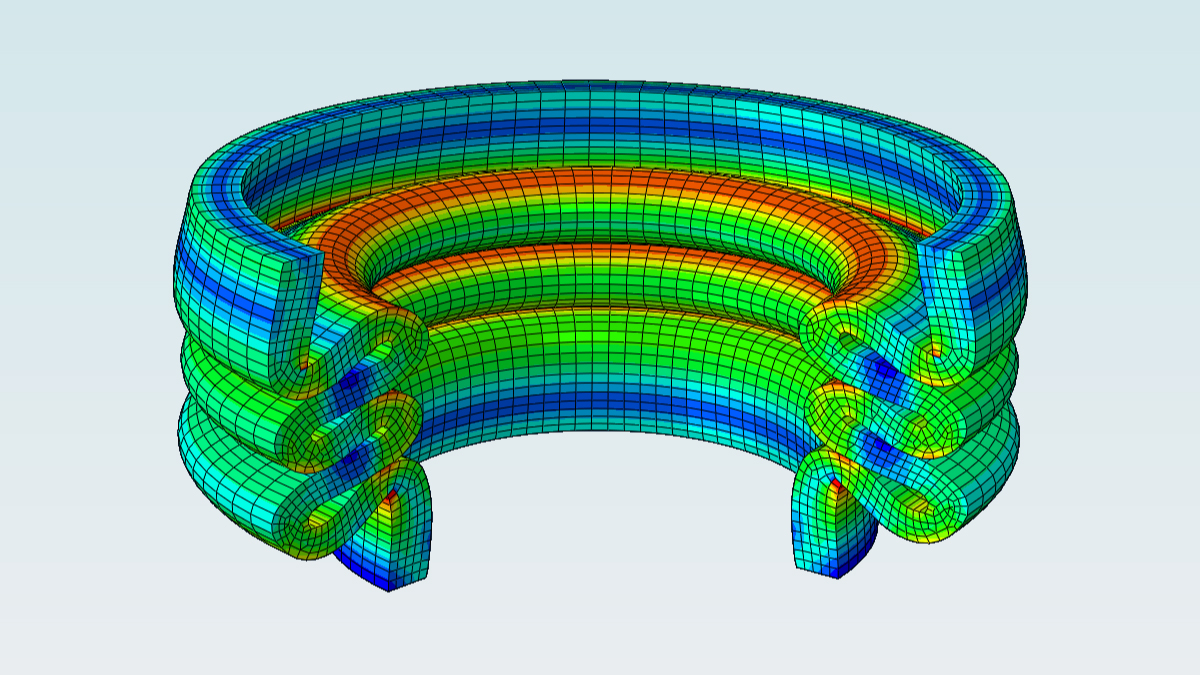

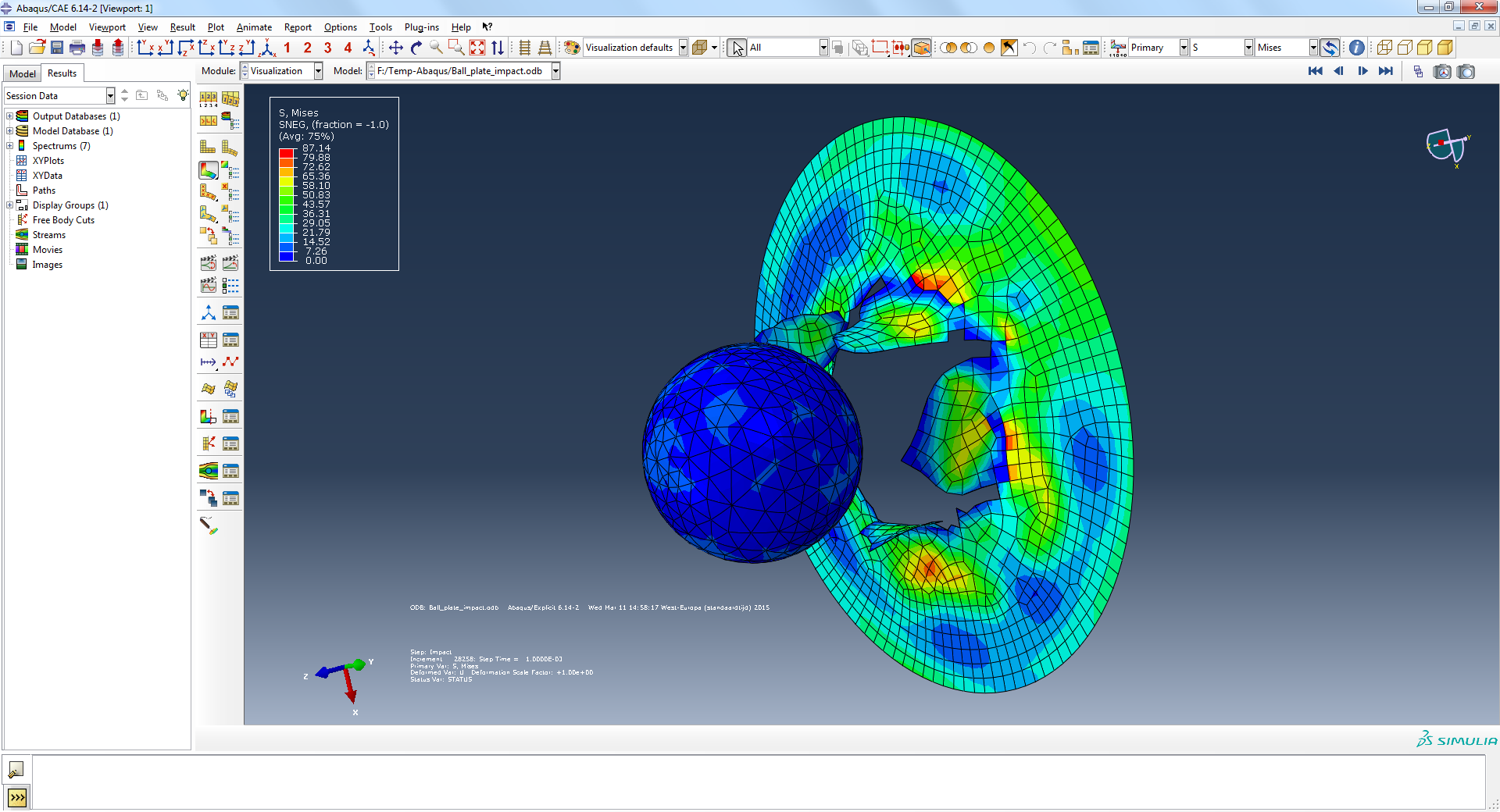

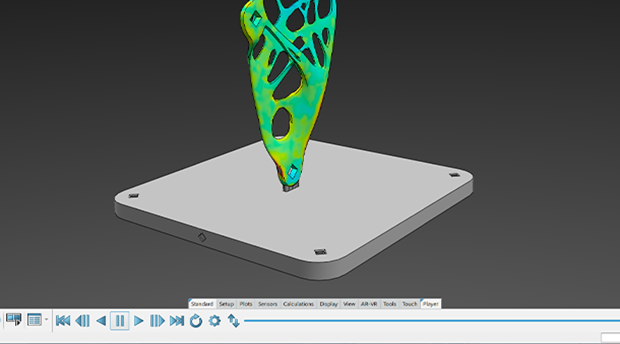

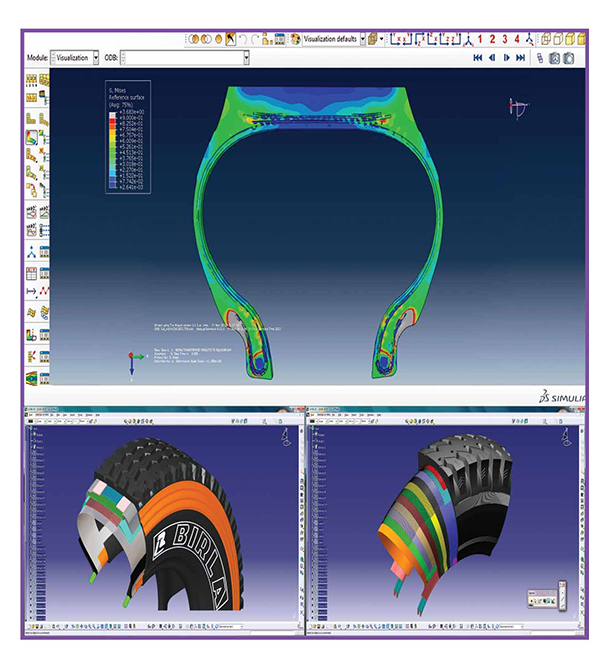

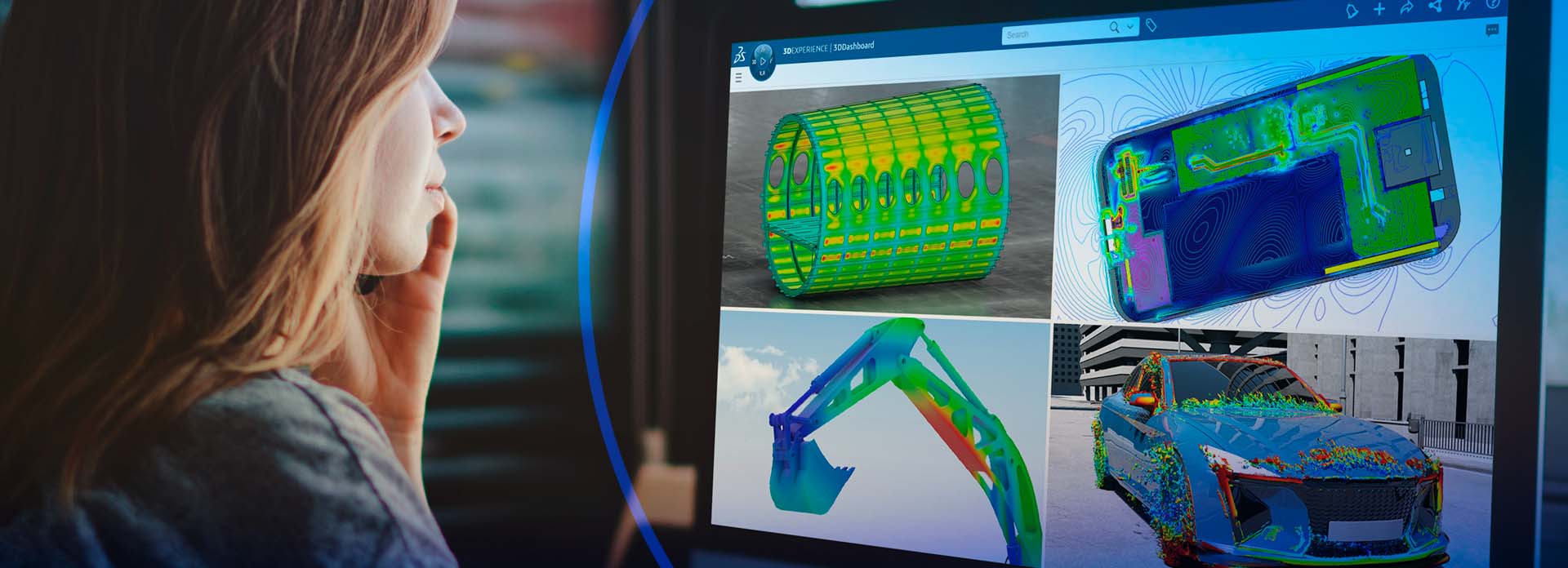

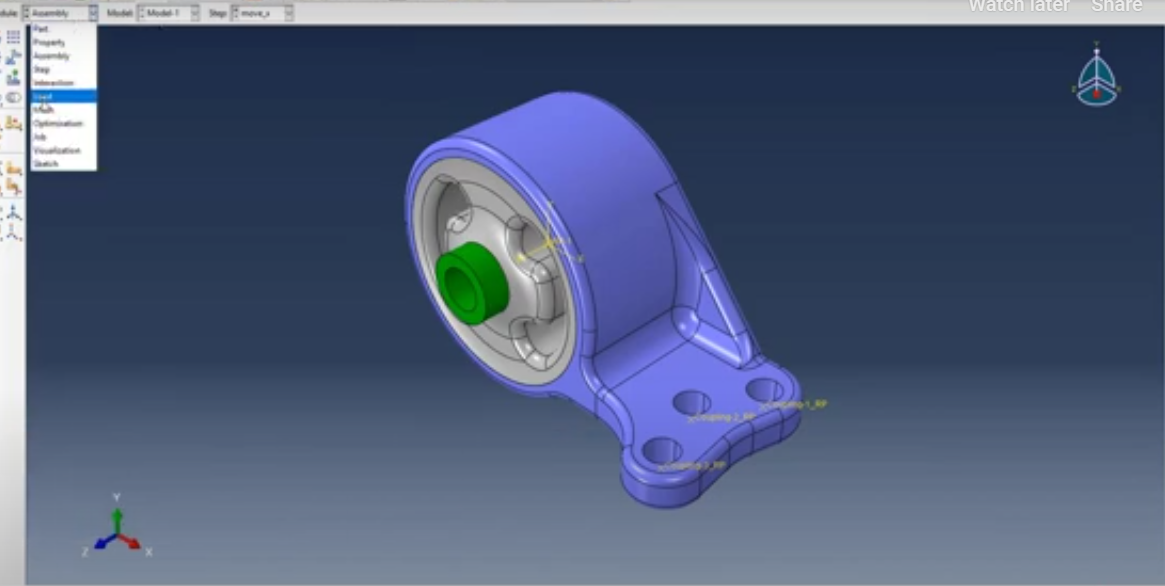

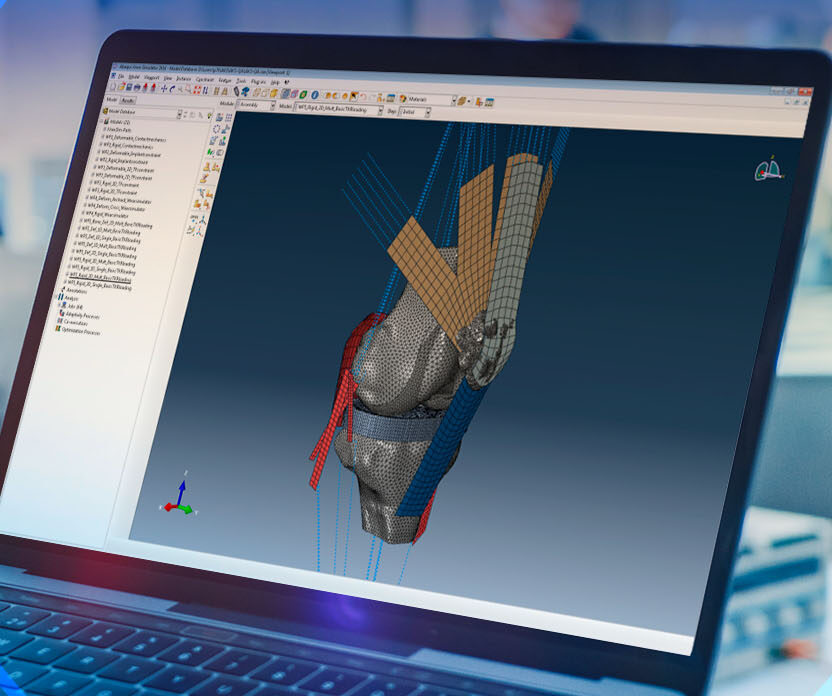

Abaqus/CAE offers an efficient platform for creating, editing, and visualizing advanced analyses through its intuitive interface, which integrates modeling, analysis, job management, and results visualization. It supports familiar Computer-Aided Engineering concepts like feature-based modeling and GUI customization, allowing users to create geometry, import CAD models for meshing, or use geometry-based meshes. Associative Interfaces with CAD software like CATIA V5 and SolidWorks enable quick model updates while preserving analysis features. Additionally, the open customization toolset facilitates process automation, and comprehensive visualization options enhance the interpretation of results.

Scope

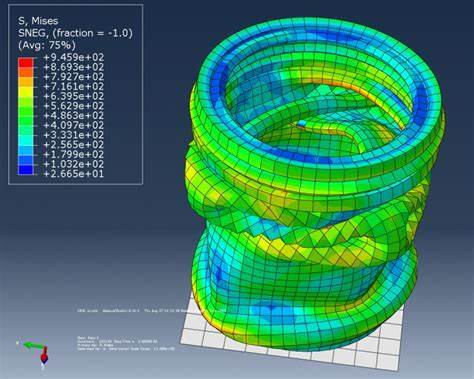

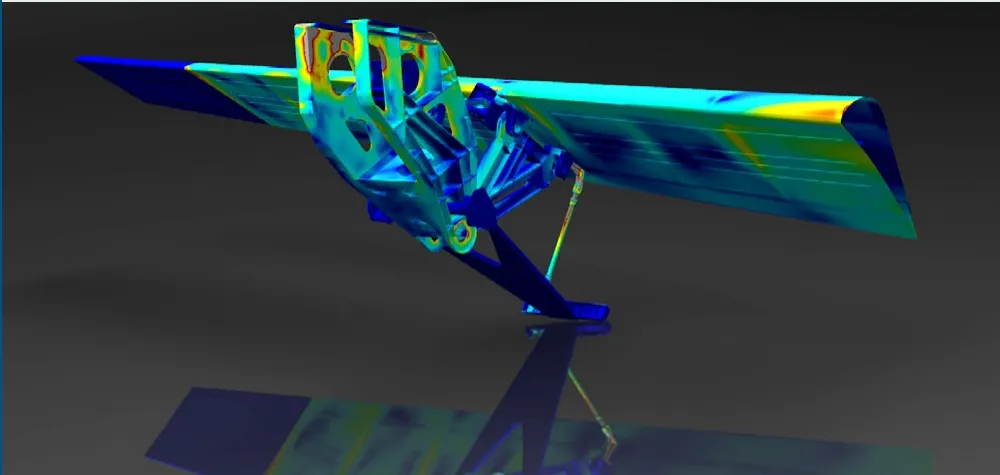

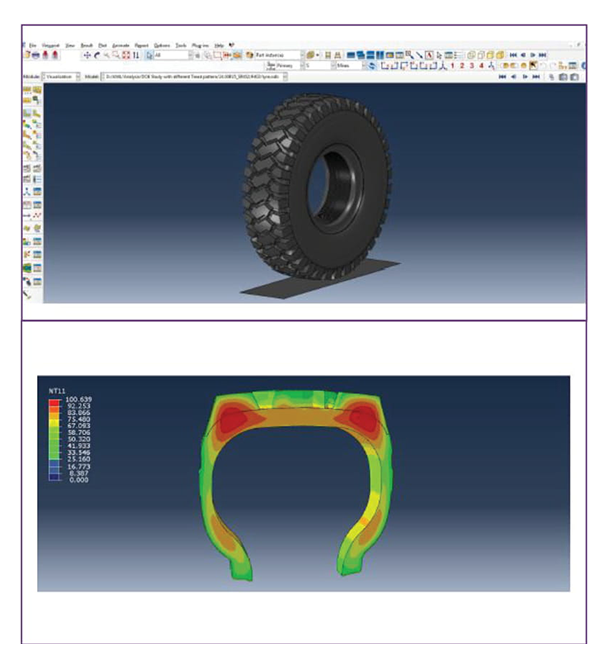

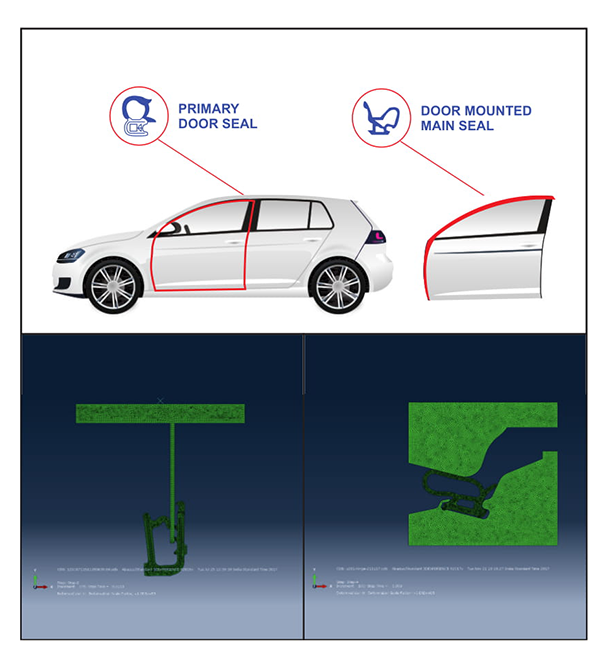

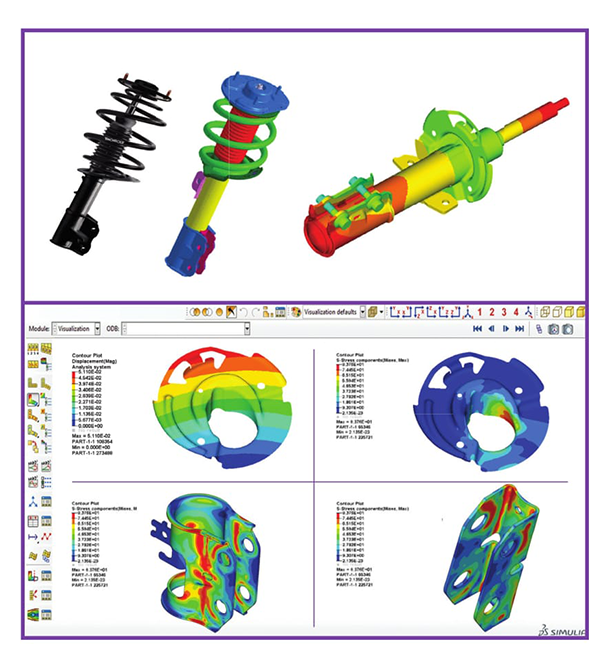

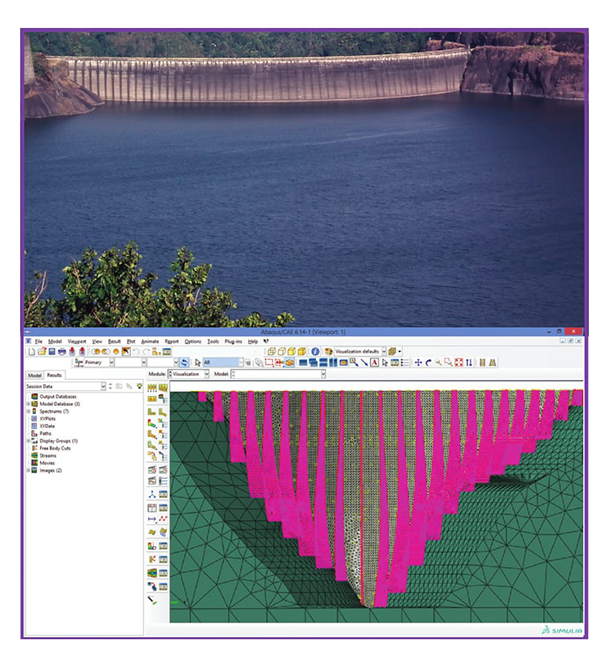

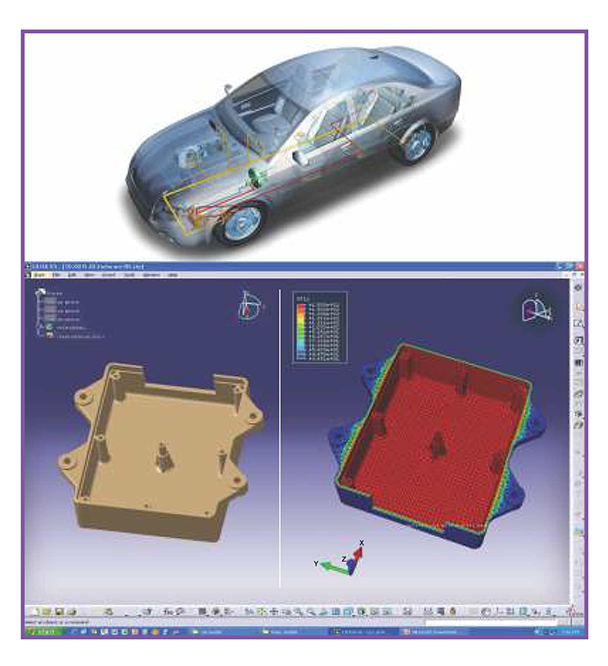

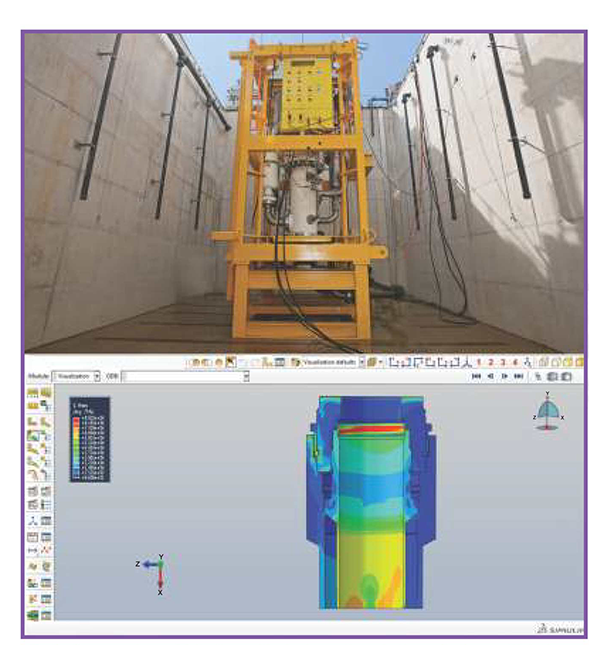

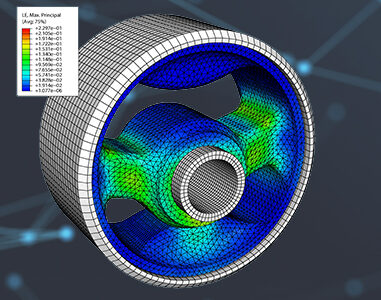

- Comprehensive Finite Element Analysis: Provides a complete environment for performing finite element analysis (FEA) across various engineering fields.

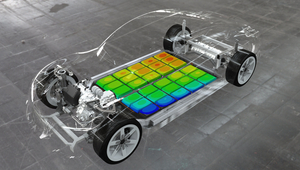

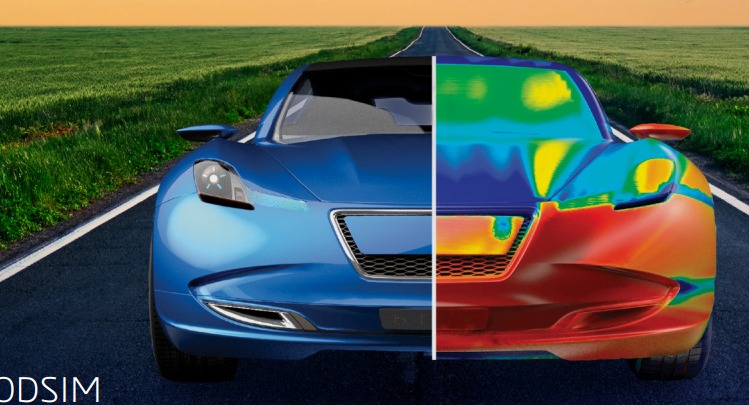

- Multi-Physics Simulations: Supports coupled analysis, allowing users to model complex interactions, including thermal, mechanical, and fluid dynamics.

- Advanced Material Models: Offers extensive libraries for different material behaviors, including metals, composites, polymers, and more.

- Pre- and Post-Processing Capabilities: Integrates geometry creation, meshing, solving, and result visualization in one platform, streamlining the workflow.

- Customization and Scripting: Allows users to customize analyses and automate processes using Python scripting, enhancing efficiency.

Applications

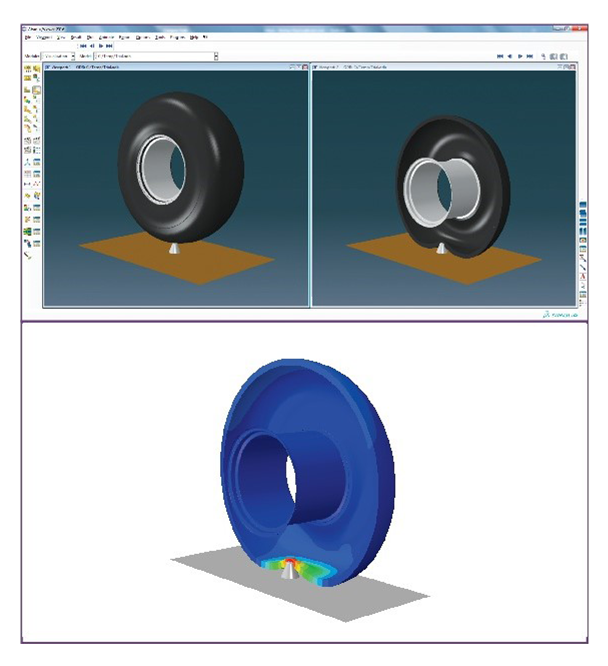

- Aerospace Engineering: Used for structural analysis of aircraft components, crash simulations, and fatigue assessments.

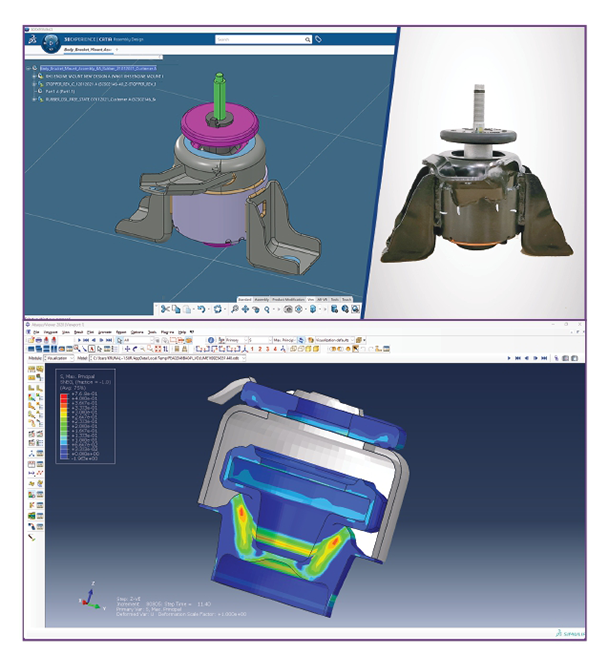

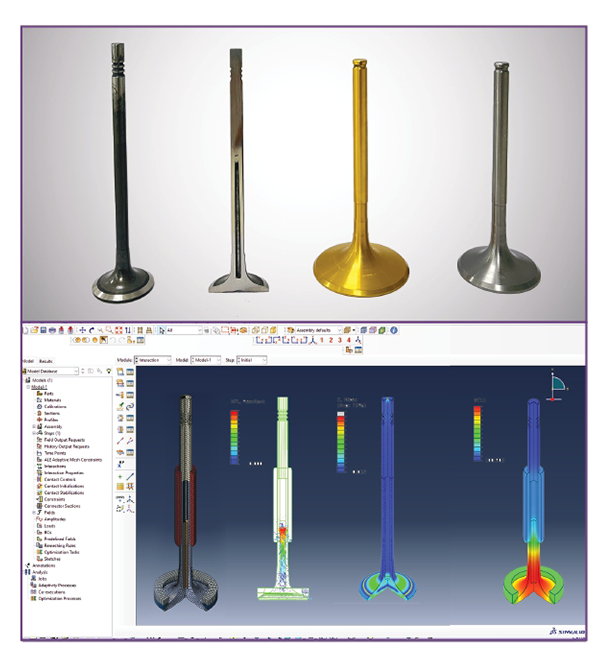

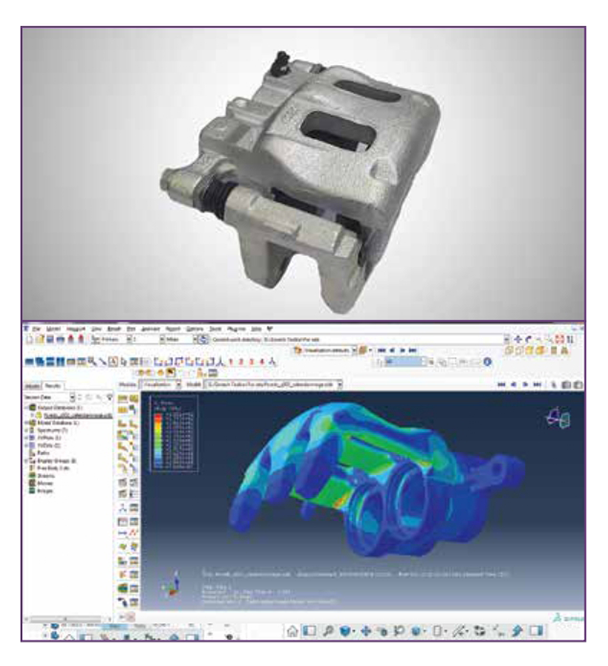

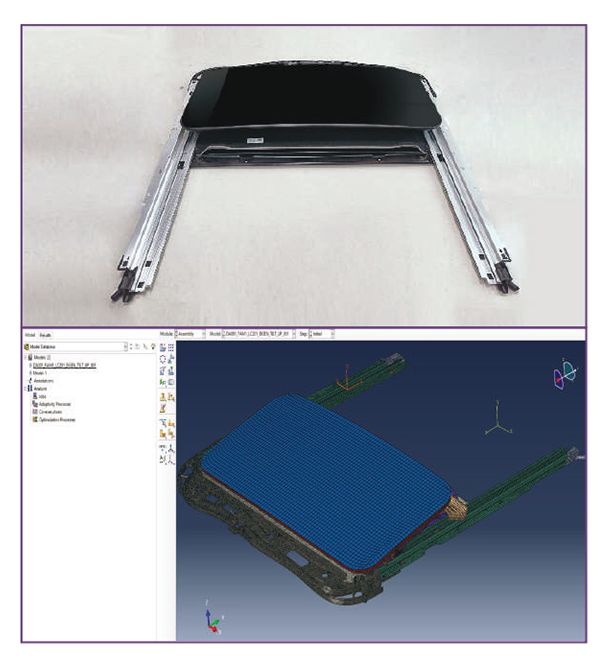

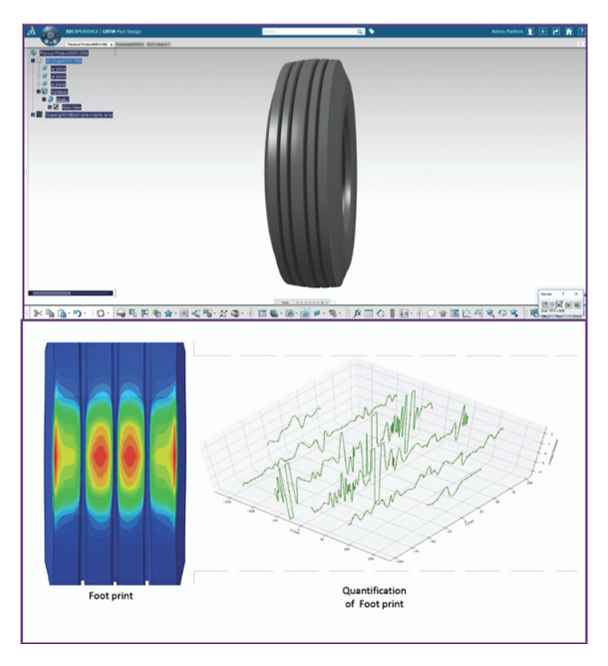

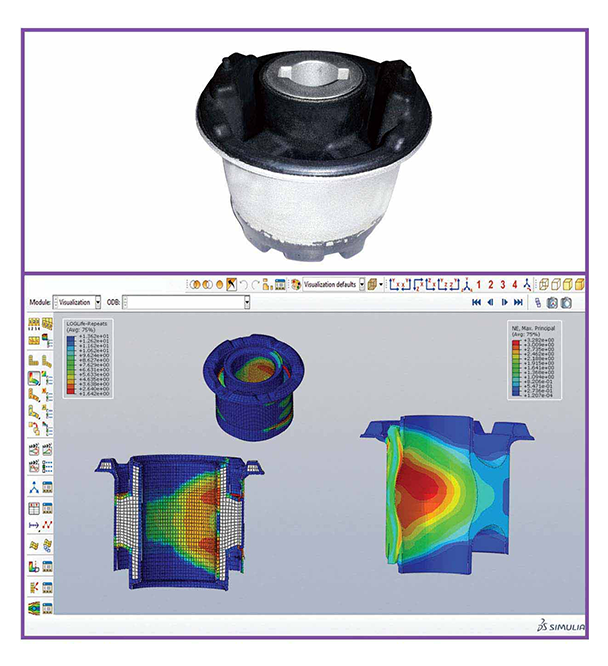

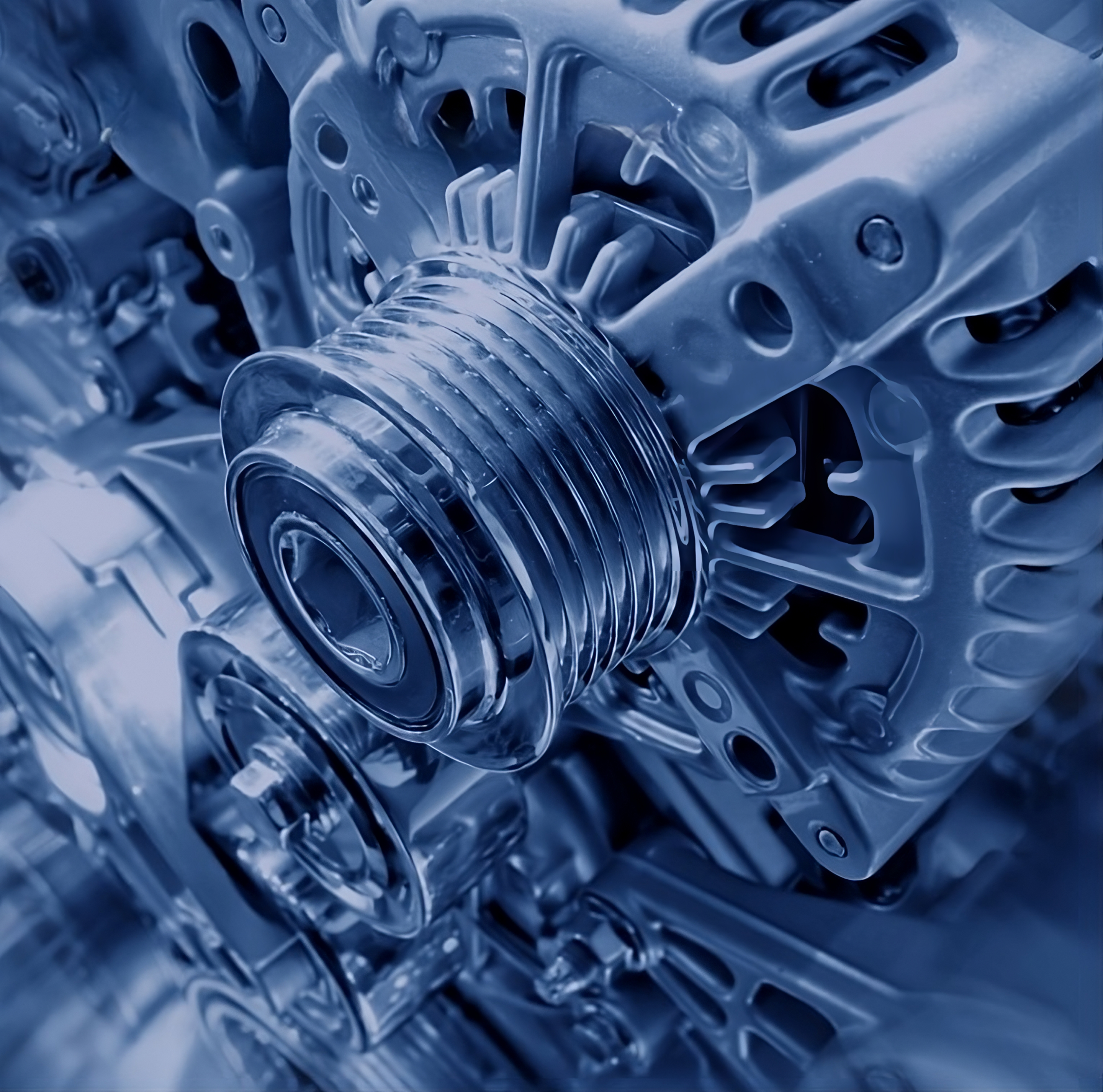

- Automotive Industry: Applied in crashworthiness studies, impact analysis, and optimization of vehicle components for performance and safety.

- Civil Engineering: Utilized for analyzing structures like bridges, buildings, and dams, especially under various loading conditions.

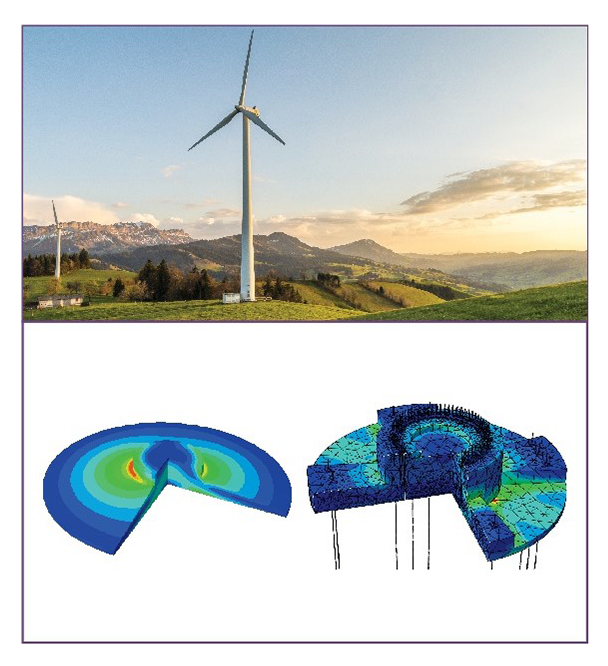

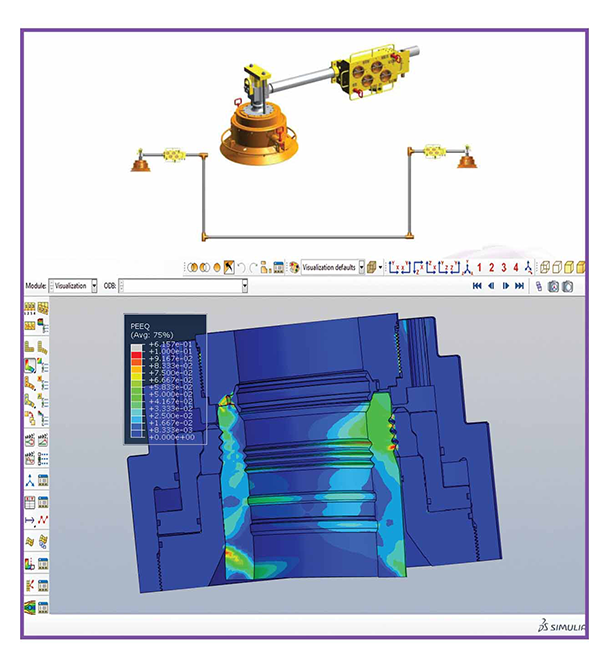

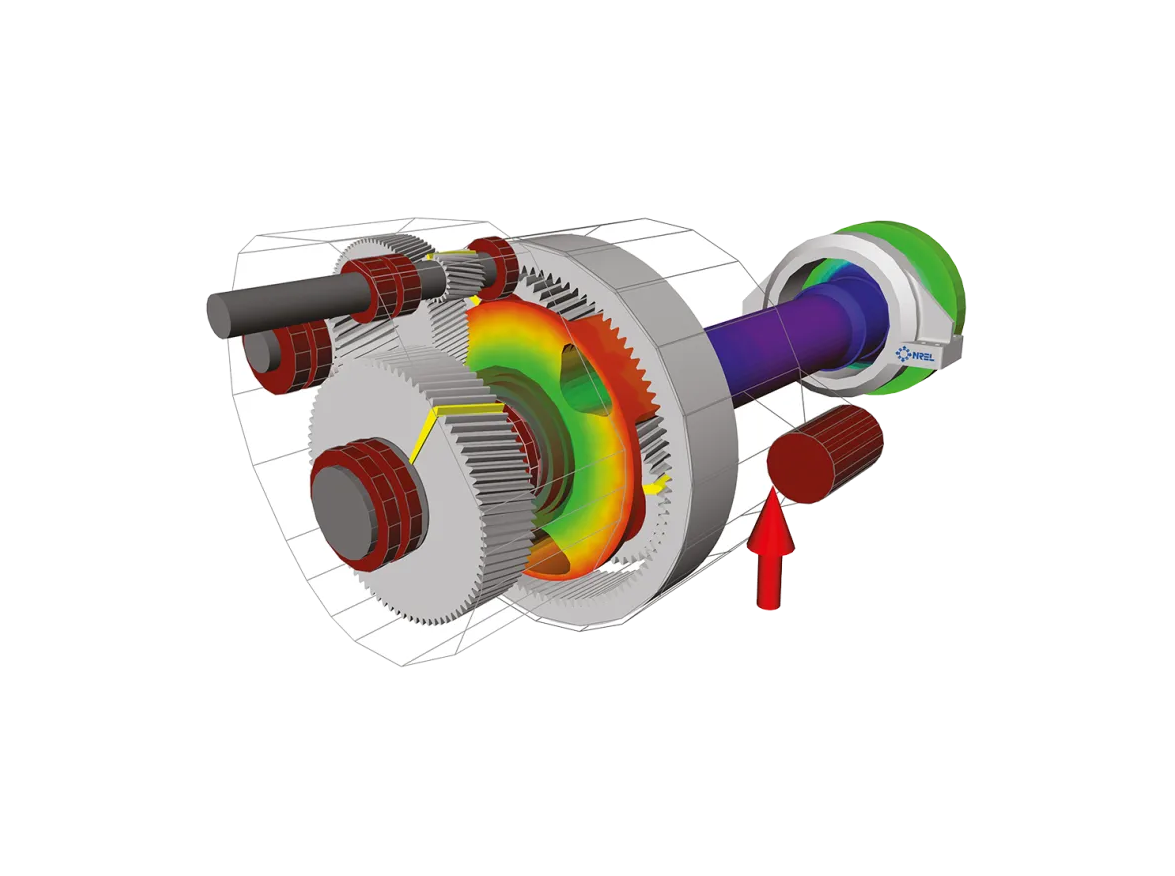

- Energy Sector: Employed in the analysis of wind turbines, pipelines, and other structures subjected to dynamic loads.

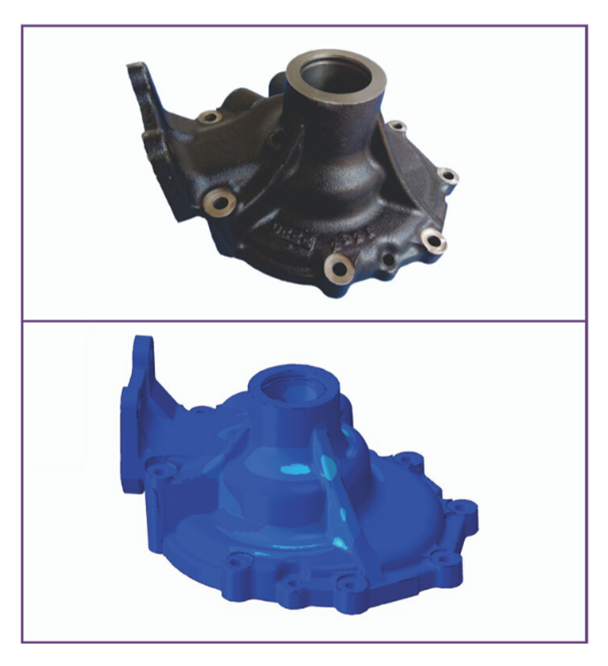

- Manufacturing Processes: Used for simulating forming processes, including stamping, casting, and machining.

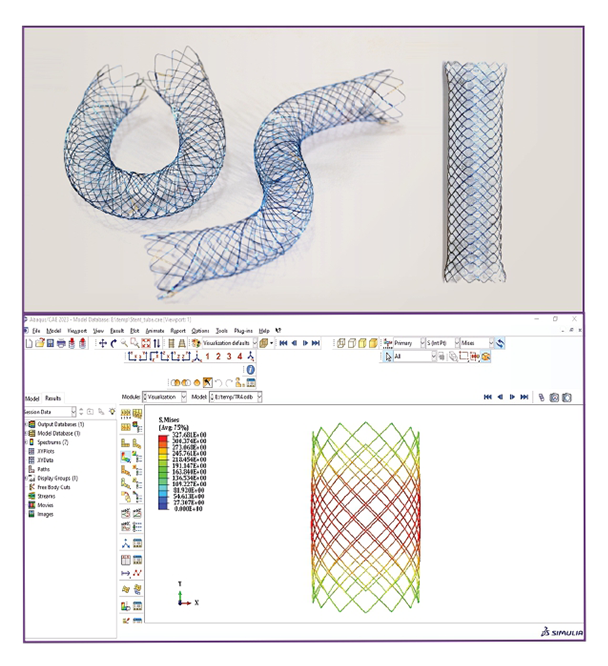

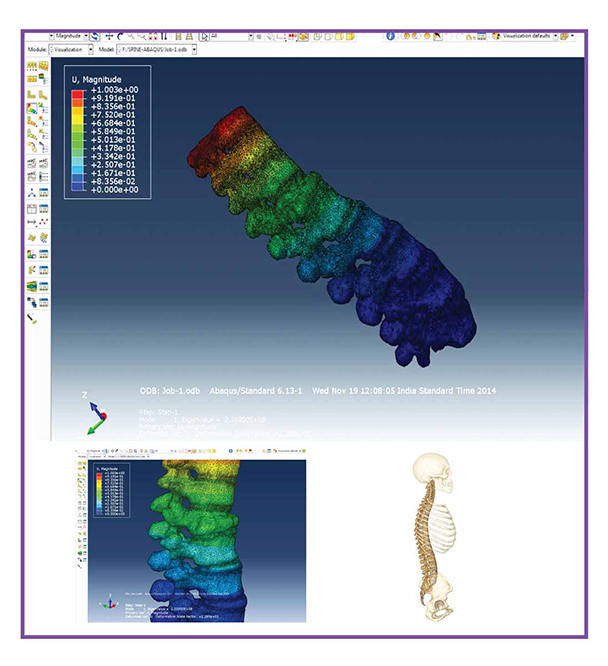

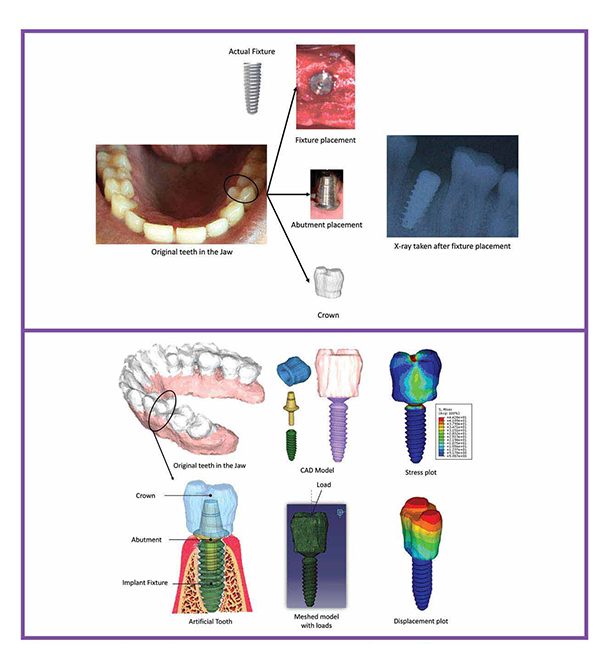

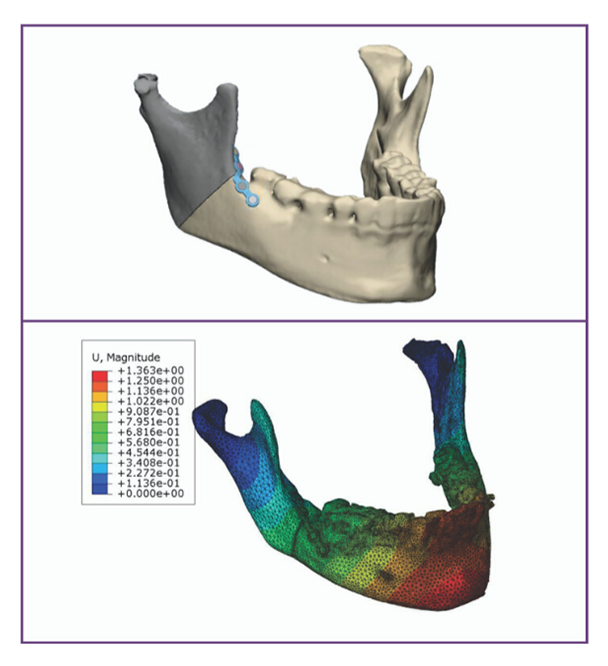

- Biomedical Engineering: Applicable in the study of implants, prosthetics, and other medical devices to ensure performance and safety.

Benefits

- Enhanced Product Performance

- Accelerated Time to Market

- Cost Savings and Risk Mitigation

- Improved Innovation and Collaboration

- Reduced Environmental Impact

- Continuous Improvement

Discover Abaqus Modules

Abaqus/Standard

Solution Technology for Linear and Nonlinear Finite Element Analysis

Abaqus/Explicit

Solution Technology for Highly Nonlinear Transient Events

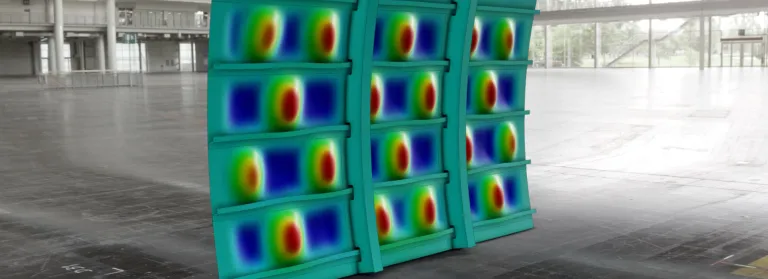

Abaqus Multiphysics

Complete Solutions for Realistic Simulation

Abaqus CAD Associative Interface

Associative Interfaces Between Abaqus and CAD Systems

Composites Modeler for Abaqus/CAE

Advanced Model Build for Ply and Fiber Materials

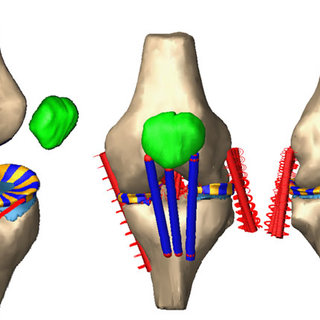

Abaqus Knee Simulator

Advanced Knee Implant Analyses and Simulation

Czone for Abaqus

Crush Simulation for Laminated Composites

Explore Other Apps

Abaqus

Finite Element Analysis for Mechanical and Civil Engineering Excellence

Fe-safe

Durability Analysis Software for Finite Element Models

Tosca

Unlocking Efficiency: Optimization Through Advanced FEA and CFD Simulations

Isight

Transforming Innovation Through Process Automation and Design Exploration

Simpack

Powerful Multibody System Simulation Software for Comprehensive Dynamic Analysis