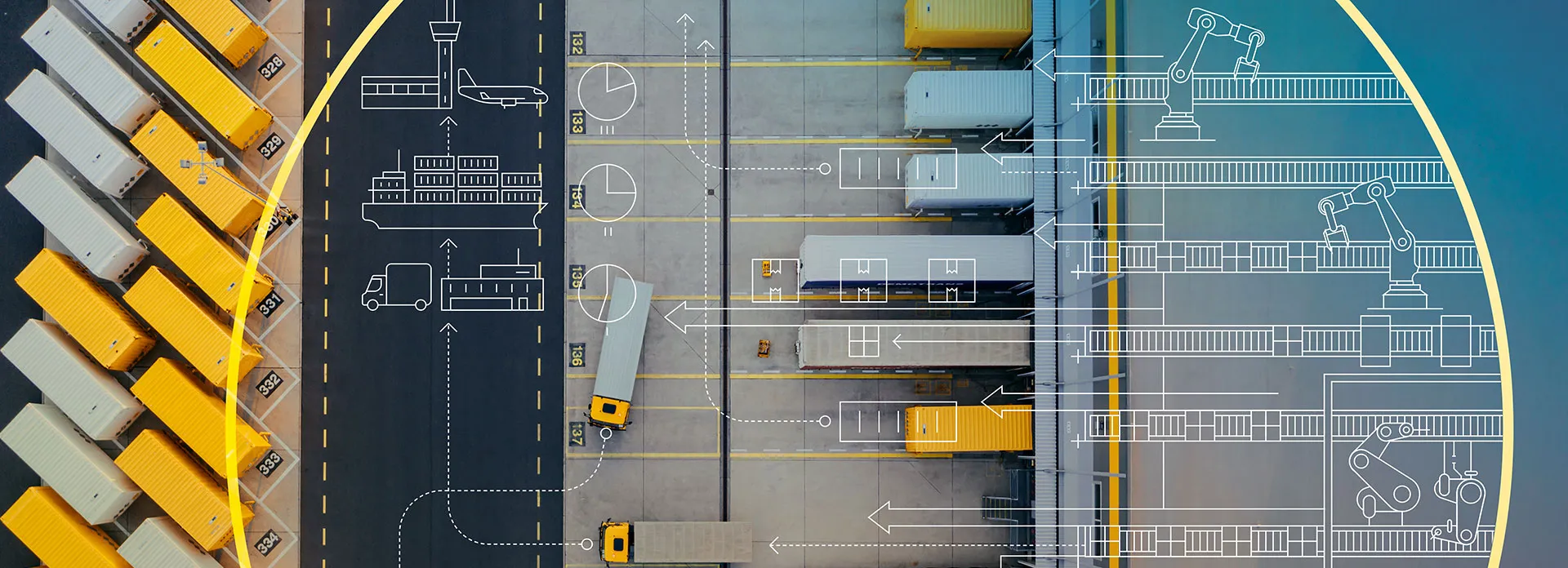

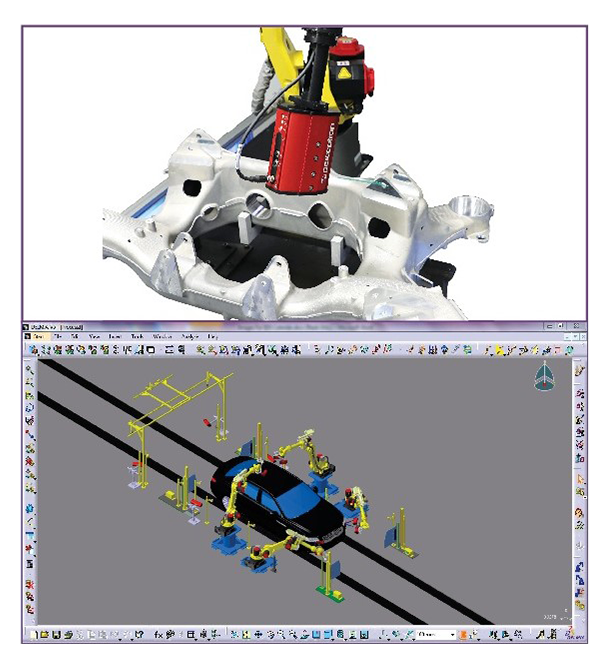

DELMIA Ortems Synchronized Requirements Planner optimizes material flow and capacity for Just-in-Time (JIT) demand across all Bill of Materials (BOM) levels. It enhances inventory planning by synchronizing purchase and work orders from raw materials to finished products while managing inventory constraints. By linking semi-finished and finished product work orders, it works alongside DELMIA Ortems Production Scheduler and Manufacturing Planner to balance loads and improve flow efficiency.

Advanced Capabilities

- JIT Integration: Aligns demand and manufacturing across BOM levels.

- Multi-Level BOM: Coordinates orders to accelerate flow lines.

- Inventory Management: Integrates inventory constraints into scheduling.

- Pegging Links: Connects semi-finished and finished work orders.

- Load Balancing: Optimizes distribution with Production Scheduler and Planner.

Applications

- Inventory Optimization: Reduces excess stock by aligning material flow.

- Accurate Scheduling: Enhances scheduling with synchronized orders.

- Supply Chain Visibility: Improves collaboration with real-time insights.

- Efficiency Improvement: Coordinates material movement for faster production.

- Responsive Planning: Quickly adjusts to changes in demand.

Benefits

- Reduces Buffer Inventory: Lowers excess stock levels.

- Multi-Level BOM Synchronization: Aligns all BOM levels effectively.

- Impact Analysis: Evaluates effects across manufacturing processes.

- Customer-to-Supplier Traceability: Enhances tracking of materials.

- Improves Customer Service: Increases lead-time reliability.