Other trends

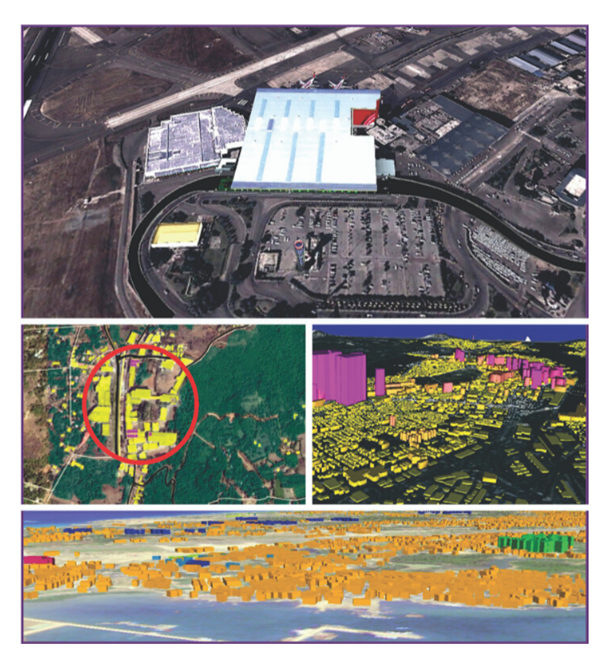

Unlocking the Future of Defence Systems with Digital Twin Technology

The defence industry is constantly evolving, requiring highly advanced and reliable systems to meet modern security challenges. Traditional methods of designing and testing defence systems can be time-consuming and costly. Synopsys Virtual Prototyping, powered by Digital Twin technology, transforms this process by creating

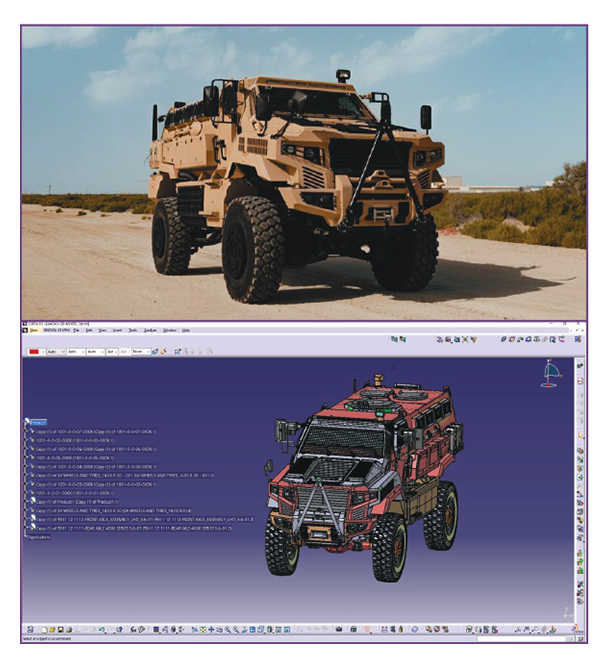

Driving Innovation in Defence with Collaborative Mechatronics Engineering

In the defence sector, the integration of mechanical, electrical, and software systems—referred to as mechatronics—is crucial for developing advanced, high-performance defence technologies. Achieving this requires seamless collaboration across multiple engineering disciplines to ensure the systems operate reliably and efficiently in demanding environments. ENOVIA, a leading product lifecycle management (PLM) solution, enables this collaboration by providing a unified platform that connects teams, manages data, and streamlines workflows throughout the entire development process. By using ENOVIA, defence organizations can integrate mechatronics systems more effectively, optimize design iterations, reduce development time, and ensure higher quality and reliability in their defence solutions, driving innovation while enhancing operational readiness and security.

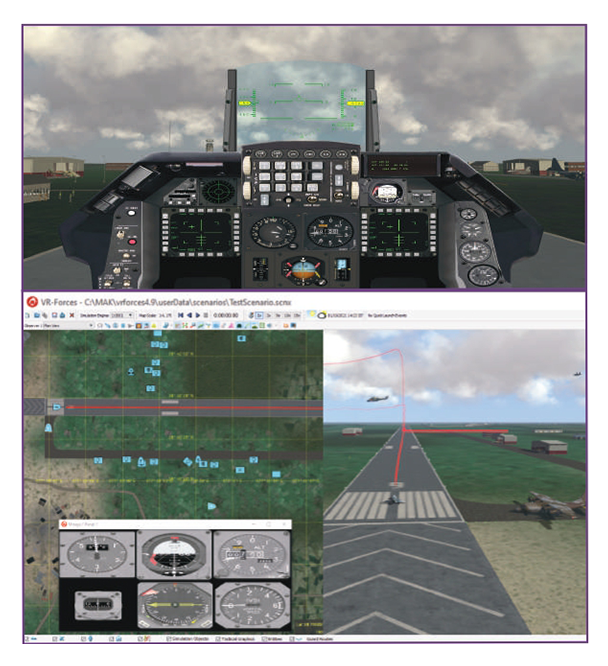

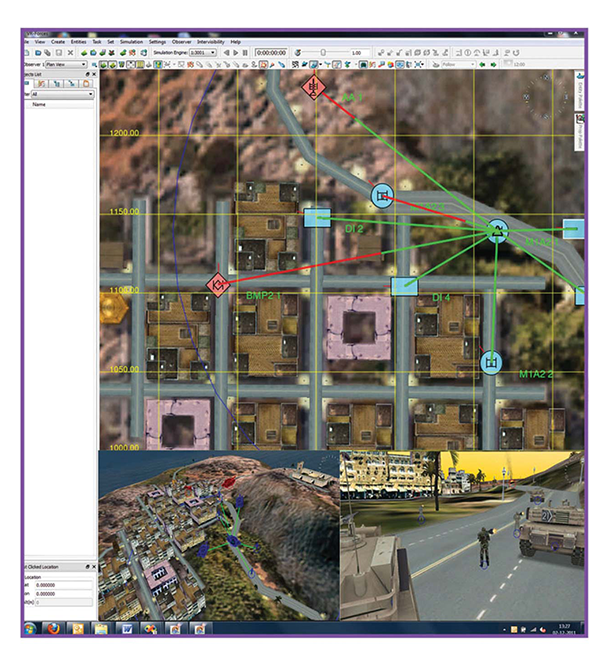

Enhance Defence Systems with Advanced Virtual Testing and Simulation

n the defence sector, the ability to test protective gear, such as bulletproof jackets, and other high-impact defence systems under extreme conditions is essential for ensuring safety and performance. Traditional methods of physical testing, such as subjecting materials to firearm recoil, blast waves, or projectile impacts, can be costly and time-consuming. SIMULIA’s advanced virtu