Enhancing the Additive Manufacturing Process with Dassault Systemes Solutions

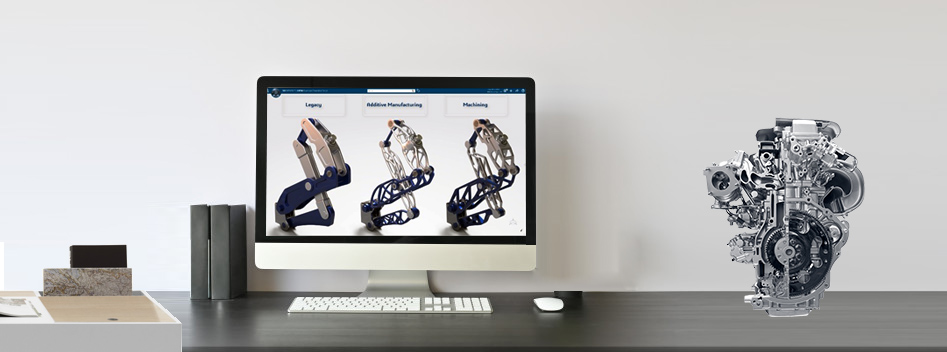

Additive Manufacturing (AM) has the capability to redefine manufacturing in your organization in multiple aspects effectively. Manufacturing companies of various sizes are looking at AM as an alternative and/or complimentary solution.

Additive Manufacturing can significantly reduce material waste and the typical multiple steps of production. It helps in reducing the part weight and manufacturability of components with complex design, which drives any company to be more competitive and adopt quick go-to-market strategies. AM eliminates the traditional process of the prototype, which directly removes the need for complex manufacturing setup, more time on production setups, huge investments, resource allocation, and more.

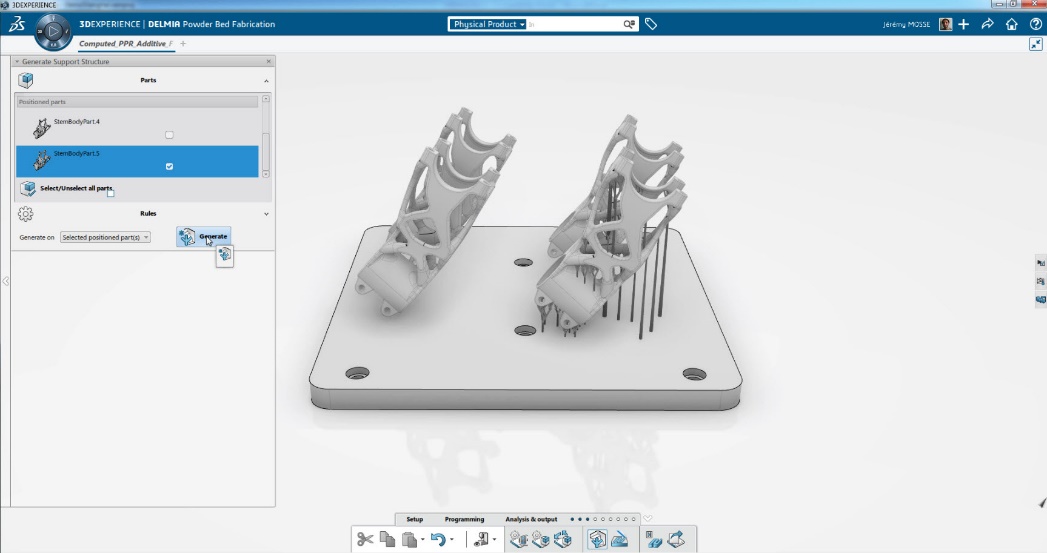

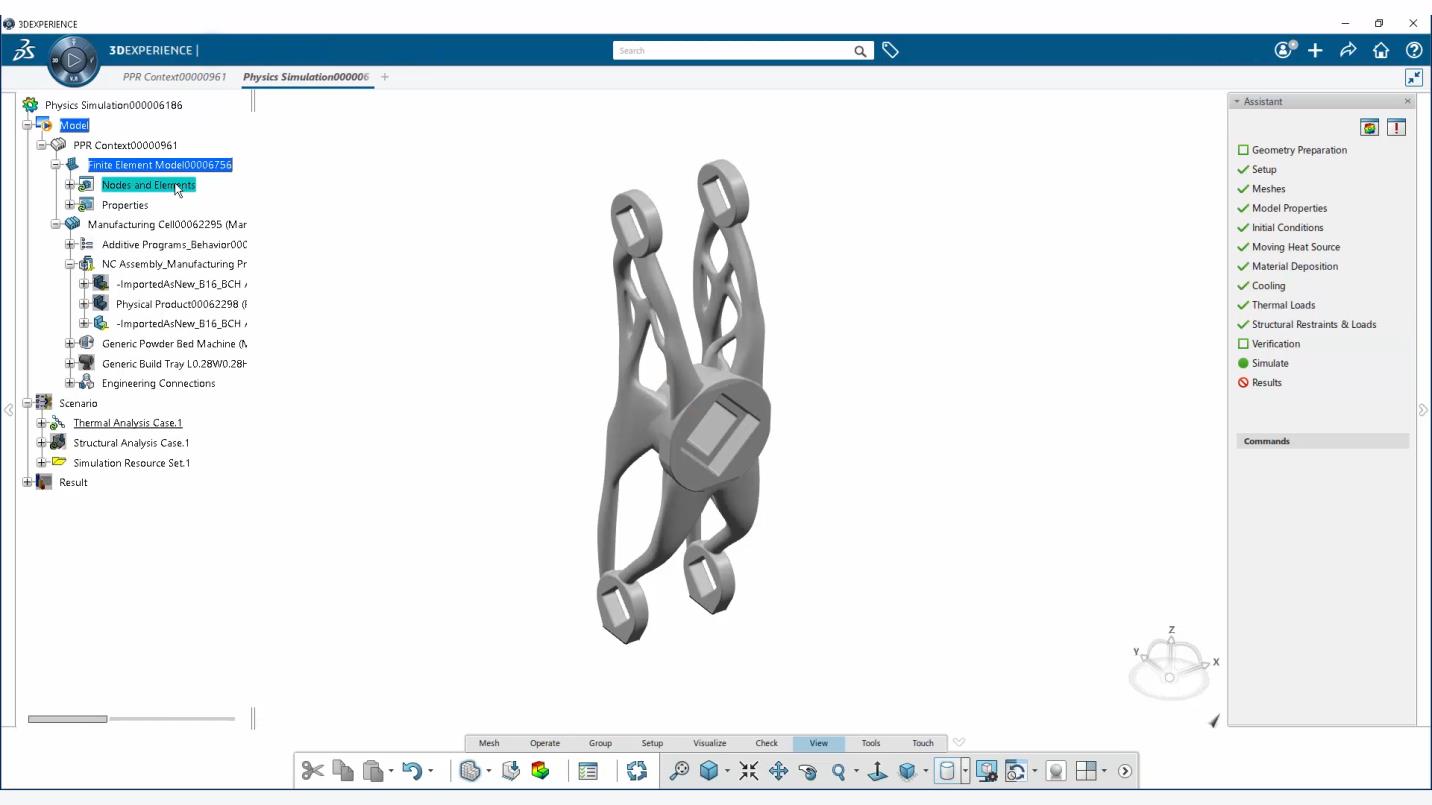

With the help of Dassault Systemes’ Additive manufacturing solutions, manufacturing companies are able to achieve their production excellence along with a multi-discipline approach that covers Design, Analysis, and Manufacturing. Topology optimization is one of the key areas where all the manufacturers are looking to reduce the part weight while keeping the design intent un-compromised. This is where an innovative & sustainable solution is required. CATIA 3DEXPERIENCE has a rich set of functionalities which can address end to end needs of any Additive Manufacturing process. It has a powerful set of capabilities that not only addresses the design optimization but also the manufacturability of the optimized design.

CATIA, powered by the 3DEXPERIENCE platform, delivers unmatched capabilities of integration with the existing processes and tools of any organization. 3DEXPERIENCE platform provides a single source of truth Dashboard to the entire business line of a company. The solution empowers organizations to manage changes and introduce disruptive approach. Lesser number of iterations for the New Developed Products means faster launches, lesser wastage, and more profitability.

Both CATIA and the 3DEXPERIENCE platform together can take the innovation, adaptability, profitability, and efficiency to a whole new level.

When the target is excellence, the processes and tools must be perfect.

Mr. Goutham started his career as Design Engineer, worked on different CAD software applications. He is currently working as Solution Consultant with EDS Technologies & he is part of CATIA 3DEXPERIENCE CoE team. He has good exposure on manufacturing aspects with respect to Aerospace Industry. He carries a rich experience of 8 years in the field of PLM/Digital EXPERIENCE platform.