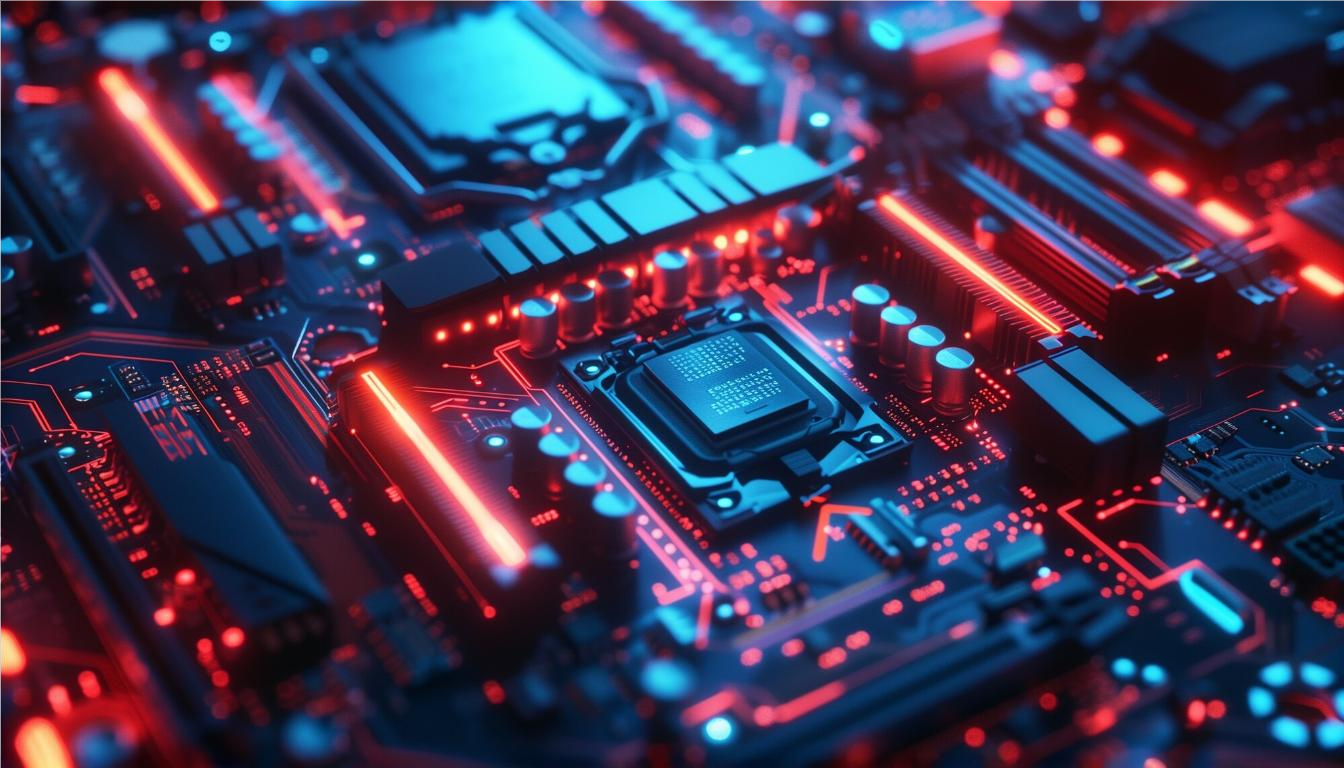

Semiconductors

Accelerate time-to-market for semiconductors by leveraging advanced design, simulation, and verification solutions, while ensuring the production of high-precision semiconductor components using additive manufacturing for electronics. This integrated approach streamlines the development process, reduces production time, and enhances the accuracy of components, enabling faster and more efficient innovation in the semiconductor industry.

Solutions for Semiconductors

Advanced Electronic Design Automation for Semiconductor Innovation

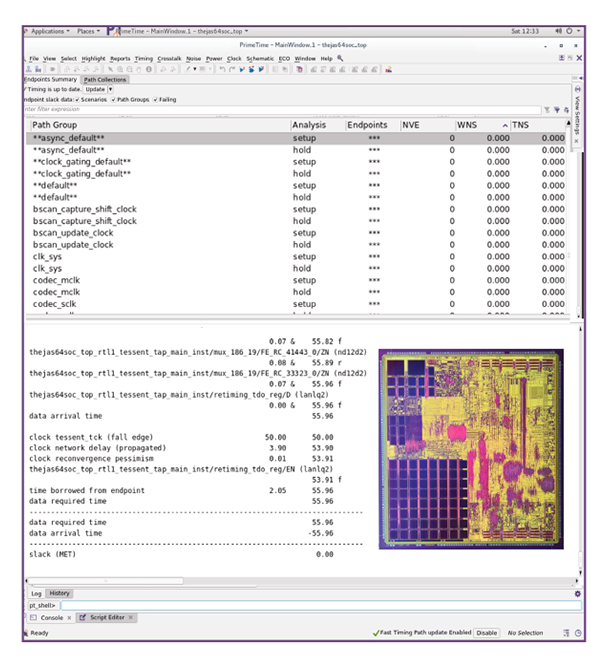

Designing and developing semiconductor devices require precise tools to manage complex processes such as chip design, layout, and verification. Synopsys provides state-of-the-art Electronic Design Automation (EDA) solutions that streamline the design process, enabling engineers to create innovative and efficient semiconductor devices. These tools allow for advanced circuit design, optimization, and verification, ensuring that chips meet performance, power, and area requirements.

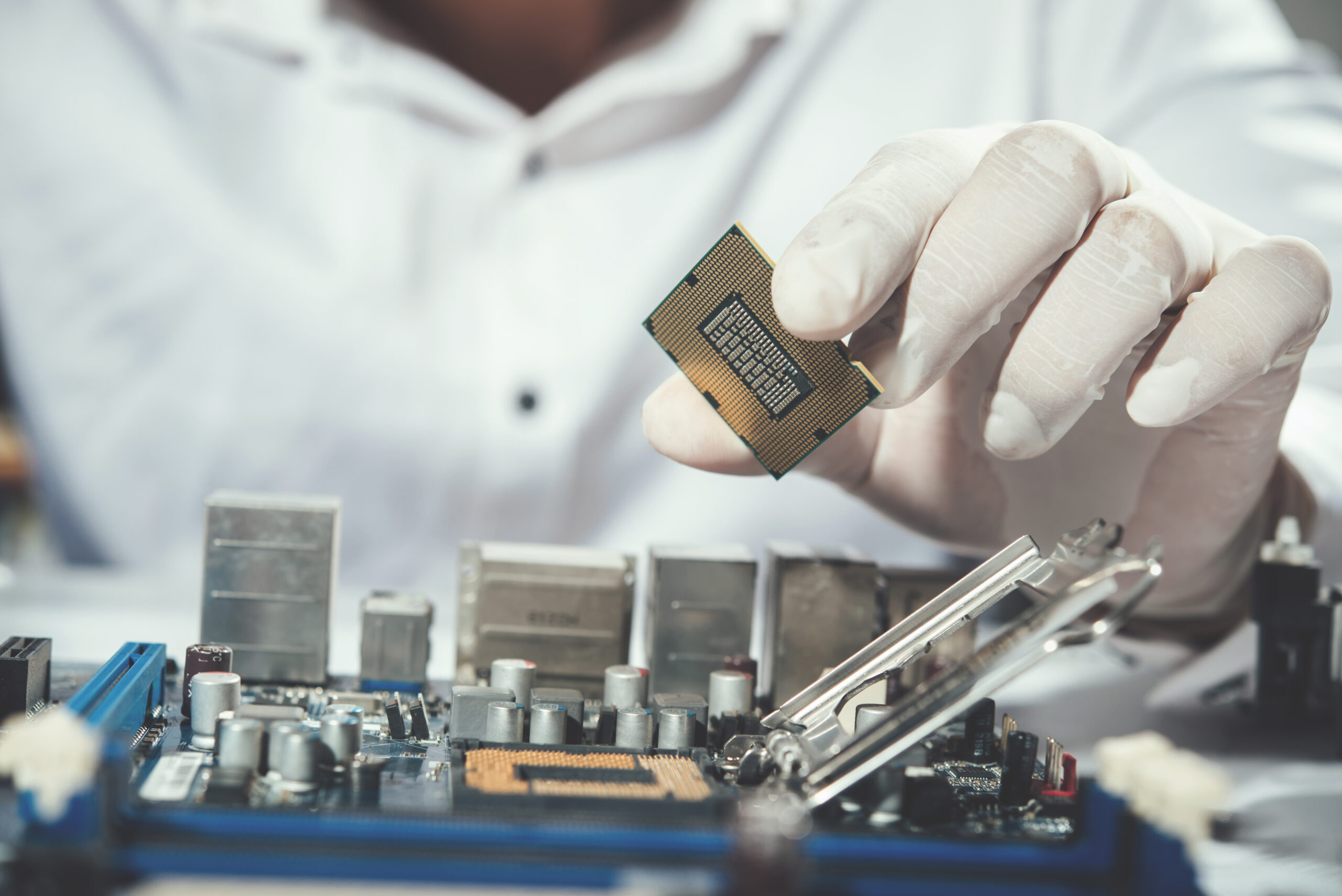

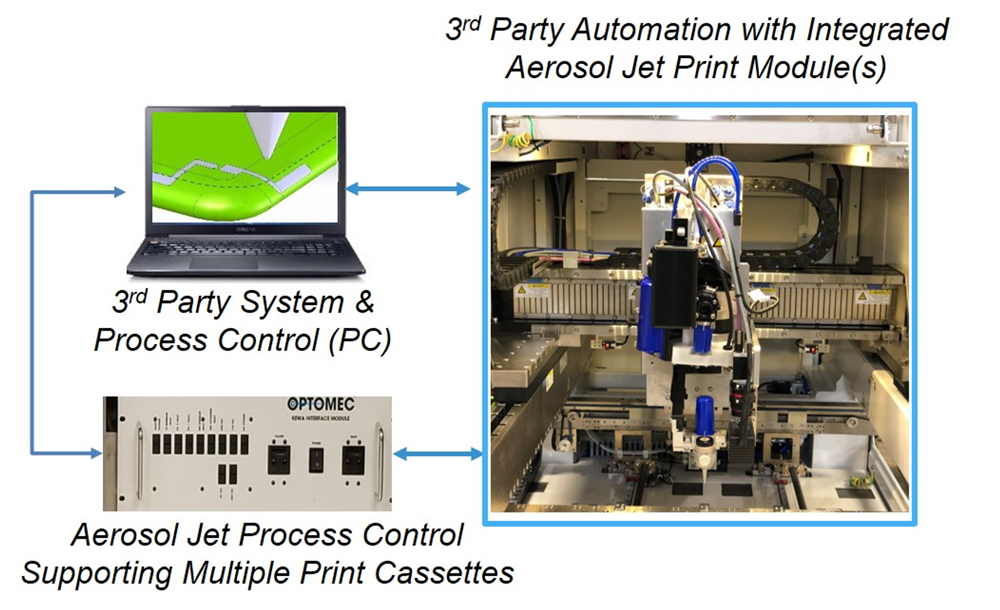

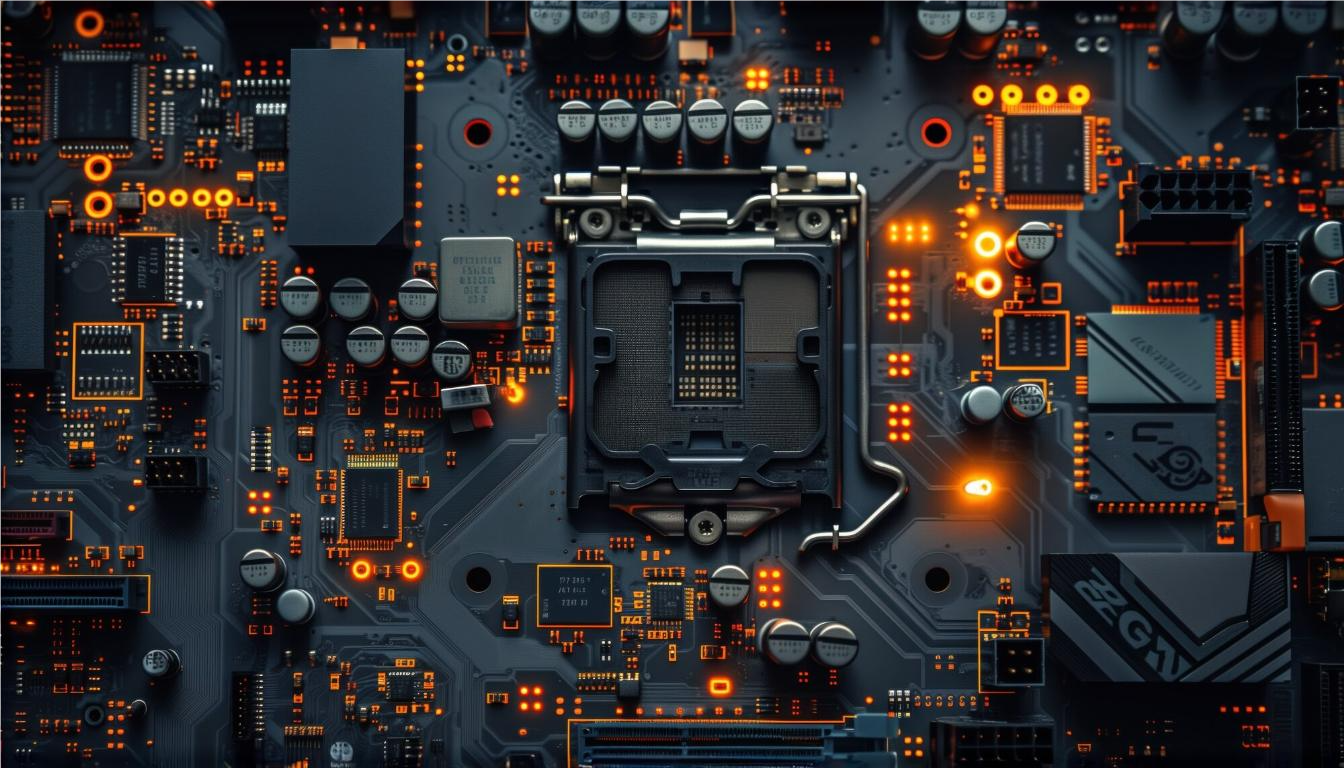

High-Precision Additive Manufacturing for Semiconductor Components

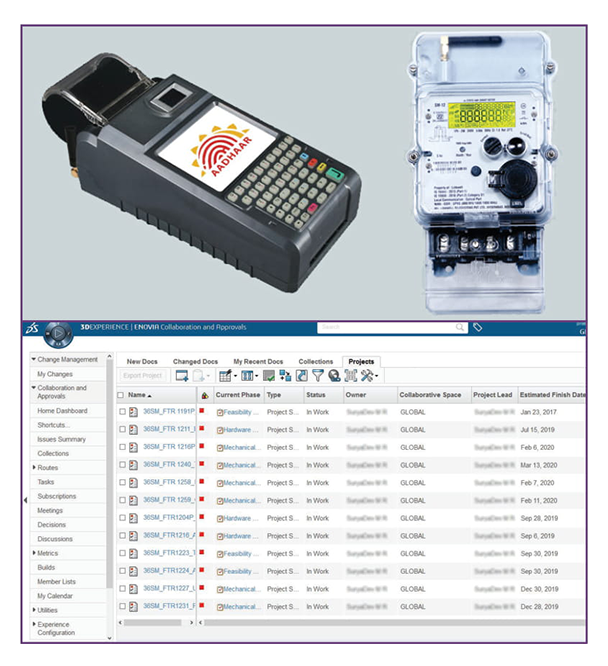

The semiconductor industry increasingly relies on additive manufacturing to create intricate components with high precision. Optomec provides cutting-edge additive manufacturing solutions that support the production of complex semiconductor parts, including printed electronics, interconnects, and conductive pathways. By leveraging Optomec's Aerosol Jet technology, manufacturers can achieve unparalleled precision, scalability, and cost efficiency.

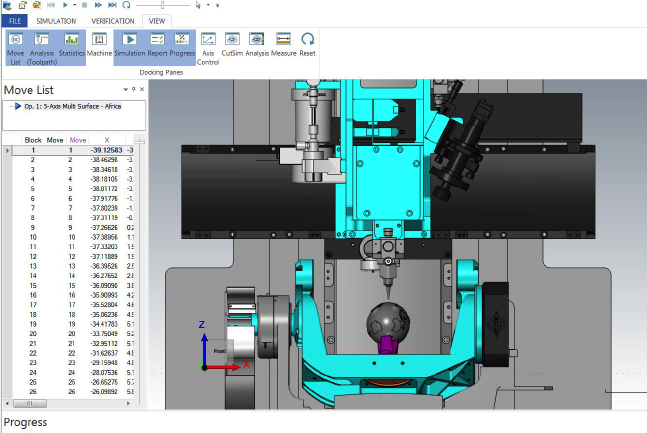

Driving Semiconductor Efficiency with Precise Circuit Simulation and Verification

Semiconductor manufacturing demands precise simulation and verification to ensure the performance and reliability of devices. Synopsys provides advanced solutions for circuit simulation, enabling engineers to validate designs under real-world conditions before production. These tools help identify potential issues early, reducing the risk of costly failures and improving overall efficiency.

Optimized Design for Additive Manufacturing (DFAM)

Design for Additive Manufacturing (DFAM) transforms traditional design processes by enabling more efficient, innovative, and cost-effective solutions tailored for additive manufacturing technologies. This approach ensures that designs are optimized for 3D printing, making it possible to create complex geometries that were previously difficult or impossible to manufacture. By integrating advanced simulation, material selection, and process planning, DFAM accelerates product development cycles while maintaining or improving performance, reducing weight, and cutting costs.

Products

CATIA

Design intricate, high-precision components for cutting-edge high-tech applications with CATIA

Synopsys Electronic Design Automation

Optimize complex electronic designs with advanced EDA solutions for high-performance and reliable systems

Optomec 3D Printers

Enable rapid, flexible production of high-tech electronic parts with additive manufacturing solutions

Trends

Aerosol Jet Printing for High-Resolution Circuitry

Aerosol Jet Printing for high-resolution circuitry is transforming the semiconductor industry by enabling precise and flexible production of complex electronic components. However, key challenges include achieving the required resolution for fine features, ensuring material consistency, and maintaining high throughput in a cost-effective manner. OPTOMEC 3D Printers address these challenges by using advanced Aerosol Jet Printing technology, which enables the deposition of conductive materials with micron-level precision. This technology allows semiconductor manufacturers to print high-resolution circuitry directly onto various substrates, reducing the need for traditional photolithography and accelerating the prototyping and production processes, ultimately enhancing efficiency and reducing costs.

The Future of Printed Electronics for Flexible Devices

The future of printed electronics for flexible devices in the semiconductor industry presents exciting possibilities, but challenges such as achieving high-performance circuitry on flexible substrates, ensuring fine resolution, and optimizing designs for manufacturability persist. OPTOMEC 3D Printers and Synopsys EDA tool

Enabling Precision Fabrication of Electronic Circuits with Aerosol Jet Printing

Enabling precision fabrication of electronic circuits is crucial for advancing semiconductor technology, particularly as demand for smaller, more efficient devices increases. However, challenges in the industry include achieving high-resolution circuit patterns, ensuring accurate material deposition, and maintaining reliability at micro and nano scales. OPTOMEC 3D Printers, using Aerosol Jet Printing

Latest Blog Posts

Discover our most recent posts across all industries, branchs and topics

Accelerating the Digital Transformation of Semiconductor Development with 3DEXPERIENCE

Semiconductors are among the simplest electronic components, yet they perform some of the most intricate functions conceivable. These components are produced from silicon, which is…