|

As we enter the era of personalized healthcare, custom-built implants and 3D printed grafts are rapidly gaining preference. These offer a critical advantage over off-the-shelf implants, which could cause ill fitment and limited functionality. Despite a high survival rate of dental implants (between 90% and 95% on an average), healthcare professionals are struggling to locate the root cause of implant failure, and complications arising from poor placement continue to plague patients. Custom-designed and 3D printed implants could resolve all of this by tailoring the shape and fitment perfectly to individual placements. However, several factors prevent customized and 3D printed grafts from becoming mainstream. There are patient-specific challenges such as in-vivo performance and post-grafting safety. Also, there are reliability issues when printing the implant, ensuring that it is perfectly aligned to design.

Emerging technologies will play a key role when addressing these areas, allowing healthcare professionals to accurately understand each patient’s requirements, streamline the design process, and ensure 3D prints are in-sync with actual expectations. At Dassault Systèmes, some of the digital technologies we are exploring in this regard include virtual human modeling to visualize implant performance and multiphysics simulations to account for individual anatomy. Using our 3DEXPERIENCE Platform, all of these tasks can be integrated into a singular workflow for seamless ‘concept to patient fit’ alignment. Let us look at how technologies like these can aid custom bone graft development, in greater detail.

A. Improving Collaboration through Intelligent Workflow Design

Personalized grafts require multiple stakeholders to work together using a variety of tools. From Image-to-CAD reconstruction to the final additive manufacturing step, project management must be tailored to these unique requirements. The 3DEXPERIENCE Platform is an open technology framework where the tools, capabilities, and team members required to successfully 3D print bone grafts, are intersected. Such an environment is vital for encouraging collaboration across personas (engineering, analysts, SMEs, and project managers) and orchestrating their contributions.

B. Ensuring Quality with Multiphysics Simulations

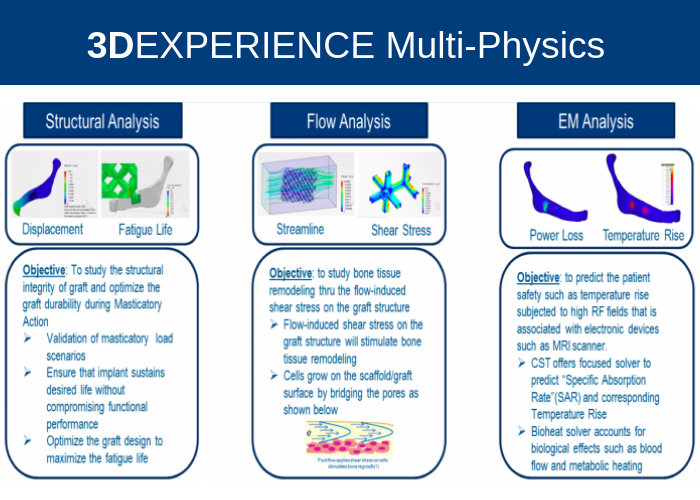

As mentioned, one of the key challenges faced is the variance in patient anatomy, physiology, and activity. When we are custom developing the implant, designs have to ensure first-time-right, with very limited means for physical testing. Here, realistic simulations can make a major difference, enabling virtual test and optimization before we even commence 3D printing. Designs are tested against parameters like durability, bone remodeling, and EM safety, making sure the graft can handle all kinds of scenarios. For example, depending on patient needs, three kinds of physics simulations might be recommended as part of the workflow on the 3DEXPERIENCE Platform: structural, fluid dynamics, and electromagnetics (illustrated below).

C. Perfecting Compatibility with Virtual Human Modeling

One of the main roadblocks to implementing custom grafts is the lack of personalized test cases. Healthcare professionals need to validate exactly how a 3D printed graft will interact with in-vivo surroundings and its long-term impact.

A virtual human model recreates all the anatomical and musculature features as per a specific patient’s condition. Using the 3DEXPERIENCE Platform, it is possible to model a bone tissue’s biomechanical behavior, as well as other conditions representing typical motions by drawing from a variety of literature and SME expertise. This virtual human model will ascertain that a designed graft is ready to be 3D printed and placed in the required context, overcoming the scarcity of testing infrastructure.

D. Completing Development through Additive Manufacturing (3D Printing)

Bone grafts can be geometrically complex (so they can easily support post-surgical growth) and this makes them ideal for additive manufacturing. However, to make the 3D printing process error-free and design synchronized, parameters like printing speed and temperature should be carefully controlled. Furthermore, digital continuity is needed so the graft designer can easily publish CAD models along with optimal printing parameters to a 3D marketplace. This direct flow of information will minimize the risk of discrepancies.

The 3DEXPERIENCE Platform offers an out-of-the-box solution with robust design simulation capabilities. Key parameters are tested to understand their impact on performance, as well as identifying which parameters make little to no difference. For successfully manufacturing patient-specific 3D printed bone grafts, this capability is critical.

E. Augmenting Capabilities via a Power’By approach

Essential to the entire ‘design to 3D printing and final graft delivery’ lifecycle, is the strategic utilization of various roles and capabilities. At critical junctures of the workflow, the 3DEXPERIENCE Platform interpolates Power’By roles such as Abaqus Specialist and CST Specialist. These help to leverage innovative tools from Dassault Systemes’ SIMULIA powered by 3DEXPERIENCE Platform. For instance, our TOSCA Shape Optimizer can improve a graft’s fatigue, while CST Studio Suite predicts patient safety with greater accuracy. Healthcare professionals can thus achieve digital continuity, witho

|